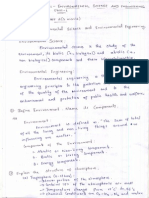

Esd 1

Diunggah oleh

arul_elvisJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Esd 1

Diunggah oleh

arul_elvisHak Cipta:

Format Tersedia

Electronic System Design Lab Manual

VI SEMESTER ECE

1

LIST OF EXPERIMENTS LIST OF EXPERIMENTS LIST OF EXPERIMENTS LIST OF EXPERIMENTS

EC1355 EC1355 EC1355 EC1355 ELECTRONIC SYSTEM DESIGN LAB ELECTRONIC SYSTEM DESIGN LAB ELECTRONIC SYSTEM DESIGN LAB ELECTRONIC SYSTEM DESIGN LAB 0 0 3 100 0 0 3 100 0 0 3 100 0 0 3 100

1. DC power supply design using buck boost converters

Design the buck-boost converter for the given input voltage variation, load current and

output voltage. Plot the regulation characteristics.

2. DC power supply design using fly back converter (Isolated type)

Design the fly back converter using ferrite core transformer for the given input voltage

variation load current and output voltage.

Plot the regulation characteristics.

3. Design of a 4-20mA transmitter for a bridge type transducer.

Design the Instrumentation amplifier with the bridge type transducer (Thermistor or any

resistance variation transducers) and convert the amplified voltage from the

instrumentation amplifier to 4 20 mA current using op-amp. Plot the variation of the

temperature Vs output current.

4. Design of AC/DC voltage regulator using SCR

Design a phase controlled voltage regulator using full wave rectifier and SCR, vary the

conduction angle and plot the output voltage.

5. Design of process control timer

Design a sequential timer to switch on & off at least 3 relays in a particular sequence

using timer IC.

6. Design of AM / FM modulator / demodulator

i. Design AM signal using multiplier IC for the given carrier frequency and modulation

index and demodulate the AM signal using envelope detector.

ii. Design FM signal using VCO IC NE566 for the given carrier frequency and demodulate

the same using PLL NE 565.

7. Design of Wireless date modem.

Design a FSK modulator using 555 and convert it to sine wave using filter and transmit

the same using IR LED and demodulate the same PLL NE 565.

8. PCB layout design using CAD

Drawing the schematic of simple electronic circuit and design of PCB layout using CAD

9. Microcontroller based systems design

Design of microcontroller based system for simple applications like security systems

combination lock etc. using 89c series flash micro controller.

Electronic System Design Lab Manual

VI SEMESTER ECE

2

10. DSP based system design

Design a DSP based system for simple applications like echo generation, etc. using TMS

320 DSP kit.

Electronic System Design Lab Manual

VI SEMESTER ECE

3

1. DC POWER SUPPLY DESIGN USING BUCK 1. DC POWER SUPPLY DESIGN USING BUCK 1. DC POWER SUPPLY DESIGN USING BUCK 1. DC POWER SUPPLY DESIGN USING BUCK BOOST CONVERTERS BOOST CONVERTERS BOOST CONVERTERS BOOST CONVERTERS

Aim Aim Aim Aim

Design the buck-boost converter for the given input voltage variation, load current and output

voltage. Plot the regulation characteristics.

Apparatus Required Apparatus Required Apparatus Required Apparatus Required

DC DC DC DC- -- -DC Converter Basics DC Converter Basics DC Converter Basics DC Converter Basics

A DC-to-DC converter is a device that accepts a DC input voltage and produces a DC

output voltage. Typically the output produced is at a different voltage level than the input. In

addition, DC-to-DC converters are used to provide noise isolation, power bus regulation, etc. This

is a summary of some of the popular DC-to-DC converter topologies:

1. 1. 1. 1. Buck Converter Step Buck Converter Step Buck Converter Step Buck Converter Step- -- -Down Converter Down Converter Down Converter Down Converter

In this circuit the transistor turning ON will put voltage Vin on one end of the inductor.

This voltage will tend to cause the inductor current to rise. When the transistor is OFF, the

current will continue flowing through the inductor but now flowing through the diode. We initially

assume that the current through the inductor does not reach zero, thus the voltage at Vx will

now be only the voltage across the conducting diode during the full OFF time. The average

voltage at Vx will depend on the average ON time of the transistor provided the inductor current

is continuous.

Fig. 1: Buck Converter

Electronic System Design Lab Manual

VI SEMESTER ECE

4

Fig. 2: Voltage and current changes

To analyse the voltages of this circuit let us consider the changes in the inductor current over

one cycle. From the relation

the change of current satisfies

For steady state operation the current at the start and end of a period T will not change. To get a

simple relation between voltages we assume no voltage drop across transistor or diode while

ON and a perfect switch change. Thus during the ON time Vx=Vin and in the OFF Vx=0. Thus

which simplifies to

or

and defining "duty ratio" as

Electronic System Design Lab Manual

VI SEMESTER ECE

5

the voltage relationship becomes Vo=D Vin Since the circuit is lossless and the input and output

powers must match on the average Vo* Io = Vin* Iin. Thus the average input and output current

must satisfy Iin =D Io These relations are based on the assumption that the inductor current does

not reach zero.

