RT Procedure

Diunggah oleh

Ravindra S. JivaniHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

RT Procedure

Diunggah oleh

Ravindra S. JivaniHak Cipta:

Format Tersedia

RADIOGRAPHIC TESTING

PROCEDURE

Page 1 of 22

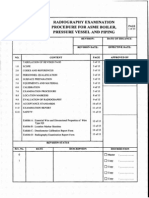

RADIOGRAPHIC TESTING PROCEDURE

Page 2 of 22

RADIOGRAPHIC TESTING PROCEDURE

Contents

1. SCOPE...............................................................................5

2. REFERENCE DOCUMENTS....................................................5

4. SURFACE PREPARATION......................................................6

5. IDENTIFICATION OF RADIOGRAPH........................................6

6. EXTENT OF EXAMINATION...................................................6

7. RADIATION ENERGYSOURCE OF RADIATION.........................6

!. SOURCE SI"E.....................................................................7

#. FI$M..................................................................................7

1%. IMAGE &UA$ITY INDICATORS...............................................!

11. DENSITY AND DENSITOMETER CA$I'RATION.......................1%

12. GEOMETRICA$ UNSHARPNESS...........................................11

1(. 'AC) SCATTER RADIATION................................................12

14. RADIOGRAPHIC TECHNI&UE..............................................12

15. $OCATION MAR)ERS.........................................................12

16. IMAGE &UA$ITY INDICATORS.............................................12

17. MATERIA$ FOR I&I............................................................12

1!. SE$ECTION OF I&I.............................................................1(

1#. P$ACEMENT OF I&I...........................................................1(

2%. NUM'ER OF I&I................................................................1(

21. I&I SENSITI*ITY................................................................1(

22. PROCESSING....................................................................1(

2(. *IE+ING OF RADIOGRAPHS..............................................14

24. ACCEPTANCE CRITERIA.....................................................14

25. RADIOGRAPHIC TECHNI&UE DETAI$S CUM REPORT FORM....14

Anne,-.e I..............................................................................15

Anne,-.e II.............................................................................16

Anne,-.e III............................................................................17

Anne,-.e I*............................................................................1!

Anne,-.e *.............................................................................1#

Anne,-.e *I............................................................................2%

Page 3 of 22

RADIOGRAPHIC TESTING PROCEDURE

1. SCOPE

This procedure describes the methodology for the Radiographic Testing

of pipeline welds in West Qurna Field Phase 2 Project. The scope of this

procedure includes Welding procedure qualication tests! Welder "

Welding #perator performance tests and Production welds.

2. REFERENCE DOCUMENTS

St/n0/.0s

$%&' ()*.+ ,as Transmission and -istribution Piping %ystems

$%&' ()*.. Pipeline Transportation %ystem for /iquid

0ydrocarbons and #ther /iquids

$%&' %ection 1 2on -estructi3e '4amination

$%2T5T65*$ Personnel Qualication and 6ertication in 2on5

destructi3e Testing

$P7 **8. Welding of Pipelines and Related Facilities 928*8:

$%T& ';. %tandard Practice for Radiographic Testing

$%T& '<.< %tandard Practice for -esign! &anufacture and

&aterial ,rouping 6lassication of Wire 7mage

Quality 7ndicators 97Q7: =sed for Radiology

Co12/n3 Do4-1ents

+8*>58*>*5TP7T5885888.8.885?%65)28*58*5(5'2 Pipeline

6onstruction %pecication

P.o5e4t Do4-1ents

+8*>58*>*5T'5T'605/&'/58882) Project Quality Plan

+8*>58*>*5T'5T'605/&'/58888) 0%' 6onstruction Plan 9=nder

Re3iew:

+8*>58*>*5T'5T'605/&'/58888< ?ourney &anagement Plan 9=nder

Re3iew:

2.1 DEFINITIONS & ABBREVIATIONS

TERMS AND DEFINITIONS

6#&P$2@ /uAoil &id5'ast /imited

6#2TR$6T#R Techno 'ngineering %er3ices 9P3t: /td

&ay #ne possible course of action

%hall"&ust"7s To (e $ mandatory requirement

%hould $ non5mandatory requirement

A''RE*IATIONS

$F6 $ppro3ed For 6onstruction

F''- Front 'nd 'ngineering B -esign

PP' Personal Protecti3e 'quipment

R#W Right of Way

'7$ 'n3ironmental 7mpact $ssessment

0%' 0ealth! %afety B 'n3ironmental

Page 4 of 22

RADIOGRAPHIC TESTING PROCEDURE

(. PERSONNE$ &UA$IFICATION

).* $ll personnel performing radiographic e4amination shall be certied

to minimum 2-' /e3el 7 in RT.

).2 Personnel performing interpretation and e3aluation of radiographs

shall be certied to minimum /e3el 77 in RT.

).) $ll 2-' personnel shall ha3e $%2T! P62 or 'qui3alent le3el577

6erticate.

).. 7nterpretation '3aluation of test result and preparation of report

shall be done only by 2-' le3el577 or /e3el5777.

).> 1alid 2-T 6erticates and 61 of personnel shall be submitted to

client B third party for 3erication and appro3al.

4. SURFACE PREPARATION

..* Weld ripples or weld surface irregularities on both the inside 9where

accessible: and outside shall be remo3ed by grinding to such a

degree that the resulting radiographic image due to any surface

irregularity shall not masA or be confused with the image of any

discontinuity.

..2 The nished surface of all butt5welded joints may be Cush with the

base material or may ha3e reasonably uniform crowns! with

reinforcement not to e4ceed that specied in the referencing code

sections. 9$pplicable edition and addenda:

5. IDENTIFICATION OF RADIOGRAPH

The identication system used to produce permanent identication on

the radiographs shall be plainly and permanently included on the

radiograph. These identication system need not to appear as

radiographic images. These may form an image or may be written on

the radiographs with an indelible inA marAer. 7n any case! this

information shall not obscure the area of interest.

2ecessary informationDs required to be present on the radiographs

shall beE

*. ?ob 2umber

2. 'quipment or line no.

). Weld identication

.. Weld identication symbol.

