Servo Drives Indramat

Diunggah oleh

Bladimir Tirzo EspinozaDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Servo Drives Indramat

Diunggah oleh

Bladimir Tirzo EspinozaHak Cipta:

Format Tersedia

Starting Lockout Function

in TDM Servo Drive Modules

DOK-ANAX**-TDM*ANL*FKT-ANW1-EN-P

Applications manual

mannesmann

Rexroth

engineering

Indramat

258241

2 TDM Starting Lockout 9.555.012.4-05 4/94

Title:

Type of Documentation:

Doc. No.:

Internal File Ref.:

Replaces:

The purpose

of this document

Copyright:

Validity:

Copying of this document, and giving it to others and the use or

communication of the contents thereof without express authority are

forbidden. Offenders are liable to the payment of damages. All rights

are reserved in the event of the grant of a patent or the registration

of a utility model or design.

We reserve the right to make changes to the documents and in

product delivery.

About this Documentation

Starting Lockout Function in TDM Servo Drive Modules

Application Manual

9.555.012.4-05 EN / 4/94

File No. 4 / startinglockout TDM EN

9.555.012.4-03 DE / 3/93

This document serves:

to define possible application and operating conditions

to assist in project planning and installation

the commissioning and monitoring of the starting lockout function

3 TDM Starting Lockout 9.555.012.4-05 4/94

Please note the guidelines outlined in Section 3 prior to

commissioning the starting lockout!

Table of Contents

Table of Contents Page

1. Possible applications of the starting lockout 7

1.1. A safe way to power down separate

working areas in machinery or plant ................................... 7

1.2. Operating individual axes during installation .................... 10

2. How the starting lockout works 11

2.1. The function of the motor control ...................................... 11

2.2. Using the starting lockout signal to safely

power down the motor ...................................................... 11

3. Installation and operating guidelines 14

3.1. Application guidelines for disconnecting the power mains,

standstills and securing against unintentional start-ups ... 14

3.1.1. Using the master switch to disconnect the mains ............. 14

3.1.2. Using the mains contactor to disconnect the mains ......... 14

3.1.3. Using the starting lockout to secure against intentional

start ups ............................................................................ 14

3.2. Connecting terminals ....................................................... 15

3.3. Sequence and procedures when using the starting

lockout ............................................................................... 16

3.4. Testing .............................................................................. 19

3.5. Examples of appliations .................................................... 19

4. Controller types and related plans 23

4.1. Summary of the types of controllers ................................ 23

4.2. Frontal view....................................................................... 24

4.3. Dimensional data .............................................................. 29

4.4. Installation dimensions...................................................... 31

4.5. Terminal interconnect diagrams ....................................... 34

4 TDM Starting Lockout 9.555.012.4-05 4/94

5 TDM Starting Lockout 9.555.012.4-05 4/94

1.1. A safe way to power

down separate working areas

in machinery or plant

1. Applications

Production systems, transfer lines and machine tools often consist of

spatially separated working areas, e.g., processing units, transport,

handling and storage systems (see Figure 3).

It is frequently necessary for personnel to either work or access

something in one working area while machinery is running in an

adjacent working area. This means that the drive axes within an

individuals working area must be secured against any uninten-

tional motions so that an individual is not at risk from dangerous

drive motions caused by a fault somewhere else in the facility.

If the drive axes in adjacent working areas and in the danger zone are

centrally connected to the power mains by a supply unit (e.g., supply

modules TVM, KDV, TVD, KVR), then each direct-drive motor must

be individually secured against unintentional motions. The danger

zone is the area in which the individual is working.

The starting lockout built into every INDRAMAT drive module makes

it easy to safely power down the motor of each axis with a simple

switch. This switch disconnects the output stage from the control

electronics with the use of a relay in the hardware. The user gains the

following advantages:

1. Savings in cost and space

A single power supply unit can feed the drive axes of several

working areas. Individual power supply units are not needed for

each drive axes in every spatially separated working area.

In several applications, a large three-phase motor contactor with

one or two axes is built into the motor supply lines. The motor

contactors make it possible to safely switch off these axis motors,

and to use only one supply unit to operate all drives.

