Model rs-36

Diunggah oleh

pwmvsiJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Model rs-36

Diunggah oleh

pwmvsiHak Cipta:

Format Tersedia

MODELING C&NWs LONE RS36 IN HO SCALE

By Dennis Eggert

All photos by the author

The Prototype:

Prototype photo: Mankato, MN May 1976

In 1962, the C&NW sent the remains of wreck damaged RS3 #1553 back to Alco. The replacement for

1553 rolled out of Alcos Schenectady, NY plant in August of 1962 in the form of an RS36 numbered

904. The RS36 was Alcos state of the art, medium horsepower 4-axel locomotive at that time. It was

powered with an 1800 horsepower, 4-stroke, 12-cylinder turbocharged engine and featured

transistorized controls. In 1966, the 904 was renumbered to 405. By the late 1960s, all of the Alco

road switchers, including 405, were assigned to Huron, South Dakota and worked on the famous Alco

Line between Winona, MN and Huron, SD. In 1981, the 405 was transferred to Green Bay, Wisconsin

and worked switching assignments in upper Michigan. In 1982, the 405 was renumbered again to 4259.

After 24 years of service, the 4259 was retired in 1986. The 904/405/4259 was the only RS36 on the

C&NWs all-time diesel roster. The C&NW purchased ten former Conrail (PC/NYC) RS32s (road

numbers 4240 to 4249) in 1979, which were very similar externally to an RS36.

The Model:

The HO scale 405 began life as an Atlas RS11 painted in Norfolk and Western dark blue with a high

short hood. There was no mass-produced model available that had the long notched low nose and wide

windshield required for a low nose RS36. The nose was constructed using information in the article

titled A low nose for an Atlas RS11 in the J uly 1986 issue of Railroad Model Craftsman. Scale

drawings of an RS36 were used from the August 1988 issue of Mainline Modeler. To start the kit

bashing process, the model was completely disassembled and the shell was stripped using Chameleon

paint stripper.

Low nose:

Prototype photo:

Waseca, MN J uly 1975

The unique low nose was built first, since

it was the most challenging part of the

model. The low nose notches have the

same angle as the high nose, but are not as

deep and lack number boards. The high

nose from the Atlas RS11 was first cut

into slices. The top slice was moved

foreword to make the notches shallower.

Moving the top section foreword created a

rectangular hole in the front of the top

section, which was filled with scrap

material. There was also a filler piece

added at the rear of the top slice. The

photo shows the top slice with the filler

pieces added.

After the nose slices were cut, they were

sanded smooth and squared-up using a flat

sanding block with fine sand paper. The

slices were then cemented together, and

the assembly was sanded.

Cab:

The front cab wall was made from a piece of

scrap Atlas shell material. The frame

around the windshield was made from a

single stick of styrene .010 x .010 stock.

After applying liquid plastic cement, the

corners were bent to shape. The number

board/headlight housing was scratch built

using styrene. To add the roof over the

number board housing, a new cab roof was

made by laminating a .010 styrene sheet

over the existing roof. Notches were routed

into the sides of the cab just above the side

windows to allow the .010 sheet to blend

into the sides.

Long Hood:

The sub-assembly with the most amount

of labor was the long hood. The overall

dimensions of the RS11 hood were

correct, but several large cast-on details

existed that were not correct for an RS36.

The most significant problem was the

short access doors on the sides. Other

incorrect features were the large

intercoolers, dynamic brake apparatus on

the roof and boxes in the upper right

corner of the radiator intakes. If I were to

remove all of the incorrect features, not

much would be left. This is why I made the decision to essentially scratch-build the long hood.

This photo shows the long hood in the

early stage of construction. The assembly

was made using a pine block jig, which

held the pieces in alignment.

The car body filters, exhaust stack,

crankcase breather, and radiator section

were cut away from the Atlas long hood.

The radiator intakes were opened up and

rebuilt using styrene strips in an effort to

remove the rectangular boxes in the upper

right corners, which were incorrect for the

405.

