Single Phase To Three Phase Converter

Diunggah oleh

Gabriel MejiaDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Single Phase To Three Phase Converter

Diunggah oleh

Gabriel MejiaHak Cipta:

Format Tersedia

AbstractA new single phase to three phase converter topology

for small industries is presented in this paper: Phase converter,

include this paper, is a new technology that supplies three phase

power from a single phase source to power inductive, resistive and

capacitive loads with distinct advantages over any existing converter

technology. The converter consists of DC power supply, a MOSFET

Hex-bridge, integrated gate drive IC, and a DSP to generate the

switching signals. The switching signals generated are a unique

version of selective harmonic elimination, which produces a

consistent starting point for the switching functions, independent of

the number of harmonics eliminated

This converter covers the basis of induction motors and different

types of other motors. They are ideal for farms, workshops, garages

and large building etc.

KeywordsMOSFET Hex-bridge, DC power supply, gate drive

IC, switching signal static converter, rotary converter.

I. INTRODUCTION

wide variety of commercial and industrial electrical

equipment requires three-phase power. Electric utilities

do not install three-phase power as a matter of course because

it costs significantly more than single-phase installation. As an

alternative to utility installed three-phase, rotary phase

converters, static phase converters and phase converting

variable frequency drives (VFD)have been used for decades to

generate three-phase power from a single-phase source.

Construction of three-phase power lines can cost as much as

$50,000 per mile and can have an undesirable environmental

impact. Even when three-phase lines are nearby, the cost of

installation is considerable. Based on anticipated electricity

demand for the three-phase application, the utility may or may

not charge the customer for the cost of installation. Continuing

monthly surcharges for the service are also common. Phase

converters have historically been employed where utility

three-phase power was unavailable, or where the electricity

demand did not justify the cost of utility three-phase

installation. Reduced motor life caused by voltage and current

imbalance, harmonics that pollute the power grid and damage

equipment, or the inability to operate sensitive equipment or

multiple loads are just some of the problems that have limited

the use of phase converters. This phase converter is a new,

patented technology that supplies three-phase power from a

single phase source to power inductive, resistive and

capacitive loads with distinct advantages over any existing

converter technology. There are various phase conversion

Authors are with the Mandalay Technological University, Myanmar (e-

mail: awalyacho@gmail.com., tunlinthida@gmail.com).

technologies.

II. PHASE CONVERTERS

A. Static Converter

The Static Converter is made up of two small components:

A voltage sensitive relay and a standard capacitor (Cs)

connected to your motor application (Red Box). The capacitor

delays waveforms (or shifts the phase) during the start-up of

your motor application. The relay disconnects this start

capacitor after the motor has started. From this point, the

motor will continue turning on the single phase supply. The

performance of such a motor is fairly poor and can be

compared to a car motor running on only a few cylinders

Motors operated on a static converter will produce about 50-

60% of their name plate power. When you add another low

cost run capacitor (Red Dotted Box) to the simple design,

rated power goes up to around 70% of the motors name plate

power. To help with understanding, the Start Capacitor (Cs) is

used only to start the motor and then it is switched out

completely. The Run Capacitor (Cr) is always in the circuit

and is carefully sized to balance the voltages at one load rating

(generally around 50% full load). Since Cr is fixed the voltage

balancing at either end (0% and 100%) is quite poor.

Fig. 1 One line diagram of the static converter

B. Rotary Converter

Add an idle running motor to a static converter; is called

rotary converter. The added motor will compensate for some

of the static converter weaknesses and help extend the range

of motor sizes and loads. The internal motor is inactive at

average load, but works hard when loads dont match the

value of the chosen run capacitor (Cr). Rotary converters are

clearly somewhat better than static converters. They can run

several motors of different sizes. Large motors will produce

up to 90% of their nameplate power, small motors (motor

being much smaller than the converters idling motor or pilot

motor) a bit more. If the manufacturers oversize these motors,

Single Phase to Three Phase Converter

Naung Cho Wynn, and Tun Lin naing

A

World Academy of Science, Engineering and Technology 42 2008

343

the output symmetry, start capability and capacity will all be

increased.

C. Document Modification

Fig. 2 One line diagram of the rotary converter

Both rotary and static converters have difficulty adjusting

voltage balance to accommodate changing load conditions.

Voltage regulation schemes for rotary converters are available

which switch in different amounts of capacitance as the load

changes. However, it is still difficult to get good control, and

the high current pulses created in the system as the capacitors

are switched in and out can be a problem. Digital Phase

Converters are purely electronic and non-mechanical in

nature. As such they are able to produce decently balanced

three phase power. Another benefit of this type of phase

converter is that they are very quiet. On the downside, this

type of phase converter takes a sign wave, chops it up and

spits out a somewhat choppy synthesized 3 phase sign waves -

their output harmonic distortion tends to be greater than a few

other types of phase converters.

