Bi Directional Speed Control of DC Motor and Stepper

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Bi Directional Speed Control of DC Motor and Stepper

Hak Cipta:

Format Tersedia

IJRET: International Journal of Research in Engineering and Technology

__________________________________________________________________________________________

Volume: 02 Issue: 11 | Nov-2013, Available @

BI DIRECTIONAL SPEED CONTROL OF DC MOTOR AND STEPPER

MOTOR THROUGH MAT LAB USING PIC MICRO CONTROLLER

Ozwin Dominic Dsouza

1

BMS Institute of Technology

ozwindsouza@gmail.com,

In any industry speed control of an electric drive system is very critical and crucial. Every designer aims at achieving a co

methodology having high degree of precision. But industry needs are ever evolving in nature. Hence it is very much essential

along with conventional speed control mechanisms we must also have simple interactive graphical based control strategies. Sev

algorithms/methodologies have been developed over the years to achieve speed control of motors. In this context by encomp

usability of Mat Lab, work has been done to control the speed of stepper motor and DC motor using microcontroller. Microcontr

is programmed to achieve bi directional speed control. The main objective of this work is to develop the graphical

motor control through mat Lab guide and the interface of the same with hardware via serial communication. PIC is used as the

controller.

Keywords DC, PIC, C, AC, GUI, IC

---------------------------------------------------------------------

1. INTRODUCTION

DC motors are widely used in adjustable speed drives and

position control applications. In DC motor speeds below its

base speed is controlled by armature voltage control

[2]. Speeds above base speed are achieved by encompassing

field flux control method. Speed controls of DC motors are

much cheaper and simpler as compared to AC motors. This is

mainly because in DC motor speed control only two control

parameters are sufficient (voltage or flux). On the contrary an

AC motor speed control requires three control parameters.

A stepper motor is a marvel in simplicity [1]

electromechanical device which converts electrical pulses into

discrete mechanical movements. Unlike DC motors it has no

brushes and contacts and is a synchronous motor with the

magnetic field electronically switched to rotate the armature

magnet. The essential function of a stepper motor is to translate

switching excitation changes into precisely defined increments

of rotor position. A stepper motor can divide a full rotation into

a large number of steps, for example 200 steps. The motor thus

can be made to rotate through a precise angle. The sequence of

applied pulses is directly related to the direction of motor

rotation. There are different types of stepper motors; namely (i)

permanent magnet (ii) variable reluctance (iii) Hybrid motors.

The basic block diagram of stepper motor is shown in figure 1

below.

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319

__________________________________________________________________________________________

2013, Available @ http://www.ijret.org

BI DIRECTIONAL SPEED CONTROL OF DC MOTOR AND STEPPER

MOTOR THROUGH MAT LAB USING PIC MICRO CONTROLLER

Ozwin Dominic Dsouza

1

, Manjunathababu. P

2

, Babu Naik

BMS Institute of Technology, Bangalore, India

ozwindsouza@gmail.com, manjubabup@gmail.com

Abstract

In any industry speed control of an electric drive system is very critical and crucial. Every designer aims at achieving a co

methodology having high degree of precision. But industry needs are ever evolving in nature. Hence it is very much essential

along with conventional speed control mechanisms we must also have simple interactive graphical based control strategies. Sev

algorithms/methodologies have been developed over the years to achieve speed control of motors. In this context by encomp

usability of Mat Lab, work has been done to control the speed of stepper motor and DC motor using microcontroller. Microcontr

is programmed to achieve bi directional speed control. The main objective of this work is to develop the graphical

motor control through mat Lab guide and the interface of the same with hardware via serial communication. PIC is used as the

---------------------------------***--------------------------------------------------------------------

DC motors are widely used in adjustable speed drives and

position control applications. In DC motor speeds below its

base speed is controlled by armature voltage control method [1]

. Speeds above base speed are achieved by encompassing

field flux control method. Speed controls of DC motors are

much cheaper and simpler as compared to AC motors. This is

mainly because in DC motor speed control only two control

icient (voltage or flux). On the contrary an

AC motor speed control requires three control parameters.