To easily locate the holes for the wire

grab-irons, new holes were marked and

drilled using the cast-on bolt heads for

center marks. After drilling, the cast-on

grab irons were removed. The headlight

casting was removed and replaced with

Detail Associates #1003.

There are no Cannon & Company parts available for Alcos, so scratch building was required for the

hood doors and hinges. To keep the doors all the same height, a .005 styrene strip was cut to the

vertical dimension of the doors. Then, the doors were cut individually from the strip and kept arranged

in the order they were cut. This way, any slight imperfections in the door cutting would cancel, as they

were cemented to the hood.

There are 96 hinges on the long hood made from .005 styrene. For each hinge, two rectangular pieces

were used, one on the door and one on the hood. The hinge knuckles were made from .010 x .010

square strip. For each set of three hinges in a vertical pattern, one piece of .010 x .010 was cemented

in place across all three hinges. When the cement was dry, the .010 x .010 between the hinges was

removed with a sharp knife. This kept the three pieces in alignment and eliminated the handling of very

tiny pieces. Door handles are made from .012 brass rod.

A Detail Associates #2703 photo-etched fan grille was

used. The diameter of the Atlas fan housing had a

slightly smaller diameter than the brass grille. To

increase the diameter of the fan housing, a strip of .010

styrene was wrapped around the outside.

Handrails:

Prototype photo:

Waseca, MN J uly 1975

The prototype handrail stanchions are made up of a round

vertical rod or tube, with a casting at the top, which joins it to

the horizontal railing.

The original Atlas handrails were not

used, and the large rectangular holes in

the walkway were plugged with

styrene and sanded smooth. There are

no handrail stanchions available for

this era of Alco road switchers, so

scratch-building was required to make

prototypically correct handrails. Brass

rods were first cut to rough lengths and

fastened to the walkway. A horizontal

rod was then soldered to the outside of

the vertical rods. Care was taken to

keep everything squared-up when

soldering.

After soldering, the vertical rods were

snipped-off flush with the top of the

horizontal rod. Each solder joint was

purposely left extra large and then

filed to the shape of the prototype

joint. The left joint in the photo has

not yet been shaped.

The finished handrail stanchions.

Fuel and Air Tanks:

The air tanks were scratch built

from styrene tubes. Sawing and

filing was required on the chassis

to properly locate the tanks. A

styrene filler was added to the

bottom of the chassis to allow the

fuel tank assembly to fit squarely

on the chassis.

The fuel tank was scratch built to

fit over the cast metal frame. To

help give the finished model a low

center of gravity, lead weights

were built into all of the available

spaces. The fuel tank assembly is

fastened to the chassis with two 2-

56 flat head machine screws.

Details West #166 fuel fillers were

used.

Chassis:

The Atlas RS11 used for the base model was one of the early versions produced in the early 1990s.

The chassis on the early Atlas RS11s had incorrect truck center dimensions. The RS11s made currently

by Atlas have the correct dimensions. Using the RS36 drawing from Mainline Modeler, the truck center

dimensions were corrected by cutting the bolsters from the chassis with a fine tooth razor saw. The

bolsters were then reattached in the correct locations with CA adhesive. A thin styrene spacer was glued

to the bottom of each bolster to make up for the saw cut.

Final Assembly:

These photos show the final assembly before painting with all detail parts added. Brass wire was used

to fabricate the grab irons and pin lifters. The footboards were made from brass bar stock and scrap

photo-etched roof walk material.

Painting:

The model was disassembled, and all sub assemblies were painted primer gray. The long hood and nose

were painted yellow. The yellow is a 50/50 mixture of Polyscale CNW yellow and EL yellow. The

yellow paint was left to dry for one week before the sub assemblies were masked and painted Polyscale

CNW green. The frame and trucks were painted black. Polyscale aluminum was used to trim the

window frames.