D. Design calculation for power supply circuit

Fig. 3 200V DC Power Supply for H-bridge Inverter

There are two separate power supply used in this variable

speed drive. The 200V DC power supply was used for H-

bridge inverter and 12V regulated power supply was used for

PWM frequency control circuit and driver circuit. This 200V

DC power supply circuit is shown in Fig. 3.

The maximum current of secondary transformer side is

s

max

max

V

P

I (1)

Where;

P

max

= maximum power of secondary transformer side

V

s

= secondary voltage

And, the turn ration is

s

max

p

s

V

P

V

V

(2)

Where;

N

s

= number of secondary turns

N

p

= number of secondary turns

V

p

= primary voltage

And,

s

p

s

p

p

s

N

N

V

V

V

V

(3)

Where;

I

s

= secondary current

I

p

= primary current

For specifications P

max

= 500VA,V

s

= 18V, V

p

= 230V;

By using equation 1, I

max

= 28A

By using equation 2, Np = 13 N

s

By using equation 3, I

s

= 13 I

p

The peak voltage of secondary transformer side is

rms p V 2 V (4)

Where;

V

rms

= rms value of primary voltage

The average voltage is

2V

V

p

avg (5)

Where;

V

p

= peak voltage

And the ripple voltage yields

2CF

1

Vripple (6)

Where;

C = filter capacitance

F = operating frequency

The output DC voltage is obtained

ripple p DC V V V (7)

By using above equation 4, 5, 6, and 7, the supply

voltage 200V DC are calculated.

E. Hex-bridge

The heart of a standard three-phase inverter is the hex-

bridge. The hex-bridge takes a dc bus voltage and uses six

switches arranged in three phase legs as shown in Fig. 4.

From the middle of each phase leg comes the line which

connects to the motor. The waveforms on these lines need to

be a balanced three-phase sinusoidal waveform in order to

drive the induction motor. This is achieved by applying

carefully controlled switching waveforms to the gate of the

switches.

+

200V

DC

MB351

.0

D1

D2

D3

D4

C1

470

C2

220

C3

220

220V

AC

World Academy of Science, Engineering and Technology 42 2008

344

A B C

+

V

dc

-

Fig. 4 Hex-bridge

There are two kinds of switches that can be used for our

fairly high power application, Insulated Gate Bipolar

Transistors (IGBTs) or MOSFETs. To meet our specifications

the switch needed minimum ratings of 400V and 10A. In

addition we wanted a switch which minimized losses;

therefore, switches with lower resistances are more desirable.

The IGBT considered for this design was the

HGTP12N60B3D, which has a small equivalent resistance of

approximately 0.07, but IGBTs also have a voltage drop at

all times due to the collector emitter saturation voltage, which

in this case is equal to 1.7V. The MOSFET investigated was

the FQP17N40, which has an on-state resistance of 0.27.

0 2 4 6 8 10

0

5

10

15

20

RMS current (A) [Single Frequency Sinusoid]

A

v

e

r

a

g

e

C

o

n

d

u

c

t

i

o

n

B

a

s

e

d

P

o

w

e

r

L

o

s

s

FQP17N40

HGTG12N60B3D

Fig. 5 Power losses in IGBT vs. FET

The power losses of the IGBT and the FET are plotted

against the current. The IGBT has a fairly linear loss curve

because the loss is mostly due to the IV

sat

, while the MOSFET

losses are due to the I

2

R

DS(on)

. The MOSFET losses increase

faster with current, but the MOSFET losses do not surpass the

IGBT losses until I is approximately greater than 9A. The

motor used in our project is rated for 3A so the current should

never reach 9A.

In addition to having smaller losses in our operating region,

the FQP17N40 is cheaper. It is $0.96 in a quantity of 1000,

while the HGTP12N60B3D is $1.70 in the same quantity.

The HGTP12N60 is rated for 600V which is the very low end

of IGBT ratings. IGBTs are usually used in higher power

applications, so this part is not extremely common. The

savings in losses and price prompted us to choose the

FQP17N40 as the switch to be implemented in the hex-bridge.

