Order Information Sheet (OIS) : Insertion Air/Gas Mass Flow Meter

Diunggah oleh

jakkyjeryDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Order Information Sheet (OIS) : Insertion Air/Gas Mass Flow Meter

Diunggah oleh

jakkyjeryHak Cipta:

Format Tersedia

1755 La Costa Meadows Drive | San Marcos, California 92078 USA

760-744-6950 Toll Free (US): 800-854-1993 Fax: 760-736-6250

www.uidcomponents.com

Order Information Sheet (OIS)

ST100

Insertion Air/Gas Mass Flow Meter

INSTRUCTIONS: To order an ST100, please ll in each numbered block above by selecting required codes from the corresponding categories below. Use of any W or

*

codes requires prior approval

from FCI. For special data, documentation, test reports or required quality reports, refer to FCIs Engineering and Quality Assurance Order Information Sheets (OIS).

Flow Element (FE) Flow Transmitter (FT) Calibration General

ST100

-

0

-

E

- -

Block No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19

Table A Flange [ BLOCK 4 ]

CS

15

316L SS Hast C Material

D 1 C ANSI 1 inch 150 lb

E A G ANSI 1 inch 300 lb

F 2 H ANSI 1 1/2 inch 150 lb

K B J ANSI 1 1/2 inch 300 lb

P 3 M ANSI 2 inch 150 lb

R L N ANSI 2 inch 300 lb

T DIN DN25 PN40

V DIN DN40 PN40

6 DIN DN50 PN16

Y DIN DN50 PN40

W Agency appvd, custmr specd

Notes

1. Compression tting process connections not valid with 850 F [454 C] service. Process

connection (Block 3) must be xed type (Code Y or F) or retractable packing gland type.

Transmitter maximum temperature is 140 F [60 C]; remote mounting (Block 9, Code 2 or B)

and use of Teon jacketed cable (Block 10, Code 1, 2, 3 or 4) is recommended.

2. Teon packing material must be ordered when the process media is ozone, chlorine or

bromine. Contact FCI.

3. Teon ferrule maximum is 200 F [93 C], 150 psig [10 bar (g)]. Metal ferrule maximum is

500 F [260 C], 1000 psig [69 bar (g)].

4. S style sensor is retractable (will recess) into both 3/4 and 1 NPT. FP style sensor is

retractable (will recess) into 1 NPT only.

5. Minimum ange size is 1 1/2 or DN40.

6. Transmitter enclosure has four (4) conduit ports, NPT = 1/2 , metric = M20x1.5. Local

enclosure (attached to ow element) conduit ports vary by base model and process

connection selected:

Model Process Connection NPT Metric

ST100, ST100L, ST102 All, except with medium (2) 1/2 (2) M20x1.5

pressure packing gland

or stainless steel enclosure

ST100, ST102 With medium pressure packing gland (1) 1 (1) M20x1.5

and/or stainless steel enclosure

ST110, ST112, all STP All (1) 1 (1) M20x1.5

15. Cannot select carbon steel ange when Hastelloy type ow element is selected in Block 1.

17. Selection of medium pressure packing gland requires remote mount conguration.

Block 9 must be Code 2 or B.

Copyright 2011 Fluid Components International LLC. All rights reserved. Subject to change without notice. Order Information Sheet effective 10/2012 Doc. No. 01SA011470 B Page 1 of 2

Flow Element

Code [ BLOCK 1 ] Flow Element: Temperature Service,

Type and Materials of Construction

350F

[177C]

500F

[260C]

850F

[454C]

1 2 3

1

FPC style; 316L stainless steel

A B C

1

FPC style; Hastelloy C276

4 5 6

1

FP style; 316L stainless steel

D E F

1

FP style; Hastelloy C276

7 8 9

1

S style; 316L stainless steel

G H J

1

S style; Hastelloy C276

W W W

1

Agency approved, customer specied

* * *

Other, not agency approved

Code [ BLOCK 2 ]

0

Block 2 Code is always 0

Code Code [ BLOCKS 3-4 ]

