Chart Torques WG

Diunggah oleh

ebastien2Deskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Chart Torques WG

Diunggah oleh

ebastien2Hak Cipta:

Format Tersedia

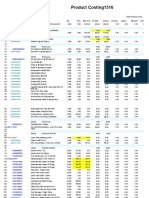

Spiral Wound Gasket CG

NPS (in.)

0.5

0.75

1

1.25

1.5

2

2.5

3

3.5

4

5

6

8

10

12

14

16

18

20

24

NPS

0.5

0.75

1

1.25

1.5

2

2.5

3

4

5

6

8

10

12

14

16

18

20

24

Class 150

Min Torque Max Torque

30

40

30

40

30

40

30

40

30

60

60

90

60

110

90

120

60

90

70

120

100

160

130

200

180

200

170

320

240

320

300

490

310

490

500

710

430

710

620

1000

Class 300

Class 400

Class 600

Min Torque Max Torque Min Torque Max Torque Min Torque Max Torque

30

40

30

40

30

40

60

70

60

70

60

70

60

70

60

70

60

70

60

70

60

70

60

70

100

120

100

120

100

120

60

70

60

70

60

70

100

120

100

120

100

120

100

120

100

120

100

120

100

120

160

190

170

210

100

140

160

200

190

240

110

160

210

260

280

360

110

160

190

240

260

330

180

260

310

400

400

510

250

290

340

440

500

590

360

420

510

640

500

610

360

420

500

890

680

800

500

590

680

800

800

940

500

680

680

810

1100

1290

500

740

800

940

1100

1290

800

1030

1500

1750

2000

2340

Class 900

Max Torque

Min Torque

q

q

70

120

70

120

110

190

110

190

170

290

110

190

170

290

140

230

255

420

360

600

300

500

485

800

505

800

570

850

630

940

910

1290

1570

2340

1745

2570

Class 1500

Class 2500

Min Torque

Max Torque

Min Torque

Max Torque

q

q

q

q

70

120

50

100

70

120

70

100

110

190

110

160

135

190

210

250

200

290

310

360

130

190

220

250

190

290

300

360

265

360

460

500

415

520

585

800

530

680

Not Applicable

Use CGI

845

1100

1565

2000

Not Applicable

Use CGI

Not Applicable Use CGI

Notes:

Torque Values are in ft.-lbs., and assume Alloy Steel Bolts (A193 B7 w/ 2H Nuts) with oil/graphite lubrication.

(Nut factors used on these charts are within .15 to .19)

Flexitallic does not generally recommend a bolt stress above 60,000 PSI

Torque values limit minimum and maximum gasket seating stresses based upon pressure class and certain operating conditions.(i.e: maximum pressure

ratings for given pressure class,not hydrotest pressure), Extreme operating conditions such as high temperature may reduce bolt yield strength. Caution

should be used in these applications. The above torque values are for general use only. For critical or extreme applications (high temperature/pressure)

consult with Flexitallic engineering.

Flexitallic does not accept responsibility for the misuse of this information.

This Document is the property of Flexitallic, L.P. and is not to be reproduced, transmitted to another, nor used for the purpose of manufacturing of articles for

sale to anyone but Flexitallic, L.P. without Flexitallic's specific written permission.

09/13

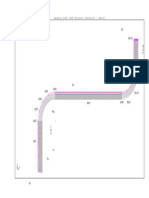

Spiral Wound Gasket CGI

NPS (in.)

