Vertical Roller Mill

Diunggah oleh

Joko DewotoHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Vertical Roller Mill

Diunggah oleh

Joko DewotoHak Cipta:

Format Tersedia

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Vertical Roller Mill Introduction

Vertical Roller Mill is a new kind of large scale power mill which is designed specially to solve the problems of low capacity and high

consumption of industry mills. With a decade of years research of mills, Vertical Roller Mill is designed and manufactured based on our

advanced design idea, and in combination with the European technology and the market demand. It adopts reliable structure and

reasonable process flow, integrated with drying ,milling, classifier , elevator. Especially ,it can fully meets the requirement of clients in the

high production of powder and its main technical and economy indicator reaches the international level.

Application:

Specialized for the high production of superfine pyrophyllite

powder making in glass fiber industry

Specialized for the high production of gangue powder making

in coal industry

Specialized for the high production of various of chemical raw

material powder making in the chemical industry.

It is a necessary equipment for the high production of mineral

powder in the non-mental mine industry and large scale

powder making in many other industries.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Working principles of the Vertical Mill CLM:

The motor dives the grinding table to turn through the speed reducer. At the

same time, hot air comes into the roller mill from the air inlet. The materials fall

down the centre of grinding table from the feeder. Because of the centrifugal

force, the materials move to the edge of grinding table from the centre .The

materials are crushed by the grinding roller when by pass of the groove on the

grinding table. The crusher materials continue to move to the edge of the

grinding table until taken away by the airstream. Then the bigger materials fall

down the grinding table and the process of crushing continues. When the

materials in the airstream pass the separator on the top of the mill, the

materials fall down the grinding table from the taper filler under the force of

guide leaf blade. The fine powder comes out with the airstream, and is gathered

by the dust catcher of the system. The powder gathered is the final product of

roller mill. In the process of the contact of airstream , the materials are dried to

meet the clients need at the proper moisture. Through the adjustment of the

angle between the separator and the leaf of winds direction (not suitable to the

small type of vertical mill), and also the speed of the separator rotor, it can

reach the proper fineness of the materials.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

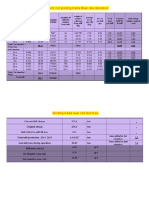

Technical data of CLM series roller mill(Coal or Cement Industry)

Specification

Capacity(t/h)

Humidity of Raw Coal

Fineness of Powder

Humidity of Powder(%)

Motor Powerkw

CLM1250M

7-12

<15%

5-12%

132

CLM1300M

10-15

<15%

5-12%

185

CLM1400M

12-17

<15%

5-12%

200

CLM1500M

16-22

<15%

5-12%

250

CLM1700M

20-28

<15%

5-12%

315

CLM1900M

26-35

<15%

5-12%

400

CLM2200M

35-45

<15%

5-12%

500

CLM2400M

40-50

<15%

5-12%

560

CLM2800M

50-62

<15%

5-12%

710

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

CLM series roller mill Technical data of raw meal mill(Cement Industry)

Specification

Capacity(t/h)

Humidity of Raw Coal

Fineness of Powder

Humidity of Powder(%)

Motor Power(kw)

CLM1500M

7-12

<10%

12%

280

CLM1700M

10-15

<10%

12%

400

CLM1900M

12-17

<10%

12%

500

CLM2200M

16-22

<10%

14%

800

CLM2400M

20-28

<10%

14%

900

CLM2800M

26-35

<10%

14%

1120

CLM3400M

35-45

<10%

15%

1800

CLM3700M

40-50

<10%

15%

2240

CLM4800M

50-62

<10%

15%

3800

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Technical data of CLM series roller mill(Desulphurizat ion of Fume)

Specification

Capacity(t/h)

Humidity of Raw Material

Fine of Limestone Power

Powder of Main Motor

CLM1250X

6-9

325

132

CLM1300X

9-13

200

CLM1500X

13-18

280

CLM1700X

18-25

355

CLM1900X

25-32

450

CLM2200X

32-40

560

CLM2400X

40-50

710

CLM2800X

50-65

900

90%

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Technical data of CLM series roller mill(Metallurgy Industry)

Specification

Capacity

Humidity of Raw Coal

CLM800M

3-5

10(%)

CLM1100M

5-8

12(%)

Fineness of Coal owder

Humidity of Powder(%)

Power of Main Motor

55

110

80%

CLM1250M

9-13

15(%)

132

CLM1300M

13-17

15(%)

160

CLM1500M

18-22

15(%)

250

CLM1700M

22-30

15(%)

315

CLM1900M

30-40

15(%)

400

CLM2200M

40-50

15(%)

