Goulds Vertical Reader

Diunggah oleh

Margaret Daugherty0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

45 tayangan20 halamanGoulds vertical turbine pumps have one thing in common - the hydraulic design of the pump bowl assembly. The bowl assembly is designed to deliver the head and capacity that your system requires in the most efficient way possible. The many bowl assembly options available ensure that the vertical turbine pump satisfies the users' needs for safe, efficient, reliable and maintenance-free operation.

Deskripsi Asli:

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniGoulds vertical turbine pumps have one thing in common - the hydraulic design of the pump bowl assembly. The bowl assembly is designed to deliver the head and capacity that your system requires in the most efficient way possible. The many bowl assembly options available ensure that the vertical turbine pump satisfies the users' needs for safe, efficient, reliable and maintenance-free operation.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

45 tayangan20 halamanGoulds Vertical Reader

Diunggah oleh

Margaret DaughertyGoulds vertical turbine pumps have one thing in common - the hydraulic design of the pump bowl assembly. The bowl assembly is designed to deliver the head and capacity that your system requires in the most efficient way possible. The many bowl assembly options available ensure that the vertical turbine pump satisfies the users' needs for safe, efficient, reliable and maintenance-free operation.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 20

Vertical Turbine Pumps

Models VIT, VIC and VIS

2 Goulds Vertical Turbine Pumps

Flexibility by Design:

Three Pump Models, One Common Bowl Assembly

The three different pump models in the vertical turbine line

have one thing in common the hydraulic design of the

pump bowl assembly. Using state-of-the-art techniques in

turbine pump design, Goulds vertical turbine line covers a

wide range of hydraulic conditions to meet virtually every

pumping service in the industry with optimum efficiency.

Goulds flexibility of design allows the use of a wide

range of materials and design features to meet the

custom requirements of the user. No matter what the

requirements, Goulds can design and manufacture the

pump to best satisfy them, specifically and thoroughly.

This bulletin is designed to assist the user in selecting

the best pump for the conditions required; however, any

questions will be answered promptly by calling the Goulds

sales office or representative in your area.

Model VIT Model VIC Model VIS

Bowl

Assembly

Bowl

Assembly

Flanged

Column

Fabricated

Discharge

Head

Driver

Driver

Fabricated

Discharge

Head

Flanged

Column

Can

Bowl

Assembly

Discharge

Adapter

Bowl

Assembly

Suction

Adapter

Submersible

Motor

Goulds Vertical Turbine Pumps 3

Goulds Vertical Turbine Pumpsev v

Pump Bowl Assembly

The bowl assembly is the heart of the vertical turbine

pump. The impeller and diffuser type casing are designed

to deliver the head and capacity that your system requires

in the most efficient way possible. The fact that the vertical

turbine pump can be multi-staged allows maximum

flexibility both in the initial pump selection and in the

event that future system modifications require a change in

the pump rating.

A variety of material options allows the selection of a

pump best suited for even the most severe services. The

many bowl assembly options available ensure that the

vertical turbine pump satisfies the users needs for safe,

efficient, reliable and maintenance-free operation.

Standard Design Features

Suction Bell - Allows smooth entry of liquid into first

stage impeller eye, minimizes foundation opening.

Suction Bell Bearing - Provided for shaft stability.

Sand Collar - Prevents solids from entering

suction bearing.

Impeller - Semi-open or enclosed for

appropriate service.

Pump Shaft - Heavy duty 416SS standard, other

alloys available for strength and corrosion resistance.

Flanged Bowls - Registered fits ensure positive

alignment, ease of maintenance.

Diffuser Bowl - Available in variety of cast materials.

Sleeve Type Bearing - Provided at each stage to

assure stable operation.

Keyed Impellers - Standard for API applications, 18

and larger sizes; furnished on all pumps for

temperatures above 180 F (82 C) and on cryogenic

services. Regardless of size, keyed impellers provide

ease of maintenance and positive locking under

fluctuating load and temperature conditions.