This function is now easy to perform without a power contactor on

the drive module by controlling the starting lockout input. This

represents a savings in cost and space in the control cabinet.

1. Possible applications of the starting lockout

6 TDM Starting Lockout 9.555.012.4-05 4/94

2. Increased safety and reliability:

Personnel safety and facility reliability are increased because a

mains contactor is not needed to disconnect the motor from the

drive module.

Eliminated are breakdowns caused by frequent switching, gum-

ming or burning of the contacts of this contactor due to high load

currents.

The danger of damage to the motor mains contacts from improper

handling or commissioning is eliminated.

The motors no longer brake uncontrolled with a power failure.

A motor contactor without a mechanical locking mechanism is

dropped in a power failure. This means the motor will idle and the

DC bus energy cannot be used for braking.

The existing mains contactor is presently used to secure against

unintentional motions. It is switched on and off once during every

duty cycle. With a starting lockout in an INDRAMAT drive module

the mains contactor does not need to be frequently switched, i.e.,

with every cycle. It is only used with E-stops, for maintenance and

inspection work throughout the plant, and with every total shut-

down. There is less wear and tear, and failures occur less

frequently.

If two faults occur simultaneously, then a motor can run up

uncontrolled if a motor contactor is used to secure against uninten-

tional motions .

Example:

speed command voltage at maximum due to fault in NC, and,

the motor contactor fails.

In the unlikely event that two faults occur simultaneously in the

power supply, then the motor will only jerk if an internal starting

lockout is in the INDRAMAT drive amplifier.

The internal control circuits and the output stage control are

internally locked for additional safety. An external motor contactor

does not ensure an additional internal locking of the drive electron-

ics.

1. Applications

7 TDM Starting Lockout 9.555.012.4-05 4/94

1. Applications

The drive is secured by applying power to the starting lockout

input. This meets the following safety requirements:

I. Quickest possible standstill

The drives must be brought to a standstill as quickly as possible

in an emergency, in other words, in a dangerous situation (VDE

Guidelines 0113/EN 60204, Part 1, Para. 5.6.1).

If an external voltage failure should occur in the control circuit of the

AS starting lockout while the motor is rotating, then the drive is not

switched off and cannot continue to run. If a drive is running or

something is being processed at the time this happens, no tool or

workpiece will be damaged once the drive is cleared.

There can be a controlled electrical shutdown of the drives via the

NC and the drive module.

II. No automatic restarts

The drives cannot automatically restart when power is reapplied

to the starting lockout input (VDE 0113/EN 60204, Part 1, Para.

5.4, VDI 2853, Sec. 3.1.2.3). The drives are blocked.

III. Remaining in a safe state with a fault

A drive will remain in a safe state even with a fault, e.g., the control

voltage drops off at the lockout input. This is in accordance with the

Guidelines VDE 0113/EN 60204, Part 1, Para. 5.7.2 (Special

current circuits that serve safety purposes must take on their

secure state in the event of a failure.), and VDE 2853, Para.

3.1.2.1.1.

This condition is met because

the controller enable signal and the command input keep the drive

blocked, and,

once the fault has occurred, the mains contactor immediately

disconnects the power supply unit from the mains via the mains

contactor by the acknowledgement contact on the drive controller.

This completely switches all drives dead.

8 TDM Starting Lockout 9.555.012.4-05 4/94

1.2. Operating individual axes

during installation

Drives are frequently run individually during installation. In this case

as well, personnel is often found within the danger zone. Generally,

the acknowledgement switch is used to switch on the mains contactor

to operate the axes. The mains contactor is then switched off again

if unwanted movement occurs, or at the end of an operation.

The safety of personnel within a danger zone is increased, if the

starting lockout is additionally built into INDRAMATs drive modules.

It helps to secure against unwanted starts during installation. This

is possible because the internal, forcibly-connected contacts mean

that the axes not being run can be additionally blocked.

In addition, using this relay to switch the motors on and off reduces

wear and tear. In effect, it also increases reliability and safety.