Weathering:

The model was first given a wash of thinned-down black paint with a brush. This fills in all of the

cracks around the doors and blackened the carbody filters. The radiator shutters were given a heavy

brush coat of grimy black. Next, the model was lightly sprayed with a mixture of grimy black and

railroad tie brown to simulate the many years of road dirt that was accumulated on the prototype. The

roof of the long hood was airbrushed with engine black, to simulate the exhaust soot on the prototype.

After the airbrush weathering, a pencil eraser was used to rub off some the weathering where human

contact tends to wipe off accumulated dirt on the prototype. The trucks and under frame were dusted

with a beige colored chalk to simulate sand dust. Couplers were airbrushed off the model with a mixture

of rust and railroad tie brown. The outsides of the coupler knuckles were polished with a sanding block.

The coupler trip pins were painted flat black.

DCC and Lighting:

The 405 is equipped with a Digitrax model DH163

decoder. The front and rear headlights, front

classification lights and rotary beacon were lighted

with Miniatronics 1.5-volt lamps. The dual beam

headlights are connected with the two lamps in a

series circuit with a single 8200-ohm current limiting

resistor. The Miniatronics lamps have an integral

lens, which focuses the light, similar to a prototype

headlamp. The tiny lamp lenses are made with a wide

tolerance, and some tend to direct the light beam in

random directions. When pairing up dual headlamps,

I typically use a Miniatronics 20-pack, and hand pick

two lamps with similar lens properties. The

classification lights are also in a series circuit, but

with a 1000-ohm current limiting resistor to give

them a more subdued lighting effect.

Materials Used:

Atlas RS11 Norfolk and Western, RTR

Details West #166 Fuel Filler

Details West #265, MU hoses 4-cluster

Details West #126 Western-Cullen Rotary Beacon

Details West #186 Nathan M3 Air Horn

Detail Associates #1003 Dual Pyle headlight

Detail Associates #3703 Alco photo-etched fan grille 57

Kadee #58 Scale Couplers

Overland Models #977 Winterization Cab Window 3-pane

Digitrax #DH163 6-function decoder

Miniatronics #18-001 Incandescent lamps, 1.5-volt, 15mA, 1.2mm Dia. (.050)

Send questions or comments to: dennis@yardoffice.com

Anda mungkin juga menyukai

- 2020-04-01 Australian Model Railway MagazineDokumen72 halaman2020-04-01 Australian Model Railway Magazine洪冠Belum ada peringkat

- The Norris Locomotive Works: A Forgotten Industrial Giant of PhiladelphiaDokumen4 halamanThe Norris Locomotive Works: A Forgotten Industrial Giant of PhiladelphiaHarry KyriakodisBelum ada peringkat

- Developing A Scenery StrategyDokumen64 halamanDeveloping A Scenery StrategyMagnus ChristersonBelum ada peringkat

- Installing DCC DecodersDokumen20 halamanInstalling DCC Decodersauberry53500% (1)

- Getting Starting With Model Trains PDFDokumen24 halamanGetting Starting With Model Trains PDFJoseMolina10100% (2)

- WGH Fullbooklet 2014Dokumen24 halamanWGH Fullbooklet 2014l1nt4n9luku100% (2)

- Australian Model Railway December 2015 PDFDokumen80 halamanAustralian Model Railway December 2015 PDFSlobodan DugandzijaBelum ada peringkat

- MRH11 05 May2011 PDFDokumen115 halamanMRH11 05 May2011 PDFDarius GussoBelum ada peringkat

- 618265TwoGreatLayouts PDFDokumen14 halaman618265TwoGreatLayouts PDFMichael BusseBelum ada peringkat

- Operations ClinicDokumen16 halamanOperations Clinicaromero888100% (3)

- Garden Rail - N°292 - 2018-12Dokumen64 halamanGarden Rail - N°292 - 2018-12Valery GagichBelum ada peringkat

- B&O Railroad North Vernon ArticleDokumen6 halamanB&O Railroad North Vernon ArticlewicksjrBelum ada peringkat

- Nskalemagazineyune 2009Dokumen64 halamanNskalemagazineyune 2009Nenad Petrovic100% (2)