Pump Bowl Assembly Options

Choice of Semi-Open or Enclosed Impellers

Available in alloy construction for a wide range of

corrosive/abrasive services.

Hardfacing & Rifle Drilled Shaft

Hardfacing the surface of bearing and/or shaft to protect

against wear from abrasives in the bearing area. Rifle

drilling of bowl shafts available for bearing protection on

abrasive services. Discharge bowl included with enclosed

lineshaft construction.

4 Goulds Vertical Turbine Pumps

Semi-Open

Closed

Dual Wear Rings

Available for enclosed impellers and bowls; permits

re-establishing initial running clearances and efficiency at

lower cost. Hard facing of wear rings can be flushed when

solids are present in pumpage.

Strainers/Vortex Suppressor

Basket strainers are available to provide protection from

large solids.

First Stage-Low NPSH X Impeller or

Double Suction

For low NPSHA applications, either large eye or double

suction first stage available to minimize pump length.

Hydraulic Balanced Impeller

Optional dynamic balance to ISO Grade 1.0 (4 w/n)

Goulds Vertical Turbine Pumps 5

Flanged Column

Open Lineshaft Bearing

Flanged column / product lubricated lineshaft is

recommended for ease of maintenance. Renewable shaft

sleeve or hard facing of shaft available for longer life.

Threaded Lineshaft Coupling

Threaded lineshaft coupling is commonly used for lower

horsepower pumps. It is more economical.

Enclosed Lineshaft

The lineshaft is protected by water flushing the enclosing

tube bearing on corrosive / abrasive services. Oil lubricated

lineshaft available on long settings.

Alignment is attained by register fit between the

flange faces.

Keyed Lineshaft

Keyed lineshaft coupling is recommended for motors

larger than 700 HP. It provides ease of maintenance.

Column sections are provided with flanged ends incorporating registered fits for ease of alignment during assembly to

ensure concentricity. Our standard bearing retainers are welded into the column section.

Discharge Heads

6 Goulds Vertical Turbine Pumps

Discharge Heads

The discharge head functions to change the direction of flow from vertical to horizontal and to couple the pump to the

system piping in addition to supporting and aligning the driver. Discharge head accommodates all types of driver

configurations. Optional sub-base can be supplied. Goulds offers three basic types for maximum flexibility.

VIC DISCHARGE HEAD

VIC can also be supplied with the pump

suction in the can.

BELOW GROUND DISCHARGE HEAD

Use whenever VIT pump is required to

adapt to an underground discharge

system.

liniIe LlemenI Analysis is Iypically

recommended on this

configuration to evaluate the

pumps dynamic behavior and

capability to withstand the loads

PobusI design as a resulI o Ihe

cantilever load distribution

applied to the foundation and

anchor bolts

CusIomized design Io minimize

the foundation opening

VIT DISCHARGE HEAD

Suitable for all service conditions

such as high or low temperature or

corrosive services. Various materials

available. Segmented elbow

available for efficiency

improvement. Access ports for

easy access to seals and couplings.

Base flange can be machined to

match ANSI tank flange.

FAN AIR COOLED THRUST POT

CasI sIeel body meeIing

API standard

25,000hour L!0 bearing lie

Two or Ihree bearing

configurations

MomenIary upIhrusI

capability

lnpro seals prevenI oil

contamination

VibraIion and IemperaIure

monitoring are standard

provisions

Oil lubricaIed IhrusI bearings

& permanently-lubricated

radial bearings

Seals & Couplings

Goulds Vertical Turbine Pumps 7

Adjustable Coupling (Type A)

For vertical solid shaft driver, impeller

adjustment made by using

adjustable plate in the coupling.

Adjustable Spacer Coupling

(Type AS)

Same function as Type A coupling

with addition of spacer. Spacer

may be removed for mechanical

seal maintenance without

removing the driver.

Packed Box With or Without

Sleeve Open Lineshaft

Whenever packing lubrication

leakage can be tolerated and the

discharge pressure does not exceed

!50 psi, a packed box may be used.