F. Gate Drive

The gate drive circuit needs to provide an interface between

the switching signals coming from the DSP or arbitrary

waveform generator and the FETs in the hex-bridge. The

DSP gives a 3.3V signal, while the waveform generators

allow for a specified voltage level. The gate to source voltage

needed for desired operation of the FQP17N40 FETs is on a

12 to 15V level. In addition, the high side FETs in the hex-

bridge do not have the source connected to ground, so the

actual voltage needed to drive the gate depends on the varying

voltage at the source. A single chip solution was found, the

IR21362, which implements all six gate drives, including the

circuitry that takes into account the issues with the high side

FETs. There were other options, such as the IR2121,

consisting of a single gate drive on a chip, but in the interest

of lowering component count and cost, the IR21362 was

chosen. Since six IR2121s would be needed, it is apparent that

the single chip solution (IR21362) is more cost effective.

G. Switching Signal Methodology

Currently small motor drive systems are expensive and

implement control schemes that use relatively high switching

frequencies such as sine-triangle PWM, space vector PWM,

or hysteresis current control. One drawback to the high

switching frequencies is the decrease in efficiency that occurs

from switching loss. However, the previously mentioned

control methods do have their own merits. Each control

scheme has been used widely and generates little acoustic

noise since the switching frequency is on the upper end of the

audible acoustic range (20 kHz). These control schemes also

provide good dynamic performances.

However, this application does not need good dynamic

performance since there are no dynamic load and speed

requirements. The switching signals implemented are a

unique version of selective harmonic elimination, which is

currently an active research area in power electronics. This

technique lowers the switching frequency considerably

compared to the previously mentioned methods. In addition,

this switching scheme provides direct control over harmonics

present in the waveform. The selective harmonic elimination

method will be implemented in a switching waveform, while

sine-triangle PWM will be used as a back-up.

H. Switching Signal Implementation

Two DSP development boards for motor control

applications are available for proto-typing DSP code

development. They are the eZdsp F2407 and the eZdsp F2812

boards. The F2407 has a lower cost then F2812. However, the

F2812 has a faster clock at 150 MHz compared to the 30 MHz

clock on the F2407. The F2812s analog-to-digital converter

has a 12 bit resolution, whereas the F2407 only has 10 bit

World Academy of Science, Engineering and Technology 42 2008

345

resolution. This makes the F2812 more desirable since it will

give a better resolution for the speed commands. In addition,

constructed harmonic elimination PWM implementation in the

DSP requires the use of a large switching table that cannot fit

into the F2407 FLASH.

The eZdsp kit provides a complete development

environment: DSP board, power supply, on-board JTAG

compliant emulator, and an eZdsp specific Code Composer

Studio

TM

full featured, with debugger IDE, and ANSI C and

C++ compliant compiler. The DSP board has all peripheral

signals needed on the board headers, making it easy to

interface the board with the 3-phase inverter circuit.

I. Inverter Control

The control method implemented is open loop and based

upon constant volts per hertz ratio. Although the inverter uses

a 200V dc bus, the voltage is able to be varied by adjusting

the modulation depth of the switching signals. Additionally,

in order to meet the speed specifications over the given load

range an efficient load compensation method will be used to

determine optimal values of voltage and frequency to be

applied to the machine at a given operating point.

III. DESIGN DETAILS

A. Hex-Bridge and Gate Drive (Component Selection)

The FQP17N40 was chosen as the switch in the hex-bridge.

Often, MOSFETs need external circuitry, called a snubber, in

order to improve the switching trajectory during the

commutation period. The switching trajectory of the

FQP17N40 was measured (see Fig. 6) and appears to be fairly

rectangular, as desired for an inductive load.

Fig. 6 Switching trajectory

In addition, thermal issues needed to be taken into

consideration. The FQP17N40 is rated for 10.1A continuous

at 100C. Since the motor used is rated for 3A, the current

should never be greater than 5A continuously. In addition, the

final product is intended to be on a printed circuit board

(PCB) that is mounted to the end of the motor. There will be

a fan attached to the rotor which actively cools the FETs.

These facts lead to the decision to forego the use of heatsinks.

The IR21362 gate drive chip requires some external

circuitry. The gate resistors (R11-R16), bootstrap capacitors

(C4, C5, and C7), and decoupling capacitors (C3 and C6)

were chosen based on information found in [2, 3]. A resistor

and capacitor (R2 and C5) had to be chosen to provide a time

constant which is used for the fault clearing time. A time

constant of greater than 1.5s was desired so values of 33k

and 47F were chosen. The FAULT pin needs to be pulled

high because it is active low. A LED was added in for visual

output in the case of a fault.

The protection circuitry, which includes R7, R9, R19, and

C1, is chosen based on the fact that a fault occurs if the

voltage on the ITRIP pin is larger than 0.5V. The variable

resistor, R7, can be adjusted so that a fault is given at a

desired current value. The values were chosen with the

intention of initiating a fault at currents larger than 10A.