1.1 Transition between continuous and discontinuous 1.1 Transition between continuous and discontinuous 1.1 Transition between continuous and discontinuous 1.1 Transition between continuous and discontinuous

When the current in the inductor L remains always positive then either the transistor T1 or the

diode D1 must be conducting. For continuous conduction the voltage Vx is either Vin or 0. If the

inductor current ever goes to zero then the output voltage will not be forced to either of these

conditions. At this transition point the current just reaches zero as seen in Figure 3. During the

ON time Vin-Vout is across the inductor thus

(1)

The average current which must match the output current satisfies

(2)

Fig. 3: Buck Converter at Boundary

If the input voltage is constant the output current at the transition point satisfies

Electronic System Design Lab Manual

VI SEMESTER ECE

6

(3)

1.2 Voltage Ratio of Buck Converter (Discontin 1.2 Voltage Ratio of Buck Converter (Discontin 1.2 Voltage Ratio of Buck Converter (Discontin 1.2 Voltage Ratio of Buck Converter (Discontinuous Mode) uous Mode) uous Mode) uous Mode)

As for the continuous conduction analysis we use the fact that the integral of voltage across the

inductor is zero over a cycle of switching T. The transistor OFF time is now divided into segments

of diode conduction ddT and zero conduction doT. The inductor average voltage thus gives

(Vin - Vo ) DT + (-Vo) dT = 0 (4)

Fig. 4: Buck Converter - Discontinuous Conduction

(5)

for the case . To resolve the value of consider the output current which is half the

peak when averaged over the conduction times

(6)

Considering the change of current during the diode conduction time

(7)

Thus from (6) and (7) we can get

Electronic System Design Lab Manual

VI SEMESTER ECE

7

(8)

using the relationship in (5)

(9)

and solving for the diode conduction

(10)

The output voltage is thus given as

(11)

defining k* = 2L/(Vin T), we can see the effect of discontinuous current on the voltage ratio of

the converter.

Fig. 5: Output Voltage vs Current

Electronic System Design Lab Manual

VI SEMESTER ECE

8

As seen in the figure, once the output current is high enough, the voltage ratio depends only on

the duty ratio "d". At low currents the discontinuous operation tends to increase the output

voltage of the converter towards Vin.

2. BOOST CONVERTER STEP 2. BOOST CONVERTER STEP 2. BOOST CONVERTER STEP 2. BOOST CONVERTER STEP- -- -UP CONVERTER UP CONVERTER UP CONVERTER UP CONVERTER

The schematic in Fig. 6 shows the basic boost converter. This circuit is used when a higher

output voltage than input is required.

Fig. 6: Boost Converter Circuit

While the transistor is ON Vx =Vin, and the OFF state the inductor current flows through the diode

giving Vx =Vo. For this analysis it is assumed that the inductor current always remains flowing

(continuous conduction). The voltage across the inductor is shown in Fig. 7 and the average

must be zero for the average current to remain in steady state

This can be rearranged as

and for a lossless circuit the power balance ensures

Electronic System Design Lab Manual

VI SEMESTER ECE

9

Fig. 7: Voltage and current waveforms (Boost Converter)

Since the duty ratio "D" is between 0 and 1 the output voltage must always be higher than the

input voltage in magnitude. The negative sign indicates a reversal of sense of the output voltage.

3. BUCK 3. BUCK 3. BUCK 3. BUCK- -- -BOOST CONVERTER BOOST CONVERTER BOOST CONVERTER BOOST CONVERTER

Fig. 8: schematic for buck-boost converter

With continuous conduction for the Buck-Boost converter Vx =Vin when the transistor is ON and

Vx =Vo when the transistor is OFF. For zero net current change over a period the average voltage

across the inductor is zero

Electronic System Design Lab Manual

VI SEMESTER ECE

10

Fig. 9: Waveforms for buck-boost converter

which gives the voltage ratio

and the corresponding current

Since the duty ratio "D" is between 0 and 1 the output voltage can vary between lower or higher

than the input voltage in magnitude. The negative sign indicates a reversal of sense of the

output voltage.

RESULT: RESULT: RESULT: RESULT:

Electronic System Design Lab Manual

VI SEMESTER ECE

11

2. DC POWER SUPPLY DESIGN USING FLYBACK CONVERTERS 2. DC POWER SUPPLY DESIGN USING FLYBACK CONVERTERS 2. DC POWER SUPPLY DESIGN USING FLYBACK CONVERTERS 2. DC POWER SUPPLY DESIGN USING FLYBACK CONVERTERS

Aim Aim Aim Aim

Design the fly back converter using ferrite core transformer for the given input voltage

variation load current and output voltage.

Apparatus Required Apparatus Required Apparatus Required Apparatus Required

Isolated DC Isolated DC Isolated DC Isolated DC- -- -DC Converters DC Converters DC Converters DC Converters

In many DC-DC applications, multiple outputs are required and output isolation may need to be

implemented depending on the application. In addition, input to output isolation may be

required to meet safety standards and / or provide impedance matching.

1. Flyback Converter 1. Flyback Converter 1. Flyback Converter 1. Flyback Converter

The flyback converter can be developed as an extension of the Buck-Boost converter. Fig 1

shows the basic converter; Fig 2 replaces the inductor by a transformer. The buck-boost

converter works by storing energy in the inductor during the ON phase and releasing it to the

output during the OFF phase. With the transformer the energy storage is in the magnetisation of

the transformer core. To increase the stored energy a gapped core is often used.

In Fig 3 the isolated output is clarified by removal of the common reference of the input and

output circuits.

Fig. 1: Buck-Boost Converter

Electronic System Design Lab Manual

VI SEMESTER ECE

12

Fig. 2: Replacing inductor by transformer

Fig. 3: Flyback converter re-configured

2. Forward Converter 2. Forward Converter 2. Forward Converter 2. Forward Converter

The concept behind the forward converter is that of the ideal transformer converting the input

AC voltage to an isolated secondary output voltage. For the circuit in Fig. 4, when the transistor

is ON, Vin appears across the primary and then generates

The diode D1 on the secondary ensures that only positive voltages are applied to the output

circuit while D2 provides a circulating path for inductor current if the transformer voltage is zero

or negative.