Optional headshaft sleeve or shaft

hardfacing available to protect shaft.

Water Flush or Oil

Lubricated Enclosed

Lineshaft

Water flush tube connection is

supplied when pressurized water

is introduced into the enclosing

tube for bearing protection on

abrasive services.

Single Seal

Most popular method used

for low to medium pressures.

Cartridge style for ease of

installation and maintenance.

Dual Seals

Two seals mounted in-line.

Chamber between seals can be

filled with a buffer liquid and

may be fitted with a pressure

sensitive annunciating device

for safety.

Model VIT

8 Goulds Vertical Turbine Pumps

Vertical Industrial Turbine Pump

For higher flows refer to high capacity section

llows Io 70,000 GPM (!5,900 m

3

/Hr)

Heads Io J,500 eeI (!,060 m)

Pressures Io 2,500 psi (76kg/cm')

8owl sizes rom 6 Io 55 (!52.4 mm Io !,400 mm)

TemperaIures Io 500 l (260 C)

Horsepower Io 5,000 HP (J,7J0 KW)

Design Advantages

labricaIed discharge head and langed column

llanged bowl consIrucIion

4!6SS shaIing

Alloy consIrucIion wiIh exIernal lush o criIical wear

areas available for corrosive/abrasive services

8uilIin alignmenI and simple piping or less cosIly

installation and ease of maintenance / reduced

downtime

Typical Services

Cooling WaIer

SeawaIer and Piver WaIer lnIake

lndusIrial Process Pumps

UIiliIy CirculaIing WaIer

Condenser CirculaIing WaIer Pumps

lire Service

Peclaimed WaIer

Cross Sectional

VIT (Product Lube)

TYPICAL MARKETS SERVED

Power GeneraIion

Oil & Gas

Mining

Municipal

General lndusIry

Chemical

Motor

Motor Key

(Supplied By Motor Vendor)

Hub - Motor

Ring - Retaining

Plate - Adjusting

Hub - Pump

Pump Key

Gland / Split

Packing

Stuffing Box

Headshaft

Head

Capscrew - Col / Head

Column - Top

Capscrew - Col / Col

Hex Nut

Column - Intermediate

LineshaI

8earing LineshaI

Column - Bottom

Coupling LineshaI

Pumpshaft

Capscrew - Col / Bowl

Bearing - Bowl

Capscrew - Bowl / Bell

Bowl

Suction Bell

Strainer (Basket Type)

Capscrew

Motor / Support

Motor Support

Coupling Guard

Stud / Nut

Capscrew Support / Head

Gasket

Bearing

8yPass Line Assembly

(Tube & Fitting)

Mounting Holes

By-Pass Return To Sump

Soc. HD. Capscrew

Thrust Ring

Key - Impeller

Impeller

Wear Ring - Bowl

Wear Ring - Imp

Bearing - Suction

Pipe Plug

Goulds Vertical Turbine Pumps 9

VIT (Enclosed Lineshaft)

TYPICAL MARKETS SERVED

Mining

Oil & Gas

Municipal

Power GeneraIion

General lndusIry

Chemical

Motor

Motor Key

(Supplied By Motor Vendor)

Hub - Motor

Ring - Retaining

Soc HD Capscrew

Plate - Adjusting

Hex Nut

Hub - Pump

Pump Key

Pipe Plug

Head

Tube Nipple

Capscrew Col / HD

Headshaft

Column - Top

Tube Lncl.