500

CLM2400M

5-70

15(%)

630

CLM2800M

70-100

15(%)

800

Anda mungkin juga menyukai

- V SK VSK: Focus On EfficiencyDokumen8 halamanV SK VSK: Focus On EfficiencyGerman Gabriel Anaya VegaBelum ada peringkat

- Vertical Roller MillDokumen2 halamanVertical Roller MillAhmed Younis0% (2)

- Cpi VRMDokumen26 halamanCpi VRMRobert Brown100% (1)

- Vertical Roller MillDokumen3 halamanVertical Roller MillChaitanya Chinta0% (1)

- Cement Grinding Vertical Roller Mills Versus Ball Mills 1654248086Dokumen17 halamanCement Grinding Vertical Roller Mills Versus Ball Mills 1654248086Salah Romdani100% (1)

- Third Generation Separators - Part 1Dokumen2 halamanThird Generation Separators - Part 11qwerBelum ada peringkat

- Cement Mill: History Materials Ground Temperature Control Ball MillsDokumen5 halamanCement Mill: History Materials Ground Temperature Control Ball MillsAli HadiBelum ada peringkat

- HTML version of LURM mill process control documentDokumen6 halamanHTML version of LURM mill process control documentkamjulajayBelum ada peringkat

- Clinker Cooler OperationDokumen5 halamanClinker Cooler OperationJCSBelum ada peringkat

- Operating Manual for Slag Grinding UnitDokumen41 halamanOperating Manual for Slag Grinding UnitPushpendra Kumar KushwahaBelum ada peringkat

- Loesche Seminar VCM Study Dec03Dokumen132 halamanLoesche Seminar VCM Study Dec03stelios nikoladosBelum ada peringkat

- FLSmidth IndiaDokumen31 halamanFLSmidth IndiaGughapriya Ramalingam100% (1)

- Cement Mill Grinding Media Wear Rate Calculation PDFDokumen2 halamanCement Mill Grinding Media Wear Rate Calculation PDFBùi Hắc HảiBelum ada peringkat

- MHR21924 CMC Chapter CCDokumen48 halamanMHR21924 CMC Chapter CCDede KaladriBelum ada peringkat

- .Improvement in Performance of Ball Mill in Cement GrindingDokumen4 halaman.Improvement in Performance of Ball Mill in Cement Grindingdeni jakaBelum ada peringkat

- Jaypee Cement Project ReportDokumen29 halamanJaypee Cement Project ReportPurnendu MishraBelum ada peringkat

- VRM OKoookuuiiiiljjjjyggyyDokumen8 halamanVRM OKoookuuiiiiljjjjyggyyRakaBelum ada peringkat

- Presentation-Hydraulic System in VRPMDokumen24 halamanPresentation-Hydraulic System in VRPMmsvprasadBelum ada peringkat

- Modefied Cooler2Dokumen71 halamanModefied Cooler21977jul100% (2)

- Cement Separator & Ball Mill OptimizationDokumen29 halamanCement Separator & Ball Mill OptimizationAdelezzat OmranBelum ada peringkat

- Jaypee Cement Plant Grinding Uniit-3Dokumen27 halamanJaypee Cement Plant Grinding Uniit-3sunil kumar patelBelum ada peringkat

- Cement Production Operator Training GuideDokumen7 halamanCement Production Operator Training GuidemkpqBelum ada peringkat

- Vertical roller mill grinding efficiencyDokumen11 halamanVertical roller mill grinding efficiencybkchoudhury1993Belum ada peringkat

- Gebr. Pfeiffer Brochure Passion For Grinding enDokumen28 halamanGebr. Pfeiffer Brochure Passion For Grinding enRollerJonnyBelum ada peringkat

- MPS Vertical Roller Mills for Slag GrindingDokumen4 halamanMPS Vertical Roller Mills for Slag Grindinglijosh_rexy1983Belum ada peringkat

- Atox 20 Coal Mill Critical Interlock SheetDokumen6 halamanAtox 20 Coal Mill Critical Interlock SheetValipireddy NagarjunBelum ada peringkat

- High-Efficiency Cyclone: Machine Manual En-22330.003-BDokumen31 halamanHigh-Efficiency Cyclone: Machine Manual En-22330.003-BRahmat YusufBelum ada peringkat

- Multifuel Rotary Kiln Burner: Presented At: "1 Burner Day" 18 February 2004"Dokumen38 halamanMultifuel Rotary Kiln Burner: Presented At: "1 Burner Day" 18 February 2004"mustafBelum ada peringkat

- Tromp Curve Example PDFDokumen3 halamanTromp Curve Example PDFThaigroup Cement100% (1)

