Xas 186 126 106 116 136 156 146

Diunggah oleh

EdisonNainggolan0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

648 tayangan6 halamanAir Compressor Atlas Copco

Judul Asli

xas 186 126 106 116 136 156 146

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniAir Compressor Atlas Copco

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

648 tayangan6 halamanXas 186 126 106 116 136 156 146

Diunggah oleh

EdisonNainggolanAir Compressor Atlas Copco

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 6

Atlas Copco Portable air compressors

XA(S)136, -186, XAHS106, -146, -186, XATS116, -156, XAVS136 Dd

101 -185 l/s (6.1 -11.1 m

3

/min, 215 - 392 cu.ft/min) 7 - 14 bar (102 - 204 psig)

Series 6

Our commitment to your compressed air needs

The Series 6 of oil injected, rotary screw compres-

sors from Atlas Copco has built up an enviable rep-

utation for reliability and efficiency since its

introduction to the market a few years ago. Our

constant search for innovation and our commit-

ment to your business has resulted in another

extension to this range of single axle machines.

XA(S)146 to -186 Dd have been specially designed

for heavy duty environments such as the renova-

tion industry (sandblasting) and quarries. They can

assist in installing fibre optic cables, or be com-

bined with combinations of pneumatic tools such

as rock drills, rammers, to name a few. High alti-

tudes and extremely high and low ambient tem-

peratures are not a problem. Four pressure

variants make these units fit for almost any applica-

tion. And one type can also be foreseen with an

optional generator that provides simultaneous

power for fusion welding, light poles, heating of

cabins and electric hand tools.

Designed to your individual needs

Atlas Copco listened to the sales force, and more

importantly to you. We understood your

requirements and reacted accordingly by designing

exactly the air compressor you want: ensuring a

long lifetime, low operating cost and high resale

value.

We matched a highly efficient new screw element

with rugged, turbocharged, watercooled and oil-

cooled 4-cylinder Deutz diesel engines and built

them into a sturdy canopy, which can withstand

rough treatment on all terrains. The modular con-

cept of these Series 6 compressors allows you to

add the options you need: for example, freezing of

pneumatic tools is a problem of the past if you

choose a built in aftercooler with reheater.

We are committed to the environment

All compressors meet current European and US

legal requirements for the working environment

and regulations for safety, exhaust emissions, and

noise. The new 2011, 2012 and 1013 Deutz engines

fully comply with COM II and EPA II exhaust

emission regulations.

Atlas Copco has fully implemented its

Environmental Management System into the

design and manufacture of these machines, fulfill-

ing the requirements of the ISO 14001 standard.

ISO 9001: our quality assurance standard

Atlas Copco Series 6 compressors are manufac-

tured and tested to perform in the most demanding

conditions. We follow the stringent standards of

the ISO 9001 regulations to assure that every unit

meets your quality expectations.

Series 6

Innovative design ensures your peace of mind

Routine maintenance takes less time with all replace-

ment parts within easy reach of your mechanic.The

undercarriage can easily be removed to mount the unit

permanently on a truck.

Ease of operation: controls and instruments are

where they should be close to the outlet valves

on a single panel for monitoring at a glance.

A plastic cover provides safety and protection.

The compressor only delivers the

amount of air you need and at a stable

working pressure. Economical power

consumption is assured by the fully

automatic, stepless speed regulator that

adapts engine speed to air demand.

Hence, the high capacity fuel tank car-

ries you through a full working shift.

A highly efficient fuel filtration system

is one of the assets of the Deutz engines.

The engine and compressor

are heavily protected against

dust and dirt particles in the

intake air by a highly effi-

cient filtration system con-

sisting of two-stage air

intake filters. A service indi-

cator warns you when main-

tenance is due.

A water level sensor is

mounted as standard to pro-

tect the engine against too

low a cooling water level.

(Not applicable to oilcooled

2011 engines.)

The sturdy canopy doors can easily be

opened with the assistance of gas springs.

Series 6 compressors are highly sound

dampened to allow you to operate at

night, in residential areas, near schools

and hospitals.

For cost effective mainte-

nance Atlas Copco has sets

of genuine parts available.

Your first Service Pak is

delivered with the unit.