6. EXTENT OF EXAMINATION

The e4tent of e4amination shall be as specied by the

-rawing"7nspection test Plan

Page 5 of 22

RADIOGRAPHIC TESTING PROCEDURE

7. RADIATION ENERGYSOURCE OF RADIATION

Recommended F5ray energy"radioisotopes are as per Table *.

T/67e 1

T894:ness ./n;e M/te.9/7

Ene.;3Isoto2e

-se0

Re1/.:s

(elow )mm $ll %teel *.8G1 ma4imum

There is no limitation of

F5energy or 7sotope

used. 7f the

recommendations are

followed consistent

result will be achie3ed.

0owe3er! the energy

employed shall achie3e

the density and 7Q7

image requirements of

this procedure.

$bo3e )mm to

*8mm

$ll %teel 2.8G1 ma4imum

or

7r. *;2.

$bo3e *8mm to

28mm

$ll %teel

)88G1 ma4imum

or 7r.*;2

$bo3e 28mm to

>8mm

$ll %teel

7r.*;2

$bo3e >8mm to

<>mm

$ll %teel

7r *;2 or 6o H8

$bo3e <> mm to

+8mm

$ll %teel 6o5H8

!. SOURCE SI"E

The isotope source manufacturers or suppliers written statement

documenting the actual or ma4imum source siIe or focal spot shall be

used for source siIe 3erication.

#. FI$M

Radiographs shall be made using industrial radiographic lm only. The

lm brand and designation shall be selected from the Table 2 gi3en

belowE5

T/67e 2

Film &aAe Film -esignation

$,F$ -<"->"-.

GodaA $$.88"T288"&F *2>

'qui3alent lms from other brands can also be used. $ll lm used for

radiographic e4amination shall be within the date of its e4piry as

mentioned on the carton of the lm. Films shall be handled in such way

so that physical damages such as scratch! crimps and pressure marAs

will be minimiIed.

The lms should not be stored for a longer period in a room

temperature abo3e 2> degree and the relati3e humidity shall not be

more than H>J to a3oid fogging of lms due to heat and moisture for a

longer period.

Page 6 of 22

RADIOGRAPHIC TESTING PROCEDURE

The safe light under which the lm will be handled for loading and

de3eloping shall be checAed for its fogging capability. The safelight

conditions shall be adjusted in such a way that the ma4imum fog

density including base shall not be more than 8.) when e4posed to all

the safelights for )8 minutes. The safelight fog le3el shall be tested

once in ) months or whene3er the bulb is replaced.

The procedure for fog le3el test shall be as follows.

*. &aAe sure that the darA room for loading and de3eloping are free

from any e4ternal light leaAs.

2. 7f found any! seal those leaAs.

). 6ut pieces of highest speed lm 9HK4)K siIe: and place it under

each safelight a3ailable in the darA room.

.. '4pose the lm to all safelight on for )8 minutes.

>. -e3elop the lm as per regular de3eloping procedure.

H. -ry and measure the density of the lm.

<. The ma4imum and the a3erage density measured from > random

locations shall not be more than 8.).

+. 7f the density found more than 8.)! the safelight intensity may be

reduced by reducing the bulb watt! changing the lter and"or

increasing the safelight distance and redo the abo3e test.

$ tag shall be displayed on or near the safelight and the tag shall

contain the following informations.

*. %afelight identication 2umber.

2. -ate of safelight fog le3el test.

). &a4imum density obser3edE

.. 2e4t date of fog le3el checA.

>. 2ame and signature of the indi3idual done the checA.

1%. IMAGE &UA$ITY INDICATORS

10.1 0ole or wire type 7Q7 manufactured and identied in accordance

with the requirements or $lternates allowed in %'5*82> 9for hole

type: and %'5<.< 9for wire type:! e4cept that the largest wire

number or the identity number may be omitted. $%&' standard

7Q7Ds shall consist of those in Table ) for hole type and Table . for

wire type.

10.2I&I Con<o.1/n4e Ce.t9=4/tes <.o1 t8e M/n-</4t-.e.

$t the time of purchase! a certicate a testing to the conformance of

material type B dimensional tolerance shall be obtained from

manufacture and shall be retained.

Page 7 of 22

RADIOGRAPHIC TESTING PROCEDURE

$ll wire 7Q7 used shall be designed manufactured B certied as per

%' <.< of $rticle 22 of $%&' %ection 1.

$ll hole type 7Q7 used shall be designed! manufactured B certied as

per %'*82> of $rticle 22 of $%&' %ection 1.

*8.)Pe.9o094 Ins2e4t9on o< I&I

The 7Q7 shall be checAed before each B e3ery use for under wear or

damage B the shift of the wire. 7f found defecti3e or damage! the

same shall be discarded.

T/67e (

0ole type 7Q7 -esignation! ThicAness and 0ole -iameters

Page 8 of 22

RADIOGRAPHIC TESTING PROCEDURE

T/67e 4

Page 9 of 22

7Q7

-esignati

on

7Q7

ThicAness!

mm

9inches:

*T 0ole

diameter!

mm9inches:

2T 0ole

diameter!

mm9inche

s:

.T 0ole

diameter!

mm9inches:

> 8.*)

98.88>:

8.2>

98.8*8:

8.>*

98.828:

*.82

98.8.8:

< 8.*;

98.88<>:

8.2>

98.8*8:

8.>*

98.828:

*.82

98.8.8:

*8 8.2>

98.8*8:

8.2>

98.8*8:

8.>*

98.828:

*.82

98.8.8:

*2 8.)2

98.8*2>:

8.)2

98.8*2>:

8.H.

98.82>:

*.2<

98.8>8:

*> 8.)+

98.8*>:

8.)+

98.8*>:

8.<H

98.8)8:

*.>2

98.8H8:

*< 8...

98.8*<>:

8...

98.8*<>:

8.+;

98.8)>:

*.<+

98.8<8:

28 8.>*

98.828:

8.>*

98.828:

*.82

98.8.8:

2.8)

98.8+8:

2> 8.H.

98.82>:

8.H.

98.82>:

*.2<

98.8>8:

2.>.

