Effect of Approching Temperature On The Performance and Size of Libr-Water Vapour Absorption Refrigeration in The Absence of Solution Heat Exchanger

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Effect of Approching Temperature On The Performance and Size of Libr-Water Vapour Absorption Refrigeration in The Absence of Solution Heat Exchanger

Hak Cipta:

Format Tersedia

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

__________________________________________________________________________________________

Volume: 03 Special Issue: 03 | May-2014 | NCRIET-2014, Available @ http://www.ijret.org 704

EFFECT OF APPROCHING TEMPERATURE ON THE PERFORMANCE

AND SIZE OF LiBr-WATER VAPOUR ABSORPTION REFRIGERATION

IN THE ABSENCE OF SOLUTION HEAT EXCHANGER

Sunil.B.S

1

, Manu S

2

, C.V.Mahesh

3

,

T.K.Chandrashekar

4

1

M.Tech, 4

th

sem Mechanical Engineering, SSIT, Tumkur.

2

Assistant Professor, Department of Mechanical Engineering, SSIT, Tumkur

3

Professor, Department of Mechanical Engineering, SSIT, Tumkur

4

Professor, Department of Mechanical Engineering, MIT, Moodabidri

Abstract

In this study, a detailed thermodynamic analysis of the water/lithium bromide absorption refrigeration cycle is performed. The

influences of approaching temperatures, conductance and coefficients of performance are investigated. Plots of coefficients of

performance and conductance are shown against approaching temperatures of the system. It is concluded that the performance and

conductance decreases with increase in approaching temperature of all the components.

Keywords: Refrigeration, Absorption, Water/Lithium bromide.

----------------------------------------------------------------------***------------------------------------------------------------------------

1. INTRODUCTION

During the recent years research has attempted to develop new

technologies that can reduces energy consumption and cost

without decreasing the level of comforts. By this reason

absorption refrigeration technologies has greater advantages

compared to conventional refrigeration systems because the

system utilises waste heat and it is friendly with environment.

Among different combination of refrigerant and absorbent,

Lithium Bromide Water (LiBr-H

2

O) showed the promising

solution for effective ultisation of waste heat and zero

determental effect on the atmospher since it uses water has

refrigerant and Lithium-Bromide solution as absorbent

Number of research has been carried out to enhance the

performance of the system and reduce the size of the system.

A.Kececiler et al. [1] conducted experiments in laboratory on

LiBr H2O system which uses low temperature geothermal

energy as a powering source. The result showed that, low-heat

geothermal sources cannot be used efficiently in electricity

generation and effective for the storing range at 4-10C. Da-

Wen Sun [2] performed simulation on LiBr H2O absorption

refrigeration systems. The simulation provides the detailed

thermodynamic design data and optimum design map and also

for new absorbent/refrigeration pairs. O. Kaynakli et al. [3]

investigated the effect of operating temperature on the

performance of single effect LiBr H2O absorption

refrigeration cycle. The result showed that as the generator

and evaporator temperature increases there is a drastic

increase of COP (Coefficient of Performance) but decreases

with rise of condenser and absorber temperatures. M.

Izquierdo et al. [4] performed trials to investigate the

performance of a commercial 4.5 kW air cooled, single effect

LiBr H2O absorption chillier which is used for residential.

The result showed as the cooling power tends to decreases

with increase of outdoor dry bulb temperature and for the

temperature ranges of 35 to 41.3C but the chilled water outlet

temperature of evaporator peaks to 15C. Mostafavi and

Agnew [5] investigated the effect of ambient temperature on

the surface area of the component of an air-cooled absorption

machine. The objective of the study to investigate the effect of

approaching temperature on the performance of single stage

water cooled LiBrwater absorption machine. The theoretical

simulation is performed using MAT lab Software for the

capacity of 0.5kW.

1.1 Approaching Temperature

The approaching temperature refers to the maximum heat

transfer for hot body to the cold body. If the approaching

temperature is less then greater is the heat transfer. This

approaching temperature play key role on the performance of

the system because the system is cooled by the water and

refrigeration effect is aborbed by the chilled water. There are

mainly four approaching temperatures comes in the system

and they are as follows:-Approaching absorber temperature

(DTa). It is the temperature difference between T12 and T15,

Approaching evaporator temperature (DTe), It is the

temperature difference between T16and T1, Approaching

generator temperature (DTg), It is the temperature difference

between T10 and T7.Approaching Condenser temperature

(DTc), It is the temperature difference between T14 and T13.

