CN-Crankcase Explosion Relief Valves

Diunggah oleh

Tapas ChaudhuriHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

CN-Crankcase Explosion Relief Valves

Diunggah oleh

Tapas ChaudhuriHak Cipta:

Format Tersedia

Indian Register of Shipping

CLASSIFICATION NOTES

Type Testing Procedure for

Crankcase Explosion Relief Valves

Contents

1. Scope, Application

2. Recognized Standards

3. Purpose

4. Test Facilities

5. Explosion Test Process

6. Testing of Valves

7. Method

8. Assessment and Records

9. Approval of Design of Series Produced Valves

10. Test Report

11. Approval

Page 2 of 16

Type Testing Procedure for Crankcase Explosion Relief Valves

Indian Register of Shipping

Classification Notes

Page 3 of 16

Indian Register of Shipping

Type Testing Procedure for

Crankcase Explosion Relief Valves

1. Scope, Application

1.1 This type testing procedure specifies standard conditions under which crankcase

explosion relief valves intended to be fitted to diesel engines can be tested to

demonstrate that they satisfy IRS and engine builders requirements for type testing.

1.2 This test procedure is also applicable to explosion relief valves intended for gear

cases.

1.3 Standard repeatable test conditions have been established using methane gas and air

mixture.

1.4 The test procedure is only applicable to explosion relief valves fitted with flame

arresters.

Note : Where internal oil wetting of a flame arrester is a design feature of an

explosion relief valve, alternative testing arrangements that demonstrate compliance

with this Classification Notes may be proposed by the manufacturer. The alternative

testing arrangements are to be agreed by IRS.

1.5 Engines are to be fitted with components and arrangements complying with these

Notes when:

i) the engine is installed on existing ships (i.e. ships for which the date of contract

for construction is before 1 July 2008) and the date of application for

certification of the engine is on or after 1 July 2008; or

ii) the engine is installed on new ships (i.e. ships for which the date of contract for

construction is on or after 1 July 2008).

Page 4 of 16

Type Testing Procedure for Crankcase Explosion Relief Valves

Indian Register of Shipping

2. Recognised Standards

2.1 EN 12874:2001: Flame arresters-Performance requirements, test methods and limits

for use.

2.2 EN ISO/IEC 17025:2005: General requirements for the competence of testing and

calibration laboratories.

2.3 EN 1127-1:1998: Explosive atmospheres-explosion prevention and protection. Part 1.

Basic concepts and methodology.

2.4 EN 1070:1998: Safety of Machinery-Terminology.

2.5 VDI 3673: Part 1: Pressure Venting of Dust Explosions.

2.6 IMO MSC/Circular 677-Revised Standards for the Design, Testing and Location of

Devices to Prevent the Passage of Flame into Cargo Tanks in Tankers.

Classification Notes

Page 5 of 16

Indian Register of Shipping

3. Purpose

3.1 The purpose of type testing crankcase explosion relief valves is to:

3.1.1 verify the effectiveness of the flame arrester.

3.1.2 verify that the valve closes after an explosion.

3.1.3 verify that the valve is gas/air tight after an explosion.

3.1.4 establish the level of over pressure protection provided by the valve.

Page 6 of 16

Type Testing Procedure for Crankcase Explosion Relief Valves

Indian Register of Shipping

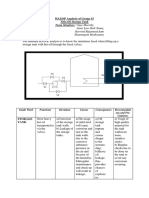

4. Test Facilities

4.1 The test facilities for carrying out type testing of crankcase explosion relief valves are

to meet the following criteria:

4.1.1 It should be accredited to a National or International Standard e.g. ISO/IEC 17025 for

the testing of explosion protection devices and acceptable to IRS.

4.1.2 The test facilities are to have:

- Necessary equipments so that they can control and record explosion testing in

accordance with this procedure.

- Equipment for controlling and measuring a methane gas in air concentration within

a test vessel to an accuracy of + 0.1%.

- Effective means for point located ignition of methane gas in air mixture.

4.1.3 The measuring equipment is to be capable of measuring the pressure in the test vessel

in at least two positions. One at the valve and the other at the test vessel center. The

measuring arrangements are to be capable of measuring and recording the pressure

changes throughout an explosion test. The result of each test is to be documented by

video recording and if necessary by recording with a heat sensitive camera.