98.*88:

)8 8.<H

98.8)8:

8.<H

98.8)8:

*.>2

98.8H8:

).8>

98.*28:

)> 8.+;

98.8)>:

8.+;

98.8)>:

*.<+

98.8<8:

).>H

98.*.8:

.8 *.82

98.8.8:

*.82

98.8.8:

2.8)

98.8+8:

..8H

98.*H8:

.> *.*.

98.8.>:

*.*.

98.8.>:

2.2;

98.8;8:

..><

9 8.*+8:

>8 *.2<

98.8>8:

*.2<

98.8>8:

2.>.

98.*88:

>.8+

98.288:

H8 *.>2

98.8H8:

*.>2

98.8H8:

).8>

98.*28:

H.*8

98.2.8:

<8 *.<+

98.8<8:

*.<+

98.8<8:

).>H

98.*.8:

<.**

98.2+8:

+8 2.8)

98.8+8:

2.8)

98.8+8:

..8H

98.*H8:

+.*)

98.)28:

*88 2.>.

98.*88:

2.>.

98.*88:

>.8+

98.288:

*8.*H

98..88:

*28 ).8>

98.*28:

).8>

98.*28:

H.*8

98.2.8:

*2.*;

98..+8:

*.8 ).>H

98.*.8:

).>H

98.*.8:

<.**

98.2+8:

*..22

98.>H8:

*H8 ..8H

98.*H8:

..8H

98.*H8:

+.*)

98.)28:

*H.2H

98.H.8:

288 >.8+

98.288:

>.8+

98.288:

*8.*H

98..88:

L.

2.8 H.*8

98.2.8:

H.*8

98.2.8:

*2.*;

98..+8:

L.

2+8 <.**

98.2+8:

<.**

98.2+8:

*..22

98.>H8:

L.

RADIOGRAPHIC TESTING PROCEDURE

Wire type 7Q7 -esignation! Wire diameter and Wire identity

%'T 6 %'T -

W7R

'

-7$

72

mm

W7R'

-7$&'T'

R 72

7260'%

W7R'

7-'2T7T@

W7R

'

-7$

72

mm

W7R'

-7$&'T'

R 72

7260'%

W7R'

7-'2T7T@

8.+* 8.8)2 ** 2.>. 8.*88 *H

*.82 8.8.8 *2 ).28 8.*2H *<

*.2< 8.8>8 *) ..8H 8.*H8 *+

*.H8 8.8H) *. >.8+ 8.288 *;

2.8) 8.8+8 *> H.)> 8.2>8 28

2.>. 8.*88 *H +.*) 8.)28 2*

11. DENSITY AND DENSITOMETER CA$I'RATION

**.*Film shall be e4posed so that the density through the weld metal is

not less than 2.8 and should not be greater than ).> for single lm

3iewing. Radiographs with density up to ..8 may be acceptable if

adequate 3iewing conditions are pro3ided. Films shall not be

3iewed when wet.

**.2 -ensitometer shall be calibrated at least for e3ery ;8 days during

use. $ step wedge calibration lm! traceable to a national standard

step tablet and ha3ing at least > steps with neutral densities from

at least*.8 through ..8! shall be used for densitometer calibration.

**.)The step wedge calibration lm shall be maintained in the original

light5tight and waterproof sealed pacAage! prior to rst use.

**..The step wedge calibration lm may be used for densitometer

calibration and periodic 3erication for one year upon opening

without 3erication if it is within the manufacturerDs stated shelf

life.

Page 10 of 22

%'T $ %'T (

W7R'

-7$ 72

mm

W7R'

-7$&'T'

R 72

7260'%

W7R'

7-'2T7T@

W7R'

-7$ 72

mm

W7R'

-7$&'T'

R 72

7260'%

W7R'

7-'2T7T@

8.8+ 8.88)2 * 8.2> 8.8*8 H

8.*8 8.88. 2 8.)) 8.8*) <

8.*) 8.88> ) 8..* 8.8*H +

8.*H 8.88H) . 8.>* 8.828 ;

8.28 8.88+ > 8.H. 8.82> *8

8.2> 8.8*8 H 8.+* 8.8)2 **

RADIOGRAPHIC TESTING PROCEDURE

**.>&anufacturersD step5by5step instructions for the operation of the

densitometer shall be followed.

**.HFor calibration purpose! the density closest to *.8! 2.8! ).8! and ..8

on the step wedge calibration lm shall be read.

**.<The densitometer is acceptable if the density readings do not 3ary

by more than M 8.8> units from the actual density stated on the

step wedge calibration lm.

**.+$ calibration certicate shall be made and the following

informationDs shall be detailed in the certicate.

a: -ensity meter &anufacturer! &odel and %erial 2umber.

b: %tep wedge calibration lm &anufacturer and %erial 2umber.

c: The step numbers used for density 3erication.

d: The density of each step.

e: The actual density measured by the densitometer.

f: The 3ariations obser3ed.

g: -ate of calibration done.

h: 2ame and /e3el of indi3idual performed the calibration.

i: 2e4t due date for calibration.

**.; Periodic calibration 3erication shall be done as per **.* to **.+

shall be performed at the beginning of each shift! after + hours of

continuous use! or after change of apertures! whiche3er comes

rst. The periodic densitometer 3erication checAs do not ha3e to

be documented.

12. GEOMETRICA$ UNSHARPNESS

Radiography shall be performed so that ,eometrical =nsharpness of

the radiograph does not e4ceed the following limits.

&aterial ThicAness in in.

9mm:

=g ma4imum in in. 9mm:

=nder 2 9>8:

8.828 98.>*:

2 through ) 9>85<>: 8.8)8 98.<H:

#3er ) through . 9<>5*88: 8.8.8 9*.82:

,reater than . 9*88: 8.8<8 9*.<+:

Note> M/te.9/7 t894:ness 9s t8e t894:ness on ?8948 t8e I&I 9s

6/se0.

&inimum %F-" FF- in order to achie3e this shall be calculated as

followsE5

9-MT: N %F- N % 4 T M T

Page 11 of 22

RADIOGRAPHIC TESTING PROCEDURE

=g

Where!