0.5

0.75

1

1.25

1.5

2

2.5

3

3.5

4

5

6

8

10

12

14

16

18

20

24

NPS

0.5

0.75

1

1.25

1.5

2

2.5

3

4

5

6

8

10

12

14

16

18

20

24

Class 150

Min Torque Max Torque

30

50

30

50

30

60

30

60

30

60

60

120

60

120

90

120

60

120

70

120

100

200

130

200

180

200

170

320

240

320

300

490

310

490

490

710

430

710

620

1000

Class 300

Class 400

Class 600

Min Torque Max Torque Min Torque Max Torque Min Torque Max Torque

30

40

30

40

30

40

60

80

60

80

60

80

60

80

60

80

60

80

60

80

60

80

60

80

100

140

100

140

100

140

60

80

60

80

60

80

100

140

100

140

100

140

100

150

100

150

100

150

100

170

160

290

170

290

100

200

160

320

190

320

110

200

210

320

280

490

110

200

190

320

260

460

180

320

310

490

400

700

250

460

360

710

500

800

360

700

510

1000

500

850

360

610

500

870

680

950

500

920

680

1250

800

1210

500

1000

680

1340

1100

1790

500

1000

800

1430

1100

1640

800

1600

1500

2270

2000

2670

Class 900

Max Torque

Min Torque

q

q

70

120

70

120

110

190

110

190

170

290

110

190

170

290

140

230

260

420

360

600

300

500

485

800

505

800

560

850

630

940

910

1290

1570

2340

1745

2570

2945

5140

Class 1500

Class 2500

Min Torque

Max Torque

Min Torque

Max Torque

q

q

q

q

70

120

50

100

70

120

63

100

110

190

110

160

140

190

210

250

200

290

310

360

130

190

220

250

190

290

300

360

270

360

460

500

420

520

710

800

590

800

1280

1500

530

680

1870

2200

850

1100

1780

2200

1570

2000

3040

4400

1500

2200

4610

5920

2120

3180

2940

4400

3950

5920

5150

7720

8340

12500

Notes:

Torque Values are in ft.-lbs., and assume Alloy Steel Bolts (A193 B7 w/ 2H Nuts) with oil/graphite lubrication.

(Nut factors used on these charts are within .15 to .19)

Flexitallic does not generally recommend a bolt stress above 60,000 PSI

Torque values limit minimum and maximum gasket seating stresses based upon pressure class and certain operating conditions.(i.e: maximum pressure

ratings for given pressure class,not hydrotest pressure), Extreme operating conditions such as high temperature may reduce bolt yield strength. Caution

should be used in these applications. The above torque values are for general use only. For critical or extreme applications (high temperature/pressure)

consult with Flexitallic engineering.

Flexitallic does not accept responsibility for the misuse of this information.

This Document is the property of Flexitallic, L.P. and is not to be reproduced, transmitted to another, nor used for the purpose of manufacturing of articles for

sale to anyone but Flexitallic, L.P. without Flexitallic's specific written permission.

09/13

Anda mungkin juga menyukai

- Torque FlexitallicDokumen2 halamanTorque FlexitallicLuis Arturo Ramirez Esteban100% (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDari EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsBelum ada peringkat

- CharttorqueswgDokumen2 halamanCharttorqueswgYutana RuxnakBelum ada peringkat

- chartTorqueSwg PDFDokumen2 halamanchartTorqueSwg PDFSebastian Andres Beltran AlvaradoBelum ada peringkat

- Felpro chartTorqueFlexproDokumen1 halamanFelpro chartTorqueFlexprogerry_pomBelum ada peringkat

- V BeltsDokumen58 halamanV BeltsBhavesh PanchalBelum ada peringkat

- 201306041352190Dokumen8 halaman201306041352190subratcetbBelum ada peringkat

- Tecnocentro Eng SRL - Minimum Distance Between Centre Pipes TableDokumen1 halamanTecnocentro Eng SRL - Minimum Distance Between Centre Pipes TableJhonny BBelum ada peringkat

- New Order ListDokumen40 halamanNew Order ListManoj ShahBelum ada peringkat

- Urv Compressor CurveDokumen3 halamanUrv Compressor CurveafsuarezcoBelum ada peringkat

- CATALOGO Festo Controls Reference ListDokumen46 halamanCATALOGO Festo Controls Reference Listanon_385650136Belum ada peringkat

- Asignar Ubicacion - 6Dokumen53 halamanAsignar Ubicacion - 6Recepción Pesquera diamanteBelum ada peringkat

- Tevi Fitinguri PVC KGDokumen5 halamanTevi Fitinguri PVC KGCatalin StefanBelum ada peringkat

- Shimpo Able EVS BrochureDokumen4 halamanShimpo Able EVS BrochureElectromateBelum ada peringkat

- Balmoral RWH HH Direct ManualDokumen2 halamanBalmoral RWH HH Direct ManualAlberto DiazBelum ada peringkat

- Handbook of ElectromotorDokumen16 halamanHandbook of ElectromotorfrdnBelum ada peringkat

- Armada Tubes - Adige Tc720 - 2004 Speed Feed ChartDokumen1 halamanArmada Tubes - Adige Tc720 - 2004 Speed Feed ChartMatt ThompsonBelum ada peringkat

- Master File 16-01-2011Dokumen255 halamanMaster File 16-01-2011ahmedbahr20% (1)

- Estimate of PVC Pipes & Fittings: Sl. No Nomenclature Brand Qnty UnitDokumen6 halamanEstimate of PVC Pipes & Fittings: Sl. No Nomenclature Brand Qnty UnitDibya Jyoti NeogBelum ada peringkat