As standard: 1x1

1

2 valve an 3x

3

4 valves

Pneumatic equipment such as hoses and

breakers can easily be locked away inside

the canopy if no generator is installed.

Series 6

A wide choice of options

Vessel type EC

Asme

Towing bar Adjustable with brakes (A1)

Fixed with brakes (A2) (not on XAHS 186)

Fixed without brakes (not on XAHS 186)

Without towing bar Support (without undercarriage)

Towing eyes Atlas Copco

DIN

Ball

Italian

NATO

Towbar support Leg

Jockey wheel

Wheel chocks

Road signalisation (B)

Air quality equipment Aftercooler + water separator

Aftercooler + water separator + fine filter

Aftercooler + water separator + fine filter + reheater (C)

Aftercooler + water separator + reheater

Lubricator on 7 bar units

Generator (D) 12 kVA 230/400 V 50 Hz (Only on XA/S 136)

Additional pressure gauge (standard on XAHS 186)

Inlet filter safety cartridge (standard on XAHS 186)

Refinery equipment Spark arrestor

Inlet shut down valve

Cold start -20C (-4F)

Customer colour Single

Double

Triple

A. Series 6 units meet your local safety regulations and are available

with overrun and parking brakes.

B. Reflectors and lights for safety on the road.

C. Quality air through the aftercooler, reheater and fine filters.

D. Simultaneous electric and pneumatic power.

A1

A2

B

C

D

Principal data

Compressor

Type XAS XA(S) XA(S) XA(S) XATS XATS XAHS XAHS XAHS XAVS

126 altitude 136 136 DdG 186 116 156 106 146 186 136

Normal effective working pressure bar(e) 7 7 7 7 10.3 10.3 12 12 12 14

psig 102 102 102 102 150 150 175 175 175 204

Actual free air delivery guaranteed l/s 128 135 103 185 113 166 101 141 175 133

according to ISO 1217 m

3

/min 7.7 8.1 6.2 11.1 6.8 10 6.1 8.5 10.5 8

ed. 3 1996 annex D cu.ft/min 275 290 220 392 240 352 215 299 371 282

Sound power acc. 2000/14/EC dB(A) 101 101 101 101 101 100 101 100 101 100

Sound pressure level dB(A) 73 73 73 73 73 72 73 72 73 72

acc. ISO 2151 at 7 m

Oil capacity l 14.5 14.5 14.5 24 14.5 24 14.5 24 24 24

US gal 3.8 3.8 3.8 6.3 3.8 6.3 3.8 6.3 6.3 6.3

Max. ambient temperature C 50 50 50 50 50 50 50 50 45 50

F 122 122 122 122 122 122 122 122 113 122

Generator 230/400V-50Hz

Electric power* 1 phase kW/kVA - - 9.6/12 - - - - - - -

3 phase kW/kVA - - 9.6/12 - - - - - - -

Sockets Schuko 1 phase A - - 1x16 - - - - - - -

CEE 3 phase A - - 2x16 - - - - - - -

* complying with ISO 8528/8 DIN 6280/10

Engine

Deutz BF4M BF4M BF4M BF4M BF4M BF4M BF4M BF4M BF4M BF4M

2011 2011 2011 2012C 2011 2012C 2011 2012C 1013EC 2012C

Number of cylinders 4 4 4 4 4 4 4 4 4 4

Full load speed r/min 2300 2300 2300 2400 2300 2400 2300 2400 2300 2400

Output at rated speed kW 56.5 56.5 56.5 90 56.5 90 56.5 90 107 90

Capacity of fuel tank l 175 175 175 175 175 175 175 175 175 175

US gal 46.23 46.23 46.23 46.23 46.23 46.23 46.23 46.23 46.23 46.23

Weight Without brakes With brakes

(ready to operate/full fuel tank**) Fixed towbar Fixed towbar Adjustable towbar

XAS126 altitude, XA(S)136, kg 1515 1545 1585

XATS116, XAHS106 lbs 3340 3406 3494

XA(S)136 DdG kg 1585 1615 1655

lbs 3494 3560 3649

XA(S)186, XATS156, kg 1705 1800 1825

XAHS146, XAVS136 lbs 3759 3969 4024

XAHS186 kg N.A. N.A. 1883

lbs N.A. N.A. 4152

Outlets: 1 x 1

1

2

and 3 x

3

** with generator + 70 kg/154 lbs

2

9

3

5

0

5

6

5

3

7

-

S

u

b

j

e

c

t

t

o

m

o

d

i

f

i

c

a

t

i

o

n

w

i

t

h

o

u

t

p

r

i

o

r

n

o

t

i

c

e

.