%F- N %ource" Focal spot to lm distance 9%F-" FF-:

% N The ma4imum projected dimension of the radiating source

in the plane perpendicular to the distance - from the weld

or object being radiographed or eOecti3e focal

spot in case of an F5ray machine.

T N distance from the source side of Weld or object to the lm.

=g N ,eometrical =nsharpness.

- N -istance from the source of radiation to weld or object

being

radiographed.

- and T shall be determined to the appro4imate center of the area

of interest.

1(. 'AC) SCATTER RADIATION

$s a checA on (acA %cattered Radiation! a lead letter P(D with minimum

dimension of Q in. 9*)mm: in height and *"*Hin. 9*.>mm: in thicAness

shall be attached to the bacA of each lm holder. %hould a light image

of the letter P(D be clearly appear on the Radiograph! correcti3e

measures shall be taAen and the area shall be Re5radiographed until

satisfactory results are obtained.

$ darA image of the S(K on a lighter bacAground is not a cause for

rejection.

14. RADIOGRAPHIC TECHNI&UE

$ single wall e4posure technique shall be used for radiography

where3er practical.

S9n;7e +/77 Te48n9@-e A S9n;7e +/77 *9e?9n; BS+SIC>

7n %ingle Wall Technique! the radiation passes through only one wall of

the Weld or object! which is 3iewed for acceptance.

$nne4ure 5 7 and $nne4ure 5 77 illustrates diOerent e4posure

arrangement for %ingle Wall Radiographic Technique.

15. $OCATION MAR)ERS

/ocation marAers shall appear as Radiographic images. They shall be

placed on the part and not on the e4posure holder cassette. Their

locations shall be permanently marAed on the surface of the part

being radiographed or on a map in a manner permitting the area of

interest on a radiograph to be accurately located on the part! so as to

pro3ide guidance on the radiograph that the required co3erage of the

region being e4amined has been obtained.

Page 12 of 22

RADIOGRAPHIC TESTING PROCEDURE

*>.* /ead location marAers will be placed on the part at clearly

marAed inter3als.

*>.2 /ocation marAers will be placed according to that illustrated in

$nne4ure T 777.

16. IMAGE &UA$ITY INDICATORS

The 7mage Quality 7ndicators used shall be either $%T& %'5*82> 0ole

type or $%T& %'5<.< Wire type.

*H.* The 0ole type 7Q7Ds may be used with shims when required.

*H.2 0ole types 7Q7Ds are a3ailable in siIes as gi3en in Table ).

*H.) Wire type 7Q7! wire diameter and wire identity are as gi3en in

Table ..

*H.. Wire type 7Q7 designed and manufactured in accordance with

other national or international standards may be used pro3ided

the alternati3e wire 7Q7 essential diameter is equal or less than

the required $%T& '5<.< standard 7Q7 essential wire.

17. MATERIA$ FOR I&I

*<.* The material of the 7Q7 shall be of similar Radiographic density to

that material under e4amination i.e. %teel for %teel! $luminum

for $luminum.

*<.2 When special alloy materials are required to be radiographed

reference shall be made to $%&' %ec 1! $rticle 22 %'*.2 for

selection of appropriate 7Q7 material type.

1!. SE$ECTION OF I&I

*+.* 7Q7 shall be selected as specied in $nne4ure T 71. $ thinner or

thicAer 0ole type 7Q7 may be substituted for any section

thicAness as gi3en in $nne4ure 5 71 pro3ided an equi3alent 7Q7

sensiti3ity is maintained.

+e70s ?9t8 Re9n<o.4e1ent> The thicAness on which the 7Q7 is

based is the nominal %ingle5Wall thicAness plus the estimated

reinforcement! not to e4ceed the acceptable reinforcements as per

reference code sections. The actual reinforcement thicAnesses need

not to be measured. (acAing rings or strips shall not be considered

as part of the Weld thicAness in 7Q7 selection.

+e70s ?9t8o-t Re9n<o.4e1ents> The thicAness on which the 7Q7 is

based is the nominal %ingle5Wall thicAness. (acAing rings or strips

shall not be considered as part of the Weld thicAness in 7Q7 selection.

1#. P$ACEMENT OF I&I

*;.* The Wire type 7Q7 shall be placed on the source side! across the

weld so that the wires are at ;8

o

to the seam. The plaque type

Page 13 of 22

RADIOGRAPHIC TESTING PROCEDURE

7Q7 shall be placed adjacent to the Weld appro4. *"+K 9) mm:

away from weld edge.

*;.2 Where inaccessibility pre3ents placement of the 7Q7 on the

%ource %ide! a lm side 7Q7 may be used and letter F shall be

placed adjacent to or on the 7Q7 without disturbing the hole or

wire.

2%. NUM'ER OF I&I

28.* 7Q7 shall be placed so that at least one 7Q7 is 3isible on each

radiograph.

28.2 Where one or more lm are used and complete circumference is

radiographed by panoramic shot! at least three 7Q7Ds shall be

used each located at appro4imately *28

o

apart.

28.) When Panoramic Technique is used the no. of e4posures" lms

represented by the lm containing 7Q7! shall be documented in

the technique sheet to enable correct identication of

radiographs that would require re5shoots due to improper

sensiti3ity e4hibited on the reference radiograph.

21. I&I SENSITI*ITY

Radiography shall be performed with a technique of suUcient

sensiti3ity to display the designated hole type 7Q7 image and the 2 T

hole! or the essential wire of a wire 7Q7. The radiographs shall also

display the 7Q7 identifying numbers and letters.

22. PROCESSING

22.* Processing will be manual or automatic.

22.2 &anual -e3elopment of lm is to be done following the Time "

Temperature correction chart as recommended by lm

manufactures. Films shall be agitated for rst *8sec.of each

minute during de3elopment. This will help lm de3elop e3enly.

22.) The de3eloper solution should be changed immediately after the

quantity of lms de3eloped e4ceeds <888 sq. inches per gallon of

de3eloper solution.

22.. Preparation of de3eloper solution shall be used compensating the

de3eloper solution le3el coming away by the lm B hanger.