Bearing - Tube

Column - Intermediate

Capscrew - Col / Col

Hex Nut

LineshaI

Column - Bottom

Dish Bowl

Pumpshaft

Capscrew - Bowl / Disch Bowl

Bearing - Throttle

Capscrew - Bowl / Bowl

Bowl

Capscrew - Bowl / Bell

Capscrew - Strainer

Strainer (Basket Type)

Suction Bell

Capscrew

Motor / Support

Motor Support

Coupling Guard

Capscrew Support / Head

Tension Plate

Oil Lube

Water Flush

Mounting Holes

Soc HD Capscrew

Thrust Ring

Key - Impeller

Impeller

Wear Ring - Bowl

Wear Ring - Imp

Sand Collar

Bearing - Suction

Pipe Plug

Cross Sectional

10 Goulds Vertical Turbine Pumps

Vertical Industrial Can-Type Pump

llows Io 70,000 GPM (!5,900 m

3

/Hr)

Heads Io J,500 eeI (!,060 m)

Pressures Io 2,500 psi (76kg/cm')

8owl sizes rom 6 Io 55 (!52.4 mm Io !,400 mm)

TemperaIures Io 500 l (260 C)

Horsepower Io 5,000 HP (J,7J0 KW)

Design Advantages

labricaIed discharge head and langed column

llanged bowl consIrucIion

4!6SS shaIing

lnLine sucIion and discharge simpliies insIallaIion

OpIional sucIion in can or siIe piping lexibiliIy

lnherenI design eaIures on Model VlC allow eicienI

operation at any NPSH available

Alloy consIrucIion or corrosive / abrasive services

Typical Services

Pipeline 8oosIer

ProducI Transer, Peinery 8lending

lnjecIion Secondary Pecovery

Chemical Transer

8oiler leed

CondensaIe

Cryogenics

LNG Transer

LighI Hydrocarbons

WaIer Services

Model VIC

Goulds Vertical Turbine Pumps 11

VIC Commercial

12 Goulds Vertical Turbine Pumps

VIC

TYPICAL MARKETS SERVED

Power GeneraIion

Chemical

Mining

General lndusIry

Capscrew

Motor / Support

Motor Support

Coupling Guard

Gland

Soc HD Capscrew - Gland / Housing

Soc HD Capscrew - Housing / Head

Capscrew - Support / Head

O-Ring - Housing / Head

Bearing - Seal Housing

Mounting Holes

Capscrew - Impeller

Thrust Ring

Key - Impeller

Impeller

Wear Ring - Bowl (Optional)

Wear Ring - Imp (Optional)

OpIional Taper Lock

Bearing - Suction

Cross Sectional

Motor

Motor Key

(Supplied By Motor Vendor)

Hub - Driver

Ring - Retaining

Soc HD Capscrew /

Hex Nut

Spacer

Soc. HD. Capscrew / Hex Nut

Plate - Adjusting

Key - Pump

Hub - Pump

O-Ring - Gland / Housing

Housing - Seal

Head

Seal Flush Plan 13

Headshaft

Capscrew - Head / Barrel

O-ring

Capscrew - Col / Head

Column - Top

Capscrew - Col / Col

Hex Nut

Integral Bearing Retainer

Column - Intermediate

LineshaI

OpIional Loose PeIainer

8earing LineshaI

Column - Bottom

Coupling LineshaI

Pumpshaft

Capscrew Col / Bowl

Bearing - Bowl

Bowl - Top

Capscrew - Bowl / Bowl

Bowl

Capscrew - Bowl / Bell

Suction Bell

Barrel

VIC Commercial

Goulds Vertical Turbine Pumps 13

Cross Sectional

VIT (Per API-610)

TYPICAL MARKETS SERVED

Oil & Gas

Chemicals

Pipeline Transer

Mining

Motor horsepower margin

Motor design required to APl 54!

Motor thrust bearing life at rated

condition

Motor thrust bearing life at maximum

loads

Motor thrust bearing location

Motor to be VSS

Coupling will be balanced as assembly

Special coupling as required

Socket welded or flanged piping plan

required (tubing also available)

NDL o nozzle welds

Nozzle load 1 x API (standard)

For other than steel construction VPO

will advise nozzle loads

Post weld heat treatment may be

Required on carbon steel fabs

Separate sub-base as required

One piece shaft as required (as length

permits)

Corrosion resistant bolting (typical)

TESTING NOTES

(Per API-610 Latest Edition)

If vibration test is required, pump is to

be fully tested with job motor.

CMTRs are only required if required

by customer.