- TestDokumen8 halamanTestVeera ManiBelum ada peringkat

- Table of Ampacities For Wire Sizes, Conversion of AWG To Metric Sizes and Number of Conductors in A ConduitDokumen20 halamanTable of Ampacities For Wire Sizes, Conversion of AWG To Metric Sizes and Number of Conductors in A ConduitJay Sunga Villan0% (1)

- Flexitallic Tabla de TorqueDokumen2 halamanFlexitallic Tabla de TorqueWalter100% (1)

- Torque Chart Spiral Wound GasketsDokumen2 halamanTorque Chart Spiral Wound GasketsMocanu MarianBelum ada peringkat

- Pinbush - Tyre Coupling 2014Dokumen4 halamanPinbush - Tyre Coupling 2014Priyam NandwanaBelum ada peringkat

- Timing Curve AdvancedDokumen198 halamanTiming Curve AdvancedSmoking WheelsBelum ada peringkat

- Ctg. O-RingsDokumen38 halamanCtg. O-RingsFelipe RamirezBelum ada peringkat

- CanevaroDokumen15 halamanCanevaroLuis Eduardo Donaires SalinasBelum ada peringkat

- Change Torque Chart 11-30-2017Dokumen1 halamanChange Torque Chart 11-30-2017Titino AlejandroBelum ada peringkat

- Inventronics LED Driver Selection GuideDokumen69 halamanInventronics LED Driver Selection GuideAhmet SeçenBelum ada peringkat

- Fault PlotDokumen6 halamanFault PlotCarlos MohanBelum ada peringkat

- R-KER Vinylester Resin + Steel Rods 5.8 M8 - M30: Technical Data SheetDokumen7 halamanR-KER Vinylester Resin + Steel Rods 5.8 M8 - M30: Technical Data SheetChristian LazzariniBelum ada peringkat

- Anel Back-Up - Vedação Auxiliar: Exemplo de Montagem: Modelo BK-01Dokumen9 halamanAnel Back-Up - Vedação Auxiliar: Exemplo de Montagem: Modelo BK-01cristinaBelum ada peringkat

- Consolidado StockDokumen490 halamanConsolidado StockMagoKanduBelum ada peringkat

- Partes para Bombas Triplex Oil WellDokumen2 halamanPartes para Bombas Triplex Oil WellFelipe EstradaBelum ada peringkat

- Valve LiftDokumen4 halamanValve Liftcaliniclodean7737Belum ada peringkat

- Nonreturn Tilting Disc Check Valve Art c01Dokumen2 halamanNonreturn Tilting Disc Check Valve Art c01zayerirezaBelum ada peringkat

- Valvula Cheque 150Dokumen7 halamanValvula Cheque 150WILLIAM ROMEROBelum ada peringkat

- Cost Table For Product - Fountaindesigner PDFDokumen4 halamanCost Table For Product - Fountaindesigner PDFGia Minh Tieu TuBelum ada peringkat

- Funeec Solid Carbide - Price ListDokumen12 halamanFuneec Solid Carbide - Price ListdpshradhaBelum ada peringkat

- Catalogue FSA 50Hz Rev.02Dokumen6 halamanCatalogue FSA 50Hz Rev.02Heri SulasionoBelum ada peringkat

- Siemens 3RV Motor Starter ProtectorDokumen16 halamanSiemens 3RV Motor Starter ProtectorAliff AzleeBelum ada peringkat

- Standard Test Seive Sizes: Mesh Size Tyler ASTM-E11 BS-410 DIN-4188Dokumen2 halamanStandard Test Seive Sizes: Mesh Size Tyler ASTM-E11 BS-410 DIN-4188I. Murali KrishnaBelum ada peringkat

- Ensival Moret PRE Pumps (French-English)Dokumen3 halamanEnsival Moret PRE Pumps (French-English)Benicio Joaquín Ferrero BrebesBelum ada peringkat

- OIl Level Gauge 1614-9184-00Dokumen2 halamanOIl Level Gauge 1614-9184-00UbanAirlanggaBelum ada peringkat

- Especificacion API 5lDokumen44 halamanEspecificacion API 5ljpcc1986100% (1)

- 20090610144043A ProductsDokumen24 halaman20090610144043A Productsidontlikeebooks100% (1)

- Produ To SPP NeusDokumen44 halamanProdu To SPP NeusMarcos PradoBelum ada peringkat

- Erhard Ball VslveDokumen11 halamanErhard Ball VslveRizky edytyaBelum ada peringkat