- 15th NCB Technical PaperDokumen10 halaman15th NCB Technical PaperSalah RomdaniBelum ada peringkat

- Cement manufacturing technologies for energy efficiency and emission reductionDokumen22 halamanCement manufacturing technologies for energy efficiency and emission reductionnecdetdalgicBelum ada peringkat

- High Efficiency Separators 3Dokumen9 halamanHigh Efficiency Separators 3gldiasBelum ada peringkat

- Presep Air Separator VTP enDokumen6 halamanPresep Air Separator VTP enBrunoBelum ada peringkat

- Cement raw material gas flow balance sheetDokumen4 halamanCement raw material gas flow balance sheetAli Hüthüt100% (1)

- Ball Mill GrindingDokumen78 halamanBall Mill GrindingFran jimenezBelum ada peringkat

- Optimization of Vertical roller Mill (VRM) TemperatureDokumen2 halamanOptimization of Vertical roller Mill (VRM) TemperatureVijay BhanBelum ada peringkat

- Kiln Systems - An Overview of Rotary Kiln Process TypesDokumen19 halamanKiln Systems - An Overview of Rotary Kiln Process TypesSantanu PachhalBelum ada peringkat

- Newly Developed 0-Sepa Air Separator Provides Sharp Particle ClassificationDokumen7 halamanNewly Developed 0-Sepa Air Separator Provides Sharp Particle ClassificationTomas Masquimillan Peñailillo100% (1)

- Unwanted False Air in Cement Plants Can Be A Big Problem and Has To Be Taken SeriouslyDokumen5 halamanUnwanted False Air in Cement Plants Can Be A Big Problem and Has To Be Taken SeriouslyharyantoaditBelum ada peringkat

- Verticle Roller Mill: Presented By-Mahesh Kumar Nyati Get-MeDokumen34 halamanVerticle Roller Mill: Presented By-Mahesh Kumar Nyati Get-Mevikas100% (1)

- Coal Preparation: Chris HoltDokumen24 halamanCoal Preparation: Chris HoltAhmed ElbehairyBelum ada peringkat

- 01 RP-History & Stages of DevelopmentDokumen29 halaman01 RP-History & Stages of DevelopmentMAYANK BURMANBelum ada peringkat

- CFsiloloreslowres PDFDokumen8 halamanCFsiloloreslowres PDFtaghdirimBelum ada peringkat

- GasHandlingManual K1Dokumen57 halamanGasHandlingManual K1eeekkkggg100% (3)

- Tips On Kiln OperationDokumen1 halamanTips On Kiln OperationJohn GiannakopoulosBelum ada peringkat

- Clinker CoolersDokumen74 halamanClinker CoolersMuhammed EmamiBelum ada peringkat

- Bag House Differential Pressure: Key Indicator of Operation and TroubleshootingDokumen8 halamanBag House Differential Pressure: Key Indicator of Operation and TroubleshootingZegera Mgendi100% (2)

- Ilara RM - CS P.11002 - P.12610 - 15092021 - 18092021 - Technichal ReportDokumen16 halamanIlara RM - CS P.11002 - P.12610 - 15092021 - 18092021 - Technichal ReportBen100% (1)

- Technical Specification of VSK PDFDokumen28 halamanTechnical Specification of VSK PDFmaran.suguBelum ada peringkat

- Raw MealDokumen48 halamanRaw Mealrashmiranjan1110Belum ada peringkat

- Loesche - Loesche Cement Mills Concept Large CapacityDokumen26 halamanLoesche - Loesche Cement Mills Concept Large Capacityphucdc095041Belum ada peringkat

- Diagnostic Study For Cement Mill OptimizationDokumen9 halamanDiagnostic Study For Cement Mill OptimizationHilmy MuhammadBelum ada peringkat

- FK PumpDokumen29 halamanFK PumpPP2 Common ID/OperationBelum ada peringkat

- Rugged Single-Shaft Hammer Crusher for 2500mm MaterialsDokumen1 halamanRugged Single-Shaft Hammer Crusher for 2500mm MaterialspeymanBelum ada peringkat

- 05 RP - Process Know HowDokumen25 halaman05 RP - Process Know Howaff bear100% (2)

- 11.30 DR Stefan Seemann, KHD Humboldt Wedag GMBHDokumen15 halaman11.30 DR Stefan Seemann, KHD Humboldt Wedag GMBHMohd AliBelum ada peringkat

- Historical Spanish document on diplomatic relationsDokumen5 halamanHistorical Spanish document on diplomatic relationsAJSBelum ada peringkat