Observed testing is considered

witness.

Customer is to define inspection

requirements.

CusIomer is Io deine NDL

requirements.

Hydro testing as required.

Performance testing as required.

Motor

Horizontal alignment

Screws as required

1/16 Thread

Clearance on 1-1/2

and Greater

Auxiliary sealing required for condensate application

ligure 25, sIuds and nuIs aI sealing housing

Mechanical seal required

Mechanical seal to API 682

Additional seal and gland vent tap

Pressure boundary components stress level

Unless otherwise specified the suction region may be designed

for maximum suction pressure

1/8 Corrosion allowance

If specified can mounting

flange may be required

Bearing spacing as required

Welded retainers

Keyed impellers (standard)

Impeller dynamically balanced to 8W/N

Bowl wear ring required

Set screw or tack weld wear rings

Different hardness required (by material)

14 Goulds Vertical Turbine Pumps

Model VIS

Vertical Industrial Turbine Pump

llows Io 70,000 GPM (!5,900 m

3

/Hr)

Heads Io J,500 eeI (!,060 m)

Pressures Io 2500 psi (76kg/cm')

8owl sizes rom 6 Io 55 (!52.4 mm Io !,400 mm)

Design Advantages

ldeal or deep seI applicaIions where use o lineshaI

pumps is impractical

CompleIe uniI is insIalled underground, resulIing in

quiet operation and space saving

Long lie / low mainIenance no lubricaIion,

alignment

Services

lrrigaIion

Service WaIer

Deep Well

Sea WaIer LiI

Cross Sectional

Goulds Vertical Turbine Pumps 15

VIS

TYPICAL MARKETS SERVED

General lndusIry

Oil & Gas

VIS

Discharge

Suction

Discharge Adapter

Bearing - Suction Adapter

Sand Collar

Bowl

Bearing - Bowl

OpIional Taper Lock

Impeller

Wear Ring - Bowl

Pumpshaft

Screen Suction

Bearing - Suction Adapter

Coupling

Suction Adapter

Optional Shroud

Submersible Motor

Hydraulic Coverage

16 Goulds Vertical Turbine Pumps

High Capacity Pumps

Goulds Vertical Turbine Pumps 17

Model WC-GP

DESIGN FEATURES FOR OPTIMUM EFFICIENCY,

RELIABILITY AND COST SAVINGS

Hydraulic selecIion aI besI eiciency poinI using

advanced JD Iools wiIh parameIric design. Lach pump is

designed for optimum hydraulic and mechanical

conditions for the required application. The suction bell

provides flared inlet controls to accelerate the fluid to the

desired inlet velocity. Outer wall on the bowls provides

structural integrity and the flanges with precise rabbet fits

are located at each end for positive alignment. The

contour of the diffuser/bowl provides accurate fit to the

impeller for optimum operating efficiency.

CanIilever roIor design wiIh no Iail bearings. LxIra long

length bearing or double bearing for added stability in

the upper bearing above the first stage impeller. No

auxiliary lubrication system needed. The process fluid

ensures proper lubrication at all times for increased life

expecIancy. LliminaIion o Ihe Iail bearing provides lower

NPSHR values and improved fluid inlet conditions for

hydraulic performance.

CompuIaIional luid dynamic analysis is available Io

determine the sump flow conditions at the pump inlet for

superior performance.

Using a Ihermal casIing solidiicaIion simulaIion

program, Goulds Pumps is able to design optimum

castings to meet specific customer conditions,

providing better design standards in the market.

ShaI sleeves opIional. Provides renewable bushings.

Prevents wear of shaft itself. Materials can be provided

to resist abrasion which are not available in shafting in

some cases. Recommended on large shafts due to the

shaft replacement cost and lead times.

PullouI design is opIional. This opIion provides an

effective way to maintain the equipment and replace

wear components without the need to remove the

complete pump and disconnect the flanges from the

main pipe. The removable component is only the rotor

for optimum reliability and to reduce costs during

maintenance.