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

__________________________________________________________________________________________

Volume: 03 Special Issue: 03 | May-2014 | NCRIET-2014, Available @ http://www.ijret.org 705

1.2 Circulation Ratio

The circulation ratio (CR) can be defined as the ratio of the

mass flow rate of the solution coming from the generator to

the absorber to the mass flow rate of the working fluid.

CR =

m

s

m

H

2

o

2. VAPOUR ABSORPTION REFRIGERATION

(VAR) SYSTEM

.

Fig-1: Schematic diagram of LiBr-H

2

O vapour absorption

refrigeration cycle

The refrigerant is vaporized in the evaporator after taking heat

from the water. It is then sent to the absorber where the

refrigerant vapours get condensed. During the process, latent

heat liberated during condensation of refrigerant vapours is

taken by the cooling water in absorber. The weak solution

coming from absorber and rich in refrigerant concentration is

pressurized through pump upto generator pressure where it is

heated to give off refrigerant vapour, forming strong

concentration refrigerant solution. This strong concentration

refrigerant solution then returns to absorber and mixes with

refrigerant vapours coming from evaporator, forming a strong

concentration refrigerant solution which is then re-circulated

in the circuit. The refrigerant vapours are condensed in the

condenser liberating heat of condensation. Throttle valve and

expansion valve are used to reduce the pressure of poor

concentration refrigerant solution and refrigerant coming out

from condenser to absorber and evaporator pressure

respectively. The heat is supplied to the generator by hot

water. The heat rejected in the condenser is passed to the

circulating cold water.

3. RESULTS AND DISCUSSION

3.1 Effect of Approaching Condenser Temperature

Fig-2(a) and (b) shows the variation of condenser approaching

temperature on the performance of the system and the

conductance. The simulation was performed by varying

condenser approaching temperatures for

DTa=DTg=DTe=5C. The Fig 2(a), (b) shows an approaching

temperature of condenser increases there is a decrease in the

performance and conductance of the condenser. This is due to

decrease in the heat transfer rate to the cooling water resulting

in decrease in the condensate rate this reduces the performance

of the system. Decreasing in the conductance of the condenser

is due increase in the condenser temperature.

0 1 2 3 4 5

0.46

0.48

0.50

0.52

0.54

0.56

0.58

0.60

0.62

0.64

0.66

P

e

r

f

o

r

m

a

n

c

e

Approach Condenser Temperature (DTc) (

O

C)

COP

Fig-2(a): Condenser approaching temperature

Vs. Variation of performance

0 1 2 3 4 5

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

C

o

n

d

u

c

t

a

n

c

e

(

W

K

-

1

)

Approach Condenser Temperature (DTc) (

O

C)

UAa

UAc

UAe

UAg

Fig- 2(b): Condenser approaching

temperature Vs. Conductance

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

__________________________________________________________________________________________

Volume: 03 Special Issue: 03 | May-2014 | NCRIET-2014, Available @ http://www.ijret.org 706

3.2 Effect of Approaching Evaporator Temperature

Fig-3(a) and (b) shows the variation of evaporator

approaching temperature on the performance of the system

and the conductance. The simulation was performed by

varying evaporator approaching temperatures for

DTa=DTg=DTc=5C.The Fig-3(a) and (b) shows an

approaching temperature of evaporator increases there is a

decrease in the performance and conductance of the

evaporator. This is due to decrease in the heat transfer rate to

the water resulting in decrease in the evaporation rate of

refrigerant resulted in reduction in the performance of the

system. Decreasing in the conductance of the evaporator is

due increase in the evaporator temperature.

3.3 Effect of Approaching Generator Temperature

Fig-4(a) and (b) shows the variation of generator approaching

temperature on the performance of the system and the

conductance. The simulation was performed by varying

generator approaching temperatures for DTa=DTe=DTc=5C.

The Fig 4(a) and (b) shows an approaching temperature of

generator increases there is a decrease in the performance and

conductance of the generator. This is due to decrease in the

heat transfer rate to the cooling water resulting in decrease in

the generation rate of refrigerant this reduces the performance

of the system. There is a drastic decreasing in the conductance

of the generator is due increase in the generator temperature.

3.4 Effect of Approaching Absorber Temperature

Fig-4(a) and (b) shows the variation of absorber approaching

temperature on the performance of the system and the

conductance. The simulation was performed by varying

absorber approaching temperatures for DTe=DTg=DTc=5C.