Finally, three phase power for induction motor is got when

DC power supply connected with Hex-bridge and gate drive.

World Academy of Science, Engineering and Technology 42 2008

346

B. Detailed Schematic

Fig. 7 Hex-bridge and gate drive circuitry

ACKNOWLEDGMENT

The First named author expresses sincere thanks to the

university of Mandalay Technological University.

REFERENCES

[1] P. T. Krein, Elements of Power Electronics. New York and Oxford:

Oxford University Press, 1998. International Rectifier, Appl. Note 978.

International Rectifier, Appl. Note INT985.

[2] H. S. Patel and R. G. Hoft, Generalized techniques of harmonic

elimination and voltage control in thyristor inverters: Part I Harmonic

elimination, IEEE Trans. Ind. Applicat., vol. IA-9, no.3, pp. 310-317,

May/June 1973.

[3] Hur Namho, Jung Junhwan, Nam K wanghee. Fast Dynamic DC-link

Power balancing Scheme for a PWM converter-inverter System [A].

IECON 99 Proceedings[C]. The 25th Annual conference of the IEEE,

1999, 2:767~772

[4] Jung Jinhwan, Lim Sunkyoung, Nam Kwanghee. A Feed-back

Linearizing Control Scheme for a PWM Converter inverter Having a

very Small DC-Link Capacitor[J].IEEE Trans. on Ind. Appl.,

1999,35(5):1124~1131

[5] Li Li, D. Czarkowski, Yaguang Liu and P. Pillay, Multilevel selective

harmonic elimination PWM technique in series-connected voltage

inverters, IEEE Trans. Ind. Applicat., vol. 36, pp. 160-170, Jan/Feb.

2000.

[6] J D Van Wyk. .Power Quality, Power Electronics and Control in

Proceedings EPE.93, 1993, pp 17-32.

[7] Z Yang and P C Sen. Recent Developments in High Power Factor

Switchmode Converters, IEEE Proceedings CCECE.98, 1998, pp 477-

480.

[8] H Akagi. .New Trends in Active Filters for Power Conditioning.. IEEE

Transactions Industry Applications, vol 32, November/December 1996,

pp 1312-1322.

[9] H Endo, T Yamashita and T Sugiura. .A High Power-factor Buck

Converter, Proceedings IEEE PESC.92, 1992, pp 1071-1076.

H

I

N

3

D

2

M

U

R

1

6

0

H

I

N

1

C

6

1

u

M

3

F

Q

P

1

7

N

4

0

V

1

2

0

0

V

R

5

3

3

k

C

5

1

u

M

2

F

Q

P

1

7

N

4

0

B

_

T

O

_

M

O

T

O

R

C

4

1

u

M

5

F

Q

P

1

7

N

4

0

R

1

4

2

5

R

1

1

2

5

D

4

L

E

D

M

6

F

Q

P

1

7

N

4

0

R

1

9

0

.

0

5

C

7

1

u

R

7

5

0

0

k

P

O

T

1

3

2

R

9

1

0

0

C

2

4

7

u

D

3

M

U

R

1

6

0

U

4

I

R

2

1

3

6

2

123456789

1

0

1

1

1

2

1

3

1

4

1

5

1

6

1

7

1

8

1

9

2

0

2

2

2

3

2

1

2

4

2

5

2

6

2

7

2

8

V

C

C

H

I

N

1

H

I

N

2

H

I

N

3

L

I

N

1

L

I

N

2

L

I

N

3

F

A

U

L

T

I

T

R

I

P

E

N

R

C

I

N

V

S

S

C

O

M

L

O

3

L

O

2

L

O

1

N

C

V

S

3

H

O

3

V

B

3

V

S

2

H

O

2

N

C

V

B

2

N

C

V

S

1

H

O

1

V

B

1

V

C

C

R

1

2

2

5

M

1

F

Q

P

1

7

N

4

0

R

8

5

0

0

H

I

N

2

C

3

1

u

5

V

R

1

6

2

5

A

_

T

O

_

M

O

T

O

R

D

1

M

U

R

1

6

0

M

4

F

Q

P

1

7

N

4

0

F

A

U

L

T

R

1

5

2

5

C

_

T

O

_

M

O

T

O

R

R

1

3

2

5

C

1

0

.

