F500

Diunggah oleh

back1949Deskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

F500

Diunggah oleh

back1949Hak Cipta:

Format Tersedia

250

90 170 280 500

190 1170 2,5 280 5 500

14 250

7 7 7

3

1

14

2

1

L2, S2 L4, S4 L4,S4 L4, S4

QVMZO-20 QVMZO-32 QVMZO-40

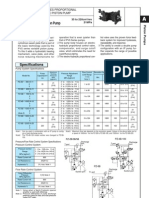

Regulation characteristics

Maximum pressure [bar]

Maximum flow [l/min]

Flow regulation range [l/min]

Pressure regulation range [bar]

Compensating p [bar]

Hysteresis [%]

Repeatability [%]

Minimum piloting pressure [bar]

Hysteresis [%]

Repeatability [%]

Model

F

L

O

W

C

O

N

T

R

O

L

Q

QVMZO are double proportional valves,

which provide the indipendent flow and

pressure control in systems with fixed

displacement pump, according to the

electronic reference signal.

They operate in association with elec-

tronic drivers, see sect. , which sup-

ply the proportional valves with correct

current signal to align valve regulation

to the reference signal supplied to the

electronic driver.

The cartridge regulates the flow at

port A accordi ng to the reference

signal Q.

The cartridge operates as 3-way

pressure compensator between P and

A ports discharging excess flow throu-

gh port T.

The pressure is regulated according to

the reference signal P.

The pressure relief valve with manual

setting operates as safety valve.

The coils are fully plastic encapsulated

(insulation class H) and valves have

antivibration, antishock and weather-

proof features.

Surface mounting: ISO size 16, 25, flan-

ge attachment 1 1/4 SAE 3000.

Max flow up to 170 l/min, 280 l/min, 500

l/min respectively with compensating

p = 7 bar.

Max pressure: 250 bar.

HYDRAULIC CHARACTERISTICS (based on mineral oil ISO VG 46 at 50 C)

Maximum pressure

250 = 250 bar

V T P A

Series number

www.atos.com

Proportional pressure and flow control valves type QVMZO

indipendent pressure and 3-way compensated flow regulation

Table F500-11/E

QVMZO - A

Double proportional

valve for pressure

and flow control

A = without integral transducer

Regulation characteristics:

L2 = linear (only for size 20); S2= progressive (only for size 20)

L4 = linear; S4= progressive

20 / 3 /* ** / 250

Coil voltage (only for -A execution)

- = standard coil for 24VDC Atos drivers

6 = optional coil for 12VDC Atos drivers

18= optional coil for low current drivers

18 / L4 -

1 MODEL CODE

QVMZO-A-20

2

F500

3 = 3-way

Size:

20 = ISO 6263 size 20

32 = ISO 6263 size 25

40 = flange 1 1/4 SAE 3000

P

R

E

S

S

U

R

E

C

O

N

T

R

O

L

P

Above performances data refer to valve coupled with Atos electronic drivers, see section .

Note: plug on port V is normally open.

V port can be used for optional connection to a solenoid valve for

venting.

Reference signal Q Reference signal P

P = Pump port

A = User port

T = Tank port

V = Venting port

. .

Pr

.

Q

.

.

.

.

Seals material:

omit for NBR (mineral

oil & water glycol)

PE = FPM

Note:

- electrical signals (e.g. actual - feedback signals) taken via

valve electronics must not be used to switch off the machine

safety functions. This is in accordance with the regolations to

the European standard (Safety requirements of fluid techno-

logy systems and components - hydraulics).

- basic information for commissioning and start-up are present

on installation notes always enclosed to the specific techni-

cal tables and relevant components.

Electric wiring to reference generators must be made using shielded cables: the sheat must be connected to the power supply zero on the generator

side. The power supply must be properly stabilized or rectified and filtered. For complete electric wiring with all available options, see section G

4 ELECTRIC WIRING

Connector

COIL LEAD

COIL LEAD

EARTH CONDUCTOR

ZO-A

E

-

*

-

A

C

-

0

*

F

PIN

1

2

Pilot valve

Flow control ZO-A

E

-

*

-

A

C

-

0

*

F

Pilot valve

Pressure control

Assembly position Any position

Subplate surface finishing Roughness index Ra 0,4 - flatness ratio 0,01/100 (ISO 1101)

Ambient temperature -20C +70C

Fluid Hydraulic oil as per DIN 51524 ... 535 for other fluids see section

Recommended viscosity 15 100 mm

2

/s at 40C (ISO VG 15100)