- Standard EditionDokumen120 halamanStandard Editiondonzi7218100% (1)

- Himno Del SevillaDokumen108 halamanHimno Del SevillaValentin Garcia Morillas100% (1)

- Model Railroad Hobbyist 15-03-Mar2015Dokumen311 halamanModel Railroad Hobbyist 15-03-Mar2015Justin Gilmore100% (2)

- 87.MRH17 05 May2017 LEDokumen134 halaman87.MRH17 05 May2017 LEkarkinoli4073Belum ada peringkat

- Price: Forever FreeDokumen143 halamanPrice: Forever FreeolgumbyBelum ada peringkat

- 52MRH14 06 Jun2014 LDokumen135 halaman52MRH14 06 Jun2014 Latsfr100% (1)

- Model Railroader 2014-09Dokumen88 halamanModel Railroader 2014-09Darcco Fakafel100% (10)

- Lionel Catalogue 2002Dokumen8 halamanLionel Catalogue 2002Monica Monica MonicaBelum ada peringkat

- How To Model Today's Railroads Special2016Dokumen84 halamanHow To Model Today's Railroads Special2016pe100% (1)

- The Road To ParadiseDokumen40 halamanThe Road To ParadiseBob Diamond100% (1)

- Locomotive - August 2019Dokumen102 halamanLocomotive - August 2019rona41br100% (1)

- Australian Model Railway Magazine - December 2019 PDFDokumen72 halamanAustralian Model Railway Magazine - December 2019 PDFPaco LopezBelum ada peringkat

- PHM - Clyde Engineering Photographic Collection Railway and Rolling StockDokumen9 halamanPHM - Clyde Engineering Photographic Collection Railway and Rolling Stock4493464100% (1)

- Red Oak Layout: MagazineDokumen33 halamanRed Oak Layout: MagazineJackSiedschlag100% (2)

- Realistic Railroads You Can Model - Winter 2020Dokumen86 halamanRealistic Railroads You Can Model - Winter 2020Adam C Bmk100% (2)

- 03 Model Airplane News - SuperunitedkingdomDokumen100 halaman03 Model Airplane News - SuperunitedkingdomvalivilcuBelum ada peringkat

- Great Model Railroads 2008Dokumen124 halamanGreat Model Railroads 2008Ricardo KutzBelum ada peringkat

- The Salt Lake RouteDokumen31 halamanThe Salt Lake RouteDick BosBelum ada peringkat

- Australian Model Railway Magazine - February 2020 PDFDokumen72 halamanAustralian Model Railway Magazine - February 2020 PDFPaco Lopez100% (1)

- Classic Trains May 2021Dokumen102 halamanClassic Trains May 2021mur100% (2)

- Room Size Model RailroadsDokumen14 halamanRoom Size Model Railroadscbento86% (7)

- Pennsylvania Flyer Ready-To-Run Train Set Owner's ManualDokumen20 halamanPennsylvania Flyer Ready-To-Run Train Set Owner's ManualFrank SchipaniBelum ada peringkat

- Room Size Model RairoadDokumen14 halamanRoom Size Model RairoadJulio0% (1)

- MR Ejemplar de Muestra PDFDokumen50 halamanMR Ejemplar de Muestra PDFchito23j100% (8)

- Design ConceptsforyournextlayoutDokumen15 halamanDesign ConceptsforyournextlayoutMike50% (2)

- Chapter 5 - Wiring PointsDokumen15 halamanChapter 5 - Wiring PointsAnthony FarrellBelum ada peringkat

- Tracklaying TipsDokumen20 halamanTracklaying TipsGoran Timotijevic100% (7)

- HK 450Dokumen31 halamanHK 450Julian PascuBelum ada peringkat

- Freight Yard Design PDFDokumen14 halamanFreight Yard Design PDFRakesh Kapoor100% (2)

- Tales of Battle CreekDokumen177 halamanTales of Battle CreekTaylor A. Warsop100% (1)

- Australian Model Railway - February 2016Dokumen80 halamanAustralian Model Railway - February 2016Meep100% (5)