0

2

2

u

World Academy of Science, Engineering and Technology 42 2008

347

Anda mungkin juga menyukai

- PRINCE2 Quick Reference GuideDokumen2 halamanPRINCE2 Quick Reference Guidespm9062100% (5)

- Installation Instructions - 4.5" Murphy LevelGaugeDokumen4 halamanInstallation Instructions - 4.5" Murphy LevelGaugebmdickeyBelum ada peringkat

- Activity 5 Topic: Blender/Mixer ObjectivesDokumen12 halamanActivity 5 Topic: Blender/Mixer Objectivesmizsuet100% (1)

- Schrage Motor With Control PanelDokumen1 halamanSchrage Motor With Control PanelVirender Rana0% (1)

- NETA Handbook Series II ArcFlash Vol 2 PDFDokumen63 halamanNETA Handbook Series II ArcFlash Vol 2 PDFblem_0075Belum ada peringkat

- Fire Safety PolicyDokumen39 halamanFire Safety Policydidik0% (1)

- Control of Single Phase To Three Phase AcDokumen10 halamanControl of Single Phase To Three Phase Acpriya dharshiniBelum ada peringkat

- Designing Planar Magnetics DixonDokumen26 halamanDesigning Planar Magnetics Dixonarulsrini77Belum ada peringkat

- Single Phase To Three Phase Converstion Using Two Parallel RectifiersDokumen89 halamanSingle Phase To Three Phase Converstion Using Two Parallel RectifiersThriveni Maddineni83% (6)

- Basic Types of Drilling MachinesDokumen4 halamanBasic Types of Drilling Machinessujit_ranjanBelum ada peringkat

- Hall Effect Sensors TheoryDokumen12 halamanHall Effect Sensors TheoryPrateek BhatnagarBelum ada peringkat

- Exp 11 Single Phase Inverter Part IDokumen7 halamanExp 11 Single Phase Inverter Part Iusmpowerlab0% (1)

- Types of Motor Used in Traction SystemDokumen8 halamanTypes of Motor Used in Traction SystemShrestha Sanju100% (1)

- SPWM V/HZ InverterDokumen51 halamanSPWM V/HZ InverterLabi BajracharyaBelum ada peringkat

- Voltage Source Inverter - 2Dokumen99 halamanVoltage Source Inverter - 2dhamu66990% (1)

- Wireless Remote Control For Eot Crane Using Avr Micro Controller IJERTCONV5IS20024 PDFDokumen4 halamanWireless Remote Control For Eot Crane Using Avr Micro Controller IJERTCONV5IS20024 PDFsujit kcBelum ada peringkat

- Building A Phase ConverterDokumen11 halamanBuilding A Phase ConverterAlvaro Del Cid100% (1)

- A DQ Frame Controller For Single Phase Inverters ETDDokumen135 halamanA DQ Frame Controller For Single Phase Inverters ETDkripansh0% (1)

- Induction CookersDokumen5 halamanInduction CookersVăn LinBelum ada peringkat

- When A Relay Is Used To Switch A Large Amount of Electrical Power Through Its ContactsDokumen4 halamanWhen A Relay Is Used To Switch A Large Amount of Electrical Power Through Its ContactsJay ChampBelum ada peringkat

- High Performance Portable BenchSupply, DIYDokumen9 halamanHigh Performance Portable BenchSupply, DIYBryan Fantasía FuryBelum ada peringkat

- Bypass & Coupling CapacitorsDokumen6 halamanBypass & Coupling Capacitorsanandmn7026100% (1)

- Sine Wave Generation and Implementation Using DsPIC33FJDokumen27 halamanSine Wave Generation and Implementation Using DsPIC33FJpaaraib100% (1)

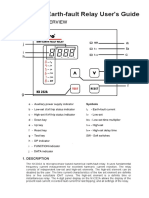

- NX232A Earth-Fault Relay User's Guide: 1. DescriptionDokumen4 halamanNX232A Earth-Fault Relay User's Guide: 1. DescriptiondienlangchuBelum ada peringkat

- AC DrivesDokumen120 halamanAC DrivesVenkata GanesanBelum ada peringkat

- External Current Limiting CircuitDokumen3 halamanExternal Current Limiting CircuitmikcomiBelum ada peringkat

- What Is PantographDokumen6 halamanWhat Is PantographTriskaBelum ada peringkat

- Winding Consists of 1. 2. 3. 1 2 3 1 2 3 Insulator ConductorDokumen61 halamanWinding Consists of 1. 2. 3. 1 2 3 1 2 3 Insulator ConductoriraqnewBelum ada peringkat

- Static Stabilizer Single Phase User ManualDokumen15 halamanStatic Stabilizer Single Phase User ManualPankaj D PatelBelum ada peringkat

- No Load and Block Rotor Test: Premier Trading CorporationDokumen11 halamanNo Load and Block Rotor Test: Premier Trading CorporationKsr Akhil100% (1)