Fluid contamination class ISO 4406 class 20/18/15 NAS 1638 class 9, in line filters of 10 m (10 _ >75 recommended)

Fluid temperature -20C +60C (standard seals and water glycol) -20C +80C (/PE seals)

3 MAIN CHARACTERISTICS OF PROPORTIONAL PRESSURE AND FLOW VALVES QVMZO

5 TYPICAL APPLICATION IN PLASTIC INJECTION MACHINES

1 = Moulding clamping cylinder

2 = Five-point double toggle joint

3 = Injection screw

4 = Screw-driving hydraulic motor

5 = Injection cylinder

6 = Injection unit sliding cylinder

7 = Injection manifold

8 = Double, flow and pressure, propor-

tional control type QVMZO

9 = Tank and motor pump unit

3.1 Coils characteristics

Standard option /6 option /18

Valve model QVMZO

Coil resistance R at 20

Max. solenoid current

Max. power

Protection degree (CEI EN-60529) IP65

Duty factor Continuous rating (ED=100%)

Flow control Q

Pressure control P

Flow control Q

Pressure control P

Flow control Q

Pressure control P

3 3,3

30 W

35 W

30 W

35 W

30 W

35 W

13 13,4 2 2,2

2,2 A

2,4 A 0,9 A

0,75 A 1,75 A

2 A

F500

6 DIAGRAMS

6.1 Regulation diagrams for valves with

Atos electronic drivers

1 = QVMZOL2, L4

2 = QVMZOS2, S4

3 = QVMZO (pressure regulation)

6.2 Regulation diagrams: driving current

vs. regulated flow and vs. regulated

pressure

1 = QVMZO-A-20/3L2

2 = QVMZO-A-20/3S2

3 = QVMZO-A-20/3L4

4 = QVMZO-A-20/3S4

5 = QVMZO-A-32/3L4

6 = QVMZO-A-32/3S4

7 = QVMZO-A-40/3L4

8 = QVMZO-A-40/3S4

9 = QVMZO (pressure regulation)

Note:

(1) = with standard coil 12 VDC

(2) = with coil 18 VDC

R

e

g

u

l

a

t

e

d

f

l

o

w

[

%

o

f

t

h

e

m

a

x

]

P

r

e

s

s

u

r

e

a

t

p

o

r

t

P

[

%

o

f

t

h

e

m

a

x

]

Reference signal Q [% of the max] Reference signal P

R

[% of the max]

R

e

g

u

l

a

t

e

d

f

l

o

w

[

l

/

m

i

n

]

R

e

g

u

l

a

t

e

d

f

l

o

w

[

l

/

m

i

n

]

Driving current [mA] Driving current [mA]

3

4

1

2

1 2 3

5 6

R

e

g

u

l

a

t

e

d

f

l

o

w

[

l

/

m

i

n

]

R

e

g

u

l

a

t

e

d

p

r

e

s

s

u

r

e

[

b

a

r

]

Driving current [mA] Driving current [mA]

8

7

9

(1)

(2)

(1)

(2)

(1)

(2)

(1)

(2)

7 ELECTRONIC DRIVERS FOR QVMZO-A*

For complete information about the drivers characteristics and relevant options, see the technical data sheet specified in the table.

Valve model

Data sheet

Drivers model E-MI-AC-01F

G010

-A

E-MI-AS-IR

G020

E-BM-AC-011F

G025

E-BM-AS

G030

E-ME-AC-01F

G035

E-RP-AC-01F

G100

07/13

8 INSTALLATION DIMENSIONS [mm]

QVMZO-20

QVMZO-A-20

QVMZO-A-32

QVMZO-A-40

QVMZO-32

QVMZO-40

ISO 6263: 1999

Mounting surface: 6263-08-15-1-97

Fastening bolts: 4 socket head screws M16x120 class 12.9

Tightening torque = 300 Nm

Seals: 4 OR 4112, 1 OR 2050

Ports diameter:

25 mm (P, A, L, T);

5 mm (V)