Process Connections BLOCK 3 BLOCK 4

Compression Fitting, Teon Ferrule

3

C 0 3/4 inch, male NPT

4

D 0 1 inch, male NPT

4

G Table A Flange, tapped and threaded for 3/4 inch tting

15

Compression Fitting, Metal Ferrule

3

Metal ferrule permanent locks after tightening

M 0 3/4 inch, male NPT

4

N 0 1 inch, male NPT

4

J Table A Flange, tapped and threaded for 3/4 inch tting

15

Retractable Packing Gland, Low Pressure; 50 psig [3,5 bar (g)]

2

P 0 1 1/4 inch, male NPT; graphite packing

H 0 1 1/4 inch, male NPT; Teon packing

Q Table A Flange

5, 15

; graphite packing

K Table A Flange

5, 15

; Teon packing

Retractable Packing Gland, Medium Pressure; 500 psig [34 bar (g)]

2, 17

R 0 1 1/4 inch, male NPT; graphite packing

L 0 1 1/4 inch, male NPT; Teon packing

T Table A Flange

5, 15

; graphite packing

V Table A Flange

5, 15

; Teon packing

Fixed

Y 0 1 inch, male NPT

F Table A Flange

15

Other or Special

W W Agency approved, customer specied

* *

Other, not agency approved

Code Code Code [ BLOCKS 5-7 ]

Insertion Length BLOCK 5 BLOCK 6 BLOCK 7

0 6 0 Variable length: 1 inch to 6 inch [25 mm to 152 mm]

1 2 0 Variable length: 1 inch to 12 inch [25 mm to 305 mm]

2 1 0 Variable length: 1 inch to 21 inch [25 mm to 533 mm]

3 6 0 Variable length: 1 inch to 36 inch [25 mm to 914 mm]

6 0 0 Variable length: 1 inch to 60 inch [25 mm to 1524 mm]

.

Fixed length (required if Code Y or F in Block 3) or custom variable length;

specify reqd length to 0.1 inch E.g. 18 inches = 18.0, max. length is 99.9 inches

Code [ BLOCK 8 ] Pipe Mounting and Flow Direction

1 Horizontal, ow right-to-left or vertical up

2 Horizontal, ow left-to-right or vertical down

Transmitter and Electronics

Code [ BLOCK 9 ] Transmitter Mounting, Enclosure Material and Cable Entry Threading

1 Integral mount, aluminum; NPT cable entries

6

A Integral mount, aluminum; metric cable entries

6

2 Remote mount, aluminum; NPT cable entries

6

B Remote mount, aluminum; metric cable entries

6

3 Integral mount, stainless steel; NPT cable entries

6

C Integral mount, stainless steel; metric cable entries

6

4 Remote mount, stainless steel; NPT cable entries

6

D Remote mount, stainless steel; metric cable entries

6

W Agency approved, customer specied

*

Other, not agency approved

(continued next page)

Notes

7. Remote cable in an ST100 Series model is 8-conductor; remote cable in an STP100 Series

model is 10-conductor. For user-supplied cable, overall shielded conductor type is required

and wire resistance must be less than 8 Ohms.

8. Cable suitable for conduit and some cable gland systems. For other cable gland system

choices, see ST100 accessories list or contact FCI to supply separately. PVC cable

maximum temperature 176 F [80 C]; Teon cable maximum temperature 392 F [200 C].

9. No analog, frequency/pulse, relay outputs or other digital bus communications.

10. FCI standard conditions are 14.7 psia [1,01 bar(a)] and 70 F [21.1 C].

11. Calibration codes must be selected using FCIs proprietary AVAL application evaluation

software.

12. Transmitter setup, changes to factory supplied standard settings, verication or

modication to calibration parameters or diagnostics requires external source

communication with the transmitter.

13. Customer specied calibration must not exceed temperature and pressure limitations of

the ST100 Series product specications.

14. May specify up to three (3) additional calibrations for a total of ve (5). Contact FCI for

instructions on how to specify third, fourth and/or fth calibration.