- HPED Assignment 2: DC DrivesDokumen4 halamanHPED Assignment 2: DC DrivesShadBelum ada peringkat

- Lab 3 Squirrel Cage Induction Machine-1Dokumen8 halamanLab 3 Squirrel Cage Induction Machine-1max100% (1)

- Exp 9 Boost ConverterDokumen8 halamanExp 9 Boost ConverterusmpowerlabBelum ada peringkat

- DC To DC BoosterDokumen4 halamanDC To DC BoosterIdrissa NikiemaBelum ada peringkat

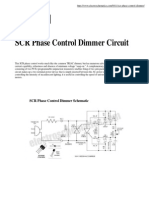

- SCR Phase Control Speed ControlDokumen3 halamanSCR Phase Control Speed ControlWil NelsonBelum ada peringkat

- BeagleBoneBlack TutorialsDokumen24 halamanBeagleBoneBlack Tutorialstuyen1989100% (1)

- Ac Motor Control k2636 - Rev2Dokumen12 halamanAc Motor Control k2636 - Rev2kobiBelum ada peringkat

- Fer 44 01 000 1998 PDFDokumen36 halamanFer 44 01 000 1998 PDFDoDuyBacBelum ada peringkat

- Synchronous Generator - LeelDokumen42 halamanSynchronous Generator - LeelLeelananda100% (1)

- Origins of The Inverter: I IndustryDokumen3 halamanOrigins of The Inverter: I IndustrylayconBelum ada peringkat

- Yaskawa Manuals 212Dokumen31 halamanYaskawa Manuals 212Pham LongBelum ada peringkat

- Design Construction of A 220 V Voltage StabilizerDokumen50 halamanDesign Construction of A 220 V Voltage StabilizerSamuel OlusanyaBelum ada peringkat

- Power Presentation On Design of InverterDokumen18 halamanPower Presentation On Design of Inverteraa bbBelum ada peringkat

- LXM23D and BCH Servo Drive System Product ManualDokumen403 halamanLXM23D and BCH Servo Drive System Product ManualLau Yuk LunBelum ada peringkat

- Permanant Magnet Synchronous MotorDokumen47 halamanPermanant Magnet Synchronous Motorsubaganesh232Belum ada peringkat

- Estabilizador Voltage ChopperDokumen52 halamanEstabilizador Voltage ChopperArmandinho CaveroBelum ada peringkat

- Eddy Current Drives-Holland IndustrialDokumen3 halamanEddy Current Drives-Holland IndustrialAirton FloresBelum ada peringkat

- 3 Phase Cascaded H-Bridge InverterDokumen7 halaman3 Phase Cascaded H-Bridge InverterAnil ShahBelum ada peringkat

- Digital Phase Selector: A Mini-Project Report Submitted in Partial Fulfillment Requirements For The Award ofDokumen53 halamanDigital Phase Selector: A Mini-Project Report Submitted in Partial Fulfillment Requirements For The Award ofdondbBelum ada peringkat

- Servo Motor - Servo Mechanism - Theory and Working PrincipleDokumen6 halamanServo Motor - Servo Mechanism - Theory and Working PrincipleBrahmanand SinghBelum ada peringkat

- WebInterface Configuration Manual BasicsDokumen32 halamanWebInterface Configuration Manual BasicsprenticBelum ada peringkat

- Numerical RelaysDokumen38 halamanNumerical Relaysashutosh2009Belum ada peringkat

- Snubber Circuit Design CalculatorsDokumen3 halamanSnubber Circuit Design CalculatorsteomondoBelum ada peringkat

- Single Phase AC Voltage ControllerDokumen6 halamanSingle Phase AC Voltage Controllermozaher1Belum ada peringkat

- Inverters For Ac Motor DriveDokumen17 halamanInverters For Ac Motor DriveAslam SdBelum ada peringkat

- Speed Control of DC Motor Using ChopperDokumen7 halamanSpeed Control of DC Motor Using ChopperKoustav DasguptaBelum ada peringkat

- Small Engine Ignition Systems CH10Dokumen30 halamanSmall Engine Ignition Systems CH10Manny AnacletoBelum ada peringkat

- Answers of Power Electronics NewDokumen9 halamanAnswers of Power Electronics NewSyed ZabiullahBelum ada peringkat

- Static Balancing of Grinding WheelsDokumen3 halamanStatic Balancing of Grinding WheelsloosenutBelum ada peringkat