P

r

i

n

t

e

d

i

n

B

e

l

g

i

u

m

.

C

o

p

y

r

i

g

h

t

2

0

0

3

,

A

t

l

a

s

C

o

p

c

o

A

i

r

p

o

w

e

r

n

.

v

.

,

W

i

l

r

i

j

k

,

B

e

l

g

i

u

m

.

Adjustable towbar

Fixed towbar

1

6

6

1

m

m

6

5

.

4

1

6

6

1

m

m

6

5

.

4

X

A

H

S

1

8

6

:

1

7

2

1

m

m

-

6

7

.

8

1701 15 mm

67 0.6

4356 mm 172

3941 mm 155

1701 15 mm

67 0.6

Visit our website: www.atlascopco.com

Never use compressed air as breathing air without prior

purification in accordance with local legislation and standards.

T

h

e

f

a

c

e

o

f

i

n

n

o

v

a

t

i

o

n

Unit dimensions

Anda mungkin juga menyukai

- "7" Series: Portable Concrete PumpsDokumen2 halaman"7" Series: Portable Concrete PumpsArsène TIA MAN100% (1)

- KaeserDokumen2 halamanKaeserMekhmanBelum ada peringkat

- Installation and Operation Manual for W60.000 Weight IndicatorDokumen44 halamanInstallation and Operation Manual for W60.000 Weight Indicatorsblnt2008100% (1)

- 6025e PDFDokumen43 halaman6025e PDFmuppetscrapBelum ada peringkat

- Atlas CopcoDokumen26 halamanAtlas Copcobenjamin100% (1)

- Clivet Carel PcoDokumen80 halamanClivet Carel PcoToni Dlabac100% (2)

- CAT079 SwitchDokumen232 halamanCAT079 SwitchDan688100% (1)

- Problems PDFDokumen246 halamanProblems PDFJasdeep singhBelum ada peringkat

- Atlas Copco XRVS 476Dokumen2 halamanAtlas Copco XRVS 476ibilge100% (1)

- IRN37K–45K–OF Compressor Parts ManualDokumen49 halamanIRN37K–45K–OF Compressor Parts Manualcherry vinesBelum ada peringkat

- CyberplusDokumen108 halamanCyberplusAlberto Sanchez100% (1)

- Portable Air Compressor FeaturesDokumen159 halamanPortable Air Compressor FeaturesahmedBelum ada peringkat

- Xas 47 Spec1 PDFDokumen4 halamanXas 47 Spec1 PDFacarisimovicBelum ada peringkat

- Membrane Generator PDFDokumen2 halamanMembrane Generator PDFSudar MyshaBelum ada peringkat

- Basic Repair Kit 2010 JanDokumen32 halamanBasic Repair Kit 2010 JanJhonathan CamposBelum ada peringkat

- PCT Group LTD: Loadwise Model 500Dokumen2 halamanPCT Group LTD: Loadwise Model 500John de BellBelum ada peringkat

- Atlas Copco Rental: 100% Oll-Free Air Compressor Diesel DrivenDokumen1 halamanAtlas Copco Rental: 100% Oll-Free Air Compressor Diesel DrivenpowermanagerBelum ada peringkat

- S 125Dokumen317 halamanS 125ronaldosilva2100% (1)

- Broom WadeDokumen20 halamanBroom WadeRamon SanhuezaBelum ada peringkat

- Datakom-Dkg 517Dokumen39 halamanDatakom-Dkg 517Hernan100% (2)

- WoodWard Egcp 2Dokumen4 halamanWoodWard Egcp 2Julian Pompy Buitrago Carrascal100% (1)

- Backhoe Loader: Stage II CompliantDokumen20 halamanBackhoe Loader: Stage II CompliantTamquadistu AlexBelum ada peringkat