- Ref Acci OnesDokumen2 halamanRef Acci OnesantonioBelum ada peringkat

- Lista de Peças Sobressalentes (91391800) Spare Parts List G 2500 VHDokumen26 halamanLista de Peças Sobressalentes (91391800) Spare Parts List G 2500 VHJARDINS MÁQUINASBelum ada peringkat

- 6r 6d Bore StrokeDokumen4 halaman6r 6d Bore StrokeMariana ParedesBelum ada peringkat

- V-Belts: Section Z Section A Section A Section B Section B Section BDokumen2 halamanV-Belts: Section Z Section A Section A Section B Section B Section Bmihai37Belum ada peringkat

- British Commercial Computer Digest: Pergamon Computer Data SeriesDari EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesBelum ada peringkat

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesDari EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesPenilaian: 5 dari 5 bintang5/5 (1)

- British Commercial Computer Digest: Pergamon Computer Data SeriesDari EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesBelum ada peringkat

- Enhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsDari EverandEnhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsPenilaian: 5 dari 5 bintang5/5 (1)

- Interbond 1202UPC: Universal Pipe CoatingDokumen4 halamanInterbond 1202UPC: Universal Pipe Coatingebastien2Belum ada peringkat

- CH 4 QuizDokumen4 halamanCH 4 Quizebastien2Belum ada peringkat

- Jotatemp 1000 Ceramic: Technical Data SheetDokumen5 halamanJotatemp 1000 Ceramic: Technical Data Sheetebastien2Belum ada peringkat

- Flexitallic SF 3300: 6915 HWY 225, Deer Park, TX 77536 USA TEL: 281.604.2400 FAX: 281.604.2415Dokumen2 halamanFlexitallic SF 3300: 6915 HWY 225, Deer Park, TX 77536 USA TEL: 281.604.2400 FAX: 281.604.2415ebastien2Belum ada peringkat

- Pointer Flutter / Dampening: Customer Information Bulletin 06 ... Dampening - WPD Revised 12-18-2012Dokumen1 halamanPointer Flutter / Dampening: Customer Information Bulletin 06 ... Dampening - WPD Revised 12-18-2012ebastien2Belum ada peringkat

- FS Sagd PDFDokumen1 halamanFS Sagd PDFebastien2Belum ada peringkat

- Bta CT 0001Dokumen8 halamanBta CT 0001ebastien2Belum ada peringkat

- Bermuda Grass (Cynodon Dactylon) As A Pollen Resource For Honey Bee Colonies in The Lower Colorado River Agroecosystem1Dokumen7 halamanBermuda Grass (Cynodon Dactylon) As A Pollen Resource For Honey Bee Colonies in The Lower Colorado River Agroecosystem1ebastien2Belum ada peringkat

- ER80S Ni1 PDFDokumen2 halamanER80S Ni1 PDFebastien2Belum ada peringkat

- Sports3 CDadapco AM PDFDokumen20 halamanSports3 CDadapco AM PDFebastien2Belum ada peringkat

- Brochure Laserreinigen P-Laser 2016Dokumen4 halamanBrochure Laserreinigen P-Laser 2016ebastien2Belum ada peringkat

- Expanded MetalDokumen2 halamanExpanded Metalebastien2Belum ada peringkat

- Haven-Lockhart Marriage BondDokumen1 halamanHaven-Lockhart Marriage Bondebastien2Belum ada peringkat

- FEA Model: Stress ClassificationDokumen1 halamanFEA Model: Stress Classificationebastien2Belum ada peringkat

- AC2000i Install HelpDokumen47 halamanAC2000i Install Helpebastien2Belum ada peringkat

- Foam Concentrate For Producing Mechanical Foam For Fire Fighting - SpecificationDokumen26 halamanFoam Concentrate For Producing Mechanical Foam For Fire Fighting - SpecificationInyamul HasanBelum ada peringkat

- Course Outline For Reinforced Concrete IDokumen2 halamanCourse Outline For Reinforced Concrete ITefera TemesgenBelum ada peringkat

- Bulk Metal Forming, Sheet Metal FormingDokumen6 halamanBulk Metal Forming, Sheet Metal FormingAbdulfattah TawfiqBelum ada peringkat

- WS Grade 10 IG Chemistry 23-24 - Rate of ReactionDokumen6 halamanWS Grade 10 IG Chemistry 23-24 - Rate of ReactionSiyaBelum ada peringkat