P = Inlet port

A= Outlet port

T = Tank port

L = Drain port

V = Vent port

ISO 6263: 1999

Mounting surface: 6263-07-11-1-97

Fastening bolts: 4 socket head screws M10x80 class 12.9

Tightening torque = 70 Nm

Seals: 4 OR 130; 1 OR 2050

Diameter of ports A, P, T: = 20 mm

P = Inlet port

A= Outlet port

T = Tank port

L = Drain port

V = Vent port

View X

View X

View X

Mass: 18,5 Kg

Mass: 32,8 Kg

Mass: 37,5 Kg

Fastening bolts: M8 class 12.9

Tightening torque = 35 Nm

Port attachments:

A, P, T = 1 1/4 SAE 3000

L = G 1/4

P = Inlet port

A = Outlet port

T = Tank port

L = Drain port

Anda mungkin juga menyukai

- Re29564 2007-011Dokumen12 halamanRe29564 2007-011engineer86Belum ada peringkat

- F410Dokumen8 halamanF410back1949Belum ada peringkat

- Proportional Control Valves D631 Series ISO 4401 Size 05Dokumen8 halamanProportional Control Valves D631 Series ISO 4401 Size 05Devendra BangarBelum ada peringkat

- Moog ServovalvesDokumen8 halamanMoog Servovalvesdylan_dearing@hotmail.com100% (1)

- 4wre 6-10 Sew1xDokumen12 halaman4wre 6-10 Sew1x2267airportBelum ada peringkat

- Atos Industrial ValvesDokumen22 halamanAtos Industrial ValvesM S GokulBelum ada peringkat

- Series 10 Subplate Mounting ISO 4401-03 (CETOP 03) P Max: Bar Max (See Performances Table)Dokumen4 halamanSeries 10 Subplate Mounting ISO 4401-03 (CETOP 03) P Max: Bar Max (See Performances Table)chekit9Belum ada peringkat

- Valvulas Moog Hoja de DatosDokumen24 halamanValvulas Moog Hoja de DatosLuis Alberto RamosBelum ada peringkat

- 200711111524631291Dokumen16 halaman200711111524631291Navneet GuptaBelum ada peringkat

- Bul 36115 Servo Valve OperationDokumen12 halamanBul 36115 Servo Valve Operationrikkitech100% (1)

- TDV 100Dokumen6 halamanTDV 100林育豪Belum ada peringkat

- SDM 141 eDokumen28 halamanSDM 141 eseaqu3stBelum ada peringkat

- 62 SeriesDokumen8 halaman62 SeriesDevendra BangarBelum ada peringkat

- METALMECDokumen20 halamanMETALMECClayton PedroBelum ada peringkat

- Válvula Rexroth STW 0195 Size 6 - Papelera San FranciscoDokumen20 halamanVálvula Rexroth STW 0195 Size 6 - Papelera San FranciscoJose FloresBelum ada peringkat

- Denison Hydraulics Proportional Pressure Control Valves: Series P2 & 4VP01Dokumen12 halamanDenison Hydraulics Proportional Pressure Control Valves: Series P2 & 4VP01abuzer1981Belum ada peringkat

- Rexroth 92500Dokumen48 halamanRexroth 92500EVCY100% (1)

- 4/2-And 4/3 - Proportional Directional Valves Direct Operated, Type 4WRA, Series 1XDokumen8 halaman4/2-And 4/3 - Proportional Directional Valves Direct Operated, Type 4WRA, Series 1XlizbethdiosesBelum ada peringkat

- A6 VDokumen40 halamanA6 VWesame Shnoda100% (1)

- Re 29564Dokumen12 halamanRe 29564Ibrahim MoamenBelum ada peringkat

- NIMCO CV300newDokumen24 halamanNIMCO CV300newBruno SamaeianBelum ada peringkat

- All About HidrolicDokumen7 halamanAll About Hidrolicpiteng1945100% (3)

- 650 e Cr304 en Actuator-Technology-TurbomachineryDokumen12 halaman650 e Cr304 en Actuator-Technology-Turbomachinerybig_ss007Belum ada peringkat

- SDM140EDokumen36 halamanSDM140Eseaqu3stBelum ada peringkat

- ALISON HIDRAULIC - Catalogue PDFDokumen250 halamanALISON HIDRAULIC - Catalogue PDFbaba0% (1)

- PLL 2097Dokumen11 halamanPLL 2097Johnny Diaz VargasBelum ada peringkat

- Moog D633Dokumen16 halamanMoog D633Balu M100% (1)

- Proportional Reducing ValveDokumen8 halamanProportional Reducing ValvediabalziabBelum ada peringkat

- A10VSO18 Bomba HidraulicaDokumen16 halamanA10VSO18 Bomba HidraulicaGuilherme RodriguesBelum ada peringkat