1. Applications

9 TDM Starting Lockout 9.555.012.4-05 4/94

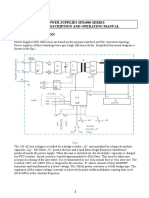

2.1. Motor controller function

2. How the Starting

Lockout Works

2. How the Starting Lockout Works

The power for motor current and thus the torque are advanced via the

final output stage (driver) of the drive module. The extent of the

current in the three phases of the three-phase motor is transmitted by

the controller electronics to the final output stage in the form of a

switch-mode pulse-width modulated signal.

In this case, the controller electronics serve the following purpose:

The greater the width of the pulse or the switch-mode ratio, the

greater the motor current. The three currents in the three phases of

the motor must additionally be adjusted, in terms of amount and

phase position, to the rotor position given at that point in time, for

sufficient torque to be produced.

There can be no motor revolutions at the motor shaft if there is no

pulse-width modulated signal at the final output stage.

The signal at terminals AS1-AS2 of INDRAMATs drive module

activates an internal relay which has two forcibly-connected contacts

(see Fig. 1). The relay has been quality controlled.

The first contact of this relay separates the internal controller voltage

of the final output stage in the hardware.

The control and controller electronics are simultaneously and addi-

tionally blocked. This achieves double redundancy.

The second contact (acknowledgement contact) signals the activa-

tion of the first contact to the outside.

A disconnection of the output stage controller is signalled via this

additional acknowledgement contact (contact) ASQ-ASQ, to verify

whether the relay has actually been activated or not. This contact is

forcibly-connected to the primary contact.

A relay failure or a wire break in the conductors to the starting lockout

inputs AS1-AS2 is immediately recognized by this zero-potential

acknowledgement contact in the external control. The central mains

contactor is then immediately disconnected.

This means it is not possible, in the event of a fault and given all

conceivable possibilities, that a switch-mode motor current (alternat-

ing current) could be produced within the electrical facilities of the

machine which could make the motor move.

It is also not possible for a current to flow through the motor even when

a fault occurs in one of the six final output stages. The drive does not

move. This fault is immediately acknowledged

as soon as personnel has moved out of the danger zone,

when the machine or sector of the facility has been properly

reblocked.

2.2. Using the starting lock-

out signal to secure power

off

10 TDM Starting Lockout 9.555.012.4-05 4/94

and the drive is reactivated

by disconnecting starting lockout inputs AS1-AS2,

by electronically enabling the controller amplifier, and,

by entering the speed set-point.

This fault causes an excessively high current which triggers a

response from the fuses in the drive module. Then the mains

contactor disconnects all drives from the mains. Message BS on the

defective drive module also displays the fault overccurrent.

2. How the Starting Lockout Works

11 TDM Starting Lockout 9.555.012.4-05 4/94

M

S

u

p

p

l

y

m

o

d

u

l

e

C

o

n

t

r

o

l

l

e

r

C

o

n

t

r

o

l

l

e

r

v

o

l

t

a

g

e

U

S

T

D

r

i

v

e

m

o

d

u

l

e

D

r

i

v

e

m

o

d

u

l

e

L

i

n

k

c

i

r

c

u

i

t

A

S

1

A

S

2

A

S

Q

A

S

Q

A

S

1

A

S

2

A

S

Q

A

S

Q

~

M

~

~

M

a

i

n

s

M

a

s

t

e

r

s

w

i

t

c

h

M

a

i

n

s

c

o

n

t

a

c

t

o

r

(

K

1

)

AS/Anwend

A

p

p

l

i

c

a

t

i

o

n

s

o

f

t

h

e

s

t

a

r

t

i

n

g

l

o

c

k

o

u

t

C

o

n

t

r

o

l

l

e

r

v

o

l

t

a

g

e

U

S

T

M

C

o

n

t

r

o

l

l

e

r

v

o

l

t

a

g

e

U

S

T

D

r

i

v

e

m

o

d

u

l

e

A

S

1

A

S

2

A

S

Q

A

S

Q

Figure 1: How the starting lockout works

2. How the Starting Lockout Works

12 TDM Starting Lockout 9.555.012.4-05 4/94

It is not permitted in these cases to just disconnect the mains

contactor or activate the starting lockout.