22.> Quantity of lms de3eloped in the darA room shall be displayed

and updated regular inter3als to Anow the amount of lms

de3eloped.

22.H Following de3elopment! the acti3ity of de3eloper in emulsion

shall be neutraliIed by an acetic acid stop acid bath for Q to *

minute with agitation for rst *8 sec.

Page 14 of 22

RADIOGRAPHIC TESTING PROCEDURE

22.< Films will be 4ed for at least twice the clearing time with

agitation for the rst *8 sec. and again at the end of the rst

minute.

22.+ Washing will be for at least *8 minutes in running water bath or

by 6ascade method.

22.; Films shall be dipped in wetting agent for * min.

22.*8 Films shall be drained! then hung and dried.

22.** $utomatic processing procedures shall be as recommended by

the &anufacturerDs recommendations.

2(. *IE+ING OF RADIOGRAPHS

1iewing facility shall pro3ide subdued bacAground lighting of an

intensity that will not cause reCections! shadows or glare on the

Radiograph that interfere with the interpretation process. The 3iewer

used shall pro3ide a 3ariable intensity light source! which will emit

suUcient illumination to enable the interpreter to distinguish all the

pertinent details of radiography.

24. ACCEPTANCE CRITERIA

$cceptance standards of radiographs as per %ection ;.) of $P7 **8.

and applicable project specications.

25. RADIOGRAPHIC TECHNI&UE DETAI$S CUM REPORT FORM

$ Radiographic technique details cum report form as per $nne4ureT17

shall be prepared during or after completion of e3aluation of

radiographs.

Anne,-.e I

E,2os-.e BSo-.4eA+e70AF971C A../n;e1ent> A

Page 15 of 22

RADIOGRAPHIC TESTING PROCEDURE

Page 16 of 22

RADIOGRAPHIC TESTING PROCEDURE

Optional Source

Location

Film Film

'4posure TechniqueE %ingle wall Technique! %ingle wall 1iewing.

&inimum '4posuresE $t least ) e4posures *28 degree to each other.

Pipe siIe /imitationsE $ny siIe.

7Q7 placementE %ource side When e3er Possible. Film %ide when hand placing is

not possible.

/ocation &arAer PlacementE Film %ide.

E,2os-.e BSo-.4eA+e70AF971C A../n;e1ent> '

Page 17 of 22

Source Location

Film Film

RADIOGRAPHIC TESTING PROCEDURE

'4posure TechniqueE %ingle Wall Technique! %ingle wall 1iewing. 9Panoramic:

&inimum '4posuresE #ne '4posure by placing the source at the a4is of weld.

Pipe siIe /imitationsE *8Kdia and abo3e.

7Q7 placementE %ource side. 7f hand placing not possible! 7Q7 can be placed on

Film side.

/ocation &arAer PlacementE Film %ide.

Anne,-.e II

E,2os-.e BSo-.4eA+e70AF971C A../n;e1ent> C

'4posure TechniqueE %ingle Wall Technique! %ingle wall 1iewing. 9%ource #ut

side Pipe:

&inimum '4posuresE $t least > e4posures at <2 degree to each other.

Pipe siIe /imitationsE *2 inch dia. and abo3e.

7Q7 placementE %ource side.

/ocation &arAer PlacementE %ource %ide.

Page 18 of 22

Source Location

Film

Film

RADIOGRAPHIC TESTING PROCEDURE

Anne,-.e III

Anne,-.e I*

Page 19 of 22

RADIOGRAPHIC TESTING PROCEDURE

IQI SELECTION

REF> ASME Se4t9on * A.t947e 2 T/67e TA276

2ominal %ingle5

Wall &aterial

ThicAness Range

I&I

So-.4e s90e F971 s90e

Ho7eA

T32e

Des9;

n/t9on

+9.eA

T32e

Esse

nt9/7

+9.e

Ho7eA

T32e

Des9;

n/t9on

+9.e

A

T32e

Esse

nt9/7

+9.e

9n. B11C

=p to

8.2>! incl.

9=p to H..!

incl.:

*2 > *8 .

#3er 8.2>

through

8.)<>

9#3er H..

through ;.>: *> H *2 >

#3er

8.)<>

through

8.>8

9#3er ;.>

through

*2.<:

*< < *> H

#3er 8.>8

through

8.<>

9#3er *2.<

through

*;.8:

28 + *< <

#3er 8.<>

through

*.88

9#3er *;.8

through

2>..:

2> ; 28 +

#3er *.88

through

*.>8

9#3er 2>..

through

)+.*:

)8 *8 2> ;

#3er *.>8

through

2.88

9#3er )+.*

through

>8.+:

)> ** )8 *8

#3er 2.88

through

2.>8

9#3er >8.+

through

H).>:

.8 *2 )> **

#3er 2.>8

through

..88

9#3er H).>

through

*8*.H:

>8 *) .8 *2

#3er ..88

through

H.88

9#3er *8*.H

through

*>2..:

H8 *. >8 *)

#3er H.88

through

+.88

9#3er *>2..

through

28).2:

+8 *H H8 *.

#3er +.88

through

*8.88

9#3er 28).2

through

2>..8:

*88 *< +8 *H

#3er

*8.88

through

9#3er 2>..8

through

)8..+:

*28 *+ *88 *<

Page 20 of 22

RADIOGRAPHIC TESTING PROCEDURE

*2.88

#3er

*2.88

through

*H.88

9#3er )8..+

through

.8H..:

*H8 28 *28 *+

#3er

*H.88

through

28.88

9#3er .8H..

through

>8+.8:

288 2* *H8 28

Anne,-.e *

E&UI*A$ENT HO$E TYPE I&I SESINTI*ITY

REF> ASME Se4t9on * A.t947e 2 T/67e TA2!(

Ho7e T32e

Des9;n/t9on

2T Ho7e

E@-9D/7ent Ho7e t32e Des9;n/t9ons

1T Ho7e 4T Ho7e

*8 *> >

*2 *< <

*> 28 *8

*< 2> *2

28 )8 *>

2> )> *<

)8 .8 28

)> >8 2>

.8 H8 )8

>8 <8 )>

H8 +8 .8

+8 *28 H8

*88 *.8 <8

*28 *H8 +8

*H8 2.8 *28

288 2+8 *.8

Page 21 of 22

RADIOGRAPHIC TESTING PROCEDURE

Anne,-.e *I

Page 22 of 22

Anda mungkin juga menyukai

- Job Procedure For RadiographyDokumen12 halamanJob Procedure For RadiographyMecon HyderabadBelum ada peringkat