- How To Run A Railroad. Everything You Need To Know About Model TrainsDokumen136 halamanHow To Run A Railroad. Everything You Need To Know About Model Trainsbuchkasper100% (3)

- 5 Easy Track PlansDokumen12 halaman5 Easy Track PlansGlennSheils100% (7)

- D&H World's Fair CarsDokumen4 halamanD&H World's Fair Carsstaustell92Belum ada peringkat

- Eclipson MXS-R-Light 3D Printed Aerobatic ModelDokumen6 halamanEclipson MXS-R-Light 3D Printed Aerobatic ModelJesùs AlfaroBelum ada peringkat

- Model Railroader Scenery Step by StepDokumen84 halamanModel Railroader Scenery Step by StepNickiedeposieBelum ada peringkat

- Getting Started in Proto 87Dokumen48 halamanGetting Started in Proto 87peBelum ada peringkat

- MRH October 2021Dokumen164 halamanMRH October 2021ckqy7bf6bcBelum ada peringkat

- Scratchbuilding Concrete Bridge PiersDokumen9 halamanScratchbuilding Concrete Bridge PiersrwaidaabbasBelum ada peringkat

- Building SceneryDokumen23 halamanBuilding SceneryAntal100% (27)

- DCC BasicsDokumen194 halamanDCC BasicsBóza GyörgyBelum ada peringkat

- Small Spaces: Great Track Plans ForDokumen12 halamanSmall Spaces: Great Track Plans ForVitor Grassi89% (9)

- American Steam Locomotives: Design and Development, 1880–1960Dari EverandAmerican Steam Locomotives: Design and Development, 1880–1960Belum ada peringkat

- The Vale of Rheidol Railway: The Story of a Narrow Gauge SurvivorDari EverandThe Vale of Rheidol Railway: The Story of a Narrow Gauge SurvivorPenilaian: 5 dari 5 bintang5/5 (1)

- Nema Abcde Torque Curves PDFDokumen2 halamanNema Abcde Torque Curves PDFvtadlimbekarBelum ada peringkat

- Bob Harpes Sd45 Project Complete StepsDokumen16 halamanBob Harpes Sd45 Project Complete StepspwmvsiBelum ada peringkat

- Simulation and Speed Control of Induction Motor DrivesDokumen76 halamanSimulation and Speed Control of Induction Motor DrivesNWALLL67% (3)

- SD45 3107 Bill of MaterialsDokumen2 halamanSD45 3107 Bill of MaterialspwmvsiBelum ada peringkat

- Synchronous GeneratorsDokumen50 halamanSynchronous GeneratorsRajAnandBelum ada peringkat

- Southern Railway Historical Association Presents - Bob Harpe S Athearn GP-38-2 Modifications Online ClinicDokumen26 halamanSouthern Railway Historical Association Presents - Bob Harpe S Athearn GP-38-2 Modifications Online ClinicpwmvsiBelum ada peringkat

- IEEE STD 835-1994Dokumen66 halamanIEEE STD 835-1994Eduardo Quintana83% (6)

- Sheet 1 Rev 01Dokumen1 halamanSheet 1 Rev 01pwmvsiBelum ada peringkat

- TY341485 - Tote Replacement Gerators - Tender - Rev 01 PDFDokumen10 halamanTY341485 - Tote Replacement Gerators - Tender - Rev 01 PDFpwmvsiBelum ada peringkat

- This Drawing Is For Tender Purposes Only. Dimensions and Data Are Subject To ConfirmationDokumen1 halamanThis Drawing Is For Tender Purposes Only. Dimensions and Data Are Subject To ConfirmationpwmvsiBelum ada peringkat

- Sheet 1 Rev 01Dokumen1 halamanSheet 1 Rev 01pwmvsiBelum ada peringkat

- Rotor Particulars D275R14 Generator: Drawn Rev Ecn/Description Approved 00 KMC Original Issue CLDokumen1 halamanRotor Particulars D275R14 Generator: Drawn Rev Ecn/Description Approved 00 KMC Original Issue CLpwmvsiBelum ada peringkat