- ME6302-Manufacturing Technology-I PDFDokumen10 halamanME6302-Manufacturing Technology-I PDFpraveen mithunBelum ada peringkat

- What Is SteelDokumen4 halamanWhat Is SteelViswatej ChoudaryBelum ada peringkat

- Wall eDokumen21 halamanWall eKetty Chavez ValdezBelum ada peringkat

- Evaluación Hidroquímica Preliminar de Reservorios de Agua para Consumo Humano Próximos A Actividades Mineras en La Microcuenca Hampaturi en La Paz, BoliviaDokumen12 halamanEvaluación Hidroquímica Preliminar de Reservorios de Agua para Consumo Humano Próximos A Actividades Mineras en La Microcuenca Hampaturi en La Paz, BoliviaBolivian Journal of ChemistryBelum ada peringkat

- Witsco Mock Examination: Integrated Science Objective QuestionsDokumen5 halamanWitsco Mock Examination: Integrated Science Objective Questionsedward nodzoBelum ada peringkat

- Preparation of Substrates and Soundproofing Systems To Combat Noise Caused by Footsteps Before Installing Ceramic Stone Resilient and Wooden FlooringDokumen72 halamanPreparation of Substrates and Soundproofing Systems To Combat Noise Caused by Footsteps Before Installing Ceramic Stone Resilient and Wooden FlooringSpyros IliakisBelum ada peringkat

- Alkane, Alkenes, AlkynesDokumen9 halamanAlkane, Alkenes, AlkynesMark AquinoBelum ada peringkat

- Silty Soil Stabilization Using Bituminous Emulsion - SabbaniVenkatesh-52Dokumen8 halamanSilty Soil Stabilization Using Bituminous Emulsion - SabbaniVenkatesh-5201 - HUTOMO KASPAR KURNIAWANBelum ada peringkat

- General Chemistry Lab Manual With DEMO DATADokumen42 halamanGeneral Chemistry Lab Manual With DEMO DATAshihab shoronBelum ada peringkat

- Contoh Laporan No 5 Tahun 2014 (Lampiran XLVII)Dokumen3 halamanContoh Laporan No 5 Tahun 2014 (Lampiran XLVII)muhammad sahabBelum ada peringkat

- E3 Group Interior and Exterior ProductsDokumen12 halamanE3 Group Interior and Exterior ProductsE3 PanelsBelum ada peringkat

- Guidelinesfor Fabricating&Processing Plate SteelDokumen97 halamanGuidelinesfor Fabricating&Processing Plate SteelFIM SA100% (1)

- Maintenance HubDokumen30 halamanMaintenance HubAdel KhalilBelum ada peringkat

- CFT - Unit V - Chemicals and AuxiliariesDokumen19 halamanCFT - Unit V - Chemicals and AuxiliariesBalaji SureshBelum ada peringkat

- Ahmad Hamidd IzomerizationDokumen6 halamanAhmad Hamidd Izomerizationاحمد حمید کارسول عزیزBelum ada peringkat

- B403-12 Standard Specification For Magnesium-Alloy Investment CastingsDokumen4 halamanB403-12 Standard Specification For Magnesium-Alloy Investment CastingsmithileshBelum ada peringkat

- Argus Metals International (2019-01-30) PDFDokumen20 halamanArgus Metals International (2019-01-30) PDFahmed awadBelum ada peringkat

- Creusabro MDokumen4 halamanCreusabro MhealgoseBelum ada peringkat

- BOQ-karwan Sport MechanicalDokumen11 halamanBOQ-karwan Sport Mechanicaldarun hussinBelum ada peringkat

- FR4Dokumen2 halamanFR4Luis MárquezBelum ada peringkat

- Railway Hardware ListDokumen80 halamanRailway Hardware ListOmkarBelum ada peringkat

- 1 s2.0 S2090447924000479 MainDokumen15 halaman1 s2.0 S2090447924000479 Main307259552Belum ada peringkat

- Technical Data Sheet Armoslip CPDokumen2 halamanTechnical Data Sheet Armoslip CP8cs5829x8sBelum ada peringkat

- Information Booklet Elements Compounds and MixturesDokumen40 halamanInformation Booklet Elements Compounds and MixturesnowhinesonchemistryBelum ada peringkat

- Anamet CatalogDokumen69 halamanAnamet CatalogMario Landeta PérezBelum ada peringkat

- Hkdse Chemistry - A Modern View (Chemistry and Combined Science)Dokumen104 halamanHkdse Chemistry - A Modern View (Chemistry and Combined Science)梁儀50% (2)