Module 4 and 5

Diunggah oleh

Kumar sssssJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Module 4 and 5

Diunggah oleh

Kumar sssssHak Cipta:

Format Tersedia

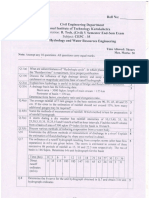

Module 4

Problem: 1

What is the highest cycle efficiency possible for a heat engine operating between 900 C and

30 C?

Answer: 74.2%

Problem:2

Two reversible heat engines operate in series between a source at 600 C and a sink at 30 C.

If the engines have equal efficiencies and the first rejects 400 kJ to the second, calculate:

(i) the temperature at which heat is supplied to the second engine;

(ii) the heat taken from the source;

(iii) the work done by each engine.

Assume that each engine operates on the Carnot cycle.

Answers: 241.3 C; 679.1 kJ; 279.1 kJ and 164.4 kJ.

Problem:3

Estimate the overall cumulative efficiency for domestic electrical and gas water heating, taking

into account energy losses in

Fuel production

Fuel transportation

Energy conversion to electricity

Transmission of electricity

Heating of water

Use the conversion efficiencies given in the table shown below:

Step Efficiency of step

(percent)

ELECTRIC (coal-fired)

Production of coal 96

Transportation of coal 97

Generation of electricity 33

Transmission of electricity 85

Water heating efficiency 92

GAS

Production of natural gas 96

Transportation of natural gas 97

Heating efficiency 64

Answers: 24.03% and 59.6%

Module 5

. Question:1

A steel pipe of 60 mm external diameter and 53 mm internal diameter carries a gas

flow at 150 C

through an air space at 10 C. Using the data below, calculate:

(i) a suitable thickness of glass fibre insulation;

(ii) the simple pay-back period for the insulation.

Data

Thermal conductivity of steel, 48 W/m K;

Thermal conductivity of glass fibre, 0.07 W/m K;

Heat transfer coefficient for inside surface of pipe, 100 W/m2 K;

Heat transfer coefficient for outside surface (with and without insulation), 10 W/m2 K;

The gas is heated by a boiler of efficiency 80 % burning gas at a cost of 1.3 c/kWh;

Plant in use for 3000 h per annum;

Insulation to be written off after five years;

Glass fibre thicknesses and costs: 19 mm at 476 c/m; 25 mm at 531 c/m; 32 mm at

632 c/m; 38

mm at 763 c/m; 50 mm at 1007 c/m.

Answers: 38 mm; 0.91 years.

Question : 2

Question:

A shell-and-tube heat exchanger similar to the one shown in the Figure below is

used to recover

energy from waste water at 30C to heat fresh water entering at 15C. The mass

flow rate of the

waste water is 2 kg/s which is the same as that of the fresh water. Using the data

given, calculate:

(i) the optimum rate of energy recovery;

(ii) the required heat transfer area;

(iii) the temperature of the fresh water at exit.

Specific heat of waste water and fresh water, 4.2 kJ/kg K.

Overall heat transfer coefficient, 2500 W/m K.

For a single shell-pass, two tube-pass heat exchanger take the following

characteristic

when R = 1.

Effectiveness 0 0.46 0.53 0.56 0.57 0.58 0.58 0.58

NTU 0 1.0 1.5 2.0 2.5 3.0 3.5 4.0

Answers: 73.08 kW; 10.08 m2; 23.7C.

\

Anda mungkin juga menyukai

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- 6th Central Pay Commission Salary CalculatorDokumen15 halaman6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Hydraulics TrainingDokumen47 halamanHydraulics Trainingmdhyderali100% (4)

- 30XA WIRING 30xa-1w PDFDokumen20 halaman30XA WIRING 30xa-1w PDFKumar sssssBelum ada peringkat

- Fan SelectionDokumen61 halamanFan SelectionJugmohunBelum ada peringkat

- Boiler Calucation SheetDokumen84 halamanBoiler Calucation Sheet9913489806Belum ada peringkat

- Dme BDokumen8 halamanDme Bdewi xiaBelum ada peringkat

- SCR PresentationDokumen85 halamanSCR PresentationariyaBelum ada peringkat

- Choosing Trays and Packings For Distillation: Back To BasicsDokumen7 halamanChoosing Trays and Packings For Distillation: Back To Basicsmsn1981Belum ada peringkat

- 50TC-A07 Spare PartsDokumen17 halaman50TC-A07 Spare PartsKumar sssssBelum ada peringkat

- Flottweg DecandersDokumen12 halamanFlottweg DecandersRagha Rag100% (1)

- Chennai ReportsDokumen273 halamanChennai ReportsKumar sssssBelum ada peringkat

- Duct DesignDokumen49 halamanDuct DesignabianshbaralBelum ada peringkat

- Lab Report Pump PerformanceDokumen20 halamanLab Report Pump Performanceamirshafiq67% (3)

- Fact Sheets On Air Emission Abatement Techniques - Final 2009 02 20 PDFDokumen152 halamanFact Sheets On Air Emission Abatement Techniques - Final 2009 02 20 PDFAini Zahra100% (1)

- Division - E HP Bypass System Volume - E1 Control Valves, Actuator and Accessories Contents ListDokumen150 halamanDivision - E HP Bypass System Volume - E1 Control Valves, Actuator and Accessories Contents ListAnonymous ZnuMEWN1Belum ada peringkat

- RMH-RA-GP-1001-Marking Penetration, Support Bracket Location (Reviewed 01042019)Dokumen3 halamanRMH-RA-GP-1001-Marking Penetration, Support Bracket Location (Reviewed 01042019)Kumar sssssBelum ada peringkat