- Fixed Frequency Sliding Mode (SM) Control Scheme Based On Current Control Manifold For Improved Dynamic Performance of Boost PFC ConverterDokumen11 halamanFixed Frequency Sliding Mode (SM) Control Scheme Based On Current Control Manifold For Improved Dynamic Performance of Boost PFC ConverterGabriel MejiaBelum ada peringkat

- A High-Efficiency 3.3-kW Bidirectional On-Board ChargerDokumen5 halamanA High-Efficiency 3.3-kW Bidirectional On-Board ChargerGabriel MejiaBelum ada peringkat

- Experimental Study On The in Uence of Dead-Time On IGBT Turn-Off Characteristics in An Inverter Leg at High and Low CurrentsDokumen5 halamanExperimental Study On The in Uence of Dead-Time On IGBT Turn-Off Characteristics in An Inverter Leg at High and Low CurrentsGabriel MejiaBelum ada peringkat

- Application Note en 20181017Dokumen40 halamanApplication Note en 20181017Nika BernazBelum ada peringkat

- A Residential 10kWh Lithium-Polymer BatteryDokumen6 halamanA Residential 10kWh Lithium-Polymer BatteryGabriel MejiaBelum ada peringkat

- A High Efficiency Bi-Directional EV ChargerDokumen6 halamanA High Efficiency Bi-Directional EV ChargerGabriel MejiaBelum ada peringkat

- An-1202 - Design Considerations For IGBT in Inverters and DrivesDokumen30 halamanAn-1202 - Design Considerations For IGBT in Inverters and Drivesjlruizmat8679Belum ada peringkat

- An Approach For Control of Battery EnergyDokumen5 halamanAn Approach For Control of Battery EnergyGabriel MejiaBelum ada peringkat

- 2008-Two-Leg Three-Phase Inverter Control ForDokumen10 halaman2008-Two-Leg Three-Phase Inverter Control ForGabriel MejiaBelum ada peringkat

- 2010 - Plestan - New Methodologies For Adaptive Sliding Mode ControlDokumen14 halaman2010 - Plestan - New Methodologies For Adaptive Sliding Mode ControlGabriel MejiaBelum ada peringkat

- PHEV-EV Charger Technology Tesis BuenaDokumen113 halamanPHEV-EV Charger Technology Tesis BuenaGabriel MejiaBelum ada peringkat

- A G2V-V2G Off-Board Fast Charger For ChargingDokumen6 halamanA G2V-V2G Off-Board Fast Charger For ChargingGabriel MejiaBelum ada peringkat

- HUNG ET AL - TIE 1993 - Variable Structure Control A SurveyDokumen21 halamanHUNG ET AL - TIE 1993 - Variable Structure Control A SurveyMoneeb AsifBelum ada peringkat

- 2008-Two-Leg Three-Phase Inverter Control ForDokumen10 halaman2008-Two-Leg Three-Phase Inverter Control ForGabriel MejiaBelum ada peringkat

- 2016-A Sliding Mode Controller Based STATCOM WithDokumen7 halaman2016-A Sliding Mode Controller Based STATCOM WithGabriel MejiaBelum ada peringkat

- 2016 - Dhanasekar - Sliding Mode Control of Electric Drives ReviewDokumen7 halaman2016 - Dhanasekar - Sliding Mode Control of Electric Drives ReviewGabriel MejiaBelum ada peringkat

- 1973 Utkin-Sliding Modes in MultidimensionalDokumen1 halaman1973 Utkin-Sliding Modes in MultidimensionalGabriel MejiaBelum ada peringkat

- 1987-Sliding Motions in BilinearDokumen15 halaman1987-Sliding Motions in BilinearGabriel MejiaBelum ada peringkat

- 1973 Utkin-Sliding Modes in MultidimensionalDokumen1 halaman1973 Utkin-Sliding Modes in MultidimensionalGabriel MejiaBelum ada peringkat

- 2006-Frequency-Domain Characterization of SlidingDokumen15 halaman2006-Frequency-Domain Characterization of SlidingGabriel MejiaBelum ada peringkat

- A Survey On The Contributions of Power Electronics To SmartDokumen18 halamanA Survey On The Contributions of Power Electronics To SmartGabriel MejiaBelum ada peringkat

- 2008-Modeling, Design and Analysis of DifferentDokumen8 halaman2008-Modeling, Design and Analysis of DifferentGabriel MejiaBelum ada peringkat

- 2016 - Dhanasekar - Sliding Mode Control of Electric Drives ReviewDokumen7 halaman2016 - Dhanasekar - Sliding Mode Control of Electric Drives ReviewGabriel MejiaBelum ada peringkat

- Koc Michigan Sample TestDokumen6 halamanKoc Michigan Sample TestEmre ÖzarslanBelum ada peringkat