Goulds Vertical Turbine Pumps 17

Model WC-GP

DESIGN FEATURES FOR OPTIMUM EFFICIENCY,

RELIABILITY AND COST SAVINGS

lnnovaIive OHead design using iniIe elemenI analysis

provides maximum equipment reliability throughout its

operating hydraulic range without high vibrations from

structural resonance frequency. In addition, lateral and

torsional rotor analysis addresses unstable rotor

dynamics.

ThrusI poI design is opIional. lI is designed Io carry Ihe

pump down thrust generated by the rotor weight and

the hydraulic action of the pump during operation.

ThrusI poIs are ideally on uniIs equipped wiIh lLC

motors where their thrust capacity is basically zero

beyond the motor weight. Thrust pots are designed for

easy dismantling without the need to remove the unit

driver. Additional advantages include capacity of the

thrust pot to withstand a large range of thrust forces,

meeting international standards for bearing

temperature and extended life, in addition to being air

cooled for most of the applications.

High Capacity Pumps

18 Goulds Vertical Turbine Pumps

The hydraulic balance achieved on Ihe roIor does noI

have balance holes in the impeller like other brands on

the market. Reducing the down thrust of the pump will

reduce the cost of the driver by reducing the size of the

thrust bearing in the motor, which makes the Goulds

Pumps design more competitive.

8elowgrade discharge elbow is opIional, and Ihe

structural analysis design considers the overturning

forces with respect to the anchor bolt location and

pump centerline. This results in robust components to

prevent equipment deformation. Discharge heads are

designed to withhold certain discharge hydraulic and

mechanical forces. It is always recommended to

minimize these external forces by supporting the

system independently. Do not use the rotating

equipment as a piping anchor.

Model WC-GP

Vertical circulating water pumps or wet pit column

pumps are classified as VS1 pumps for power generation

condenser cooling, recirculation and desalination sea

water intake, and as VS3 pumps for flood protection,

storm water disposal, waste treatment plants, industrial

services, and sump drainage.

High capacity pumps having a CCW (counter clockwise)

rotation when viewing the equipment from the top meet

Hydraulic Industry Standards and are in full compliance.

These high capacity pumps can be designed in multistage

wiIh a HLAVY DUTY coniguraIion or a wide range o

heads and extended service life, and are ideal when the

installation requires minimum floor space.

Pumps ship completely assembled to the job site as long

as they fit within freight dimension limitations. Pumps are

shipped in sub-assemblies when the complete assembly

exceeds the capacity of the transportation.

High Capacity & Higher

Head Pumps

Goulds Vertical Turbine Pumps 19

PR

services

Reliability has no quitting time.

Building on over 160 years of Goulds Pumps experience,

PRO Services provides an array of services focused on

reducing equipment total cost of ownership (TCO) and

increasing plant output, including predictive monitoring,

maintenance contracts, field service, engineered upgrades,

inventory management, and overhauls for pumps and other

rotating equipment.

Parts & Inventory

LicienI and Iimely

parts supply

Lngineered parIs or obsolete

equipment (ProCast)

Peverse engineering and

rapid pattern manufacturing

lnvenIory analysis and

management

PeplacemenI pumps

Goulds Pumps parIs

Plant Performance

LquipmenI moniIoring &

control products and services

to improve system reliability

and up-time

Full service maintenance

contracts

lTT onsiIe experIs idenIiy

and resolve bad actor

equipment issues through:

Root cause failure analysis

Lnergy perormance audiIs

and improvements

Maintenance, operator and

management training

Repair & Upgrades

Pepair Io OLM sIandards

lield service

Scheduled mainIenance and

plant shutdowns

Lngineered dropin

replacements

Upgrades:

Upgrade pumps to the

latest API standard editions

Hydraulic re-rates to

operate pumps at the

customer's required setting

Mechanical & material upgrades

Visit our website at www.gouldspumps.com

ITT Industrial Process

Vertical Products Operations

J95! CapiIol Avenue

CiIy o lndusIry, CA 9060!