- CAS45R (3) Compresor Hidroituango PDFDokumen106 halamanCAS45R (3) Compresor Hidroituango PDFluis eduardo betancur cano100% (1)

- Booster KaeserDokumen5 halamanBooster KaeserwgonzalesmBelum ada peringkat

- TR ProductDataSheetAllSeriesDokumen2 halamanTR ProductDataSheetAllSeriesAndry Setiawan100% (1)

- Lista Partes SH6 (08.2019)Dokumen64 halamanLista Partes SH6 (08.2019)Alfredo Simon Alcazar EscuderoBelum ada peringkat

- Sullair 900 1150 ControllerDokumen52 halamanSullair 900 1150 ControllerRich_78Belum ada peringkat

- Datasheet Deutz 1015 SeriesDokumen2 halamanDatasheet Deutz 1015 SeriesRizki Heru HermawanBelum ada peringkat

- 176 Series: Pump Mounted ActuatorDokumen2 halaman176 Series: Pump Mounted ActuatorKevin TtitoBelum ada peringkat

- Concrete Pump BSA 1002 - D BSA 1002 - E BSA 1003 - D: Data Sheet BP 2076-3 GBDokumen2 halamanConcrete Pump BSA 1002 - D BSA 1002 - E BSA 1003 - D: Data Sheet BP 2076-3 GBBourenaneBelum ada peringkat

- GARDNER DENVER - ELECTRAâ "SAVER - Compressor ManualDokumen58 halamanGARDNER DENVER - ELECTRAâ "SAVER - Compressor ManualJair Aguirre RamirezBelum ada peringkat

- Air Control 3 Dynamic: ManualDokumen53 halamanAir Control 3 Dynamic: ManualmadiBelum ada peringkat

- 2935 0751 31 - Large Compressors Product Grouping ChartDokumen1 halaman2935 0751 31 - Large Compressors Product Grouping ChartNicholas MurondaBelum ada peringkat

- Error Codes PDFDokumen10 halamanError Codes PDFRosemarie QuitorianoBelum ada peringkat

- QHP CatalogDokumen7 halamanQHP CatalogsanjeevvangeBelum ada peringkat

- PT650f e 2002Dokumen67 halamanPT650f e 2002lehahai100% (4)

- XATS 156 DD: Parts List For Portable CompressorsDokumen132 halamanXATS 156 DD: Parts List For Portable Compressorsdavid perezBelum ada peringkat

- 1070 WcatDokumen59 halaman1070 Wcatvictoros27Belum ada peringkat

- Electra-Saver Electra-Saver Ii Stationary Base-Mounted CompressorDokumen105 halamanElectra-Saver Electra-Saver Ii Stationary Base-Mounted CompressorJesus Enriquw Osuna RamosBelum ada peringkat

- Katalog Produk Service Air CompressorDokumen12 halamanKatalog Produk Service Air Compressorirvian_dinataBelum ada peringkat

- Manual OMIDokumen13 halamanManual OMIMatias CzarnotaBelum ada peringkat

- Legend: Parts List Operating and Service ManualDokumen39 halamanLegend: Parts List Operating and Service ManualEdwin RomaBelum ada peringkat

- Gen Auto XMDokumen47 halamanGen Auto XMCameron Ledingham100% (1)

- Powerview Model Pv780: Operations ManualDokumen20 halamanPowerview Model Pv780: Operations ManualЕлена АхметзяноваBelum ada peringkat

- SM 14Dokumen16 halamanSM 14Sanjay RajBelum ada peringkat

- CU12 B01-00-069 B en MANUALDokumen146 halamanCU12 B01-00-069 B en MANUALDoni KurniawanBelum ada peringkat

- Lube Oil Coller DesignDokumen8 halamanLube Oil Coller DesignBabar Manzoor GhauriBelum ada peringkat

- Emcp 4.1 Generator Set ControllerDokumen2 halamanEmcp 4.1 Generator Set ControllerGenivaldo Luiz de CarvalhoBelum ada peringkat