Electronic System Design Lab Manual

VI SEMESTER ECE

13

Fig. 4: Forward Converter

The problem with the operation of the circuit in Fig 4 is that only positive voltage is applied

across the core, thus flux can only increase with the application of the supply. The flux will

increase until the core saturates when the magnetizing current increases significantly and

circuit failure occurs. The transformer can only sustain operation when there is no significant DC

component to the input voltage. While the switch is ON there is positive voltage across the core

and the flux increases. When the switch turns OFF we need to supply negative voltage to reset

the core flux. The circuit in Fig. 5 shows a tertiary winding with a diode connection to permit

reverse current. Note that the "dot" convention for the tertiary winding is opposite those of the

other windings. When the switch turns OFF current was flowing in a "dot" terminal. The core

inductance act to continue current in a dotted terminal, thus

Fig. 5: Forward converter with tertiary winding

RESULT: RESULT: RESULT: RESULT:

Electronic System Design Lab Manual

VI SEMESTER ECE

14

3. DESIGN OF A 4 3. DESIGN OF A 4 3. DESIGN OF A 4 3. DESIGN OF A 4- -- -20mA TRANSMITTER FOR A BRIDGE TYPE TRANSDUCER 20mA TRANSMITTER FOR A BRIDGE TYPE TRANSDUCER 20mA TRANSMITTER FOR A BRIDGE TYPE TRANSDUCER 20mA TRANSMITTER FOR A BRIDGE TYPE TRANSDUCER

Aim Aim Aim Aim

Design the Instrumentation amplifier with the bridge type transducer (Thermistor or any Design the Instrumentation amplifier with the bridge type transducer (Thermistor or any Design the Instrumentation amplifier with the bridge type transducer (Thermistor or any Design the Instrumentation amplifier with the bridge type transducer (Thermistor or any

resistance variat resistance variat resistance variat resistance variation transducers) and convert the amplified voltage from the instrumentation ion transducers) and convert the amplified voltage from the instrumentation ion transducers) and convert the amplified voltage from the instrumentation ion transducers) and convert the amplified voltage from the instrumentation

amplifier to 4 amplifier to 4 amplifier to 4 amplifier to 4 20 mA current using op 20 mA current using op 20 mA current using op 20 mA current using op- -- -amp. Plot the variation of the temperature Vs output amp. Plot the variation of the temperature Vs output amp. Plot the variation of the temperature Vs output amp. Plot the variation of the temperature Vs output

current current current current

Apparatus required

Sl.No Sl.No Sl.No Sl.No Components Components Components Components Type/Range Type/Range Type/Range Type/Range

Quantity Quantity Quantity Quantity

1 OpAmp MA741 3

2 Thermister or RTD - 1

3 Ammeter (0-20)mA 1

4

Resister

8k,47k,

470k, 100k,

470, 1meg

1,2, 2, 2,1,4

5 DRB - 1

6 Power supply

5V, 15V,(0-5)V 1,1

A 4 A 4 A 4 A 4- -- -20ma Transmitter For A Bridge Type Transducer 20ma Transmitter For A Bridge Type Transducer 20ma Transmitter For A Bridge Type Transducer 20ma Transmitter For A Bridge Type Transducer

4 44 4- -- -20 mA 20 mA 20 mA 20 mA is an analog electrical transmission standard for industrial instrumentation and

communication. The symbol "mA" is standard SI notation for milliampere, or 1/1000 of an

ampere. The signal is a current loop where 4 mA represents zero percent signals and 20 mA

represents the one hundred percent signal.

The reason zero is at 4 mA and not 0 mA is that this "live zero" allows the receiving

instrumentation to differentiate between a zero signal and a broken wire or a dead instrument.

This standard was developed in the 1950s and is still widely used in industry today, even though

many attempts have been made to replace it with digital forms of communication such as

fieldbus and Profibus. Its benefits of being a widely followed standard, low cost, its reliability and

immunity to electrical noise keep it in regular use. Current loop is also much easier to

understand and debug than more complicated digital fieldbuses. Using fieldbuses and solving

related problems usually requires much more education and understanding than required by

simple current loop solutions. Additional digital communication to the device can be added to

current loop using HART Protocol.

Electronic System Design Lab Manual

VI SEMESTER ECE

15

Process Process Process Process- -- -control use control use control use control use

For industrial process control instruments, analog 4-20 mA and 10-50 mA current loops

are commonly used for analog signaling, with 4 mA representing the lowest end of the range

and 20 mA the highest. The key advantages of the current loop are that the accuracy of the

signal is not affected by voltage drop in the interconnecting wiring, and that the loop can supply

operating power to the device. Even if there is significant electrical resistance in the line, the

current loop transmitter will maintain the proper current, up to its maximum voltage capability.

The live-zero represented by 4 mA allows the receiving instrument to detect some failures of the

loop, and also allows transmitter devices to be powered by the same current loop (called two-

wire transmitters). Such instruments are used to measure pressure, temperature, flow, pH or

other process variables. A current loop can also be used to control a valve positioner or other

output actuator. An analog current loop can be converted to a voltage input with a precision

resistor. Since input terminals of instruments may have one side of the current loop input tied to

the chassis ground (earth), analog isolators may be required when connecting several devices in

series.

Taking the point of view of the source of current for the loop, devices may be classified as

active (supplying power) or passive (relying on loop power). For example, a chart recorder may

provide loop power to a transmitter instrument such as a pressure transmitter. The pressure

transmitter modulates the current on the loop to send the signal to the strip chart recorder, but

does not in itself supply power to the loop and so is passive. Another loop may contain two

passive chart recorders, a passive pressure transmitter, and a 24 V battery. (The battery is the

active device). Panel mount displays and chart recorders are commonly termed 'indicator

devices' or 'process monitors'. Several passive indicator devices may be connected in series, but

a loop must have only one transmitter device and only one power source (active device).

The relationship between current value and process variable measurement is set by

calibration, which assigns different ranges of engineering units to the span between 4 and 20

mA. Occasionally the mapping between engineering units and current was inverted, so that 4

mA represented the maximum and 20 mA the minimum.

Design Procedure Design Procedure Design Procedure Design Procedure

Problem: Design a (4-20) mA transmitter for a Thermister based Temperature indicator to

indicate 30

o

C to 60

0

C as 4-20 mA.

Design Data: At 30

o

C RT = 8k, at 60

o

C RT = 3k

Design of Bridge:

At 30

o

C RT = 8k, Differential Voltage

VD = ((R4/(R4 + R2) - (RT/(RT + R1) = 0V ----(1)

At 60

o

C RT = 3k, Differential Voltage

VD = ((R4/(R4 + R2) - (RT/(RT + R1) = 400mV ----(2)

From equation 1 and 2, R1 = R2 = 51.3 k 47 k, R4 = 8k.