- This Drawing Is For Tender Purposes Only. Dimensions and Data Are Subject To ConfirmationDokumen1 halamanThis Drawing Is For Tender Purposes Only. Dimensions and Data Are Subject To ConfirmationpwmvsiBelum ada peringkat

- USCG Letter of Equivalency For IEC and NEC505 Electrical Equipment For The LNG CodeDokumen14 halamanUSCG Letter of Equivalency For IEC and NEC505 Electrical Equipment For The LNG CodepwmvsiBelum ada peringkat

- Oem Reference Guide PDFDokumen129 halamanOem Reference Guide PDFpwmvsiBelum ada peringkat

- Estimating Sequence Voltages From DataDokumen12 halamanEstimating Sequence Voltages From DatapwmvsiBelum ada peringkat

- 3000 Grounding EN PDFDokumen32 halaman3000 Grounding EN PDFpwmvsiBelum ada peringkat

- Isometer®: Iso685-D iso685W-D Iso685-S iso685W-SDokumen62 halamanIsometer®: Iso685-D iso685W-D Iso685-S iso685W-SpwmvsiBelum ada peringkat

- PACSystems RX3i Ethernet Network Interface Unit User's Manual, GFK-2439DGFK2439DDokumen357 halamanPACSystems RX3i Ethernet Network Interface Unit User's Manual, GFK-2439DGFK2439DpwmvsiBelum ada peringkat

- Medium Voltage Transformers: Specification GuideDokumen39 halamanMedium Voltage Transformers: Specification GuideRaaj Eng100% (1)

- Isometer®: Iso685-D iso685W-D Iso685-S iso685W-SDokumen62 halamanIsometer®: Iso685-D iso685W-D Iso685-S iso685W-SpwmvsiBelum ada peringkat

- Oem Reference Guide PDFDokumen129 halamanOem Reference Guide PDFpwmvsiBelum ada peringkat

- 3000 Grounding EN PDFDokumen32 halaman3000 Grounding EN PDFpwmvsiBelum ada peringkat

- GFK-2224U PACS Ethernet Manual PDFDokumen311 halamanGFK-2224U PACS Ethernet Manual PDFpwmvsiBelum ada peringkat

- K-Factor and TransformersDokumen6 halamanK-Factor and TransformersasssasasBelum ada peringkat

- Addendum 3 LT NI Rev1 PDFDokumen26 halamanAddendum 3 LT NI Rev1 PDFpwmvsiBelum ada peringkat

- MV Design Guide - Circuit Breaker SpecificationDokumen10 halamanMV Design Guide - Circuit Breaker Specificationhadi saadBelum ada peringkat

- Ada279952 PDFDokumen185 halamanAda279952 PDFJuan Sebastian DiazBelum ada peringkat

- Addendum 3 LT NI Rev1 PDFDokumen26 halamanAddendum 3 LT NI Rev1 PDFpwmvsiBelum ada peringkat

- AMOS Bs 8.6 Manual Rev2Dokumen573 halamanAMOS Bs 8.6 Manual Rev2pwmvsi100% (3)

- Early Childhood Education and CareDokumen53 halamanEarly Childhood Education and CareBianca ALbuquerqueBelum ada peringkat

- Case Study On "Unilever in Brazil-Marketing Strategies For Low Income Consumers "Dokumen15 halamanCase Study On "Unilever in Brazil-Marketing Strategies For Low Income Consumers "Deepak BajpaiBelum ada peringkat

- MODULE 8. Ceiling WorksDokumen2 halamanMODULE 8. Ceiling WorksAj MacalinaoBelum ada peringkat

- CV - Mohsin FormatDokumen2 halamanCV - Mohsin FormatMuhammad Junaid IqbalBelum ada peringkat

- 2019 Auto Truck Key Blank Reference PDFDokumen188 halaman2019 Auto Truck Key Blank Reference PDFAlbert RodaBelum ada peringkat