16. ATEX/IECEx rated remote system requires use of ATEX/IECEx rated cabling and cable

gland. Must be user supplied or selected from ST100 accessories list, and ordered as

separate line items. Enter Code 0 in Block 10.

Copyright 2011 Fluid Components International LLC. All rights reserved. Subject to change without notice. Order Information Sheet effective 10/2012 Doc. No. 01SA011470 B Page 2 of 2

(continued from previous page)

Code [ BLOCK 10 ] Interconnecting Cable Length for Remote Conguration

0 Not required Specify with integral congurations, user supplied cable, or if cable ordered

as separate line item from ST100 series accessories

7, 16

A 10 feet [3 meters] PVC jacketed

8

B 25 feet [7,6 meters] PVC jacketed

8

C 50 feet [15 meters] PVC jacketed

8

D 100 feet [30 meters] PVC jacketed

8

1 10 feet [3 meters] Teon jacketed

8

2 25 feet [7,6 meters] Teon jacketed

8

3 50 feet [15 meters] Teon jacketed

8

4 100 feet [30 meters] Teon jacketed

8

*

For other lengths, armored type cable or cable glands, see accessories list and

order as a separate line item

Code [ BLOCK 11 ] Transmitter Power Supply and Display

A 24 Vdc power (19.2 Vdc to 28.8 Vdc); no digital display

B 24 Vdc power (19.2 Vdc to 28.8 Vdc); with display

C 85 Vac to 265 Vac power; no display

D 85 Vac to 265 Vac power; with digital display

Code [ BLOCK 12 ] Transmitter Outputs and Communications

1 (3) 4-20 mA outputs, one with HART; (1) frequency/pulse output

F FOUNDATION

eldbus H1

9

M Modbus 485

9

P PROFIBUS-PA

9

W Other

*

Other, not agency approved

Code [ BLOCK 13 ]

E Always E

Calibration

10, 11, 12

Code [ BLOCK 14 ] Calibration Application

Standard Calibration: General Purpose

A Air: 1.25 SFPS to 125 SFPS [0,4 NMPS to 38 NMPS]

D Compressed air: 6 SFPS to 600 SFPS [1,8 NMPS to 180 NMPS]

Custom Calibration: Calibration matched to user specied gas, ow range and conditions

B Air

C Specic gas equivalency (digester gas, ue gas, etc.)

E Nitrogen, helium, argon, CO

2

, compressed air, digester gas

F Hydrocarbons (natural gas, methane, ethane, propane, etc.)

G Hydrogen or hydrogen mixture

W

13

Agency approved, customer specied

Code [ BLOCK 15 ] Calibrations, Setup and Conditions

0 Standard

A Extended temperature compensation

B Extended range (> 100:1 turndown)

C Vortab (VEL, VFK, VIS, VMR or VSR)

1 Vortab (VIP)

D Flat velocity prole

E Extended temperature compensation and extended range

F Extended temperature compensation and Vortab (VEL, VFK, VIS, VMR or VSR)

2 Extended temperature compensation and Vortab (VIP)

G Extended temperature compensation and at velocity prole

H Extended range and Vortab (VEL, VFK, VIS, VMR or VSR)

3 Extended range and Vortab (VIP)

K Extended temperature compensation, extended range and Vortab

(VEL, VFK, VIS, VMR or VSR)

4 Extended temperature compensation, extended range and Vortab (VIP)

L Extended temperature compensation, extended range and at velocity prole

Code [ BLOCKS 16-17 ] Second Calibration

0 0 Not required

Select from Codes shown in Blocks 14-15

Code [ BLOCK 18 ] Additional Calibration Groups

0 Not required

X More than two calibrations

10, 11, 12, 14

S SR2x (split-range, double calibration points, max. 5% rdg accuracy See specications

General

Code [ BLOCK 19 ] Agency Approval

CE Mark always included

0 Not required

1 FM, FMc

3 ATEX, IECEx

16

*

Other Contact FCI for other approvals and conditions of use

Accessories

Part Number Description

022378-01 Sun Shield

Shades main transmitter, electronics, and/or display from direct sunlight;

316L stainless steel; attached directly to housing

Refer to separate ST100 Series Accessories List for a complete listing of all accessories such as

cabling, ball valves, documentation test and QA documents and certicates, and spare parts.