- Hydraulic Directional Control and Check ValvesDokumen28 halamanHydraulic Directional Control and Check ValvestunradotBelum ada peringkat

- Accumulator Unloading Valve, Type MRQADokumen2 halamanAccumulator Unloading Valve, Type MRQALibinBelum ada peringkat

- 4/3 and 4/2 Directional Control Valves With Hand Lever Type WMMDokumen8 halaman4/3 and 4/2 Directional Control Valves With Hand Lever Type WMMAhmed Abd ElhakeemBelum ada peringkat

- Universal: Flow Monitor Installation and Maintenance Instructions For Vane and Piston Style Variable Area Flow MonitorsDokumen40 halamanUniversal: Flow Monitor Installation and Maintenance Instructions For Vane and Piston Style Variable Area Flow Monitors4lk0nBelum ada peringkat

- G761 SeriesDokumen8 halamanG761 SeriesDipti BhanjaBelum ada peringkat

- SDM 102 eDokumen24 halamanSDM 102 eseaqu3stBelum ada peringkat

- Atos HidraulicaDokumen8 halamanAtos HidraulicaFabinhoTowerBelum ada peringkat

- A11vo - Re 92 500 - PDFDokumen60 halamanA11vo - Re 92 500 - PDFSyed Azhar Hussain50% (2)

- VMCDokumen32 halamanVMCJoanaRicardo FigueiredoBelum ada peringkat

- Vickers DG4V-3 DG4V-3S 6xDokumen32 halamanVickers DG4V-3 DG4V-3S 6xCarlos Javier Torrico BarreroBelum ada peringkat

- SD 16 eDokumen20 halamanSD 16 eseaqu3stBelum ada peringkat

- D 631 Series ValvesDokumen12 halamanD 631 Series ValvesJosé OlaveBelum ada peringkat

- SDM 080 eDokumen28 halamanSDM 080 eseaqu3stBelum ada peringkat

- Measurements: CDG 11 CDG 16Dokumen4 halamanMeasurements: CDG 11 CDG 16girish1950% (2)

- Re92711 2012-01Dokumen48 halamanRe92711 2012-01Edson Huarachi FloresBelum ada peringkat

- Bom A4VG - REXROTHDokumen44 halamanBom A4VG - REXROTHnamduong368100% (4)

- Axial Variable Duoble PumpDokumen40 halamanAxial Variable Duoble Pumpveljeg100% (1)

- SD 6 eDokumen16 halamanSD 6 eseaqu3stBelum ada peringkat

- F001 AtosDokumen2 halamanF001 Atoschandushar1604Belum ada peringkat

- Servo Bending TPM Ra - 29646Dokumen10 halamanServo Bending TPM Ra - 29646Fajar Wahyu Nugroho JapraksBelum ada peringkat

- SD 18 eDokumen32 halamanSD 18 eseaqu3stBelum ada peringkat

- Rexroth电磁阀手册Dokumen12 halamanRexroth电磁阀手册davidwang85120% (1)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Dari EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Belum ada peringkat

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGDari EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGBelum ada peringkat

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Dari EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Penilaian: 2.5 dari 5 bintang2.5/5 (3)

- 110 Waveform Generator Projects for the Home ConstructorDari Everand110 Waveform Generator Projects for the Home ConstructorPenilaian: 4 dari 5 bintang4/5 (1)

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideDari EverandHydraulics and Pneumatics: A Technician's and Engineer's GuidePenilaian: 4 dari 5 bintang4/5 (8)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDari EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsBelum ada peringkat

- Prevention of Actuator Emissions in the Oil and Gas IndustryDari EverandPrevention of Actuator Emissions in the Oil and Gas IndustryBelum ada peringkat

- Compatibility For EMC, Climate and Mechanical LoadDokumen4 halamanCompatibility For EMC, Climate and Mechanical Loadback1949Belum ada peringkat

- How Natural Frequency Limits Frequency of Acceleration - Hydraulics & PneumaticsDokumen7 halamanHow Natural Frequency Limits Frequency of Acceleration - Hydraulics & Pneumaticsback1949Belum ada peringkat

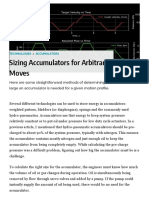

- Sizing Accumulators For Arbitrary Moves - Hydraulics & PneumaticsDokumen5 halamanSizing Accumulators For Arbitrary Moves - Hydraulics & Pneumaticsback1949100% (1)