[1]. It is basically an

electromechanical device which converts electrical pulses into

ements. Unlike DC motors it has no

brushes and contacts and is a synchronous motor with the

magnetic field electronically switched to rotate the armature

magnet. The essential function of a stepper motor is to translate

ecisely defined increments

of rotor position. A stepper motor can divide a full rotation into

a large number of steps, for example 200 steps. The motor thus

can be made to rotate through a precise angle. The sequence of

o the direction of motor

rotation. There are different types of stepper motors; namely (i)

reluctance (iii) Hybrid motors.

The basic block diagram of stepper motor is shown in figure 1

Fig 1 Block diagram of stepper

Speed control of DC motor and stepper motor through Mat Lab

using PIC microcontroller (C)

emphasize the use of two types of motors( stepper and DC

motor) together. PIC C used here enables the user to code in

such a way that the DC and stepper motors rotate in forward

and reverse direction at any given point of time as and when

specified by the user through keys. At the same time user has

an option of manual intervention in direction of rotation, as PIC

C is designed to operate in both auto and manual mode.

It is a proven fact that proven over the years that MAT Lab is a

powerful design/simulation tool. It gives greater flexibility to a

designer to analyze the circuit/product before the actual

implementation. Signals required to run in auto mode are

generated through Mat Lab using Graphical user interface

(GUI) [4]. GUI facilitates the simple coding technique through

which signals could be sent. This work describes the GUI codes

for sending signals to hardware through p

supervision of C. This type of speed control approach is

highly useful in applications where precise speed control is

required for example in computer numeral control (CNC).

eISSN: 2319-1163 | pISSN: 2321-7308

__________________________________________________________________________________________

686

BI DIRECTIONAL SPEED CONTROL OF DC MOTOR AND STEPPER

MOTOR THROUGH MAT LAB USING PIC MICRO CONTROLLER

Babu Naik

3

In any industry speed control of an electric drive system is very critical and crucial. Every designer aims at achieving a control

methodology having high degree of precision. But industry needs are ever evolving in nature. Hence it is very much essential that

along with conventional speed control mechanisms we must also have simple interactive graphical based control strategies. Several

algorithms/methodologies have been developed over the years to achieve speed control of motors. In this context by encompassing the

usability of Mat Lab, work has been done to control the speed of stepper motor and DC motor using microcontroller. Microcontroller

is programmed to achieve bi directional speed control. The main objective of this work is to develop the graphical user interface of

motor control through mat Lab guide and the interface of the same with hardware via serial communication. PIC is used as the

----------------------------------------------------------------------

Block diagram of stepper motor

Speed control of DC motor and stepper motor through Mat Lab

using PIC microcontroller (C) [3] is an initiative taken to

emphasize the use of two types of motors( stepper and DC

motor) together. PIC C used here enables the user to code in

y that the DC and stepper motors rotate in forward

and reverse direction at any given point of time as and when

specified by the user through keys. At the same time user has

an option of manual intervention in direction of rotation, as PIC

o operate in both auto and manual mode.

It is a proven fact that proven over the years that MAT Lab is a

powerful design/simulation tool. It gives greater flexibility to a

designer to analyze the circuit/product before the actual

equired to run in auto mode are

generated through Mat Lab using Graphical user interface

. GUI facilitates the simple coding technique through

which signals could be sent. This work describes the GUI codes

for sending signals to hardware through parallel port under the

supervision of C. This type of speed control approach is

highly useful in applications where precise speed control is

required for example in computer numeral control (CNC).

IJRET: International Journal of Research in Engineering and Technology

__________________________________________________________________________________________

Volume: 02 Issue: 11 | Nov-2013, Available @

2. HARDWARE DESCRIPTION

Detailed block diagram of the project is as shown in figure 2

below. It mainly consists of the following parts.

A. DC Motor

A dc motor works based on the principle of electromagnetic

induction Here a DC motor having 9-12V, 2000 RPM rating is

used. DC motor is connected to PIC C via a

motor driver integrated circuit. Motor drivers acts as current

amplifiers. They take low-current control signal and provide

high current signals. The higher current signals eventually drive

the motor in the designed program sequence.

Fig 2 Block diagram of the project

B. Stepper Motor:

A stepper motor having specification 12V, 1.8 Degrees is used

here. It is connected to PIC C via stepper motor driver IC.