4.1.4 The dimensions of the vessel are to be such that the vessel is not pipe like with the

distance between dished ends being not more than 2.5 times its diameter. The internal

volume of the test vessel is to include any standpipe arrangements.

4.1.5 The test vessel for explosion testing is to be provided with a flange for mounting the

explosion relief valve in an orientation consistent with manner in which it will be

installed in service, i.e. in the vertical plane or the horizontal plane. The flange

arrangement is to be located centrally at one end perpendicular to the vessels

longitudinal axis.

4.1.6 A circular plate having the following dimensions is to be provided for fitting between

the pressure vessel flange and valve under test.

Outside diameter = 2 x D where D is the outer diameter of the valve top cover.

The circular plate is to provide simulation of the crankcase surface.

Internal bore having the same internal diameter of the valve to be tested.

4.1.7 The test vessel for explosion testing is to have connections for measuring the methane

in air mixture in at least two positions, i.e. top and bottom.

4.1.8 The test vessel for explosion testing is to be provided means for fitting an ignition

source at a position specified in para 5.3.

Classification Notes

Page 7 of 16

Indian Register of Shipping

4.1.9 The volume of the test vessel is to be as far as practicable, related to the size and

capacity of relief valve to be tested. The free area of explosion relief valve is to be not

less than 115 cm

2

/m

3

of crankcase gross volume, i.e. the testing of a valve having

1150 cm

2

of free area, would require a test vessel with a volume of 10m

3

. Where the

free area of relief valves is greater than 115 cm

2

/m

3

of the crankcase gross volume,

the volume of the test vessel is to be consistent with the design ratio. In any case the

volume of the test vessel is not to vary by more than + 15% to 15% from the design

cm

2

/m

3

volume ratio.

Page 8 of 16

Type Testing Procedure for Crankcase Explosion Relief Valves

Indian Register of Shipping

5. Explosion Test Process

5.1 All explosion tests to verify the working/operation of crankcase explosion relief

valves, are to be carried out using an air and methane mixture with a volumetric

methane concentration of 9.5% + 0.5%. The pressure in the test vessel is to be not less

than atmospheric and not exceeding 0.2 bar.

5.2 The concentration of methane in the test vessel is to be measured in the top and

bottom of the vessel and is not to differ by more than 0.5%.

5.3 The ignition of the methane and air mixture is to be made at the centerline of the test

vessel at a position approximately one third of the height or length of the test vessel

opposite to where the valve is mounted.

5.4 The ignition is to be made using a maximum 100-joule explosive charge.

Classification Notes

Page 9 of 16

Indian Register of Shipping

6 Testing of Valves

6.1 The valves used for type testing (including testing as specified in para 6.3) are to be

manufactured and tested in accordance with procedures acceptable to IRS and

selected from the manufacturers usual production line for such valves, by IRS or

engine builder witnessing the tests.

6.2 For approval of a specific valve size, three valves are to be tested in accordance with

paras 6.3 and 7. For a series of valves para 9 refers.

6.3 The valves selected for type testing should have been previously tested at the

manufacturers works to demonstrate that the opening pressure is in accordance with

the specification within a tolerance of + 20% and that the valve is air tight at a

pressure below the opening pressure for at least 30 seconds.

Note :

This test is to verify that the valve is air tight following assembly at the

manufacturers works and that the valve begins to open at the required pressure

demonstrating that the correct spring has been fitted.

6.4 The type testing of valves is to take into consideration the orientation in which they

are intended to be installed on the engine or gear case. Three valves of each size are to

be tested for each intended installation orientation, i.e. in the vertical and/or horizontal

positions.

Page 10 of 16

Type Testing Procedure for Crankcase Explosion Relief Valves

Indian Register of Shipping

7. Method

7.1 The following requirements are to be satisfied at explosion testing.

7.1.1 The explosion testing is to be witnessed by authorized personnel from IRS where type

testing approval is required by IRS.

7.1.2 Valves are to be tested in the vertical or horizontal position consistent with the

orientation in which they are intended to be installed on an engine or gear case,

usually in the vertical position, see 6.4.

7.1.3 Where valves are to be installed on an engine or gear case with shielding

arrangements to deflect the emission of explosion combustion products, the valves are

to be tested with the shielding arrangements fitted.

7.1.4 Type testing is to be carried out for each range of valves that a manufacturer requires

IRS approval.