The Fig 4(a) and (b) shows an approaching temperature of

absorber increases there is a decrease in the performance and

conductance of the absorber. This is due to decrease in the

heat transfer rate to the cooling water resulting in decrease in

the circulation rate this reduces the performance of the system.

Fig-4(a): Generator approaching temperature Vs.

Variation of performance

0 1 2 3 4 5

0.778

0.780

0.782

0.784

0.786

P

e

r

f

o

r

r

m

a

n

c

e

Approach Generator Temperature (DTg) (

O

C)

COP

0 1 2 3 4 5

0.65

0.70

0.75

0.80

0.85

P

e

r

f

o

r

r

m

a

n

c

e

Approach Evaporator Temperature (DTe) (

O

C)

COP

Fig-3(a): Evaporator approaching temperature

Vs. Variation of performance

0 1 2 3 4 5

0.2

0.4

0.6

0.8

1.0

1.2

C

o

n

d

u

c

t

a

n

c

e

(

W

K

-

1

)

Approach Evaporator Temperature (DTe) (

O

C)

UAa

UAc

UAe

UAg

Fig- 3(b): Evaporator approaching temperature

Vs. Conductance

Fig- 4(b): Generator approaching temperature

Vs. Conductance

0 1 2 3 4 5

0

1

2

3

4

5

6

C

o

n

d

u

c

t

a

n

c

e

(

W

K

- 1

)

Approach Generator Temperature (DTg) (

O

C)

UAa

UAc

UAe

UAg

Fig-5(a): Absorber approaching temperature Vs.

Variation of performance

(DTg=DTe=DTc=5C)

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

__________________________________________________________________________________________

Volume: 03 Special Issue: 03 | May-2014 | NCRIET-2014, Available @ http://www.ijret.org 707

There is a low decreasing in the conductance of the absorber is

due increase in the absorber temperature.

4. CONCLUSIONS

The theoretical simulation was performed on single effect

water cooled vapour absorption refrigeration. The simulation

is carried on MAT Lab software by varying approaching

temperature. The paper concludes that as approaching

temperature increases in condenser, evaporator, absorber,

generator there is a decrease in the performance and

conductance.

REFERENCES

[1] Kececiler, A., H.I. Acar, and A. Dogan,

Thermodynamic analysis of the absorption refrigeration

system with geothermal energy: an experimental study.

Energy Conversion and Management, 41(1): p. 37-48,

2000.

[2] Sun, D.-W., Thermodynamic design data and optimum

design maps for absorption refrigeration systems.

Applied Thermal Engineering, 17(3): p. 211-221, 1997.

[3] Kaynakli, O. and M. Kilic, Theoretical study on the

effect of operating conditions on performance of

absorption refrigeration system. Energy Conversion

and Management, 48(2): p. 599-607, 2007.

[4] Izquierdo, M., et al., Air conditioning using an air-

cooled single effect lithium bromide absorption chiller:

Results of a trial conducted in Madrid in August 2005.

Applied Thermal Engineering, 28(8-9): p. 1074-1081,

2008.

[5] T Mostafavi, M. and B. Agnew, The impact of

ambient temperature on lithium-bromide/water

absorption machine performance. Applied Thermal

Engineering, 16(6): p. 515-522, 1996.

0 1 2 3 4 5

0.15

0.20

0.25

0.30

0.35

0.40

0.45

0.50

0.55

0.60

C

o

n

d

u

c

t

a

n

c

e

(

W

K

-

1

)

Approach Absorber Temperature (DTa) (

O

C)

UAa

UAc

UAe

UAg

Fig- 5 (b): Absorber approaching temperature Vs.

Conductance

0 1 2 3 4 5

0.775

0.780

0.785

0.790

0.795

0.800

0.805

0.810

0.815

P

e

r

f

o

r

m

a

n

c

e

Approach Absorber Temperature (DTa) (

O

C)

COP

Fig-5(a): Absorber approaching temperature Vs.