- Radiography Test Inspection Free NDT Sample Procedure 1 4Dokumen5 halamanRadiography Test Inspection Free NDT Sample Procedure 1 4Alam MD SazidBelum ada peringkat

- Radio Graphic ExaminationDokumen33 halamanRadio Graphic ExaminationSakthi PanneerSelvam Tanjai100% (6)

- Magnetic Particle Examination Procedure PorDokumen7 halamanMagnetic Particle Examination Procedure PorFasil ParuvanathBelum ada peringkat

- Asme b31.3 Acceptance RT TabulatedDokumen86 halamanAsme b31.3 Acceptance RT TabulatedWalter Trajada100% (2)

- Inspection and Test Plan: Rev Created by Checked by Approved by Date Issue StatusDokumen18 halamanInspection and Test Plan: Rev Created by Checked by Approved by Date Issue StatusoberaiBelum ada peringkat

- SAIW Certification - NDT - NDT LogbookDokumen19 halamanSAIW Certification - NDT - NDT Logbookkhairy2013Belum ada peringkat

- Procedure For Ferrit TestingDokumen11 halamanProcedure For Ferrit TestingKarrar TalibBelum ada peringkat

- Student Training Notes Floormap 3diDokumen86 halamanStudent Training Notes Floormap 3diTechnical A-Star Testing & Inspection MalaysiaBelum ada peringkat

- RT Acceptance Criteria For Welder Test According To ASME Sec IX (QW 191 1.2)Dokumen20 halamanRT Acceptance Criteria For Welder Test According To ASME Sec IX (QW 191 1.2)Oscar Iván Duque DiazBelum ada peringkat

- Ultrasonic Testing Report For PipingDokumen54 halamanUltrasonic Testing Report For Pipingeldobie3Belum ada peringkat

- Radiography Acceptance Criteria As Per B 31.3Dokumen2 halamanRadiography Acceptance Criteria As Per B 31.3mohamedBelum ada peringkat

- Radiography Testing - NDT Inspection - TWIDokumen5 halamanRadiography Testing - NDT Inspection - TWIKolusu SivakumarBelum ada peringkat

- RT SlidesDokumen21 halamanRT SlidesWellington S. França100% (1)

- RT SlideDokumen36 halamanRT SlidekbldamBelum ada peringkat

- UT Formula SheetDokumen2 halamanUT Formula SheetOktayKulBelum ada peringkat

- RADIOGRAPHIC TEST PROCEDURE (RT Procedure)Dokumen17 halamanRADIOGRAPHIC TEST PROCEDURE (RT Procedure)Senthil Kumaran100% (1)

- Vaccum Box Procedure API 650 OKDokumen7 halamanVaccum Box Procedure API 650 OKTouil Houssem100% (1)

- PTDokumen7 halamanPTMohdHuzairiRusliBelum ada peringkat

- NDE NDT Inspection BrochureDokumen16 halamanNDE NDT Inspection BrochureEngr Arfan Ali DhamrahoBelum ada peringkat

- Computed Radiographic Testing (CRT) Qualification Report: Rev. ADokumen12 halamanComputed Radiographic Testing (CRT) Qualification Report: Rev. ATrung Tinh HoBelum ada peringkat

- UT Procedure PDFDokumen14 halamanUT Procedure PDFAbhayBelum ada peringkat

- Asnt CP-189-2001Dokumen8 halamanAsnt CP-189-2001David SalgueroBelum ada peringkat

- Internal RT Procedure Spread IIDokumen4 halamanInternal RT Procedure Spread IIravi00098100% (1)

- Kerosene Leak TestDokumen3 halamanKerosene Leak TestsapkotamonishBelum ada peringkat

- MEMB453-NDT-Visual Inspection 2017Dokumen57 halamanMEMB453-NDT-Visual Inspection 2017thineshBelum ada peringkat

- Radiographic Testing ProcedureDokumen4 halamanRadiographic Testing ProcedureJimmy JohnBelum ada peringkat

- Welding of Pipelines and Related Facilities: Api Standard 1104 Nineteenth Edition, September 1999Dokumen62 halamanWelding of Pipelines and Related Facilities: Api Standard 1104 Nineteenth Edition, September 1999Riki AkbarBelum ada peringkat

- Ultrasonic Test Procedure: Rev. Date Prepared by Reviewed ApprovedDokumen8 halamanUltrasonic Test Procedure: Rev. Date Prepared by Reviewed Approvedkevin desaiBelum ada peringkat

- Silverwing B Scan ReportDokumen46 halamanSilverwing B Scan ReportpjhollowBelum ada peringkat

- Reviewed UT Procedure 10-12-2016Dokumen18 halamanReviewed UT Procedure 10-12-2016Muhammad Maulana100% (1)

- General Specification For Visual TestingDokumen5 halamanGeneral Specification For Visual Testingsyukron_a100% (1)

- Sample NTD Inspection ReportDokumen127 halamanSample NTD Inspection ReportGeorge NicolaidesBelum ada peringkat

- PSL-30 - Log of Pre-Cert ExperienceDokumen3 halamanPSL-30 - Log of Pre-Cert ExperiencerenjisyamBelum ada peringkat

- Wps & Pqr-013 (Ss Gtaw-Smaw TGS)Dokumen17 halamanWps & Pqr-013 (Ss Gtaw-Smaw TGS)Atuk SafizBelum ada peringkat

- Scope:: Area of Sample To Be Tested All Surfaces, Weld and Heat Affected Zone, Including Dimensions of HAZDokumen2 halamanScope:: Area of Sample To Be Tested All Surfaces, Weld and Heat Affected Zone, Including Dimensions of HAZAnna PariniBelum ada peringkat