7.1.5 Successive explosion testing to establish a valves functionality is to be carried out as

quickly as possible during stable weather conditions.

7.1.6 The pressure rise and decay during all explosion testing is to be recorded.

7.1.7 The external condition of the valves is to be monitored during each test for indication

of any flame release by video and heat sensitive camera.

7.1.8 The test facility is to produce a report on the explosion test findings.

7.2 Each valve undergoing type test is to be explosion tested in three stages as described

below.

7.2.1 Stage 1:

7.2.1.1 Two explosion tests are to be carried out with the flange opening fitted with the

circular plate covered by a 0.05mm thick polythene film. These tests establish a

reference pressure level for determination of the effects of a relief valve in the test

vessel, see 8.1.6.

7.2.2 Stage 2:

7.2.2.1 Two explosion tests are to be carried out on three different valves of the same size.

Each valve is to be mounted in the orientation in which it requires approval for

installation i.e., in the vertical or horizontal position with the circular plate described

in 4.1.9 located between the valve and pressure vessel mounting flange.

7.2.2.2 The first test on each valve is to be carried out with a 0.05m thick polythene bag

having a minimum diameter of three times the diameter of the circular plate and

volume not less than 30% of the test vessel enclosing the valve and circular plate.

Before carrying out the explosion test the polythene bag is to be empty of air. The

plastic bag is required to provide a readily visible means of assessing whether there is

Classification Notes

Page 11 of 16

Indian Register of Shipping

flame transmission through the relief valve following an explosion consistent with the

requirements of the standards identified in section 2.

Note :

During the test, the explosion pressure will open the valve and some unburned

methane/air mixture will be collected in the polythene bag. When the flame reaches

the flame arrester and if there is flame transmission through the flame arrester, the

methane/air mixture in the bag will be ignited and this will be visible.

7.2.2.3 Provided that the first explosion test successfully demonstrated that there was no

indication of combustion outside the flame arrester and there are no signs of damage

to the flame arrester or valve, a second explosion test without the polythene bag

arrangement is to be carried out. During the second explosion test, the valve is to be

visually monitored for any indication of combustion outside the flame arrester. The

second test is required to demonstrate that the valve can function in the event of a

secondary crankcase explosion.

7.2.2.4 After each explosion, the test vessel is to be maintained in the closed condition for at

least 10 seconds to enable the tightness of the valve to be ascertained. The tightness of

the valve can be verified during the test from the pressure/time records or by a

separate test after completing the second explosion test.

7.2.3 Stage 3:

7.2.3.1 Carry out two further explosion tests as described in Stage 1. These further tests are

required to provide an average base line value for assessment of pressure rise

recognizing that the test ambient conditions may have changed during the testing of

the explosion relief valves in Stage 2.

Page 12 of 16

Type Testing Procedure for Crankcase Explosion Relief Valves

Indian Register of Shipping

8. Assessment and Records

8.1 The explosion testing of the valves will be considered satisfactory and its

conformance to the requirements given in the Classification Notes subject to

following being complied with:

8.1.1 Design appraisal / approval of valves undergoing type tests by IRS.

8.1.2 Records as detailed below being submitted to IRS :

a) The designation, dimensions and characteristics of the valves to be tested

including free area of the valve and the flame arrester and valve lift at 0.2 bar.

b) The test vessel volume as determined and recorded.

8.1.3 For acceptance of the functioning of the flame arrester there is not to be any

indication of flame or combustion outside the valve during an explosion test. This

should be confirmed by the test laboratory taking into account measurements from the

heat sensitive camera.

8.1.4 The pressure rise and decay during an explosion is to be recorded with indication of

the pressure variation showing the maximum overpressure and steady under pressure

in the test vessel during testing. The pressure variation is to be recorded at two points

in the pressure vessel.

8.1.5 The effect of an explosion relief valve in terms of pressure rise following an explosion

is ascertained from maximum pressures recorded at the center of the test vessel during

the three stages. The pressure rise within the test vessel due to the installation of a

relief valve is the difference between average pressure of the four explosions from

Stage 1 and 3 and the average of the first tests on the three valves in Stage 2. The

pressure rise is not to exceed the limit specified by the manufacturer.

8.1.6 The valve tightness is to be ascertained by ensuring that at least 0.3 bar vacuum is

maintained in the test vessel for at least 10 seconds following an explosion. This test

is to verify that the valve has effectively closed and is reasonably gas-tight following

dynamic operation during an explosion.