This IC basically takes the control signals from C and in turn

takes controlling actions on stepper motor.

C. Buffer IC:

Buffer IC is also called as line driver IC. Buffer IC passes the

signal from one circuit to the other without any changes in

signals. The operating voltage rages from 2V to 6V.

D. H-Bridge Motor Control Circuit:

A very popular/simpler way of achieving speed control of a DC

motor is by using a single transistor based control. But the main

disadvantage of this control strategy is that, only uni

speed control is possible. But in many applications it is

necessary to operate the motor in both directions; clockwise or

anticlockwise. A very good way of achieving this is to connect

the motor to a Transistor H-Bridge circuit. With this

arrangement Bi-directional DC motor operation becomes

possible.

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319

__________________________________________________________________________________________

2013, Available @ http://www.ijret.org

project is as shown in figure 2

below. It mainly consists of the following parts.

e of electromagnetic

12V, 2000 RPM rating is

used. DC motor is connected to PIC C via a dual H-Bridge

motor driver integrated circuit. Motor drivers acts as current

current control signal and provide

high current signals. The higher current signals eventually drive

the motor in the designed program sequence.

Block diagram of the project

A stepper motor having specification 12V, 1.8 Degrees is used

here. It is connected to PIC C via stepper motor driver IC.

This IC basically takes the control signals from C and in turn

Buffer IC is also called as line driver IC. Buffer IC passes the

signal from one circuit to the other without any changes in

signals. The operating voltage rages from 2V to 6V.

A very popular/simpler way of achieving speed control of a DC

motor is by using a single transistor based control. But the main

disadvantage of this control strategy is that, only uni-directional

speed control is possible. But in many applications it is

ecessary to operate the motor in both directions; clockwise or

anticlockwise. A very good way of achieving this is to connect

Bridge circuit. With this

directional DC motor operation becomes

2.1 Basic Bi-directional H

Figure 3 shows the basic H

because the basic configuration of the four switches, transistors

resembles the letter H with the motor positioned in the center.

The transistor or MOSFET H

commonly used Bi-directional DC motor control circuit. Which

uses complementary transistor pairs, both NPN and PNP in

each branch along with motor. The transistor operates in pairs

to control the motor.

From figure 3, control input A,

direction; Forward rotation and input B operates the motor in

Reverse direction; Reverse rotation. Switching the transistors

ON or OFF in their diagonal pairs results in bi

control of the motor. Then transistor TR1 is

TR2 is OFF, point A is connected to the supply voltage (+Vcc)

and if transistor TR3 is OFF

Fig 3 H

H-Bridge circuit and transistor TR2 is OFF, point A is

connected to the supply voltage (+Vcc) and if transistor TR3 is

OFF and transistor TR4 is ON, point B is connected to ground

(GND) terminal. Then the motor will rotate in one direction

corresponding to motor terminal A being positive and terminal

B being negative. If the switching states are reversed, then the

motor will operate in the reverse direction. The H

table for the motor operation is shown in Table 1.

It is important to note that Input A and Input B must not be kept

at High Logic. If not then the power supply terminals gets short

circuited and the fuse blows. IC L293D is used in this work as

motor driver IC. This IC is a dual H

with one IC, user can interface two DC motors which can be

controlled both in forward and reverse direction. For protecting

eISSN: 2319-1163 | pISSN: 2321-7308

__________________________________________________________________________________________

687

directional H-bridge Circuit:

Figure 3 shows the basic H-bridge circuit. It is named so

because the basic configuration of the four switches, transistors

resembles the letter H with the motor positioned in the center.

The transistor or MOSFET H-bridge is probably the most

directional DC motor control circuit. Which

uses complementary transistor pairs, both NPN and PNP in

each branch along with motor. The transistor operates in pairs

From figure 3, control input A, operates the motor in one

direction; Forward rotation and input B operates the motor in

Reverse direction; Reverse rotation. Switching the transistors

ON or OFF in their diagonal pairs results in bi-directional

control of the motor. Then transistor TR1 is ON and transistor

TR2 is OFF, point A is connected to the supply voltage (+Vcc)

and if transistor TR3 is OFF

H-Bridge circuit

and transistor TR2 is OFF, point A is

connected to the supply voltage (+Vcc) and if transistor TR3 is

OFF and transistor TR4 is ON, point B is connected to ground

(GND) terminal. Then the motor will rotate in one direction

corresponding to motor terminal A being positive and terminal

B being negative. If the switching states are reversed, then the

ll operate in the reverse direction. The H-bridge truth

table for the motor operation is shown in Table 1.