- Controlling Hydraulic PressureDokumen6 halamanControlling Hydraulic Pressureback1949100% (1)

- B A C D: Quickstart BasicDokumen2 halamanB A C D: Quickstart Basicback1949Belum ada peringkat

- EibfiweubfDokumen19 halamanEibfiweubfNagesh DewanganBelum ada peringkat

- Quickstart Basic: QB100-4 Update 02-20Dokumen2 halamanQuickstart Basic: QB100-4 Update 02-20back1949Belum ada peringkat

- OPC UA TSN - A New Solution For Industrial CommunicationDokumen10 halamanOPC UA TSN - A New Solution For Industrial Communicationback1949Belum ada peringkat

- User Manual: M3000 Automation System MSC II (Moog Servo Controller)Dokumen148 halamanUser Manual: M3000 Automation System MSC II (Moog Servo Controller)back1949Belum ada peringkat

- ACOPOS P3配置解析及配置案例V0.00Dokumen16 halamanACOPOS P3配置解析及配置案例V0.00back1949Belum ada peringkat

- Load-Force-Adaptive Outlet Throttling - An Easily CommissionableDokumen13 halamanLoad-Force-Adaptive Outlet Throttling - An Easily Commissionableback1949Belum ada peringkat

- Electronification of Open Loop HydraulicsDokumen39 halamanElectronification of Open Loop Hydraulicsback1949100% (2)

- EibfiweubfDokumen19 halamanEibfiweubfNagesh DewanganBelum ada peringkat

- Nasa 2010 Iest MVFDokumen29 halamanNasa 2010 Iest MVFback1949Belum ada peringkat

- 智能科技改变机床生产格局Dokumen39 halaman智能科技改变机床生产格局back1949Belum ada peringkat

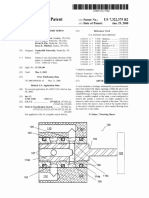

- US7322375Dokumen13 halamanUS7322375back1949Belum ada peringkat

- CasappaDokumen44 halamanCasappaback1949Belum ada peringkat

- Digital Hydraulic Valves Gaining Momentum: Newton, Ma-The Trend Toward De-Centralized Control On The Factory FloorDokumen2 halamanDigital Hydraulic Valves Gaining Momentum: Newton, Ma-The Trend Toward De-Centralized Control On The Factory Floorback1949100% (1)

- Yuken Newprodguide JC-10010-1Dokumen12 halamanYuken Newprodguide JC-10010-1back1949100% (1)

- 6 Costly Mistakes Most Hydraulics Users Make and How You Can Avoid Them!Dokumen6 halaman6 Costly Mistakes Most Hydraulics Users Make and How You Can Avoid Them!back1949Belum ada peringkat

- Industrial Hydraulic ValvesCat HY14 2500 DCVPCVServoElect 12 11Dokumen464 halamanIndustrial Hydraulic ValvesCat HY14 2500 DCVPCVServoElect 12 11back1949100% (1)

- Moog ServoValves Techn Look Overview enDokumen36 halamanMoog ServoValves Techn Look Overview enGonzalo Gutierrez100% (1)

- Fluid ContaminationDokumen4 halamanFluid Contaminationback1949Belum ada peringkat

- Rexroth and Atos Valve CompareDokumen7 halamanRexroth and Atos Valve Compareback1949Belum ada peringkat

- 高速机床跟随误差 PDFDokumen7 halaman高速机床跟随误差 PDFback1949Belum ada peringkat

- Servo Valves TechnicalDokumen24 halamanServo Valves Technicalobvert100% (2)

- QB300Dokumen2 halamanQB300back1949Belum ada peringkat

- United States Patent (10) Patent No.: US 6,367,365 B1: Weickert Et Al. (45) Date of Patent: Apr. 9, 2002Dokumen10 halamanUnited States Patent (10) Patent No.: US 6,367,365 B1: Weickert Et Al. (45) Date of Patent: Apr. 9, 2002back1949Belum ada peringkat

- F-35 Air Vehicle Technology Overview PDFDokumen28 halamanF-35 Air Vehicle Technology Overview PDFback1949Belum ada peringkat

- Vibration Analysis of The Crank-Link Mechanism of Reciprocating Bilge PumpsDokumen4 halamanVibration Analysis of The Crank-Link Mechanism of Reciprocating Bilge Pumpsback1949Belum ada peringkat