3. Installation and

Operating Guidelines

3.1. Guidelines for

disconnecting the mains,

for shutdowns and securing

against unwanted starts

The NC and the drive module cannot be used to operate the

drives once the starting lockout has been activated. The

motor is torque-free. A controlled operation of the axes is no

longer possible.

During the planning stage and at that time when the machine

is commissioned it should be determined that the starting

lockout can only be activated when the motor is standing

still. This applies to those cases where a torque-free operation

of the drive can cause damage. It is therefore necessary with

hanging axes to tightly clamp the axis before activating the

mechanical brake.

3. Installation and Operating Guidelines

The master switch must be used to disconnect all of the machines

electrical equipment from the mains in the following instances:

when cleaning the machine

for maintenance and repairs

prior to long breaks in operation

3.1.1. Using the master switch

to disconnect the mains

The master switch must adhere to the guidelines outlined in EN

60204/VDE 0113, Sec. 5.6.2. It is of extreme importance that it can

be locked into an off position.

In an emergency off/emergency stop situation the mains contactor

must be disconnected directly so that all main current circuits are

switched to zero potential. Those main current circuits that serve

safety purposes must be disconnected first, but not until these

measures have been concluded.

An emergency off situation is defined as danger to either personnel

or machinery in the presence of several faults or problems.

The starting lockout exclusively serves to secure the attached motors

against unintentional starts caused by a fault. Activating it while the

motor is running does not automatically guarantee that the drives will

be safely shutdown.

3.1.2. Using the mains

contactor to disconnect the

mains

3.1.3. Using the starting

lockout to secure against

unwanted starts

13 TDM Starting Lockout 9.555.012.4-05 4/94

3.2. Connecting Terminals

Terminal Function Connected value

designation

AS1 - AS2 Controller for activating Voltage: 2030 volts DC

the starting lockout. Current: 20 mA DC at 24 volts

The red light-emitting diode AS is lit up Power: 0,5 watts

when the starting lockout is activated:

ASQ - ASQ Acknowledgement contact at zero Contact load: 24 volts, 1 amp.

potential (make contact). It acknowledges

activation to an external

controller/monitor.

TMI - TMI (1) Motor thermostat contact

connection. Evaluated in the

servo drive module.

TMO - TMO (1) Output message Contact load: 24 volts, 1 amp.

motor excess temperature.

Relay contact opens if motor

temperature too high.

BRI+ - BRI- (1) Input for controller voltage for 24 Volt 10%

motor blocking brake.

BRO+ - BRO- (1) Motor blocking brake connection,

in acc. with connection plan.

1) Not in TDM 1.3.

3. Installation and Operating Guidelines

It is not possible to use (only) the starting lock in the following cases:

for the purpose of electrically separating the motor from the power

voltage of the drive module, e.g., when exchanging motors;

for any other maintenance, repair or cleaning work on the machine.

A master switch is used to disconnect the mains (see Section 3.1.1).

14 TDM Starting Lockout 9.555.012.4-05 4/94

3. Installation and Operating Guidelines

The function and reliability of the starting lockout in its interaction with

all other system components of the machine or facility are only as

good and as safe as the extent to which the following guidelines were

taken into consideration during planning and were checked during

the commissioning of the machine.

Figure 2 outlines the chronological sequence:

1. Shutdown drives:

The drives which are to be shutdown must first be brought to rest

before the starting lockout can be activated.

The starting lockout can only be used where a torque-free slowing

down can cause damage, and can only be activated when the motor

is standing still. It is otherwise not possible to electrically shutdown a

running drive with the use of a drive module.

A starting lockout should only be activated, even when the motor is

running, if a safe slowing down without a brake via the drive module

is guaranteed.

2. Drive electronically blocked:

The speed set-point input (terminals E1-E2, E3-OVM, E4-OVM)

must be set to zero, and the controller enable input signal (terminal

RF) of the drive amplifier must be connected to OVM. This increases

both safety and redundancy.