Copyright 2010 Fluid Components International LLC. All rights reserved. Subject to change without notice. Application Data Sheet effective 04/2011

Doc. No. 01SA011468A

1755 La Costa Meadows Drive

San Marcos, California 92078 USA

760-744-6950 / 800-854-1993 Fax: 760-736-6250

www.uidcomponents.com

Application Data Sheet (ADS)

ST100 Series

Insertion Air/Gas Mass Flow Meter

Customer Information

Customer Name: ____________________________________________________

Address: __________________________________________________________

___________________________________________________________________

Contact Name: ______________________________________________________

Phone: ____________________________ Fax: ___________________________

Email: ______________________________________________________________

P.O. No.: _____________________ Customer Order No.: ___________________

Model Number Ordered

Tag

Number

Instrument Details

Flow Element Mounting / Flow Direction

Transmitter Setup

Input Power:

c

115 Vac

c

230 Vac

c

24 Vdc

Analog Signal

Outputs

Parameter:

Eng. Units:

Zero Value:

Full Scale:

Output 1

4-20 mA

Output 2

4-20 mA

Output 3

4-20 mA

c

Flow (default)

c

Temperature

________________

4 mA = __________

20 mA = _________

c

Temp. (default)

c

Flow

________________

4 mA = __________

20 mA = _________

c

Flow (default)

c

Temperature

________________

4 mA = __________

20 mA = _________

3

Dual-Element: c ST1X2D c ST1X2E c ST1X2D c ST1X2E c ST1X2D c ST1X2E

Signal Output 4 Frequency/Pulse Output: c 0-1 kHz (default) c 0-10 kHz

Set as:

c

1 pulse per ow engineering unit

c

Full scale frequency output proportional to full scale ow rate

c

Other: ______________________________________________

Bus Communications I/O

Standard Temperature and Pressure

c 70 F and 14.7 psia [21,1 C and 1,013 bar(a)] is the factory calibration default for

standard temperature and pressure unless otherwise indicated below.

c 0 C and 1013,25 mBar (a)

Temperature Pressure

Other: ___________________________ ___________________________

Other Notes, Drawings or Details

Vortab: c Yes c No

Vortab Type: c VMR c VIS c VEL c VFK c VIP

Horizontal Pipe Vertical Pipe

c Horizontal pipe; side mount, ow left to right c Vertical pipe; ow up

c Horizontal pipe; side mount, ow right to left c Vertical pipe; ow down

c Horizontal pipe; top mount, ow left to right

c Horizontal pipe; top mount, ow right to left c Other: ______________

c HART (included with analog outputs) c FOUNDATION

eldbus H1 (no analog outputs)

c Modbus 485 (no analog outputs) c PROFIBUS PA (no analog outputs)

c Other: _________________________________________________________________

Process Details

1

If more than one (1) calibration is required (excluding VeriCal

), provide

Process Details for each calibration attach additional sheet(s) as needed.

2

For all dual-element discrete type models, provide Process Details for both main

(ST1X2D) and second (ST1X2E) element; for analog outputs, also specify which

outputs to assign to each element

3

.

Application Description

Describe type of application (example: are, digester gas, aeration line, etc.) :

___________________________________________________________________

Process Media

Include gas name and percent composition by volume (moles) or weight (mass).

Please attach a gas composition list or ll in composition below. Total composi-

tion must add up to 100%.

Gas Components: c % Volume (moles) c % Weight (mass)

_______________________________________________ _____________ %

_______________________________________________ _____________ %

_______________________________________________ _____________ %

_______________________________________________ _____________ %

_______________________________________________ _____________ %

_______________________________________________ _____________ %

_______________________________________________ _____________ %

Process Conditions

Normal Minimum Maximum Engineering Units

Flow Rate: _________ _________ _________ _________________

Temperature: _________ _________ _________ _________________

Pressure: _________ _________ _________ _________________

Required Dimensions (Include units of measure inches, mm, etc.)