- AVR R449 RuDokumen9 halamanAVR R449 RuMinaSaeedBelum ada peringkat

- TCC750Dokumen24 halamanTCC750Pillai S KumarBelum ada peringkat

- Stetter Truck Mixer BrochureDokumen12 halamanStetter Truck Mixer Brochuregsm.nkl6049Belum ada peringkat

- 2954 6220 00 - XA (H) S 107-137 KD (G) - ENDokumen92 halaman2954 6220 00 - XA (H) S 107-137 KD (G) - ENKari Mohamed100% (1)

- Ed 01 (EN) Creemers KompressorDokumen31 halamanEd 01 (EN) Creemers KompressorsebastianBelum ada peringkat

- Mixer CifaDokumen12 halamanMixer Cifapablopela100% (1)

- GD Compressor ManualDokumen51 halamanGD Compressor Manualnzj564nxgfBelum ada peringkat

- Atlas Copco TEX Breakers BrochureDokumen16 halamanAtlas Copco TEX Breakers BrochureSumit BhasinBelum ada peringkat

- CE CF - English PDFDokumen8 halamanCE CF - English PDFm.b.homsy100% (1)

- F190ac 24 PDFDokumen100 halamanF190ac 24 PDFניקולאי איןBelum ada peringkat

- Goldoni MTC 06430722 V06 GBDokumen24 halamanGoldoni MTC 06430722 V06 GBBobNesh100% (1)

- Xaths 70 185Dokumen8 halamanXaths 70 185Cristian CevallosBelum ada peringkat

- 2935 0663 31 - tcm826-1620961Dokumen8 halaman2935 0663 31 - tcm826-1620961francoBelum ada peringkat

- Atlas Copco Portable Air Compressors: 43 To 69 L/s (70 To 147 Cu - Ft/min) - 7 Bar (102 Psig)Dokumen6 halamanAtlas Copco Portable Air Compressors: 43 To 69 L/s (70 To 147 Cu - Ft/min) - 7 Bar (102 Psig)Thierry Nolla100% (1)

- Compresores Atlas PDFDokumen5 halamanCompresores Atlas PDFZapata Emiliano50% (2)

- Section 1Dokumen38 halamanSection 1EdisonNainggolanBelum ada peringkat

- 2SC4429Dokumen5 halaman2SC4429Marilou Lopez ValenzuelaBelum ada peringkat

- XAS300 XATS 250 JDU7 - tcm795-2770635Dokumen2 halamanXAS300 XATS 250 JDU7 - tcm795-2770635EdisonNainggolanBelum ada peringkat

- 04 Heavy Equipment Inspection ChecklistDokumen2 halaman04 Heavy Equipment Inspection ChecklistEdisonNainggolanBelum ada peringkat

- Compressor Atlas CopcoDokumen6 halamanCompressor Atlas CopcoEdisonNainggolanBelum ada peringkat

- 2SC4429Dokumen5 halaman2SC4429Marilou Lopez ValenzuelaBelum ada peringkat

- 2SC4429Dokumen5 halaman2SC4429Marilou Lopez ValenzuelaBelum ada peringkat

- 2SC4429Dokumen5 halaman2SC4429Marilou Lopez ValenzuelaBelum ada peringkat

- File - YANMAR ItalyDokumen22 halamanFile - YANMAR ItalyEdisonNainggolanBelum ada peringkat

- Tape Mobil JVC.Dokumen16 halamanTape Mobil JVC.EdisonNainggolanBelum ada peringkat

- ENGENIRINGDokumen7 halamanENGENIRINGMostafa Mohamed Adel0% (1)

- Tape Mobil JVC.Dokumen16 halamanTape Mobil JVC.EdisonNainggolanBelum ada peringkat

- Red Highlighted Red Highlighted: Refer Calculation Given Below (Note-8)Dokumen5 halamanRed Highlighted Red Highlighted: Refer Calculation Given Below (Note-8)Víctor RojasBelum ada peringkat

- Screw Compressors: Models: VEDokumen42 halamanScrew Compressors: Models: VEVoştinar IoanBelum ada peringkat

- Hydraulic efficiency η h= Power output Energy available ∈the jet PDokumen3 halamanHydraulic efficiency η h= Power output Energy available ∈the jet Pkimlouie petateBelum ada peringkat