3. Activating the starting lockout:

A voltage of 20 ... 30 volts must be placed between the input terminals

AS1-AS2 to activate the starting lockout (0.5 watts at 24 volts of

applied voltage).

The switching of the starting lockout relay in the drive amplifier is

hereby confirmed to the external controller by closing the potential-

free acknowledgement contact (output ASQ-ASQ).

The red diode AS on the front plate lights up simultaneously.

4. Commissioning operation:

If one or several axes are to be operated during the commissioning

operation with protective devices cancelled, then this should only be

possible if qualified personnel enable this type of operation with a key

switch.

All drives must otherwise be disconnected from the mains via the

emergency off circuit, in this case automatically. The respective

commissioning guidelines must be followed.

5. Cancelling the protective devices

The protective devices for the drives defined danger zone can now

be cancelled. Guard doors can, for example, be opened, locks and

cutoffs for the danger zone can be cancelled.

3.3. Sequence and cycle

when using the starting lock-

out

15 TDM Starting Lockout 9.555.012.4-05 4/94

3. Installation and Operating Guidelines

Once the protective devices have been cancelled, then the automatic

emergency stop must be immediately activated if one of the following

faults occur. All the drives connected to the central supply module are

halted and hereby disconnected from the mains via the mains

contactor:

Activation of the starting lockout is not acknowledged. The acknowl-

edgement contact (output ASQ-ASQ) remains open. The emer-

gency off circuit must open because it is necessary for the external

controller to definitely recognize this fault.

Possible causes: The controller signal does not arrive at input AS1-

AS2 of the drive amplifier, or the internal starting lockout relay is

defective.

There is a fault in the acknowledgement line between output ASQ-

ASQ and the external controller, which evaluates the acknowledge-

ment via this acknowledgement contact. Or there is a fault in the

controller itself.

6. Access ready:

Once all the preceding steps have been performed and checked, then

all the drives in the disconnected working area have been secured

against unwanted movement.

It is now possible for personnel to enter this zone and access the

equipment.

16 TDM Starting Lockout 9.555.012.4-05 4/94

Mechanical brakes jammed

E1

E2

RF

0VM

AS1

AS2

ASQ

ASQ

Controller

Emergency off

circuit, mains

disconnect

Speed set-point

n(set-point) at

input E1 - E2

Controller

enable signal at

terminal RF

Starting

lockout input

signal at

terminal

AS1 - AS2

t

t

0.5 sec.

NC stop: end of operation

drives halted

n(set-point) = 0

Controller enable

signal RF off

Drives halted and

electronically locked

t

Starting lockout AS

activated

t

t

Doors open,

protective device cancelled

A

S

/

Z

e

i

t

Servo drive module

n(set-point)

Set-point default

(e.g. from NC)

max. 0.2 sec.

3. Installation and Operating Guidelines

Figure 2: Chronological sequence when using the starting lockout

17 TDM Starting Lockout 9.555.012.4-05 4/94

3.4. Test

3. Installation and Operating Guidelines

The following tests should be performed on each drive in sequence

after each initial commissioning and at set intervals during operation.

No personnel should be within the danger zone during these tests.

1. Shutdown all drives.

2. The starting lockout is activated by supplying voltage to terminals

AS1-AS2. Check whether the motor is now torque-free.

3. Cancel all protective devices, by opening the safety doors for

example.

4. As a test, clamp off the line at input AS1.

In this case, the mains contactor must immediately disconnect the

central supply module with its attached drives from the mains.

This function is guaranteed by the control circuit foreseen in the

design.

5. All possible faults which could occur should be simulated individu-

ally:

in the acknowledgement lines between input ASQ-ASQ and the

external controller, and,

in the evaluation of this signal in this controler.

The following should be checked for each simulated fault:

All drives running within the danger zone must be halted as quickly

as possible, and the mains contact has to disconnect the central

supply module with its attached drives from the mains.

In those cases where this does not happen when there is a fault,

appropriate measures need to be taken to exclude these faults to

the greatest possible extent, or trigger a sufficient emergency off

release.