8.1.7 After each explosion test in Stage 2, the external condition of the flame arrester is to

be examined for signs of damage and/or deformation that may affect the operation of

the valve.

8.1.8 After completing the explosion tests, the valves are to be dismantled and the condition

of all components ascertained and documented. In particular any indication of valve

sticking or uneven opening is to be noted. Photographic records of the valve condition

are to be taken and included in the report.

Classification Notes

Page 13 of 16

Indian Register of Shipping

9. Approval of Design of Series Produced Valves

9.1 The approval of quenching devices to prevent the passage of flame can be evaluated

for other similar devices of identical design where one device has been tested and

found satisfactory.

9.2 The quenching ability of a flame screen depends on the total mass of quenching

lamellas/mesh. Provided the materials, thickness of materials, depth of

lamellas/thickness of mesh layer and the quenching gaps are the same, then the same

quenching ability can be qualified for different size of flame screen. This is subject to

(a) and (b) being satisfied.

(a)

2

1

2

1

S

S

n

n

(b)

2

1

2

1

S

S

A

A

Where:

n

1

= total depth of flame arrester corresponding to the number of lamellas of size 1

quenching device for a valve with a relief area equal to S

1

n

2

= total depth of flame arrester corresponding to the number of lamella of size 2

quenching device for a valve with a relief area equal to S

2

A

1

= free area of quenching device for a valve with a relief area equal to S

1

A

2

= free area of quenching device for a valve with a relief area equal to S

2

9.3 The approval of explosion relief valves of larger sizes than that which has been

previously satisfactorily tested in accordance with Sections 7 and 8 can be considered

provided valves are of identical type and have identical features of construction

subject to the following:

9.3.1 The free area of a larger valve does not exceed three times + 5% of the valve that has

been satisfactorily tested.

9.3.2 One valve of the largest size, subject to 9.3.1, requiring qualification is subject to

satisfactory testing required by 6.3 and 7.2.2 except that a single valve will be

accepted instead of three as given in 7.2.2.1 and the volume of the test vessel is not to

be less than one third of the volume required by 4.1.9.

9.3.3 The assessment and records are to be in accordance with Section 8 considering that

8.1.6 will only be applicable to Stage 2 for a single valve.

Page 14 of 16

Type Testing Procedure for Crankcase Explosion Relief Valves

Indian Register of Shipping

9.4 The approval of explosion relief valves of smaller sizes than that which has been

previously satisfactorily tested in accordance with Sections 7 and 8 can be considered

provided valves are of identical type and have identical features of construction

subject to the following:

9.4.1 The free area of a smaller valve is not less than one third of the valve that has been

satisfactorily tested.

9.4.2 One valve of the smallest size, subject to 9.4.1, requiring qualification is subject to

satisfactory testing required by 6.3 and 7.2.2 except that a single valve will be

accepted in 7.2.2.1 and the volume of the test vessel is not to be more than the volume

required by 4.1.9.

9.4.3 The assessment and records are to be in accordance with Section 8 considering that

8.1.6 will only be applicable to Stage 2 for a single valve.

Classification Notes

Page 15 of 16

Indian Register of Shipping

10 Test Report

10.1 The report issued by the testing laboratories is to include following information and

documents:

10.1.1 Test specification

10.1.2 Details of test pressure vessel and valves tested.

10.1.3 The orientation in which the valve was tested, (vertical or horizontal position)

10.1.4 Methane in air concentration for each test.

10.1.5 Ignition source

10.1.6 Pressure curves for each test.

10.1.7 Video recordings of each valve test.

10.1.8 The assessment and records stated in para 8.

Page 16 of 16

Type Testing Procedure for Crankcase Explosion Relief Valves

Indian Register of Shipping

11. Approval

IRS will accord approval to the explosion relief valve subject to satisfactory:

11.1 Appraisal of plans and particulars and

11.2 Review of results of type testing.

Anda mungkin juga menyukai

- 0 50 S Fuel OperationDokumen56 halaman0 50 S Fuel Operationargentum19619692Belum ada peringkat

- Sulphur 2020 Infographic 2 PageDokumen2 halamanSulphur 2020 Infographic 2 PageDimosBelum ada peringkat