Design of Differential Amplifier:

Electronic System Design Lab Manual

VI SEMESTER ECE

16

Output of Differential amplifier = (0-4)V for 30

o

C to 60

0

C Temperature variation.

Gain of Differential amplifier = 10, Assume Rf =1 Meg , Ri = Rf / 10 = 100k

Design of Summing Amplifier:

Output of Summing Amplifier = (2 to 10) V for (0-4) V input.

Assume, Gain of Summing Amplifier = 2, Rf =1 Meg , Ri = Rf / 2 = 500k 470k

V2 1V

Design of V to I Converter:

Input voltage (2 10) V

Required output Current = (4 - 20) mA

Ri = 500 470 .

4 44 4- -- -20 mA Transmitter Bridge Circuit 20 mA Transmitter Bridge Circuit 20 mA Transmitter Bridge Circuit 20 mA Transmitter Bridge Circuit

HI

1meg

100k

HI

R4

8k

1meg

470

100k

AD741

3

2

7

4

6

1

5

+

-

V

+

V

-

OUT

OS1

OS2

0

RTD

(4-20) mA

HI

AD741

3

2

7

4

6

1

5

+

-

V

+

V

-

OUT

OS1

OS2

15

0

470k

HI

AD741

3

2

7

4

6

1

5

+

-

V

+

V

-

OUT

OS1

OS2

LO

R1

47k

15

0

LO

1meg

0

V2

R2

47k

1meg

LO

LO

470k

0

5 V

Electronic System Design Lab Manual

VI SEMESTER ECE

17

Observation Observation Observation Observation

For temperature from 30

o

C to 60

0

C measure the current and tabulate the same.

Sl. No. Sl. No. Sl. No. Sl. No. Temperature ( Temperature ( Temperature ( Temperature (

o oo o

C) C) C) C)

Resistance of Resistance of Resistance of Resistance of

Thermistor (k Thermistor (k Thermistor (k Thermistor (k ) )) )

Output Output Output Output

Current(mA) Current(mA) Current(mA) Current(mA)

Result Result Result Result:

Electronic System Design Lab Manual

VI SEMESTER ECE

18

5. DESIGN OF PROCESS CONTROL TIMER 5. DESIGN OF PROCESS CONTROL TIMER 5. DESIGN OF PROCESS CONTROL TIMER 5. DESIGN OF PROCESS CONTROL TIMER

Aim Aim Aim Aim

Design a sequential timer to switch on & relays in a particular sequence using timer IC

Apparatus required Apparatus required Apparatus required Apparatus required

Sl.No Sl.No Sl.No Sl.No Components Components Components Components Type/Range Type/Range Type/Range Type/Range

Quantity Quantity Quantity Quantity

1 Counter IC 7490 1

2 AND gate IC 7408 1

3 OR gate IC 7432 1

4 NOT gate IC 7404 1

5 XOR gate IC 7486 1

6 LED 6

7 Pulse generator 1

8 Powersupply 5V 1

Process Control Timer Process Control Timer Process Control Timer Process Control Timer

RESULT: RESULT: RESULT: RESULT:

Electronic System Design Lab Manual

VI SEMESTER ECE

19

6. DESIGN OF AM / FM MODULATOR / DEMODULATOR 6. DESIGN OF AM / FM MODULATOR / DEMODULATOR 6. DESIGN OF AM / FM MODULATOR / DEMODULATOR 6. DESIGN OF AM / FM MODULATOR / DEMODULATOR

Aim Aim Aim Aim

iii. Design AM signal using multiplier IC for the given carrier frequency and modulation

index and demodulate the AM signal using envelope detector.

iv. Design FM signal using VCO IC NE566 for the given carrier frequency and demodulate

the same using PLL NE 565.

Apparatus Required Apparatus Required Apparatus Required Apparatus Required

Am Modulator Am Modulator Am Modulator Am Modulator

The basic operation performed in Amplitude Modulation is multiplying two signals

together to produce a modulated signal s(t). The first signal is called the carrier signal and is

made of a pure sine wave at a high frequency fc. The carrier signal does not contain any

information and serves mainly to "carry" the contents of the information signal to higher

frequencies so that it can be radiated through an antenna. The second signal is called the

complex envelope signal g(t). The complex envelope signal has particular meaning in AM where

it provides the slow varying envelope to the fast varying modulated signal s(t). The complex

envelope g(t) is strongly related to the modulating or information signal m(t).

Modulating signal (information) ( ) ( ) t f A t m

m m

2 cos = simple case

Complex envelope signal ( ) ( ) [ ] t m A t g

c

+ = 1 for Amplitude Modulation

Carrier signal

t f j

c

e

2

Modulated signal ( ) ( ) { }

t f j

c

e t g t s

2

Re =

It can be shown that the modulated signal s(t) reduces to the expression in Equation 1.

( ) ( ) ( ) ( ) ( ) ( ) t f f

A A

t f f

A A

t f A t s

m c

m c

m c

m c

c c

+ + + = 2 cos

2

2 cos

2

2 cos 1

The Fourier Transform for positive frequencies of the modulated signal is given by Equation 2.

( ) ( ) ( ) ( ) ( ) ( )

m c

m c

m c

m c

c

c

f f f

A A

f f f

A A

f f

A

f S + + + =

4 4 2

.2

Figure 1 shows the complex envelope signal g(t) and the carrier signal on the left and the

modulated signal for Am = 0.5 on the right. It can be seen that the complex envelope g(t)

corresponds to the slow varying envelope in the modulated signal s(t).