6. If it is possible to activate the starting lockout even with the drives

running (for example, at the control panel), then it needs to be

checked whether, by activating the starting lockout with running

drives, a dangerous situation can develop if the drives run out

torque-free in every operating state.

Figure 3 outlines two spatially separated working areas equipped with

two or three drive axes.

Figure 4 demonstrates the controller circuit principle with minimum

effort:

Acknowledgement contact ASQ-ASQ has been, like the door con-

tact, integrated into the control circuit for the emergency off se-

quence.

Auxiliary contact K3 signals that the drives are ready to operate and

ready for use.

3.5. Application Examples

18 TDM Starting Lockout 9.555.012.4-05 4/94

Access door

Mains

Working area I Working area II

Enclosure and

limitations of the

danger zone

Door lock

Door lock

Supply

module

Drive

module

Mains

contactor K1

Bb 1

A

S

1

A

S

2

A

S

Q

A

S

Q

Drive 1 Drive 2 Drive 3 Drive 4 Drive 5

A

S

/

P

r

i

n

z

Drive

module

A

S

1

A

S

2

A

S

Q

A

S

Q

A

S

1

A

S

2

A

S

Q

A

S

Q

Drive

module

A

S

1

A

S

2

A

S

Q

A

S

Q

Drive

module

A

S

1

A

S

2

A

S

Q

A

S

Q

A

S

Q

Drive

module

A

S

1

A

S

2

A

S

Q

A

S

Q

Figure 3: A sketch outlining the starting lockout applications using the example of

separated working areas.

3. Installation and Operating Guidelines

In accordance with VDE 0113/EN 60204, auxiliary contactor K4 is

made up of a relay with multichanel design which assures that contact

K4 will open even in the presence of a fault.

It it evident that the mains contactor drops off with a fault (=door

contact and acknowledgement contact ASQ-ASQ open), and the

drive package is disconnected from the mains.

The controller enable signal of the drive module and the set-point can

hereby be simultaneously set to zero. The running drives will then

brake and their energy will be fed into the d.c. voltage link circuit.

Additionally shown is the possibility of manual operations using the

key and acknowledgement switches.

19 TDM Starting Lockout 9.555.012.4-05 4/94

Figure 4: Examples of starting lockout applications: Controller circuitry of Fig. 3.

2

4

V

-

S

t

a

r

t

i

n

g

l

o

c

k

o

u

t

o

f

t

h

e

d

r

i

v

e

s

W

o

r

k

i

n

g

a

r

e

a

I

I

S

t

a

r

t

i

n

g

l

o

c

k

o

u

t

o

f

t

h

e

d

r

i

v

e

s

W

o

r

k

i

n

g

a

r

e

a

I

I

S

u

p

p

l

y

u

n

i

t

f

o

r

f

a

u

l

t

r

e

c

o

g

n

i

t

i

o

n

r

e

a

d

y

t

o

o

p

e

r

a

t

e

B

b

1

D

r

i

v

e

s

l

o

c

k

e

d

i

n

w

o

r

k

i

n

g

a

r

e

a

I

I

D

r

i

v

e

s

l

o

c

k

e

d

i

n

w

o

r

k

i

n

g

a

r

e

a

I

2

4

V

-

D

o

o

r

c

o

n

t

a

c

t

f

o

r

w

o

r

k

i

n

g

a

r

e

a

I

D

o

o

r

c

o

n

t

a

c

t

f

o

r

w

o

r

k

i

n

g

a

r

e

a

I

I

E

m

e

r

g

e

n

c

y

-

S

t

o

p

O

f

f

O

n

M

u

l

t

i

c

h

a

n

n

e

l

a

u

x

i

l

i

a

r

y

r

e

l

a

y

s

w

i

t

h

c

o

n

t

a

c

t

m

o

n

i

t

o

r

i

n

g

M

a

i

n

s

c

o

n

t

a

c

t

o

r

K

1

2

3

0

V

~

AS/manuell

A

S

Q

A

S

Q

K

4

A

S

Q

A

S

Q

A

S

Q

A

S

2

A

S

2

A

S

2

A

S

2

A

S

2

A

S

1

A

S

1

A

S

1

A

S

1

A

S

1

K

3

K

3

3. Installation and Operating Guidelines

20 TDM Starting Lockout 9.555.012.4-05 4/94

K

b

K

c

K

a

K

c

K

b

K

a

On

Emergency off

Off

K

a

On

Emergency off

Off

K

b

K

c

AS/K4/A+B

K

c

K

b

K

a

K

a

K

b

K

c

K

c

K

b

K

a

Variant A:

Variant B (no contact in this design):

Figure 5: Examples of applications for the multichannel design of auxiliary relay

K4 in Fig. 4.