- Corrosion in Cargo TanksDokumen21 halamanCorrosion in Cargo Tankssergiytitov100% (1)

- 2011 - TC ME2 EK General With AnswersDokumen64 halaman2011 - TC ME2 EK General With AnswersTapas ChaudhuriBelum ada peringkat

- Bojean CurvesDokumen9 halamanBojean CurvesjaishanakarBelum ada peringkat

- Abs-Trends Nox December2015Dokumen3 halamanAbs-Trends Nox December2015Tapas ChaudhuriBelum ada peringkat

- Double Bottom Engine RoomDokumen6 halamanDouble Bottom Engine RoomTapas ChaudhuriBelum ada peringkat

- Corrosion in Cargo TanksDokumen21 halamanCorrosion in Cargo Tankssergiytitov100% (1)

- Canada Q and A PDFDokumen53 halamanCanada Q and A PDFrajishrrrBelum ada peringkat

- Disadavantage of Radioactive Level Indicators For Co2 BottlrDokumen2 halamanDisadavantage of Radioactive Level Indicators For Co2 BottlrTapas ChaudhuriBelum ada peringkat

- KS-0179-1 Procedures For Determination of Lightship Displace ENGDokumen13 halamanKS-0179-1 Procedures For Determination of Lightship Displace ENGBharath Kumar VasamsettyBelum ada peringkat

- 213-35746 Future IMO LegislationDokumen65 halaman213-35746 Future IMO Legislationerudite_0206Belum ada peringkat

- Materials Used in ShipbuildingDokumen6 halamanMaterials Used in Shipbuildingagknair100% (1)

- Good Practice Guide CH 3 Container SpecificationsDokumen107 halamanGood Practice Guide CH 3 Container Specificationsnichaev100% (1)

- SsaDokumen2 halamanSsaTapas ChaudhuriBelum ada peringkat

- Marpol Practical Guide PDFDokumen57 halamanMarpol Practical Guide PDFCharlie MakBelum ada peringkat

- A Practical Overview of Level Measurement TechnologiesDokumen7 halamanA Practical Overview of Level Measurement TechnologiesgwinnruBelum ada peringkat

- ISM-PR-09 Procedure For Major Non-ConformitiesDokumen2 halamanISM-PR-09 Procedure For Major Non-ConformitiesTapas ChaudhuriBelum ada peringkat

- Advances in Slow-Speed Marine Diesel EnginesDokumen4 halamanAdvances in Slow-Speed Marine Diesel EnginesTapas ChaudhuriBelum ada peringkat

- Dieselfacts 2014-3 WebDokumen12 halamanDieselfacts 2014-3 WebTapas ChaudhuriBelum ada peringkat

- Weld JointDokumen44 halamanWeld JointPratiek RaulBelum ada peringkat

- Wartsila Tribo PackDokumen7 halamanWartsila Tribo Packsuper_seeker100% (1)

- Operation On Low-Sulphur FuelsDokumen14 halamanOperation On Low-Sulphur Fuelsgiannis2Belum ada peringkat

- Governor Control Systems, Inc.: Prime Movers and Governors BasicsDokumen37 halamanGovernor Control Systems, Inc.: Prime Movers and Governors BasicsTapas Chaudhuri100% (1)

- Training Manual On Life Saving AppliancesDokumen98 halamanTraining Manual On Life Saving AppliancesTapas Chaudhuri100% (5)

- Marine Diesels Co UkDokumen149 halamanMarine Diesels Co Ukvmedica94% (32)

- Reference Manual: Governing Fundamentals and Power ManagementDokumen76 halamanReference Manual: Governing Fundamentals and Power Managementr100% (2)

- Function of Fittings-ParkerDokumen36 halamanFunction of Fittings-Parkerbell_15477100% (1)

- Training Manual For Fire Safety PracticeDokumen50 halamanTraining Manual For Fire Safety PracticeMatthew BennettBelum ada peringkat

- Amsa PSC ChecklistDokumen11 halamanAmsa PSC Checklistdassi99100% (1)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5782)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Sentinels PrimerDokumen46 halamanSentinels PrimerMatthew CaulderBelum ada peringkat

- Safer Boiler OperationDokumen2 halamanSafer Boiler OperationUmangtarangBelum ada peringkat

- The Hydrogen Bomb: The Radioactive Signature ofDokumen13 halamanThe Hydrogen Bomb: The Radioactive Signature ofintensivetacticsBelum ada peringkat