1. Pipe Size: or Duct Size:

a) Outside Diameter: __________________ Height: _______________________

b) Inside Diameter: ____________________ Width: _______________________

2. Length of mounting adapter/coupling from outside pipe surface: _____________

3. Length of straight-run available: ______________________________________

4. Describe nearest upstream and downstream disturbance:

a) Upstream: __________________________________

b) Downstream: ________________________________

Other notes about installation:

____________________________________________________________________

Single-Point

c ST100 - - - -

c ST100L - - - -

c ST110 - - - -

Dual-Element

2

c ST1 2A - 0 - - -

c ST1 2D - 0 - - -

c ST1 2E - 0 0 0 - - -

Calibration

1

Anda mungkin juga menyukai

- En 09 14 Eng Rev.4 Servo Gauge 854 AtgDokumen6 halamanEn 09 14 Eng Rev.4 Servo Gauge 854 AtgTrịnh Đức HạnhBelum ada peringkat

- 3051CDokumen5 halaman3051CAntonio FloresBelum ada peringkat

- Schrack Relay ENG DS RT1 1014Dokumen4 halamanSchrack Relay ENG DS RT1 1014muhamad.badar9285Belum ada peringkat

- Type 1510 Electric Level Switch 498Dokumen3 halamanType 1510 Electric Level Switch 498lilygarciaoBelum ada peringkat

- Mag 1100 DataDokumen7 halamanMag 1100 DataAndresRojasBelum ada peringkat

- NEW HK7 Series Smart Pressure Transmitters Datasheet HOLYKELLDokumen8 halamanNEW HK7 Series Smart Pressure Transmitters Datasheet HOLYKELLRsl AliBelum ada peringkat

- DS6213 Standard EU enDokumen5 halamanDS6213 Standard EU enwinwin2302Belum ada peringkat

- Schrack RelayDokumen4 halamanSchrack RelaydadddooooBelum ada peringkat

- Local Solutions For Individual Customers Worldwide: Accumulators & AccessoriesDokumen20 halamanLocal Solutions For Individual Customers Worldwide: Accumulators & Accessoriesamjed_de_enimBelum ada peringkat

- Brooks Mass Flow Meters and Controllers: MODEL 5850TRDokumen4 halamanBrooks Mass Flow Meters and Controllers: MODEL 5850TRajinkyaBelum ada peringkat

- Opti Flux 4000 Spec SheetDokumen8 halamanOpti Flux 4000 Spec SheetAhmad Adel El TantawyBelum ada peringkat

- Principle of Operation: Target Inline FlowmeterDokumen7 halamanPrinciple of Operation: Target Inline Flowmeterابزار دقیقBelum ada peringkat

- 100 Series PyroDokumen8 halaman100 Series PyroomkarvadlooriBelum ada peringkat

- 2100 Rev H English ManualDokumen2 halaman2100 Rev H English ManualJuan HernándezBelum ada peringkat

- Excess Flow Valves Bleed Valves and Purge ValvesDokumen6 halamanExcess Flow Valves Bleed Valves and Purge ValvesNilesh MistryBelum ada peringkat

- Spirax Sarco BTM-7Dokumen3 halamanSpirax Sarco BTM-7Bambang Agung LaxmonoBelum ada peringkat

- PB TW10 GBDokumen6 halamanPB TW10 GBfebri_bontangBelum ada peringkat

- 60 Series Tube Fittings and TubingDokumen5 halaman60 Series Tube Fittings and TubingNilesh MistryBelum ada peringkat

- Cameron Model 1510 Side Mounted Level Switch Technical Data SheetDokumen4 halamanCameron Model 1510 Side Mounted Level Switch Technical Data SheetDineshBelum ada peringkat

- Welding Procedure SpecificationDokumen5 halamanWelding Procedure SpecificationFranklin londono0% (1)