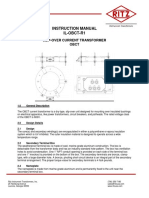

- Instruction Manual Il-Obct-R1: Slip-Over Current Transformer ObctDokumen2 halamanInstruction Manual Il-Obct-R1: Slip-Over Current Transformer Obctبوحميدة كمالBelum ada peringkat

- Guide For Sustainable Design of NEOM CityDokumen76 halamanGuide For Sustainable Design of NEOM Cityxiaowei tuBelum ada peringkat

- ShotcreteDokumen7 halamanShotcreteafuhcivBelum ada peringkat

- Encephalopathies: Zerlyn T. Leonardo, M.D., FPCP, FPNADokumen50 halamanEncephalopathies: Zerlyn T. Leonardo, M.D., FPCP, FPNAJanellee DarucaBelum ada peringkat

- Operaciones UnitariasDokumen91 halamanOperaciones UnitariasAlejandro ReyesBelum ada peringkat

- Prevention of Power Theft Using Concept of Multifunction Meter and PLCDokumen6 halamanPrevention of Power Theft Using Concept of Multifunction Meter and PLCMuhammad FarhanBelum ada peringkat

- Vishakha BroadbandDokumen6 halamanVishakha Broadbandvishakha sonawaneBelum ada peringkat

- OSX ExpoDokumen13 halamanOSX ExpoxolilevBelum ada peringkat

- Chapter5A TorqueDokumen32 halamanChapter5A TorqueShuq Faqat al-FansuriBelum ada peringkat

- Saeed Sentence Relation and Truth (Summary)Dokumen11 halamanSaeed Sentence Relation and Truth (Summary)Mohammad Hassan100% (1)

- Porsche Dealer Application DataDokumen3 halamanPorsche Dealer Application DataEdwin UcheBelum ada peringkat

- Business Mathematics (Matrix)Dokumen3 halamanBusiness Mathematics (Matrix)MD HABIBBelum ada peringkat

- ESG Conundrum PDFDokumen30 halamanESG Conundrum PDFVijay Kumar SwamiBelum ada peringkat

- 555 TimerDokumen25 halaman555 TimerDr-Muhammad Aqeel AslamBelum ada peringkat

- Procedure Manual - IMS: Locomotive Workshop, Northern Railway, LucknowDokumen8 halamanProcedure Manual - IMS: Locomotive Workshop, Northern Railway, LucknowMarjorie Dulay Dumol80% (5)

- Curry PowderDokumen8 halamanCurry PowderMahendar Vanam100% (1)

- Second Quarter Lesson 4Dokumen7 halamanSecond Quarter Lesson 4Jomarie PauleBelum ada peringkat

- Nurses Guide To Family Assessment and InterventionDokumen9 halamanNurses Guide To Family Assessment and InterventionKaye CorBelum ada peringkat

- Splices LAS 3rd Quarter Week 1Dokumen6 halamanSplices LAS 3rd Quarter Week 1Winnielyn Quarteros BarreraBelum ada peringkat

- Capacitor Trip Device CTD-4Dokumen2 halamanCapacitor Trip Device CTD-4DAS1300Belum ada peringkat

- Nursing Care Plan For AIDS HIVDokumen3 halamanNursing Care Plan For AIDS HIVFARAH MAE MEDINA100% (2)

- The Frozen Path To EasthavenDokumen48 halamanThe Frozen Path To EasthavenDarwin Diaz HidalgoBelum ada peringkat

- Enterprise GRC Solutions 2012 Executive SummaryDokumen5 halamanEnterprise GRC Solutions 2012 Executive SummarySanath FernandoBelum ada peringkat

- The Hot Aishwarya Rai Wedding and Her Life.20130105.040216Dokumen2 halamanThe Hot Aishwarya Rai Wedding and Her Life.20130105.040216anon_501746111100% (1)

- Risk Response PlanDokumen8 halamanRisk Response Planapi-639207174Belum ada peringkat