It is important to note that Input A and Input B must not be kept

at High Logic. If not then the power supply terminals gets short

fuse blows. IC L293D is used in this work as

motor driver IC. This IC is a dual H-bridge motor driver, so

with one IC, user can interface two DC motors which can be

controlled both in forward and reverse direction. For protecting

IJRET: International Journal of Research in Engineering and Technology

__________________________________________________________________________________________

Volume: 02 Issue: 11 | Nov-2013, Available @

the circuit from back emf output diodes are included within the

IC. This has made it a best choice for DC motor driver. Pin

configuration is shown in figure 4.

Table 1 H-Bridge truth table

Input A (TR1

and TR4)

Input B (TR2

and TR3)

Motor Function

0 0 Motor

Stops(OFF)

1 0 Motor rotes

forward

0 1 Motor rotates

reverse

1 1 Not Allowed

2.2 Stepper Motor Driver IC:

This IC is used to drive the current from the C to the stepper

motor. Driver IC used here is ULN2803. It consists of eight

Darlington transistors with common emitters and integral

suppression diodes for inductive loads. Input to this circuit is

given from the PORT of the

Fig 4 Pin configuration

C. Output of this IC is given to stator of stepper

2.3 PIC microcontroller (C):

PIC16F887 is used in this work. This C encompasses RISC

architecture. Operating frequency is 0-20MHz. PIC C

performs the job of a controller. This C totally controls the

entire process. It is coded in such a fashion that both manual

and automatic speed control is possible.

3. SOFTWARE DESCRIPTION

Software part of this project consists of two parts (1) Coding of

C (2) Creating GUI for speed control. Unique approach of this

project is that the GUI creation and the controlling through it.

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319

__________________________________________________________________________________________

2013, Available @ http://www.ijret.org

output diodes are included within the

IC. This has made it a best choice for DC motor driver. Pin

Bridge truth table

Motor Function

Motor

Stops(OFF)

Motor rotes

forward

Motor rotates

reverse

Not Allowed

This IC is used to drive the current from the C to the stepper

motor. Driver IC used here is ULN2803. It consists of eight

Darlington transistors with common emitters and integral

suppression diodes for inductive loads. Input to this circuit is

stepper motor.

encompasses RISC

20MHz. PIC C

performs the job of a controller. This C totally controls the

entire process. It is coded in such a fashion that both manual

Software part of this project consists of two parts (1) Coding of

C (2) Creating GUI for speed control. Unique approach of this

project is that the GUI creation and the controlling through it.

Mat Lab supports wide range of applications, including s

and image processing, communications, control design, test and

measurement etc.

GUI is a pictorial interface to a program. A good GUI can make

programs easier to use by providing them with a

appearance and with insightful

boxes, sliders, menus so on and so forth. The GUI should

behave in an understandable and

user knows what to anticipate

example, like mouse click occurs on a pushbutton. The

should initiate the action described on the label of the button.

Figure 5 shows the developed GUI for motor control.

Fig 5 GUI of Motor Control

Fig 6 Actual implementation of Motor Control

After laying out the GUI component and setting the pr

the GUI will look like as shown in figure 5. Finally ode is

written to implement the behavior associated with each call

beck function. This kind of programming is often called event

driven programming. Actual view of the project is given in

figure 6.

eISSN: 2319-1163 | pISSN: 2321-7308

__________________________________________________________________________________________

688

Mat Lab supports wide range of applications, including signal

and image processing, communications, control design, test and

GUI is a pictorial interface to a program. A good GUI can make

programs easier to use by providing them with a descriptive

insightful controls like pushbuttons, list

boxes, sliders, menus so on and so forth. The GUI should

behave in an understandable and knowable manner, so that a

anticipate when performs an action

example, like mouse click occurs on a pushbutton. The GUI

should initiate the action described on the label of the button.