- PL 008748Dokumen10 halamanPL 008748ronaldxmenBelum ada peringkat

- Agar Id200spec PDFDokumen2 halamanAgar Id200spec PDFJADBelum ada peringkat

- Eng SS 114-2157 GDokumen14 halamanEng SS 114-2157 Gsav33Belum ada peringkat

- DS 0330 Data Sheet Solenoide ValveDokumen5 halamanDS 0330 Data Sheet Solenoide ValvetueresuecoBelum ada peringkat

- Sonda AmetekDokumen4 halamanSonda Ametekeduardo2Belum ada peringkat

- 7827 Digital enDokumen4 halaman7827 Digital enFrancisco Cardenas QBelum ada peringkat

- Technical Specification of Transmitters: F:/Projects/Hpld/Ao - New/Datasheet/TransmitrsDokumen2 halamanTechnical Specification of Transmitters: F:/Projects/Hpld/Ao - New/Datasheet/Transmitrssushant_jhawerBelum ada peringkat

- 3051 SMVDokumen6 halaman3051 SMVUmar SaeedBelum ada peringkat

- 5 Clamps Connectors 220 400kv SsDokumen12 halaman5 Clamps Connectors 220 400kv SsJaswanth SaiBelum ada peringkat

- Diapham Valve PDFDokumen8 halamanDiapham Valve PDFthouche007Belum ada peringkat

- Hydraulic Tubes and PipesDokumen18 halamanHydraulic Tubes and Pipeshp_vijaykBelum ada peringkat

- NCR - SampleDokumen7 halamanNCR - SamplecamycaxBelum ada peringkat

- ENG CS 1307191 SMA Connectors 0307Dokumen24 halamanENG CS 1307191 SMA Connectors 0307Rodolfo Salazar GuerreroBelum ada peringkat

- 1510 Side Mounted Level Switch Cat498Dokumen4 halaman1510 Side Mounted Level Switch Cat498thotalnBelum ada peringkat

- Polyethylene Gas Pipe 2007Dokumen10 halamanPolyethylene Gas Pipe 2007asgharkhanBelum ada peringkat

- Electro Válvula Del CompresorDokumen4 halamanElectro Válvula Del CompresorneumaticoBelum ada peringkat

- FLR DDokumen3 halamanFLR DCharly ColumbBelum ada peringkat

- For Harsh and Hazardous Locations: Exe EnclosuresDokumen79 halamanFor Harsh and Hazardous Locations: Exe EnclosuresSimon LyonBelum ada peringkat

- Rociadores STD TycoDokumen86 halamanRociadores STD TycoIvAldreteBelum ada peringkat

- Krohne OPTIFLUX 2000Dokumen16 halamanKrohne OPTIFLUX 2000Anonymous 1LgoS05gvlBelum ada peringkat

- Manual Ecoflux en - KrohneDokumen14 halamanManual Ecoflux en - Krohnemmihai_popa2006Belum ada peringkat

- Viking Extended Coverage Quick Respons SidewallDokumen6 halamanViking Extended Coverage Quick Respons SidewallguspriyBelum ada peringkat

- Datasheet Pressure Limiting Valve pl02Dokumen2 halamanDatasheet Pressure Limiting Valve pl02D. Thanh NguyễnBelum ada peringkat

- Pgi M 675 M 775 M 678 GS 3Dokumen6 halamanPgi M 675 M 775 M 678 GS 3Juan Carlos Enríquez BarragánBelum ada peringkat

- Breather/Drain Plugs: SeriesDokumen1 halamanBreather/Drain Plugs: SeriesGolfkung PairojBelum ada peringkat

- Dezurik 100 Port Eccentric Plug Valves Pef Technical 12-60-1bDokumen24 halamanDezurik 100 Port Eccentric Plug Valves Pef Technical 12-60-1bjasonlaiymBelum ada peringkat

- Magnetic Level Gauge K-TEK Products: KM26S Standardized Configuration GuideDokumen23 halamanMagnetic Level Gauge K-TEK Products: KM26S Standardized Configuration Guidecafe negroBelum ada peringkat