Electronic System Design Lab Manual

VI SEMESTER ECE

20

0 20 40 60 80 100 120 140 160 180 200

-2

-1

0

1

2

v

o

l

t

s

complex envelope

0 20 40 60 80 100 120 140 160 180 200

-2

-1

0

1

2

time in microseconds

v

o

l

t

s

carrier

0 20 40 60 80 100 120 140 160 180 200

-2

-1.5

-1

-0.5

0

0.5

1

1.5

2

time in microseconds

v

o

l

t

s

modulated signal

Figure 1: Time representation of amplitude modulation of a sine wave

(fc = 100 kHz, fm = 10 kHz, Ac = 1 and Am = 50% modulation)

Figure 2 shows the frequency magnitude spectrum of the AM modulated signal s(t). There are

three frequency components. The strongest component occurs at the frequency of the carrier

signal fc. The other two components have the same magnitude and occur at the difference

frequency fc - fm and at the sum frequency fc + fm. One notes that the magnitude of the

components at the difference frequency fc - fm and at the sum frequency fc + fm is proportional to

Ac and Am, while the magnitude of the component at the carrier frequency fc is only proportional

to Ac. It is therefore possible to increase or decrease the magnitude of the fc - fm and at the fc +

fm components without changing the magnitude of the carrier frequency component by

changing Am. The value of Am therefore represents the relative amount of the modulating signal

m(t) compared to the carrier signal. The value of Am, often expressed in percent is called the

modulation index. More generally, the modulation index is defined as

c

A

A A

M

=

2

min max

where Amax, Amin and Ac are the maximum, minimum and average amplitudes of the envelope of

the modulated signal s(t) respectively.

|S(f)|

0 f

c

-f

m

f

c

+f

m

f

f

c

A

c

------

2

A

c

A

m

--------

4

A

c

A

m

--------

4

20 40 60 80 100 120 140 160 180

0

0.05

0.1

0.15

0.2

0.25

0.3

0.35

0.4

0.45

0.5

frequency in kHz

Figure 2: Frequency representation of amplitude modulation of a sine wave

(fc = 100 kHz, fm = 10 kHz, Ac = 1 and Am = 50% modulation)

Electronic System Design Lab Manual

VI SEMESTER ECE

21

Frequency Modulatio Frequency Modulatio Frequency Modulatio Frequency Modulation nn n

Frequency modulation (FM) is the standard technique for high-fidelity communications as

is evident in the received signals of the FM band (88-108 MHz) vs. the AM band (450-1650 KHz).

The main reason for the improved fidelity is that FM detectors, when properly designed, are not

sensitive to random amplitude variations which are the dominant part of electrical noise (heard

as static on the AM radio). Frequency modulation is not only used in commercial radio

broadcasts, but also in police and hospital communications, emergency channels, TV sound,

wireless (cellular) telephone systems, and radio amateur bands above 30 MHz.

The basic idea of an FM signal vs. an AM signal is shown in Fig. 3. In an FM signal, the

frequency of the signal is changed by the modulation (baseband) signal while its amplitude

remains the same. In an AM signal, we now know that it is the amplitude (or the envelope) of

the signal that is changed by the modulation signal. The FM signal can be summarized as

follows:

Figure 3 Figure 3 Figure 3 Figure 3: FM representation vs. AM representation.

1. The amplitude of the modulation signal determines the amount of the frequency change from

the center frequency.

2. The frequency of the modulation signal determines the rate of the frequency change from the

center frequency.

3. The amplitude of the FM signal is constant at all times and is independent of the modulation

signal.

Electronic System Design Lab Manual

VI SEMESTER ECE

22

Mathematically, an FM signal is written as:

V = Asin

c

t + m

f

sin

m

t ( )

where A = the amplitude of the signal

c

= center frequency (frequency for no modulation signal)

m

= modulation frequency

and m

f

= FM modulation index = /f

m

where = maximum frequency shift caused by the modulation signal

f

m

= frequency of the modulation signal.

The spectrum of an FM signal is quite complicated and is dependent on m

f

. Actually, it follows a

Bessel Function (you will study this in a senior-level math course) and is given by:

FM Spectrum = J

0

m

f

( )cos

c

t ( ) Center Frequency

c

( )

J

1

m

f

( )cos

c

m

( )t cos

c

+

m

( )t

[ ]

Components at

c

+ /

m

( )

+J

2

m

f

( )cos

c

2

m

( )t +cos

c

2

m

( )t

[ ]

Components at

c

+ /2

m

( )

J

3

m

f

( )cos

c

3

m

( )t cos

c

+3

m

( )t

[ ]

Components at

c

+ /3

m

( )

+ .....

where J

0

m

f

( ), J

1

m

f

( ) etc. are in volts, and are the levels of the frequency components of the

FM signal for A = 1 V.

Figure 4 gives some spectrum representation for various modulation indices. Notice from

Table 1 that for m

f

= 2.4, there is no power in the center frequency component (J

0

(2.4) =0). This

also occurs at m

f

= 5.5, 8.6, ... . This does not mean that there is no power transmitted in the

signal. All that it means is that for m = 2.4, 5.5, ..., there is no power at the center frequency and

all of the power is in the sidebands.

The bandwidth of an FM signal depends on the modulation index (m

f

), and is approximated by

the well-known Carson s Rule:

BW = 2 (+ f

m(max)

)

where f

m(max)

is the maximum frequency of the modulating signal. The factor (2) in the

equation is to account for both the upper and lower sidebands (left and right of the carrier). This

equation gives the bandwidth which contains 98% of the signal power.

Electronic System Design Lab Manual

VI SEMESTER ECE

23

Figure 4 Figure 4 Figure 4 Figure 4: Frequency spectrum of FM signals with different m

f

and same modulating frequency.

The best way to understand FM signals is to consider a real life example. Let us take an Ann

Arbor station, 107.1 FM, broadcasting at 107.1 MHz with a power of 50 KW. The bandwidth of

the modulation signal is from 30 Hz to 15 KHz which is excellent for high-fidelity broadcast. The

maximum deviation set by the FCC, (), is 75 KHz. The range of the modulation index is

therefore:

m

f(min)

= /f

m(max)

= 75 KHz/15 KHz= 5 (for f

m

= 15 KHz)

to

m

f(max)

= /f

m(min)

= 75 KHz/30 Hz = 2500! (for f

m

= 30 Hz)

Notice that the modulation index changes a lot with the modulation frequency (from 2,500 to 5).