Variation of performance

(DTg=DTe=DTc=5C)

Anda mungkin juga menyukai

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5795)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Direct Stiffness Method: BreakdownDokumen11 halamanThe Direct Stiffness Method: BreakdownShubhankar BhowmickBelum ada peringkat

- 51CBC Palestra PeterMartiDokumen28 halaman51CBC Palestra PeterMartimendoncajamBelum ada peringkat

- Seminar ReportDokumen19 halamanSeminar ReportAjit8675100% (7)

- 973-SF Analyzer: Laboratory Precision - Field ReadyDokumen4 halaman973-SF Analyzer: Laboratory Precision - Field ReadymersiumBelum ada peringkat

- En - 1999 01 07 - T - WL 21507 Ea Srbs in Polysius Vertical Roller Mill QuadropolDokumen2 halamanEn - 1999 01 07 - T - WL 21507 Ea Srbs in Polysius Vertical Roller Mill QuadropolmiteshmechBelum ada peringkat

- Geotechnical Engineering - I PDFDokumen3 halamanGeotechnical Engineering - I PDFSunny PrajapatiBelum ada peringkat

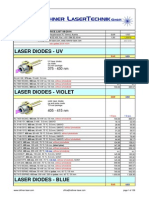

- PricelistDokumen136 halamanPricelistCervantesquijoteBelum ada peringkat

- LevellingDokumen15 halamanLevellingpushpakbhawgati27Belum ada peringkat

- Soil Model Okt 2010Dokumen22 halamanSoil Model Okt 2010HawaiiChongBelum ada peringkat

- Vray Caustic Ice Cube Tutorial PDFDokumen4 halamanVray Caustic Ice Cube Tutorial PDFandihernanBelum ada peringkat

- 3rd Q Science 2022-2023Dokumen2 halaman3rd Q Science 2022-2023Richard CruzBelum ada peringkat

- Boiler Book PDFDokumen44 halamanBoiler Book PDFmpgzyah100% (5)

- TUBE Bending FormulasDokumen3 halamanTUBE Bending FormulasPavan BhadarkaBelum ada peringkat

- Cool Machines CV Series Insulation Removal VacuumDokumen3 halamanCool Machines CV Series Insulation Removal Vacuumbrooklynarmstrong487Belum ada peringkat

- Chapter 07Dokumen35 halamanChapter 07Hassan SaeedBelum ada peringkat

- Extra High Strength Steels - Strenx vs. HardoxDokumen1 halamanExtra High Strength Steels - Strenx vs. Hardoxdavid blecicBelum ada peringkat

- 3..oil Field TubularsDokumen32 halaman3..oil Field TubularsDarshan SharmaBelum ada peringkat

- ISO-8573!3!1999 - Métodos de Prueba - HumedadDokumen4 halamanISO-8573!3!1999 - Métodos de Prueba - Humedadj_jjerfBelum ada peringkat

- Cylinder SequencingDokumen21 halamanCylinder Sequencingjoshi vivek0% (1)

- Literature ReviewDokumen32 halamanLiterature ReviewMathew Sebastian100% (6)

- Assignment1 KineticsDokumen2 halamanAssignment1 KineticsVishal HBelum ada peringkat

- Au2-13, Deka2008Dokumen11 halamanAu2-13, Deka2008ht117Belum ada peringkat

- Foundation Science For EngineersDokumen7 halamanFoundation Science For EngineersZaid HadiBelum ada peringkat

- 10 IGCSE Physics Study Stack - Forces & MotionDokumen4 halaman10 IGCSE Physics Study Stack - Forces & MotionpixelhoboBelum ada peringkat

- Grid Aquagen Pro Brochure enDokumen6 halamanGrid Aquagen Pro Brochure enNguyễn Anh DanhBelum ada peringkat

- Physics Investigatory ProjectDokumen14 halamanPhysics Investigatory Project09shasBelum ada peringkat

- A) Define: I) Latitude, Ii) Declination Angle, Iii) Hour Angle, Iv) Surface B) For New Delhi (Latitude 28Dokumen2 halamanA) Define: I) Latitude, Ii) Declination Angle, Iii) Hour Angle, Iv) Surface B) For New Delhi (Latitude 28Mahesh ReddyBelum ada peringkat

- prEN 10138-3-2006Dokumen14 halamanprEN 10138-3-2006florin0% (1)

- Tunneling-Like Wave Transmission in Non-Hermitian Lattices With Mirrored NonreciprocityDokumen6 halamanTunneling-Like Wave Transmission in Non-Hermitian Lattices With Mirrored Nonreciprocitydonniedarko817Belum ada peringkat

- Omega Air: B-DRY 110-1000 f-DRY 1200-6500Dokumen2 halamanOmega Air: B-DRY 110-1000 f-DRY 1200-6500Junaid AhmedBelum ada peringkat