- Pune Techtrol FGTDokumen2 halamanPune Techtrol FGTBenjamin StricklandBelum ada peringkat

- DB 698 GBDokumen8 halamanDB 698 GBDenial BasanovicBelum ada peringkat

- "MPF" Modular Pressure Transmitter: ApplicationsDokumen4 halaman"MPF" Modular Pressure Transmitter: Applicationsgrincheu70Belum ada peringkat

- Trampa Socket WeldDokumen2 halamanTrampa Socket WeldOscar Nieves ZamoraBelum ada peringkat

- How to prepare Welding Procedures for Oil & Gas PipelinesDari EverandHow to prepare Welding Procedures for Oil & Gas PipelinesPenilaian: 5 dari 5 bintang5/5 (1)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDari EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsPenilaian: 4.5 dari 5 bintang4.5/5 (10)

- All-in-One Manual of Industrial Piping Practice and MaintenanceDari EverandAll-in-One Manual of Industrial Piping Practice and MaintenancePenilaian: 5 dari 5 bintang5/5 (1)

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryDari EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryBelum ada peringkat

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerDari EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerPenilaian: 5 dari 5 bintang5/5 (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDari EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsBelum ada peringkat

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1Dari EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Penilaian: 3.5 dari 5 bintang3.5/5 (3)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsDari Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsPenilaian: 4 dari 5 bintang4/5 (1)

- ABB Laser Application Form VM3DDokumen4 halamanABB Laser Application Form VM3DjakkyjeryBelum ada peringkat

- Maintenance Schedule ACS800 2017 and Onwards Rev ADokumen2 halamanMaintenance Schedule ACS800 2017 and Onwards Rev AjakkyjeryBelum ada peringkat

- Section08 A4 PDFDokumen808 halamanSection08 A4 PDFjakkyjeryBelum ada peringkat

- ACS800 Portfolio PresentationDokumen80 halamanACS800 Portfolio Presentationjakkyjery100% (1)

- ST100 Series Brochure RevCDokumen20 halamanST100 Series Brochure RevCjakkyjeryBelum ada peringkat

- ST75-Brochure-RevJ (2011)Dokumen11 halamanST75-Brochure-RevJ (2011)jakkyjeryBelum ada peringkat

- ST51 Data Sheet RevCDokumen2 halamanST51 Data Sheet RevCjakkyjeryBelum ada peringkat

- Fci ST98 - ImDokumen70 halamanFci ST98 - ImjakkyjeryBelum ada peringkat

- GF Brochure RevL VeriCal RevCDokumen6 halamanGF Brochure RevL VeriCal RevCjakkyjeryBelum ada peringkat

- To Be Completed By: Name Deadline: Date To-Do List: Done? FCIDokumen4 halamanTo Be Completed By: Name Deadline: Date To-Do List: Done? FCIjakkyjeryBelum ada peringkat

- TA6000 Manual PDFDokumen138 halamanTA6000 Manual PDFLongTuanBelum ada peringkat

- Pages From B1-20-1 - 2013 PDFDokumen3 halamanPages From B1-20-1 - 2013 PDFAhmad Jukliv Pandu YoedhawanBelum ada peringkat

- Alwitco Parts CatalogueDokumen24 halamanAlwitco Parts CataloguemuppetscrapBelum ada peringkat

- 3000 FittingsDokumen4 halaman3000 FittingsAbbas RizviBelum ada peringkat

- 02 CylinderAndServiceValvesDokumen9 halaman02 CylinderAndServiceValvesSan CandyBelum ada peringkat

- Thread Rolling Solutions BasicsDokumen20 halamanThread Rolling Solutions Basicsanon_517822417Belum ada peringkat

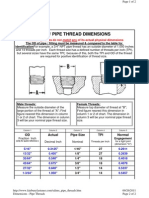

- Pipe Thread Primer - Why Is LeakingDokumen5 halamanPipe Thread Primer - Why Is LeakingCarlos Cesar FerranteBelum ada peringkat