- Job Specification For Supply: 8474L 000 JSS 1691 001 0Dokumen12 halamanJob Specification For Supply: 8474L 000 JSS 1691 001 0Kumar sssssBelum ada peringkat

- RMH-RA-GP-1002-HVAC Ducting, Dampers, Ventilation Fan, Mushroom, Louver, Insulation and Other Accessories Installation (Reviewed 01042019)Dokumen4 halamanRMH-RA-GP-1002-HVAC Ducting, Dampers, Ventilation Fan, Mushroom, Louver, Insulation and Other Accessories Installation (Reviewed 01042019)Kumar sssssBelum ada peringkat

- RMH-RA-GP-1001-Marking Penetration, Support Bracket LocationDokumen3 halamanRMH-RA-GP-1001-Marking Penetration, Support Bracket LocationKumar sssssBelum ada peringkat

- Legend: US Army Corps of Engineers Middle East DistrictDokumen1 halamanLegend: US Army Corps of Engineers Middle East DistrictKumar sssssBelum ada peringkat

- LQ Modifications-SketchDokumen13 halamanLQ Modifications-SketchKumar sssssBelum ada peringkat

- Chiller SRDokumen1 halamanChiller SRKumar sssssBelum ada peringkat

- Air System Sizing Summary For Main Deck AHUDokumen12 halamanAir System Sizing Summary For Main Deck AHUKumar sssssBelum ada peringkat

- Air Compressor Room Exhaust (8000CMH)Dokumen1 halamanAir Compressor Room Exhaust (8000CMH)Kumar sssssBelum ada peringkat

- Pressure-Relief DamperDokumen4 halamanPressure-Relief DamperKumar sssssBelum ada peringkat

- Bae72 S eDokumen1 halamanBae72 S eKumar sssssBelum ada peringkat

- Installation, Start-Up and Service Instructions: 38AH044-134 Air-Cooled Condensing Units 50/60 HZDokumen56 halamanInstallation, Start-Up and Service Instructions: 38AH044-134 Air-Cooled Condensing Units 50/60 HZKumar sssssBelum ada peringkat

- Installation, Start-Up and Service Instructions: Central Station Air Handling UnitsDokumen20 halamanInstallation, Start-Up and Service Instructions: Central Station Air Handling UnitsKumar sssssBelum ada peringkat

- Installation, Start-Up and Service Instructions: 42C, D, S, V Series Fan Coil Air ConditionersDokumen88 halamanInstallation, Start-Up and Service Instructions: 42C, D, S, V Series Fan Coil Air ConditionersKumar sssssBelum ada peringkat

- Instruction Manual PDFDokumen10 halamanInstruction Manual PDFKumar sssssBelum ada peringkat

- BE Specs VG1000 M9000 TableDokumen3 halamanBE Specs VG1000 M9000 TableKumar sssssBelum ada peringkat

- Filtration: Sizing Mega. Cartridge SizingDokumen1 halamanFiltration: Sizing Mega. Cartridge SizingKrishna PATELBelum ada peringkat

- B.tech Dec2022 Civil CEPC-35 Sem5Dokumen2 halamanB.tech Dec2022 Civil CEPC-35 Sem5012 Diksha KumariBelum ada peringkat

- Thermal Oil Boiler Vega PDFDokumen2 halamanThermal Oil Boiler Vega PDFrafiradityaBelum ada peringkat

- Combo 2 Fans and BlowersDokumen2 halamanCombo 2 Fans and BlowersJarred Tañedo100% (1)

- SIRE EKS July 2023Dokumen2 halamanSIRE EKS July 2023Mohan SBelum ada peringkat

- Ep CorDokumen3 halamanEp CorNathanBelum ada peringkat

- Wing Simulation in The Comsol 20-01-2015Dokumen68 halamanWing Simulation in The Comsol 20-01-2015AndrijaMABelum ada peringkat

- Manual de Transmisión de CalorDokumen36 halamanManual de Transmisión de CalorLuis Alfonso Martinez FdezBelum ada peringkat

- Granulation Is Done ToDokumen9 halamanGranulation Is Done ToDebasmita KumarBelum ada peringkat

- MF-02 Machinery Particulars ListDokumen9 halamanMF-02 Machinery Particulars ListpcatruongBelum ada peringkat

- Static Aeroelasticity: I H I I BL H L H U LL LL L Ul I I L U I I L 1Dokumen1 halamanStatic Aeroelasticity: I H I I BL H L H U LL LL L Ul I I L U I I L 1OSCARDELTABelum ada peringkat

- FDTC 40 ZixvdDokumen296 halamanFDTC 40 ZixvdConstantin ElenaBelum ada peringkat

- Soil Science FormulasDokumen2 halamanSoil Science Formulasgljae479Belum ada peringkat

- NHT Furnace OptimisationDokumen6 halamanNHT Furnace Optimisationcoolmanyu2k5Belum ada peringkat

- Impact of Flowfield-Radiation Coupling On AeroheatingDokumen11 halamanImpact of Flowfield-Radiation Coupling On Aeroheatingmiquelbs2001Belum ada peringkat

- BTG Biomass Gasification PDFDokumen17 halamanBTG Biomass Gasification PDFFiseha MekonnenBelum ada peringkat

- HP Hydraulic Manual Override: Hpa / HPB / HPC / Hp1Dokumen8 halamanHP Hydraulic Manual Override: Hpa / HPB / HPC / Hp1mar mayoBelum ada peringkat

- An Overview of The Hydraulics of Water Distribution NetworksDokumen35 halamanAn Overview of The Hydraulics of Water Distribution NetworksBoos yousufBelum ada peringkat

- Catalog of AquaDokumen22 halamanCatalog of AquaLao KimsengBelum ada peringkat