- Bearing Detail PDFDokumen1.152 halamanBearing Detail PDFJayesh MachhiBelum ada peringkat

- RISC Vs CISCDokumen13 halamanRISC Vs CISCBehin SamBelum ada peringkat

- SEPARATION THEORY - From Basic Separation To ALCAP SystemDokumen42 halamanSEPARATION THEORY - From Basic Separation To ALCAP SystemmgbouneBelum ada peringkat

- FM Approvals CN 1613Dokumen0 halamanFM Approvals CN 1613Marcelo PeixotoBelum ada peringkat

- Raman Spectroscopy SetupDokumen13 halamanRaman Spectroscopy SetupRafael RamosBelum ada peringkat

- Dji Phantom 4 RTK Book F-2Dokumen18 halamanDji Phantom 4 RTK Book F-2Liu Purnomo100% (1)

- Código BoogaDokumen138 halamanCódigo BoogaJazmin SeguelBelum ada peringkat

- 03 Transformers CT VTDokumen10 halaman03 Transformers CT VTEnrique G.Belum ada peringkat

- Bansilal Ramnath Agarwal Charitable Trust'sDokumen2 halamanBansilal Ramnath Agarwal Charitable Trust'sJennifer WaltonBelum ada peringkat

- 38 Meter Wind Turbine Blade Design PDFDokumen47 halaman38 Meter Wind Turbine Blade Design PDFWalid MohammedBelum ada peringkat

- Woodward 2301D ManualDokumen104 halamanWoodward 2301D ManualAbdul Samad MahmoodBelum ada peringkat

- Bomet CountyDokumen1 halamanBomet CountyPrince AliBelum ada peringkat

- Pyroelectric Array CameraDokumen7 halamanPyroelectric Array Cameraziggie_lenzBelum ada peringkat

- Projeto Experimental Fatorial para Aumentar A Produção de Metano Na Digestão de Resíduos LácteosDokumen7 halamanProjeto Experimental Fatorial para Aumentar A Produção de Metano Na Digestão de Resíduos LácteosLuís Paulo CardosoBelum ada peringkat

- Implementing Routing Facilities For Branch Offices and Mobile WorkersDokumen180 halamanImplementing Routing Facilities For Branch Offices and Mobile WorkersAlejandro Cordero OrdoñezBelum ada peringkat

- PR RTXDokumen27 halamanPR RTXletanbaospkt06100% (1)

- CH 19Dokumen147 halamanCH 19Kathy YellaBelum ada peringkat

- 3 Esrtos IntroDokumen8 halaman3 Esrtos IntroVijayaraghavan VBelum ada peringkat

- Foaming of Friction Stir Processed Al /mgco3 Precursor Via Ame HeatingDokumen27 halamanFoaming of Friction Stir Processed Al /mgco3 Precursor Via Ame HeatingArshad SiddiqueeBelum ada peringkat

- Architecture Concerns of TST and NATO TST ToolDokumen9 halamanArchitecture Concerns of TST and NATO TST Tooldorupara718747Belum ada peringkat

- PCTDS 027 Fendolite MII Cold Wet Weather ApplicationDokumen2 halamanPCTDS 027 Fendolite MII Cold Wet Weather ApplicationMohammed AhteshamBelum ada peringkat

- Unit 16Dokumen35 halamanUnit 16api-334267616Belum ada peringkat

- A340-Elec Emer ConfigDokumen13 halamanA340-Elec Emer ConfigGerhard StorbeckBelum ada peringkat

- Centum VPDokumen101 halamanCentum VPgopalBelum ada peringkat

- TSM SmokeDokumen2 halamanTSM SmokeSudin AmatyaBelum ada peringkat

- ESPRIT Milling Tutorial 02Dokumen11 halamanESPRIT Milling Tutorial 02Sandaruwan සුජීවBelum ada peringkat

- Standards of MeasurementDokumen12 halamanStandards of MeasurementShubham KheraBelum ada peringkat

- Maxstar140str (KK013519)Dokumen52 halamanMaxstar140str (KK013519)mrtans0% (1)

- MR ValvesDokumen56 halamanMR ValvesIdris SiddiquiBelum ada peringkat

- Legend:-: General Arrangement ACS550-124A-4 YN3A205086-GAADokumen12 halamanLegend:-: General Arrangement ACS550-124A-4 YN3A205086-GAANeeraj SharmaBelum ada peringkat