Figure 5 shows the developed GUI for motor control.

GUI of Motor Control

Actual implementation of Motor Control

After laying out the GUI component and setting the property,

the GUI will look like as shown in figure 5. Finally ode is

written to implement the behavior associated with each call

beck function. This kind of programming is often called event-

driven programming. Actual view of the project is given in

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

__________________________________________________________________________________________

Volume: 02 Issue: 11 | Nov-2013, Available @ http://www.ijret.org 689

CONCLUSIONS

In this work a computer program has been developed for

programming and driving stepper and DC motors via the

parallel port of a PC; a GUI performing all defined motions

individually are also improved. In addition, the GUI allows

programmers to define the user defined functions. So, the

programmers can make stepper motors and DC motors to rotate

in all manners. The developed programs are tested with a

stepper motor of 1.80 step angle in forward and reverse with

speed variation modes. Also the developed program is tested

with a DC motor for forward and reverse motion control. Very

satisfactory results are obtained from experimental setup. The

program can be used in applications containing steeper and DC

motors performing complex motions. From the obtained results

it is concluded that speed control of DC motor and Stepper

motor can be used in robotic systems, DC drive systems, paper

printing mills, CNC machines.

FUTURE WORK

As a future expansion, work is under progress, so as to control

the motors using sensor less technique using faster C or DSP.

Work is also under progress in the control software loop.

Design of Fuzzy control, neural network control, Adaptive

control algorithms are currently under progress.

ACKNOWLEDGMENT

The authors would like to thank Dr. S.C. Sharma, Chief Mentor

BMSIT and BMSSA for providing constant thrust/ inspiration

to achieve more. The authors also thank Prof. S.

Venkateswaran Principal BMSIT for his constant support. The

efforts of final year Electrical students while realizing this work

is also acknowledged.

REFERENCES

[1] A. E. Fitzgerald, Charles Kingsley Jr, Stephen Umans

Electric Machinery McGraw-Hill Higher Education, Sixth

Edition

[2] Bimal K Bose, Power Electronics And Motor Drives:

Advances and Trends. Academic Press, 2006 edition

[3] J. Petrovciv, S. Strmcnik,A microcomputer based speed

controller for lift drives IEEE Trans. Ind.Appl.,24(3), vol.34,

pp.487-498,1998.

[4] Mat Lab, Creating Graphical User Interfaces, Version 7,

The Mathworks Inc. Naticks/Ma, 2006.

BIOGRAPHIES

Ozwin Dominic Dsouza has received his masters from

National Institute of Engineering, Mysore, India. Currently

working as Assistant professor in the department of Electrical

and Electronics Engg at BMSIT Bangalore. His research

interests are in the field of electric drives and systems and

control systems, converter topologies and electrical machines.

Manjunatha Babu P obtained his B.E and M.E from

Visvesvaraya Technological University, Bangalore University.

Presently working as Assistant Professor in the Dept of

Electrical and Electronics Engineering at BMS Institute of

Technology, Bangalore, India. His interests are in the area of

power and Energy systems. Power System Operation and

Control, Power Transmission and Distributions System Studies,

FACTS Controllers.

Babu Naik Gugulothu, has received his masters from the

Indian Institute of Science (IISc) Bangalore, India. Currently

working as Assistant professor in the department of Electrical

and Electronics Engg at BMSIT Bangalore. His research

interests are in the field of Industrial drives and applications,

power systems, SMPS circuits, converter topologies and

electrical machines.

Anda mungkin juga menyukai

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5795)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Manual Mbe 4000 TallerDokumen631 halamanManual Mbe 4000 TallerCristian Muñoz100% (19)

- Method Statement For Testing Precommissioning & Commissioning of Fuel Oil PumpsDokumen3 halamanMethod Statement For Testing Precommissioning & Commissioning of Fuel Oil Pumpsvin ssBelum ada peringkat

- Volvo TWD1643GE - 613 KW PDFDokumen2 halamanVolvo TWD1643GE - 613 KW PDFvictoros27Belum ada peringkat