For the 15 KHz signal, m

f

= 5, we see that the frequency components are up high up to J

6

and

drop quickly afterwards. This means that the bandwidth of the signal is 6x15 KHz = 90 KHz on

each side of the center frequency (a total bandwidth of 180 KHz). We can also use Carsons rule

and, BW = 2 ( + f

m(max)

) = 180 KHz or 90 KHz on each side of the center frequency.

For the 30 Hz signal and m

f

= 2,500, a huge number of sidebands exist but remember that there

are now spaced at only 30 Hz apart. The total bandwidth of the signal is BW = 2 (+ f

m(min)

) =

150 KHz or 75 KHz on each side of the center frequency. This means that the bandwidth of the

FM signal changes from +/- 75 KHz to +/- 90 KHz from the carrier depending on the modulation

frequency.

Commercial FM stations are therefore spaced 200 KHz apart to avoid interference for all

modulating frequencies. In order to even isolate the stations further, FCC only assigns alternate

stations for a certain area. For example, in the Detroit/Ann Arbor area, the stations are 107.1,

107.5 (and 93.1, 93.5, 93.9, ...) spaced 400 KHz apart. In adjoining areas, such as Toledo to the

south (or Lansing to the north, but very far from Toledo), the stations are also centered at 400

KHz, but they are 107.3, 107.7, etc... (and 93.3, 93.7, 94.1 etc...). This allows inexpensive radios

with bad-to-acceptable selectivity to receive FM stations without interference from adjoining

stations (since they are 400 KHz away and not only 200 KHz away). The 200 KHz-away stations

are very far and therefore their signals would appear as noise in the receiver. However, as

mentioned before, FM receivers have excellent noise rejection and therefore are not affected by

the far-away stations.

Electronic System Design Lab Manual

VI SEMESTER ECE

24

FM Generation Using LM 566C Voltage FM Generation Using LM 566C Voltage FM Generation Using LM 566C Voltage FM Generation Using LM 566C Voltage- -- -Controlled Oscillator: Controlled Oscillator: Controlled Oscillator: Controlled Oscillator:

1. Connect the LM 566C as shown below. The center frequency is set by R

o

, C

o

, V

5

/V

+

. Set V

+

(V

cc

) to 10 V.

2. Measure the output voltage V

o

(pin #4). It should be a triangular wave with a frequency of

100-110 KHz and Vppk around 1.8 V.

3. Connect the signal generator to the modulation input (V

s

) and set it to a sine wave

with f = 5 KHz and Vppk= 200 mV. Basically, the voltage at pin #5 is now varying

by +/- 0.1 V.

The output frequency of the LM 566 will vary by +/- 10 KHz (this is the maximum deviation).

This is the case of m

f

= 2 (since f

m

=5 KHz). Notice how the amplitude of the FM signal

remains constant. Look at the output in frequency domain and check that this is correct (do

not make any sideband measurements). Choose a center frequency of 244 KHz. You will see

other sidebands due to the third harmonic of the triangular wave.

4. Change from a sine wave to a square wave with Vppk = 400 mV. You will have now only two

frequencies, one around 80 KHz and one around 120 KHz. This is an FSK signal, which is

generated by the VCO.

5. Disconnect the connection to pin #5.

6. Connect the circuit shown below to the LM 566. Notice the 10 K/560 voltage divider at

the output of the LM 566, and the 0.1 F capacitor DC block between the LM 566 and the

LM 386.

7. Measure the output of the LM 386. It should be a nice triangular wave with Vppk around

1.6 V

8. Connect a 1.6 nF capacitor in parallel with the 560 resistor. This capacitor results in a

corner frequency of around 180 KHz and therefore passes the 100 KHz components and

attenuates the third and fifth harmonic components of the triangular wave. Look at the

output waveform of the LM 386 and notice that it now resembles a sine wave.

9. Measure the frequency components of the LM 386 output for the quasi-sine waveform

(Vppk, fundamental and second/third harmonic levels only)

10. Connect V

s

to pin #5 of the LM 566 through the 4.7 F DC-block capacitor, and set V

s

to 200

mV

ppk

, f = 5 KHz sinewave. Measure the output voltage of the LM 386. Look at the resulting

waveform and plot the graph.

FM Generation Using LM 566C Voltage FM Generation Using LM 566C Voltage FM Generation Using LM 566C Voltage FM Generation Using LM 566C Voltage- -- -Controlled Os Controlled Os Controlled Os Controlled Oscillator: cillator: cillator: cillator:

Electronic System Design Lab Manual

VI SEMESTER ECE

25

FM Demodulation Using LM 565 Phase Locked Loop: FM Demodulation Using LM 565 Phase Locked Loop: FM Demodulation Using LM 565 Phase Locked Loop: FM Demodulation Using LM 565 Phase Locked Loop:

RESULT: RESULT: RESULT: RESULT:

Modulated

Output

Electronic System Design Lab Manual

VI SEMESTER ECE

26

8. PCB LAYOUT DESIGN USING CAD 8. PCB LAYOUT DESIGN USING CAD 8. PCB LAYOUT DESIGN USING CAD 8. PCB LAYOUT DESIGN USING CAD

Aim Aim Aim Aim

Drawing the schematic of simple electronic circuit and design of PCB layout using CAD

Pcb Layout Design Using Cad Pcb Layout Design Using Cad Pcb Layout Design Using Cad Pcb Layout Design Using Cad

Preparing a Capture design for Layout is a two-part process. First, you must create a valid

design and then create a netlist in an .MNL format for Layout. After you have prepared your

Capture design, you can create a new Layout design using the .MNL netlist.

Preparing a Capture design for Layout is a two-part process. First, you must create a valid

design. Then, you need to create a netlist in a .MNL format in Capture and read it into Layout.