- Dye Penetrant ProcedureDokumen7 halamanDye Penetrant Procedurezaki fadl100% (1)

- Cswip BrochureDokumen1 halamanCswip BrochureesltirchyBelum ada peringkat

- Ferrite Content Measurement ProcedureDokumen5 halamanFerrite Content Measurement ProcedureSenthil Periyasamy0% (1)

- Radiographic Acceptance Criteria: (This Table Contains Maximum Discontinuity Size Allowed)Dokumen7 halamanRadiographic Acceptance Criteria: (This Table Contains Maximum Discontinuity Size Allowed)Alzaki AbdullahBelum ada peringkat

- Ut Procedure NewDokumen10 halamanUt Procedure NewAmit HasanBelum ada peringkat

- Tubing TestDokumen16 halamanTubing Testbenergy84100% (1)

- Computer Radiography For Wall Thickness MeasurementDokumen36 halamanComputer Radiography For Wall Thickness MeasurementTonyo Ayshiyu100% (3)

- Prosedur Vacum Box TestDokumen5 halamanProsedur Vacum Box TestIkhsan Dalimunthe100% (2)

- Phased Array Ut Procedure For WeldsDokumen12 halamanPhased Array Ut Procedure For WeldsMohd Salleh Zainal100% (7)

- Dye Penetrant ProcedureDokumen8 halamanDye Penetrant ProcedureTouil HoussemBelum ada peringkat

- ASME V Presentation 1Dokumen56 halamanASME V Presentation 1hreer100% (2)

- NDT RT ProcedureDokumen16 halamanNDT RT ProcedureSandiSandii100% (1)

- 4 Asme Sec Ix Wps PQR Slide 71 To 105Dokumen35 halaman4 Asme Sec Ix Wps PQR Slide 71 To 105dhasdj100% (1)

- Welding Defects Ala'aDokumen48 halamanWelding Defects Ala'asbmmlaBelum ada peringkat

- Techno NDT Services: Ultrasonic Flaw Detection ReportDokumen1 halamanTechno NDT Services: Ultrasonic Flaw Detection Reportram dreamsBelum ada peringkat

- Eddy Current (RFT) ProcedureDokumen12 halamanEddy Current (RFT) ProcedureAnonymous gFcnQ4go83% (6)

- CN-11-Section 11 Teletest Functional Tests and Troubleshooting Rev0.1Dokumen18 halamanCN-11-Section 11 Teletest Functional Tests and Troubleshooting Rev0.1Tĩnh Hồ TrungBelum ada peringkat

- Radiography Examination Procedure For Asme Boiler, Pressure Vessel and PipingDokumen15 halamanRadiography Examination Procedure For Asme Boiler, Pressure Vessel and PipingEko Kurniawan100% (1)

- Manual-900E EP - S - X-0605 Radiation CounterDokumen34 halamanManual-900E EP - S - X-0605 Radiation CounterChristos GeorgiouBelum ada peringkat

- RT ProcedureDokumen26 halamanRT ProcedureKoshala Balasuriya100% (1)

- Larsen & Toubro Limited MSQ Up Gradation (Epcc 1) Project: LT/MSQ/P/UT/011Dokumen11 halamanLarsen & Toubro Limited MSQ Up Gradation (Epcc 1) Project: LT/MSQ/P/UT/011Saut Maruli Tua SamosirBelum ada peringkat

- Section Testing, Identification and Administration of Fiber Infrastructure Part 1 - GeneralDokumen10 halamanSection Testing, Identification and Administration of Fiber Infrastructure Part 1 - Generalssantos_303882Belum ada peringkat

- Welding Procedure SpecificationDokumen1 halamanWelding Procedure Specificationfallalovaldes100% (1)

- Piping Fabrication Procedure.Dokumen58 halamanPiping Fabrication Procedure.Janardhan Surya78% (23)

- Welding Procedure SpecificationDokumen1 halamanWelding Procedure Specificationfallalovaldes100% (1)

- Welding of Stainless Steels and Other Joining Methods: A Designers' Handbook Series N 9 002Dokumen18 halamanWelding of Stainless Steels and Other Joining Methods: A Designers' Handbook Series N 9 002Sreenivas GuduruBelum ada peringkat

- Welding Processes & Welding Defects: Welding Metallurgy Kanchan KumarDokumen74 halamanWelding Processes & Welding Defects: Welding Metallurgy Kanchan KumarsubhaBelum ada peringkat

- Heat ExchangerDokumen420 halamanHeat ExchangerRavindra S. Jivani75% (4)

- QAQC References 2Dokumen138 halamanQAQC References 2Mohd SharainiBelum ada peringkat

- Spiral Pipe FormulaDokumen5 halamanSpiral Pipe FormulaRavindra S. Jivani89% (9)

- Heat ExchangerDokumen420 halamanHeat ExchangerRavindra S. Jivani75% (4)

- Aluminium Welding Pocket GuideDokumen31 halamanAluminium Welding Pocket GuideRavindra S. Jivani100% (1)

- VESSELDokumen350 halamanVESSELRavindra S. JivaniBelum ada peringkat

- Coating Adhesion TestingDokumen37 halamanCoating Adhesion TestingRavindra S. Jivani75% (4)

- API 570 Point Recall 4Dokumen3 halamanAPI 570 Point Recall 4Ravindra S. Jivani100% (2)

- Test Pack Table of ContentsDokumen1 halamanTest Pack Table of ContentsRavindra S. JivaniBelum ada peringkat

- API 580 Closed Book QuestionsDokumen18 halamanAPI 580 Closed Book QuestionsRavindra S. Jivani86% (7)

- API-510 Questions & Answers Closed Book 1Dokumen12 halamanAPI-510 Questions & Answers Closed Book 1Ravindra S. Jivani70% (10)

- API 510 Closed Book QuestionsDokumen16 halamanAPI 510 Closed Book QuestionsRavindra S. Jivani100% (1)

- 04 - HT - QI - Rev. 0 Hardness ProcedureDokumen4 halaman04 - HT - QI - Rev. 0 Hardness ProcedureviswamanojBelum ada peringkat