- Raxton Eexd and Eexe Breather Drain PlugsDokumen2 halamanRaxton Eexd and Eexe Breather Drain PlugsbigjunkaccountBelum ada peringkat

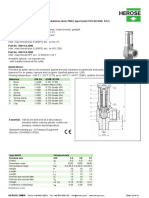

- SA1-A SA25-A: Type 4 Type 4 Flap-ValveDokumen2 halamanSA1-A SA25-A: Type 4 Type 4 Flap-Valvemperez352Belum ada peringkat

- Technical Information HANSA-FLEX Hose ConnectionsDokumen75 halamanTechnical Information HANSA-FLEX Hose ConnectionshorsanicuBelum ada peringkat

- Productcatalog King Oil ToolDokumen48 halamanProductcatalog King Oil ToolJhon CastRo0% (1)

- OEM - SITEK - SMT - MultifunctionManifold 0122 (Dokumen2 halamanOEM - SITEK - SMT - MultifunctionManifold 0122 (ChangHuiChuanBelum ada peringkat

- Instruction Manual Fisher 377 Trip Valve en 125040Dokumen20 halamanInstruction Manual Fisher 377 Trip Valve en 125040Faisal AmarBelum ada peringkat

- Uni-Directional and Bi-Directional Ranges: PX2300 SeriesDokumen1 halamanUni-Directional and Bi-Directional Ranges: PX2300 SeriesASIM RIAZBelum ada peringkat

- Quick Reference Guide For ValvesDokumen1 halamanQuick Reference Guide For ValvesEjaz Ahmed RanaBelum ada peringkat

- Pièces de Rechange Spare Parts List Ersatzteilliste Catalogo Pezzi Di RicambioDokumen48 halamanPièces de Rechange Spare Parts List Ersatzteilliste Catalogo Pezzi Di RicambioFernando FerrandoBelum ada peringkat

- Manual Despiece 2044 - InGLESDokumen221 halamanManual Despiece 2044 - InGLESMario Eduardo FernandezBelum ada peringkat

- HydroMax Weld NippleDokumen12 halamanHydroMax Weld NippleAyman AlhalfawyBelum ada peringkat

- Swivel King Oil ToolsDokumen48 halamanSwivel King Oil ToolsLuis Aparcana100% (1)

- Catalog 21Dokumen77 halamanCatalog 21tasingenieriaBelum ada peringkat

- Quick Connect QC, QF, QM & QTM Series (MS-01-138) R5Dokumen12 halamanQuick Connect QC, QF, QM & QTM Series (MS-01-138) R5herysyam1980Belum ada peringkat

- SHURflo 8000seriesDokumen8 halamanSHURflo 8000seriesab5951Belum ada peringkat

- Multi-Port Gauge Valves - M5 and M51Dokumen8 halamanMulti-Port Gauge Valves - M5 and M51Game AnimeBelum ada peringkat

- Nato Type Camlock Fittings: July 2008Dokumen12 halamanNato Type Camlock Fittings: July 2008Rockny310Belum ada peringkat

- Accessories For Lubrication Systems: Product CatalogueDokumen28 halamanAccessories For Lubrication Systems: Product CatalogueArtemBelum ada peringkat

- Piping Engineering Note Nitrogen Purge SystemDokumen20 halamanPiping Engineering Note Nitrogen Purge SystemchrysanthiiiiiiBelum ada peringkat

- Pyrogen - Delay Ejection Device: Written By: R.A.NakkaDokumen12 halamanPyrogen - Delay Ejection Device: Written By: R.A.NakkamysabetBelum ada peringkat

- Flexnet Product-Sheet Final2022Dokumen13 halamanFlexnet Product-Sheet Final2022Tahir FadhilBelum ada peringkat

- Xdims Pipe ThreadsDokumen2 halamanXdims Pipe ThreadsamevaluacionesBelum ada peringkat

- Typ 06011 1 enDokumen2 halamanTyp 06011 1 enMohamed RaafatBelum ada peringkat