- GG 3904 01 enDokumen2 halamanGG 3904 01 enSamprit BasuBelum ada peringkat

- Locon32 eDokumen88 halamanLocon32 eyoooo_74Belum ada peringkat

- ANG BulletinDokumen4 halamanANG BulletinRoron WicaksonoBelum ada peringkat

- 42CV 2012Dokumen10 halaman42CV 2012Mhd Garry LuthfiBelum ada peringkat

- XL4015Dokumen9 halamanXL4015Jose M PeresBelum ada peringkat

- Can Protection CT Be Used As Metering CT & Vice Versa - Electrical ConceptsDokumen6 halamanCan Protection CT Be Used As Metering CT & Vice Versa - Electrical ConceptsMohammad HamamdBelum ada peringkat

- Poulan Pro PP19A42 Manual enDokumen56 halamanPoulan Pro PP19A42 Manual enJohn WalesBelum ada peringkat

- D3 Remote ManualDokumen2 halamanD3 Remote ManualbobanmiBelum ada peringkat

- Placa PC Chip M909Dokumen64 halamanPlaca PC Chip M909michigato100% (1)

- Data Man Pro Plus SpecificationDokumen2 halamanData Man Pro Plus SpecificationAfolabi OlaniyiBelum ada peringkat

- Yamaha Mio M3 Parts - 01 - LNS125 MIO M3 CYLINDERDokumen1 halamanYamaha Mio M3 Parts - 01 - LNS125 MIO M3 CYLINDERbangtopiBelum ada peringkat

- Index: All Part No. & Names Are Used For Cross Referance Purpose OnlyDokumen76 halamanIndex: All Part No. & Names Are Used For Cross Referance Purpose Onlynaveen deshwalBelum ada peringkat

- DG Trouble ShootingDokumen10 halamanDG Trouble ShootingBala SubramanianBelum ada peringkat

- JVC Kd-Avx2Dokumen14 halamanJVC Kd-Avx2Jorch Ramirez EstradaBelum ada peringkat

- T2159en MVD500-4701Dokumen18 halamanT2159en MVD500-4701J KeigBelum ada peringkat

- AMM - IGO - A318/A319/A320/A321 REV DATE: Aug 01/2021 Tail Number - MSN - FSN: ALLDokumen23 halamanAMM - IGO - A318/A319/A320/A321 REV DATE: Aug 01/2021 Tail Number - MSN - FSN: ALLRameswar PradhanBelum ada peringkat

- DPC18 Display ManualDokumen12 halamanDPC18 Display ManualscribdribBelum ada peringkat

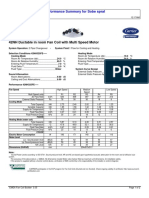

- 42NH Ductable in Room Fan Coil With Multi Speed Motor: Performance Summary For Sobe SpratDokumen2 halaman42NH Ductable in Room Fan Coil With Multi Speed Motor: Performance Summary For Sobe Spratvelikimag87Belum ada peringkat

- Atlas Programming Guide PreliDokumen181 halamanAtlas Programming Guide Prelid1140998Belum ada peringkat

- The Principle of Operation of The Magnetic BearingDokumen3 halamanThe Principle of Operation of The Magnetic BearingedgarafonsecaBelum ada peringkat

- Maintenance and Instruction Manual 1. Transport: Galperti TechDokumen7 halamanMaintenance and Instruction Manual 1. Transport: Galperti TechDavid C HouserBelum ada peringkat

- Bettery ChargerDokumen2 halamanBettery ChargerArun GuptaBelum ada peringkat

- SL1100 Hardware Manual PDFDokumen144 halamanSL1100 Hardware Manual PDFdoraemon007Belum ada peringkat

- Semikron SKD - 53 - 07232810Dokumen3 halamanSemikron SKD - 53 - 07232810shamkhairnarBelum ada peringkat

- Servo Motors ManualDokumen48 halamanServo Motors ManualJonathan ChavezBelum ada peringkat

- Applied Mechanics Lab ManualDokumen23 halamanApplied Mechanics Lab ManualEr Anoop SinghBelum ada peringkat

- Three Point and Four Point StarterDokumen7 halamanThree Point and Four Point Starterkaran nirmala gajanan shindeBelum ada peringkat