- RT InterpretationDokumen16 halamanRT InterpretationRavindra S. Jivani100% (1)

- API 570 Point Recall 4Dokumen3 halamanAPI 570 Point Recall 4Ravindra S. Jivani100% (2)

- API 570 Questions 19Dokumen4 halamanAPI 570 Questions 19Ravindra S. Jivani100% (1)

- API 570 Questions 18Dokumen5 halamanAPI 570 Questions 18Ravindra S. Jivani100% (3)

- Uv-Visibles Electronic TransitionDokumen25 halamanUv-Visibles Electronic TransitionZareen Rashid Choudhury100% (1)

- Glucopon 650 EC: Technical InformationDokumen4 halamanGlucopon 650 EC: Technical InformationJulián Herrera RestrepoBelum ada peringkat

- Kelompok 3 - Anfiskim - Spektrofotometri IR Dalam Analisis KualitatifDokumen30 halamanKelompok 3 - Anfiskim - Spektrofotometri IR Dalam Analisis KualitatifThrowaway LohanBelum ada peringkat

- Practical Examples Trasability Uncertainty and Validation in Chemistry Vol 2 PDFDokumen264 halamanPractical Examples Trasability Uncertainty and Validation in Chemistry Vol 2 PDFDoina MarquezBelum ada peringkat

- Problems in Organic UV-Visible SpectrosDokumen10 halamanProblems in Organic UV-Visible SpectrosShunmugasundaram Arunachalam100% (1)

- Shane Underwood, PH.D.: Assistant Professor, Co-Director, Senior Sustainability ScientistDokumen27 halamanShane Underwood, PH.D.: Assistant Professor, Co-Director, Senior Sustainability Scientistmikeing88Belum ada peringkat

- Analysis of Green Tea Extracts (Catechins) by HPLC-UVDokumen2 halamanAnalysis of Green Tea Extracts (Catechins) by HPLC-UVmunmun islamBelum ada peringkat

- Adsorption of Benzene and Toluene From Aqueous Solution Using A Composite Hydrogel of Alginate-Grafted With Mesoporous SilicaDokumen13 halamanAdsorption of Benzene and Toluene From Aqueous Solution Using A Composite Hydrogel of Alginate-Grafted With Mesoporous SilicaSITI NUR AFIQAH MAHAZANBelum ada peringkat

- Class VII-Half Yearly Syllabus (All Subjecs) - 2023-2024Dokumen8 halamanClass VII-Half Yearly Syllabus (All Subjecs) - 2023-202494j667mvspBelum ada peringkat

- Rumput Laut Sebagai KolagenDokumen11 halamanRumput Laut Sebagai KolagenAyyu WidyazmaraBelum ada peringkat

- SKF Explorer Sealed Spherical Roller Bearings: SKF/SRB Brochure 27/8/03 8:54 AM Page 3Dokumen6 halamanSKF Explorer Sealed Spherical Roller Bearings: SKF/SRB Brochure 27/8/03 8:54 AM Page 3Rofan Yulian RomansyahBelum ada peringkat

- Pmi ProcedureDokumen4 halamanPmi ProcedureChandrasekhar mishraBelum ada peringkat

- Exp 1 - Basic Laboratory TechniqueDokumen3 halamanExp 1 - Basic Laboratory TechniqueSiti FatimahBelum ada peringkat

- Info Iectr63025 (Ed1.0) enDokumen8 halamanInfo Iectr63025 (Ed1.0) enEdwinBelum ada peringkat

- Chapter 10 Practice Worksheet: Liquids, Solids, and Phase ChangesDokumen3 halamanChapter 10 Practice Worksheet: Liquids, Solids, and Phase ChangesLuisa TacordaBelum ada peringkat

- Bis StandardsDokumen7 halamanBis StandardsQA SCPLBelum ada peringkat

- FNSC3110 Water and Water Activity (1) - TaggedDokumen42 halamanFNSC3110 Water and Water Activity (1) - TaggedTsz ChingBelum ada peringkat

- Method 21.3WDokumen5 halamanMethod 21.3WVeronika Rengganis100% (1)

- Pre-First Year 2020 ECAT Session I Physics: Punjab Group of CollegesDokumen15 halamanPre-First Year 2020 ECAT Session I Physics: Punjab Group of Collegeslaptop 12Belum ada peringkat

- Steam TableDokumen77 halamanSteam Tableنزار الدهاميBelum ada peringkat

- ShibataFenderTeam White-Paper-Series Part-4 TestingDokumen15 halamanShibataFenderTeam White-Paper-Series Part-4 TestingNadhif MuhammadBelum ada peringkat

- TDS PC 3325Dokumen1 halamanTDS PC 3325AchmadWaluyoBelum ada peringkat

- The Third Dimension PDFDokumen244 halamanThe Third Dimension PDFwrongplanet67Belum ada peringkat

- Cambridge International Examinations Cambridge International General Certificate of Secondary EducationDokumen16 halamanCambridge International Examinations Cambridge International General Certificate of Secondary EducationWENDY MENDIOLABelum ada peringkat

- Passivation of Stainless SteelDokumen2 halamanPassivation of Stainless SteelAleksandar StojanovicBelum ada peringkat

- Acid BaseDokumen6 halamanAcid BaseJaya Chitra Degala RamaluBelum ada peringkat

- Lamara2018 PDFDokumen13 halamanLamara2018 PDFUmer HayatBelum ada peringkat

- Biochemistry 4th Edition Mathews Test Bank 1Dokumen36 halamanBiochemistry 4th Edition Mathews Test Bank 1loribowersbwknifoyxe100% (23)

- SCIENCE Grade 7: Quarter 2 - Module 2 The Compound Microscope: Focusing SpecimenDokumen10 halamanSCIENCE Grade 7: Quarter 2 - Module 2 The Compound Microscope: Focusing Specimensam patauegBelum ada peringkat

- Recipe For Hydrogen Carbonate IndicatorDokumen1 halamanRecipe For Hydrogen Carbonate IndicatorVictoria MenegazziBelum ada peringkat