To prepare your Capture design To prepare your Capture design To prepare your Capture design To prepare your Capture design

If you want to send part or net information from a Capture schematic design, add a user-defined

property with a name from the property tables and assign a value to the property. The property

name must be in uppercase, as given in the tables.

1 On your schematic page, select the objects you want to send to Layout, then right-click

and choose Edit Properties from the pop-up menu. The property editor will appear.

2 Click the down arrow on the Filter by drop-down list to expand the list, and select Layout.

The columns in the spreadsheet change to display properties available in Layout. The cells

below each property column heading appear white with hash marks, indicating that these

properties are not yet assigned to the part or net.

3 Assign values to the properties of the selected objects on the schematic by clicking on a

cell, typing in the value, and pressing ENTER or clicking Apply. The hash marks disappear and

the property is applied to the object.

4 Assign PCB footprints to each of your schematic parts. Use only Layout footprint names,

selecting from those shown in the OrCAD Layout for Windows Footprint Libraries, or those in

your custom footprint libraries.

The pin numbers for pin names where no number exists must match the pad names on the

Layout footprint.

Layout cannot accept PCB footprint names or part values that include spaces. Check your

design to eliminate spaces or tabs in these property values. Capture's spreadsheet editor is very

useful for this.

The layer names you use as property values must be among the standard Layout layer

names. The via names you use as property values must be among the standard Layout via

names.

Electronic System Design Lab Manual

VI SEMESTER ECE

27

To create a netlist for Layout To create a netlist for Layout To create a netlist for Layout To create a netlist for Layout

1 Open the Capture project.

2 Select the design in the project manager and choose Create Netlist from the Tools menu.

The Create Netlist dialog box appears.

3 Choose the Layout tab. The Layout tab appears.

4 In the PCB Footprint group box, ensure that {PCB Footprint} appears in the Combined

property string text box.

5 In the Netlist File text box, ensure that the path to the netlist file is correct. The netlist

takes the name of the Capture project and adds a .MNL extension.

6 Click OK. Capture processes the netlist, then creates an .MNL file and saves it in the

directory specified in step 6.

It is not necessary to run Capture and Layout simultaneously to take advantage of forward

annotation.

If Capture is unable to create a .MNL file, the errors are written to the Capture session log

and to the .ERR file in the target directory for the .MNL file.

Preparing PCB layout using Autoroute Preparing PCB layout using Autoroute Preparing PCB layout using Autoroute Preparing PCB layout using Autoroute

This command systematically autoroutes your printed circuit board design from start to

finish, automatically sweeping through the design. If you have set any of the fanout commands

(Fanout Board, Fanout DRC/Route Box

, or Fanout Component) before you choose the Autoroute Board command, Layout executes the

appropriate fanout operation before any routing sweeps.

You set routing priorities and characteristics using the Route Sweep, Route Pass, and Route

Layer commands.

You can interrupt autorouting at any time by pressing ESC

, then restart by choosing the Resume Routing command.

If you want to autoroute a design after you have routed it to completion, you must edit the Route

Pass spreadsheet and change the passes from Done to Yes.

Electronic System Design Lab Manual

VI SEMESTER ECE

28

Circuit Diagram Circuit Diagram Circuit Diagram Circuit Diagram

U1

AD741

3

2

7

4

6

1

5

+

-

V

+

V

-

OUT

OS1

OS2

R5

U2

AD741

3

2

7

4

6

1

5

+

-

V

+

V

-

OUT

OS1

OS2

R9

R7

R4

R1

U3

AD741

3

2

7

4

6

1

5

+

-

V

+

V

-

OUT

OS1

OS2

0

R2

R8

R10

R3

PCB Layout PCB Layout PCB Layout PCB Layout

Top layer Top layer Top layer Top layer

Electronic System Design Lab Manual

VI SEMESTER ECE

29

Bottom layer Bottom layer Bottom layer Bottom layer

Top & Bottom layer Top & Bottom layer Top & Bottom layer Top & Bottom layer

RESULT: RESULT: RESULT: RESULT:

Electronic System Design Lab Manual

VI SEMESTER ECE

30

9. MICROCONTROLLER BASED SYSTEMS DESIGN MICROCONTROLLER BASED SYSTEMS DESIGN MICROCONTROLLER BASED SYSTEMS DESIGN MICROCONTROLLER BASED SYSTEMS DESIGN

Aim Aim Aim Aim

Design of microcontroller based system for simple applications like security

systems combination lock etc.

Algorithm Algorithm Algorithm Algorithm

Microcontroller based security systems

1. Read number of bytes in the password

2. Initialize the password

3. Initialize the Keyboard Display IC (8279) to get key and Display

4. Blank the display

5. Read the key from user

6. Compare with the initialized password

7. If it is not equal, Display E to indicate Error.

8. Repeat the steps 6 and 7 to read next key

9. If enterer password equal to initialized password, Display O to indicate open.

Program Program Program Program

LABEL LABEL LABEL LABEL MNEMONICS MNEMONICS MNEMONICS MNEMONICS OPERANT OPERANT OPERANT OPERANT COMMENTS COMMENTS COMMENTS COMMENTS

MOV 51H,#

MOV 52H,#

MOV 53H,#

MOV 54H,#

MOV R1,#51

MOV R0,#50

MOV R3,#04

MOV R2,#08

MOV DPTR,#FFC2

MOV A,#00

MOVX @DPTR,A

MOV A,#CC

MOVX @DPTR,A

MOV A,#90

MOVX @DPTR,A

MOV A,#FF

MOV DPTR,#FFCO

LOOP: MOVX @DPTR,A

Electronic System Design Lab Manual

VI SEMESTER ECE

31

DJNZ R2,LOOP

AGAIN: MOV DPTR,#FFC2

WAIT: MOVX A,@DPTR

ANL A,#07

JZ WAIT

MOV A,#40

MOVX @DPTR,A

MOV DPTR,#FFCO

MOVX A,@DPTR

MOV @R0,A

MOV A,@R1

CJNE A,50H,NEQ

INC R1

DJNZ R3,AGAIN

MOV DPTR,#FFCO

MOV A,#OC

MOVX @DPTR,A

XX: SJMP XX

NEQ: MOV DPTR,#FFCO

MOV A,#68

MOVX @DPTR,A

YY: SJMP YY

Observation Observation Observation Observation

Result Result Result Result

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- E16SRXEU1 SchematicDokumen3 halamanE16SRXEU1 SchematicIstvan Fekete100% (2)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Aosense Laser Controller Spec Brief (2018/03/01) : PZT ModDokumen3 halamanAosense Laser Controller Spec Brief (2018/03/01) : PZT ModjamesBelum ada peringkat