www.itt.com

2012 ITT Corporation

Form B3A-1 11/12

Anda mungkin juga menyukai

- Yhl/ Ar Ali/ Subardi 11/6/2012 Scale Units MM No Scale CoolerDokumen1 halamanYhl/ Ar Ali/ Subardi 11/6/2012 Scale Units MM No Scale CoolerMargaret DaughertyBelum ada peringkat

- 9 07sek PDFDokumen1 halaman9 07sek PDFMargaret DaughertyBelum ada peringkat

- 9 08sek PDFDokumen1 halaman9 08sek PDFMargaret DaughertyBelum ada peringkat

- BoilerDokumen90 halamanBoilerMargaret DaughertyBelum ada peringkat

- Big Joe Type 630SEK PDFDokumen12 halamanBig Joe Type 630SEK PDFMargaret DaughertyBelum ada peringkat

- Agco Type81sek PDFDokumen15 halamanAgco Type81sek PDFMargaret DaughertyBelum ada peringkat

- Crankcase Ventilation (LEBW4958)Dokumen20 halamanCrankcase Ventilation (LEBW4958)József Nagy100% (2)

- Air Comp INGERSOLL-RAND SEK PDFDokumen16 halamanAir Comp INGERSOLL-RAND SEK PDFMargaret Daugherty100% (1)

- Cat & DdsekDokumen1 halamanCat & DdsekMargaret DaughertyBelum ada peringkat

- Cat D-3600sek PDFDokumen2 halamanCat D-3600sek PDFMargaret DaughertyBelum ada peringkat

- Programmable 2 Wire Transmitter PDFDokumen8 halamanProgrammable 2 Wire Transmitter PDFMargaret DaughertyBelum ada peringkat

- Caterpillar G3500 Top End Overhaulesek PDFDokumen18 halamanCaterpillar G3500 Top End Overhaulesek PDFMargaret Daugherty75% (4)

- 3500 TroubleshootingSEK PDFDokumen33 halaman3500 TroubleshootingSEK PDFMargaret Daugherty50% (2)

- HLR 7970 PDFDokumen17 halamanHLR 7970 PDFMargaret Daugherty100% (1)

- Cat D-3600sek PDFDokumen2 halamanCat D-3600sek PDFMargaret DaughertyBelum ada peringkat

- Hart Drywells PDFDokumen3 halamanHart Drywells PDFMargaret DaughertyBelum ada peringkat

- XB6 16mm Pusbuttons Instruction Installation PDFDokumen2 halamanXB6 16mm Pusbuttons Instruction Installation PDFMargaret DaughertyBelum ada peringkat

- FL3110 FL3111 Data PDFDokumen2 halamanFL3110 FL3111 Data PDFMargaret DaughertyBelum ada peringkat

- Rev4 PDFDokumen4 halamanRev4 PDFMargaret DaughertyBelum ada peringkat

- 'Pwhfwhxu GH Ixpph Odujh Vshfwuh Froohfwli '2$::Lgh Vshfwuxp VPRNH Ghwhfwru FroohfwlyhDokumen4 halaman'Pwhfwhxu GH Ixpph Odujh Vshfwuh Froohfwli '2$::Lgh Vshfwuxp VPRNH Ghwhfwru FroohfwlyhMargaret DaughertyBelum ada peringkat

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Warrick 26m Control de Nivel AuxiliarDokumen3 halamanWarrick 26m Control de Nivel AuxiliarCarlos WayBelum ada peringkat

- Chapter7 DigitalData 2Dokumen217 halamanChapter7 DigitalData 2orizaBelum ada peringkat

- Physics 20 Formula SheetDokumen2 halamanPhysics 20 Formula SheetcallalilBelum ada peringkat

- Oracle Alerts: Mona Lisa SahuDokumen35 halamanOracle Alerts: Mona Lisa Sahuanishokm2992Belum ada peringkat