- WA Manual PDFDokumen51 halamanWA Manual PDFLidiaInoBelum ada peringkat

- UM10724G00Dokumen377 halamanUM10724G00TuanBi Le100% (1)

- 88B09 382 Engl PDFDokumen273 halaman88B09 382 Engl PDFJaime HernandezBelum ada peringkat

- Anarchist CodebookDokumen88 halamanAnarchist CodebookjumpupdnbdjBelum ada peringkat

- Home L Comet CaseDokumen3 halamanHome L Comet CasemechaengrBelum ada peringkat

- HAZOP Analysis of Oil Storage TankDokumen2 halamanHAZOP Analysis of Oil Storage Tankvijaymoorthy14Belum ada peringkat

- Adeptus Evangelion 2.5 - Cruel ThesisDokumen276 halamanAdeptus Evangelion 2.5 - Cruel ThesisClay Mason0% (1)

- The Apocalypse and Satan's Glory HoleDokumen62 halamanThe Apocalypse and Satan's Glory HoleTimothy W. Long-Author100% (1)

- Fibc Type A B C D Classification SafetyDokumen2 halamanFibc Type A B C D Classification Safetydhineshbabu rBelum ada peringkat

- How to Trigger Powerful Combos in Dragon Age: InquisitionDokumen2 halamanHow to Trigger Powerful Combos in Dragon Age: InquisitionSimon WilkinsBelum ada peringkat

- ExplosivesDokumen5 halamanExplosivesgladsonBelum ada peringkat

- 1.1.2 Isolations Removed Too Soon: 1.1 IsolationDokumen1 halaman1.1.2 Isolations Removed Too Soon: 1.1 Isolationkara_25Belum ada peringkat

- Hazard in ConstructionDokumen11 halamanHazard in ConstructionAhamed Manazir Hazzaan100% (1)

- 1.petmalu 2. Werpa/ Lodi 3. Werpa 4. Lodi 5. Petmalu 6. Petmalu 7. Petmalu 8. Lodi 9. Crater 10. Lava 11.magma 12. Vent 13. Smoke and Ash 14.crust 15. MantleDokumen2 halaman1.petmalu 2. Werpa/ Lodi 3. Werpa 4. Lodi 5. Petmalu 6. Petmalu 7. Petmalu 8. Lodi 9. Crater 10. Lava 11.magma 12. Vent 13. Smoke and Ash 14.crust 15. MantleKangBelum ada peringkat

- GunpowderDokumen6 halamanGunpowderBrodie ZellerBelum ada peringkat

- Nonel GuideDokumen55 halamanNonel GuideIrvan Aryo Prakoso100% (5)

- Ship Structural LoadsDokumen25 halamanShip Structural LoadsPrateekBelum ada peringkat

- A Study of The Fukushima Daiichi Nuclear Accident Process What Caused The Core Melt and Hydrogen Explosion PDFDokumen241 halamanA Study of The Fukushima Daiichi Nuclear Accident Process What Caused The Core Melt and Hydrogen Explosion PDFs3dbwBelum ada peringkat

- Unit 1 Section A The Restless EarthDokumen20 halamanUnit 1 Section A The Restless EarthAlison FarrellBelum ada peringkat

- Gunslinger DeedsDokumen6 halamanGunslinger DeedsMarcoPesceBelum ada peringkat

- WWI Bloody FirstDokumen2 halamanWWI Bloody FirstokBelum ada peringkat

- Creating Flash Powder PDFDokumen6 halamanCreating Flash Powder PDFJose Miguel SantiagoBelum ada peringkat

- Blast Injuries & Gunshot WoundsDokumen93 halamanBlast Injuries & Gunshot WoundsdocpreetiBelum ada peringkat

- Gilbert - Alan Walid Raad Reinvents The ArchiveDokumen9 halamanGilbert - Alan Walid Raad Reinvents The Archivetyjames192Belum ada peringkat

- AISC Design Guide 26 Design of Blast Resistant StructuresDokumen175 halamanAISC Design Guide 26 Design of Blast Resistant Structuresfzhou100% (1)

- Man Made DisasterDokumen37 halamanMan Made DisasterDinesh RamoBelum ada peringkat

- PrimacordDokumen2 halamanPrimacordgattopazzo54Belum ada peringkat