- Q64 - Hardware Differences Between Q64 and GR64Dokumen24 halamanQ64 - Hardware Differences Between Q64 and GR64Gabriel MejiaBelum ada peringkat

- Sliding Mode Control HandoutDokumen42 halamanSliding Mode Control HandoutGabriel MejiaBelum ada peringkat

- Using TCP and UDP Under Open-AtDokumen13 halamanUsing TCP and UDP Under Open-AtGabriel MejiaBelum ada peringkat

- Impact FactorDokumen15 halamanImpact FactorsasinfotechBelum ada peringkat

- M2mpower Datasheet R1FDokumen1 halamanM2mpower Datasheet R1FGabriel MejiaBelum ada peringkat

- Not So Squeezy - Trading ManualDokumen21 halamanNot So Squeezy - Trading ManualJimmy ChowBelum ada peringkat

- Segmentation, Targeting and PositioningDokumen18 halamanSegmentation, Targeting and PositioningHussain AhmedBelum ada peringkat

- Pug Mills MixersDokumen6 halamanPug Mills MixersStefan Van CleemputBelum ada peringkat

- Pricelist Harian 20 Feb 2014Dokumen1 halamanPricelist Harian 20 Feb 2014Santo RuBelum ada peringkat

- Fisher PDFDokumen118 halamanFisher PDFtony blas cristobal100% (1)

- GB-T 1220-2007Dokumen23 halamanGB-T 1220-2007HieuBelum ada peringkat

- Water Infrastructure Design Standards and GuidelinesDokumen111 halamanWater Infrastructure Design Standards and Guidelinesahmed zakiBelum ada peringkat

- Uniform General Conditions For Construction Contracts, State of Texas, 2010 (UGC)Dokumen18 halamanUniform General Conditions For Construction Contracts, State of Texas, 2010 (UGC)AlexBelum ada peringkat

- WCDMA Accessiblity KPIsDokumen29 halamanWCDMA Accessiblity KPIsAbdoulayeAboubacar0% (1)

- DninebDokumen2 halamanDninebMouad TribakBelum ada peringkat

- FRENIC Mini (C2) CatalogDokumen24 halamanFRENIC Mini (C2) CatalogSAYAKBelum ada peringkat

- Solid State Digital Hourmeters & Counters 700 Series: FeaturesDokumen6 halamanSolid State Digital Hourmeters & Counters 700 Series: FeaturesEwerton BianchiBelum ada peringkat

- RP 12.0 Edition 1 - 2016 FINALDokumen15 halamanRP 12.0 Edition 1 - 2016 FINALKevin BryarBelum ada peringkat

- Types of Chassis LayoutDokumen8 halamanTypes of Chassis LayoutMatthew SmithBelum ada peringkat

- B450M DS3H: User's ManualDokumen42 halamanB450M DS3H: User's ManualIsmael ZamoranoBelum ada peringkat

- 54 States of Usa and Their Telephone CodesDokumen3 halaman54 States of Usa and Their Telephone CodesMuhammad TalhaBelum ada peringkat

- Y Motor Planet GearDokumen4 halamanY Motor Planet GearFabian FragosoBelum ada peringkat

- IntraOs 70 V4.0 ENG - Service InstallationDokumen52 halamanIntraOs 70 V4.0 ENG - Service Installationtaothien91100% (1)

- Building Heat Load Contributions From Medium and Low Voltage SwitchgearDokumen11 halamanBuilding Heat Load Contributions From Medium and Low Voltage SwitchgearOmar Graterol100% (1)

- GokilDokumen462 halamanGokilStefanus Heri Cahyadi100% (2)

- Manual CrusairDokumen28 halamanManual CrusairfikonfiskBelum ada peringkat

- Guidesteelworkssupervision PDFDokumen78 halamanGuidesteelworkssupervision PDFPhạm Văn ĐảngBelum ada peringkat

- TE1 Block Diagram: IntelDokumen40 halamanTE1 Block Diagram: IntelRian05 AntalBelum ada peringkat

- Smith Fibercast CENTRICAST CL-1520 PipingDokumen8 halamanSmith Fibercast CENTRICAST CL-1520 PipingDGWBelum ada peringkat

- NEXYGENPlus Spec SheetDokumen3 halamanNEXYGENPlus Spec Sheetrossifam777Belum ada peringkat

- SP020 and SP022 Quick User ManualDokumen36 halamanSP020 and SP022 Quick User Manualsekhar rajBelum ada peringkat

- Anexo 1Dokumen4 halamanAnexo 1rcusiBelum ada peringkat