- Airbus A319/320/321 Notes: Welcome To The Airbus! Resistance Is Futile, You Will Be AssimilatedDokumen128 halamanAirbus A319/320/321 Notes: Welcome To The Airbus! Resistance Is Futile, You Will Be Assimilatedejt01Belum ada peringkat

- Topic 4Dokumen23 halamanTopic 4Joe HanBelum ada peringkat

- A Lightweight Secure Data Sharing SchemeDokumen7 halamanA Lightweight Secure Data Sharing SchemeGopi KrishnaBelum ada peringkat

- Biomedical Short Learning Article CompleteDokumen169 halamanBiomedical Short Learning Article Completenebiyu mulugetaBelum ada peringkat

- 9011 VW Rebar Strainmeter (E)Dokumen2 halaman9011 VW Rebar Strainmeter (E)JasonBelum ada peringkat

- Stereological Study of Kidney in Streptozotocin-Induced Diabetic Mice Treated With Ethanolic Extract of Stevia Rebaudiana (Bitter Fraction)Dokumen10 halamanStereological Study of Kidney in Streptozotocin-Induced Diabetic Mice Treated With Ethanolic Extract of Stevia Rebaudiana (Bitter Fraction)Fenny Noor AidaBelum ada peringkat

- FSX Cessna 172SP OldDokumen4 halamanFSX Cessna 172SP Oldaccgh5Belum ada peringkat

- Project, Program and Portfolio SelectionDokumen40 halamanProject, Program and Portfolio Selectionsaif ur rehman shahid hussain (aviator)Belum ada peringkat

- Circular Motion 1 QPDokumen8 halamanCircular Motion 1 QPNovi Juniati PitrianaBelum ada peringkat

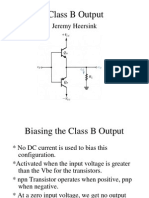

- Class B Output: Jeremy HeersinkDokumen10 halamanClass B Output: Jeremy Heersinkdummy1957jBelum ada peringkat

- Spicer Info - AXSM-8663 PDFDokumen28 halamanSpicer Info - AXSM-8663 PDFRay Ayala100% (1)

- 2 0 Tdi SSPDokumen90 halaman2 0 Tdi SSPmicol53100% (1)

- Eia Cea 608Dokumen154 halamanEia Cea 608Максим РадионовBelum ada peringkat

- 3D ShapesDokumen5 halaman3D Shapesdeez000Belum ada peringkat

- Modelsim Se InstallDokumen30 halamanModelsim Se InstallDương NgânBelum ada peringkat

- Appendix 59.docx Inventory Custodian SlipDokumen2 halamanAppendix 59.docx Inventory Custodian SlipJimmy CootBelum ada peringkat

- Experiment 6Dokumen11 halamanExperiment 6CarlosLorenzoSaninBelum ada peringkat

- Fuse Link KDokumen6 halamanFuse Link KABam BambumBelum ada peringkat

- Revised Draft Ammendment To IRS T29 MAR13Dokumen11 halamanRevised Draft Ammendment To IRS T29 MAR13Shipra MishraBelum ada peringkat

- Summative Test Ist (2nd G)Dokumen2 halamanSummative Test Ist (2nd G)Rosell CabalzaBelum ada peringkat

- Weather ForecastsDokumen5 halamanWeather ForecastsGianina MihăicăBelum ada peringkat

- AnswerDokumen51 halamanAnswersamBelum ada peringkat

- 30 MT Tyre Mounted Crane SpecificationsDokumen4 halaman30 MT Tyre Mounted Crane SpecificationsramyaBelum ada peringkat

- QP NTSE Stage 1 2016 17 AndhraPradeshDokumen27 halamanQP NTSE Stage 1 2016 17 AndhraPradeshsudhir_narang_3Belum ada peringkat

- thống số cụm phanh sau 777E KYDDokumen2 halamanthống số cụm phanh sau 777E KYDlongcpqn95Belum ada peringkat

- Types of Capacitors ExplainedDokumen16 halamanTypes of Capacitors Explainedarnoldo3551Belum ada peringkat