- Test 2 RevDokumen2 halamanTest 2 RevFady Abdel AzizBelum ada peringkat

- Physics problems on forces, motion, and accelerationDokumen2 halamanPhysics problems on forces, motion, and accelerationAlyssa ColeBelum ada peringkat

- Volvo Penta 7748089 5.0-5.7 Engine ManualDokumen176 halamanVolvo Penta 7748089 5.0-5.7 Engine ManualJohn Dahl88% (26)

- Form House KeepingDokumen40 halamanForm House KeepingJoko DewotoBelum ada peringkat

- Vertical Roller Mills KTM enDokumen6 halamanVertical Roller Mills KTM enJoko Dewoto100% (1)

- Air CAnnonDokumen58 halamanAir CAnnonJoko Dewoto50% (2)

- Calculating hot gas requirements for coal dryingDokumen2 halamanCalculating hot gas requirements for coal dryingJoko Dewoto0% (1)

- Air LeakagesDokumen1 halamanAir LeakagesJoko Dewoto100% (1)

- Presentation Coal 1Dokumen26 halamanPresentation Coal 1Joko Dewoto100% (1)

- By Pass System RCD-1 to SP3 RCD-2 to SP2 Pelabuhan Batubara TarahanDokumen18 halamanBy Pass System RCD-1 to SP3 RCD-2 to SP2 Pelabuhan Batubara TarahansutanuprojectsBelum ada peringkat

- Raymond Roller MillDokumen6 halamanRaymond Roller MillJoko Dewoto50% (2)

- Air in Standard and Normal ConditionDokumen2 halamanAir in Standard and Normal ConditionJoko DewotoBelum ada peringkat

- Energy Auditing and Recovery For Dry Type Cement Rotary Kiln Systems A Case StudyDokumen12 halamanEnergy Auditing and Recovery For Dry Type Cement Rotary Kiln Systems A Case Study1977julBelum ada peringkat

- Mastering Preheater Kiln Build-up ControlDokumen13 halamanMastering Preheater Kiln Build-up ControlJoko Dewoto100% (1)

- Pre Calci NerDokumen61 halamanPre Calci NerJoko Dewoto100% (2)

- PG 3047 3074 GasFlowMeasurement PracticalWorkDokumen28 halamanPG 3047 3074 GasFlowMeasurement PracticalWorkJoko Dewoto100% (2)

- Cement-Based Materials J Francis Young: AddressesDokumen5 halamanCement-Based Materials J Francis Young: AddressesJoko DewotoBelum ada peringkat

- Semen 30Dokumen15 halamanSemen 30Joko DewotoBelum ada peringkat

- The FLSmidth OK Mill for Cement and Slag GrindingDokumen69 halamanThe FLSmidth OK Mill for Cement and Slag GrindingJoko Dewoto100% (3)

- PackerDokumen13 halamanPackerJoko DewotoBelum ada peringkat

- Bab 2 Raw Mill System DG VRMDokumen80 halamanBab 2 Raw Mill System DG VRMJoko DewotoBelum ada peringkat

- Rotary KilnDokumen58 halamanRotary KilnFrancisco Uribe Parra100% (7)

- Comm Profile Cement PDFDokumen20 halamanComm Profile Cement PDFesvignesh100% (1)

- C Quant Software Mathematical Modeling in Quantitative Phase Analysis of Portland CementDokumen7 halamanC Quant Software Mathematical Modeling in Quantitative Phase Analysis of Portland CementJoko DewotoBelum ada peringkat

- Dust Collector InvestigationDokumen14 halamanDust Collector InvestigationJoko DewotoBelum ada peringkat

- Optionchecklistno2 Fans and BlowersDokumen1 halamanOptionchecklistno2 Fans and BlowersJoko DewotoBelum ada peringkat

- Cyclonic Separation and Dust CollectorDokumen29 halamanCyclonic Separation and Dust CollectorJoko DewotoBelum ada peringkat

- DuctingDokumen74 halamanDuctingJoko DewotoBelum ada peringkat

- General Flow SheetDokumen1 halamanGeneral Flow SheetJoko DewotoBelum ada peringkat

- General Lay OutDokumen1 halamanGeneral Lay OutJoko DewotoBelum ada peringkat

- Technical Specification Sheet: SAG KUPANG Modification ListDokumen21 halamanTechnical Specification Sheet: SAG KUPANG Modification ListJoko DewotoBelum ada peringkat

- Cement SiloDokumen10 halamanCement SiloJoko DewotoBelum ada peringkat

- Av Vibrating Screens PDFDokumen2 halamanAv Vibrating Screens PDFArnaldo BenitezBelum ada peringkat