- Nasdaq Aaon 2002Dokumen26 halamanNasdaq Aaon 2002gaja babaBelum ada peringkat

- Iapa ManualDokumen275 halamanIapa ManualJabi JabzzBelum ada peringkat

- HMCDokumen8 halamanHMCmahmoud nafieBelum ada peringkat

- Contractor instrument pressure piping hook-up documentDokumen35 halamanContractor instrument pressure piping hook-up documentTahir100% (1)

- DTC P0135 Oxyge (A/F) Sensor Heater Circuit (Bank 1 Sensor 1)Dokumen3 halamanDTC P0135 Oxyge (A/F) Sensor Heater Circuit (Bank 1 Sensor 1)Erln LimaBelum ada peringkat

- Elution and Carbon Reactivation BasicsDokumen19 halamanElution and Carbon Reactivation BasicsdiegovergaraBelum ada peringkat

- Topic 2.4 - Momentum and ImpulseDokumen38 halamanTopic 2.4 - Momentum and ImpulseKhánh NguyễnBelum ada peringkat

- Product Specifications Product Specifications: CNT CNT - 600 600Dokumen2 halamanProduct Specifications Product Specifications: CNT CNT - 600 600Antonio CorreiaBelum ada peringkat

- 01 V5 X Series Engineering Data BookDokumen212 halaman01 V5 X Series Engineering Data Bookcalvin.bloodaxe4478Belum ada peringkat

- Iptc-19474-Ms A Strategic and Flexible Approach To Through Tubing Electrical Submersible PumpDokumen15 halamanIptc-19474-Ms A Strategic and Flexible Approach To Through Tubing Electrical Submersible PumpGilbert OmittaBelum ada peringkat

- 08 Power System Transients (KP)Dokumen68 halaman08 Power System Transients (KP)Prabu KumarBelum ada peringkat

- Abiogenesis PDFDokumen16 halamanAbiogenesis PDFErik_Daniel_MajcherBelum ada peringkat

- Wattstopper Sensor The Most Advanced Energy Saving TechnologyDokumen7 halamanWattstopper Sensor The Most Advanced Energy Saving TechnologyDemo Only100% (1)

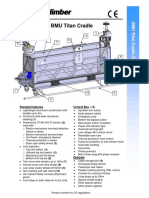

- BMU Titan Cradle: Standard Features Control BoxDokumen2 halamanBMU Titan Cradle: Standard Features Control BoxKashyapBelum ada peringkat

- Improved procedures for separating crystals from the meltDokumen10 halamanImproved procedures for separating crystals from the meltAna Mariel VenturaBelum ada peringkat

- Zenit Compact Setup Manual En3Dokumen26 halamanZenit Compact Setup Manual En3Garage Lifestyle BVGBelum ada peringkat

- SERIES AC CIRCUIT PROBLEMSDokumen4 halamanSERIES AC CIRCUIT PROBLEMSHubert Semeniano100% (1)

- Cambridge International AS Level: Environmental Management 8291/12Dokumen12 halamanCambridge International AS Level: Environmental Management 8291/12zohaibBelum ada peringkat

- World Jet Fuel Specifications 2005Dokumen51 halamanWorld Jet Fuel Specifications 2005Richo Crb100% (2)

- Response of Water Resources Systems To Climate ChangeDokumen355 halamanResponse of Water Resources Systems To Climate ChangePat Prodanovic100% (5)

- Igcse: Definitions & Concepts of ElectricityDokumen4 halamanIgcse: Definitions & Concepts of ElectricityMusdq ChowdhuryBelum ada peringkat

- 11th Five Year Plan 2007-12, India, Agriculture, Rural Development, and IndustryDokumen537 halaman11th Five Year Plan 2007-12, India, Agriculture, Rural Development, and IndustryDeepak Pareek100% (6)

- Myanmar Oil Field Info SummaryDokumen19 halamanMyanmar Oil Field Info SummaryhtutsweBelum ada peringkat

- Thermal Protector For Motor: Ballast For Fluorescent and Temperature Sensing ControlsDokumen1 halamanThermal Protector For Motor: Ballast For Fluorescent and Temperature Sensing ControlsPasilius OktavianusBelum ada peringkat