- IIYear QBDokumen31 halamanIIYear QBarul_elvisBelum ada peringkat

- PAC Process UnderwaterTraffic 2017HT13320Dokumen7 halamanPAC Process UnderwaterTraffic 2017HT13320arul_elvisBelum ada peringkat

- Ge2022 TQM NotesDokumen32 halamanGe2022 TQM NotesVelshankar MJBelum ada peringkat

- Civil Engg. Minor Project On Residential Buildning....Dokumen56 halamanCivil Engg. Minor Project On Residential Buildning....kripa8shankar8pathak50% (2)

- Notes 1Dokumen17 halamanNotes 1arul_elvisBelum ada peringkat

- ECE II To VIIIDokumen119 halamanECE II To VIIIEce ThirdyearBelum ada peringkat

- Gabor FilterDokumen23 halamanGabor Filtervitcon1909Belum ada peringkat

- Gabor FiltersDokumen6 halamanGabor Filtersarul_elvisBelum ada peringkat

- Unit 5 Laplace TransformDokumen3 halamanUnit 5 Laplace Transformarul_elvisBelum ada peringkat

- Effect of Wind-Energy Power Injection Into Weak GridsDokumen7 halamanEffect of Wind-Energy Power Injection Into Weak GridsRoger RogerBelum ada peringkat

- RealLAB2 ManualDokumen5 halamanRealLAB2 ManualDiscord GrindBelum ada peringkat

- Basic Sensors and PrinciplesDokumen46 halamanBasic Sensors and PrinciplesHasan AhmedBelum ada peringkat

- EE6301 DLC Question Bank Rejinpaul 2Dokumen8 halamanEE6301 DLC Question Bank Rejinpaul 2aruljothiBelum ada peringkat

- Ram Rom MemoryDokumen8 halamanRam Rom MemorySohit ThapaBelum ada peringkat

- Understanding Electronic Component Uses and SymbolsDokumen5 halamanUnderstanding Electronic Component Uses and SymbolsGeoff Hampson100% (2)

- Analysis and Design of High Step-Up DC-DC Converter With Coupled-Inductor TechniqueDokumen6 halamanAnalysis and Design of High Step-Up DC-DC Converter With Coupled-Inductor Techniqueharis shehzadBelum ada peringkat

- Consumer Electronics Servicing: K To 12 Basic Education CurriculumDokumen8 halamanConsumer Electronics Servicing: K To 12 Basic Education CurriculumMARFE IMPASTABelum ada peringkat

- Unisonic Technologies Co., LTD: High Voltage Fast-Switching NPN Power TransistorDokumen2 halamanUnisonic Technologies Co., LTD: High Voltage Fast-Switching NPN Power Transistortaufik hidayatBelum ada peringkat

- Ece 3084 Su 14 HW 8Dokumen5 halamanEce 3084 Su 14 HW 8Jay MehtaBelum ada peringkat

- Gcse Electronics Coursework ExamplesDokumen6 halamanGcse Electronics Coursework Examplesbdg9hkj6100% (2)

- IGCSE 2012 - Chemistry Practice TestDokumen12 halamanIGCSE 2012 - Chemistry Practice TestFunny AtomsBelum ada peringkat

- High Precision 10 V IC Reference AD581: Features Functional Block DiagramDokumen12 halamanHigh Precision 10 V IC Reference AD581: Features Functional Block DiagramE.n. ElangoBelum ada peringkat

- Static and Formal Verification of Power Aware Designs at The RTL Using UPFDokumen9 halamanStatic and Formal Verification of Power Aware Designs at The RTL Using UPFboldy00Belum ada peringkat

- Kirchof LawsDokumen33 halamanKirchof LawsZain SaleemBelum ada peringkat

- C 102Dokumen1 halamanC 102Nicky DragutescuBelum ada peringkat

- Signal Integrity BasicsDokumen39 halamanSignal Integrity BasicsArvind HanumantharayappaBelum ada peringkat

- Chemical Engineering Magazine 2017.08Dokumen68 halamanChemical Engineering Magazine 2017.08anizBelum ada peringkat

- Electrical Power Systems Wadhwa 6Dokumen1 halamanElectrical Power Systems Wadhwa 6teceeeBelum ada peringkat

- Voltage & Current Controlled Switches: Presented by Thomas MostellerDokumen15 halamanVoltage & Current Controlled Switches: Presented by Thomas MostellerRavi Prasad AmanapuBelum ada peringkat

- THe Surface Polarization Effects in High Efficiency Silicon Solar CellsDokumen4 halamanTHe Surface Polarization Effects in High Efficiency Silicon Solar Cellssaikrishna bethaBelum ada peringkat

- Stamford DM110 Voltage RegulatorDokumen71 halamanStamford DM110 Voltage RegulatorThomas Pendergrass100% (2)

- E 1252 - 98 RteyntitotgDokumen13 halamanE 1252 - 98 RteyntitotgLINA JULIANA ANDRADE OSPINABelum ada peringkat

- 1 Syllabus EtoDokumen2 halaman1 Syllabus EtoVinay PrakashBelum ada peringkat

- Silicone Elastomers: Peter JerschowDokumen8 halamanSilicone Elastomers: Peter JerschowArun BoseBelum ada peringkat

- Silicon CapacitorDokumen5 halamanSilicon Capacitorbsnl_cellone47Belum ada peringkat

- RT300MDokumen17 halamanRT300MIonel SimaBelum ada peringkat