- Experiment 1 HydraulicsDokumen9 halamanExperiment 1 Hydraulicsmon patrick pradoBelum ada peringkat

- Commonly Used SAP HR ReportsDokumen4 halamanCommonly Used SAP HR ReportsBrian GriffithBelum ada peringkat

- How To Prepare The SarDokumen107 halamanHow To Prepare The Sargoldencomet100% (1)

- 4 Retrofit of Reinforced Concrete Structures To Resist Blast EffectsDokumen7 halaman4 Retrofit of Reinforced Concrete Structures To Resist Blast EffectsbekirBelum ada peringkat

- 1 Kidde Interruptor de Baja PresiónDokumen1 halaman1 Kidde Interruptor de Baja PresiónTatiana RomeroBelum ada peringkat

- Anh Minh's Brochure (SUMO)Dokumen2 halamanAnh Minh's Brochure (SUMO)Truong Anh MinhBelum ada peringkat

- Photodetectors and Solar CellsDokumen11 halamanPhotodetectors and Solar CellsavecafeBelum ada peringkat

- Manual For Terrestrial Laser Scanner: July 2020Dokumen15 halamanManual For Terrestrial Laser Scanner: July 2020AKi Asmoro SantoBelum ada peringkat

- Learn SAS ProgrammingDokumen29 halamanLearn SAS ProgrammingSASTechiesBelum ada peringkat

- StaircaseDokumen9 halamanStaircaseubhutada100% (2)

- Tello SDK documentation for controlling Ryze Tello dronesDokumen5 halamanTello SDK documentation for controlling Ryze Tello dronesJuankarlos CondeBelum ada peringkat

- C2 ErefsuDokumen86 halamanC2 ErefsujquserBelum ada peringkat

- Alice Clayton - Seria Cocktail - Vol.1 BocanilaDokumen352 halamanAlice Clayton - Seria Cocktail - Vol.1 BocanilaAndreeaBelum ada peringkat

- ASME LECTURE-Fittings-TrainingDokumen61 halamanASME LECTURE-Fittings-Traininghcsharma1967Belum ada peringkat

- Improving Combat Efficiency of Army Engineers with MB 3 Bridge BoatDokumen4 halamanImproving Combat Efficiency of Army Engineers with MB 3 Bridge BoatAnonymous sfkedkymBelum ada peringkat

- Product Reference Guide: Spring 2006 CatalogDokumen180 halamanProduct Reference Guide: Spring 2006 Catalogjoseprudencio8848Belum ada peringkat

- ABB REA XXX LE ENDokumen2 halamanABB REA XXX LE ENluijos1Belum ada peringkat

- Ar 2018-19 English NewDokumen512 halamanAr 2018-19 English Newprem chand tiwariBelum ada peringkat

- RC Chapter 8Dokumen14 halamanRC Chapter 8ianiroy130% (1)

- Direct Voice InputDokumen26 halamanDirect Voice InputArjun SharmanBelum ada peringkat

- Oracle HRMS Work StructureDokumen36 halamanOracle HRMS Work StructureshrinawBelum ada peringkat

- Unit Diagnose and Repair Body Electrical System Diagnose and Repair Body Electrical System L.O. 3 Repair Body Electrical SystemDokumen159 halamanUnit Diagnose and Repair Body Electrical System Diagnose and Repair Body Electrical System L.O. 3 Repair Body Electrical SystemYvonne Janet Cosico-Dela FuenteBelum ada peringkat

- High School DxD, Vol. 1 - mangaDokumen1 halamanHigh School DxD, Vol. 1 - mangaCristiano D. CulabaBelum ada peringkat

- LSDI - Contributing To Libya's Future - SummaryDokumen26 halamanLSDI - Contributing To Libya's Future - SummarythegpcgroupBelum ada peringkat

- Managing Interpersonal Conflict EffectivelyDokumen6 halamanManaging Interpersonal Conflict EffectivelyJugjit SinghBelum ada peringkat

- tps60401 q1Dokumen29 halamantps60401 q1Rizwan Akram GujjarBelum ada peringkat

- SAP DB2 BLU Deployment Prerequisite: Important Points To Be CheckDokumen4 halamanSAP DB2 BLU Deployment Prerequisite: Important Points To Be Checkrajesh.9127276Belum ada peringkat

- Mster CTLG RNLD JffreyDokumen84 halamanMster CTLG RNLD JffreyCIM VLPSOBelum ada peringkat

- Entreprenuerial Skills SurveyDokumen42 halamanEntreprenuerial Skills SurveyversmajardoBelum ada peringkat