3. Installation and Operating Guidelines

21 TDM Starting Lockout 9.555.012.4-05 4/94

4. Controller types

and related plans

The following servo drive modules with starting lockout are available

in addition to standard controllers (without starting lockout).

Standard controller Controller type

(without starting lockout) with starting lockout

TDM 1 TDM 1.3 (2)

TDM 3 TDM 3.3(1) (2)

TDM 4 TDM 4.3(1) (2)

--------- TDM 6.1(1)

--------- TDM 7.1(1)

(1) It is possible with these controllers to attach a motor thermostat

contact and the controller for the blocking brake (see Chapter

3.2).

(2) The additional plug-in terminal is plugged into the unit upon

delivery and is, therefore, not a part of the connecting accessories

E...-TDM. In other words, both the standard unit and the unit

with starting lockout have the same connecting accessories.

Related plans

Plan Servo drive module with Figures

starting lockout

Front view TDM 1.3 Fig. 6

TDM 3.3 Fig. 7

TDM 4.3 Fig. 8

TDM 6.1 Fig. 9

TDM 7.1 Fig. 10

Dimension TDM 1.3 Fig. 11

sheet TDM 3.3 Fig. 12

TDM 4.3 Fig. 12

TDM 6.1 Fig. 12

TDM 7.1 Fig. 12

Mounting TDM 1.3 Fig. 13

dimensions TDM 3.3 Fig. 14

TDM 4.3 Fig. 14

TDM 6.1 Fig. 14

TDM 7.1 Fig. 14

Fan dimensions TDM 3.3 Fig. 15

for TDM 4.3 Fig. 15

TDM 6.1 Fig. 15

TDM 7.1 Fig. 15

Connection plan TDM 1.3 Fig. 16

TDM 3.3 Fig. 17

TDM 4.3 Fig. 18

TDM 6.1 Fig. 19

TDM 7.1 Fig. 20

4. Controller types and related plans

22 TDM Starting Lockout 9.555.012.4-05 4/94

+

1

5

V

0

V

M

-

1

5

V

T

a

c

h

o

B

L

C

1

B

L

C

2

B

L

C

3

0

V

M

X5

X6

ZERO ADJ

RESET

S1

X8

L+

L-

A3

A2

A1

POSITION FOR OPERATING PARAMETER

PROGRAMMING MODULE, PLUG IN

CORRECT MODULE, BEFORE START UP

Platz fr Betriebsdaten-Programmierungs-

modul. Vor dem Einschalten korrektes

Modul einstecken.

TDM ...-100-300-W0

236226 K39/91

CONTROLLER AC SERVO

SN240060-02029 A01

X1

X2

Servo drive module

Electrical connecting accessories

and programming module

A

C

P

O

W

E

R

O

U

T

P

U

T

D

A

N

G

E

R

H

I

G

H

V

O

L

T

A

G

E

M

o

t

o

r

a

n

s

c

h

l

u

WARNING

300 VDC INPUT

DISCHARGE TIME

Entladezeit > 1 Min.

POWER SUPPLY OUTPUT

VOLTAGE RATING, MUST

NOT EXCEED POWER

INPUT VOLTAGE DATA

Nur mit Versorgungseinheit

gleicher od. kleinerer POWER-

Spannungsangabe betreiben

+24V

15V

BLC1

BLC2

BLC3

Tacho

POWER

RF

Bb

TS

BS

Offset

adjust

E

3

E

1

E

4

E

2

B

b

B

b

R

F

+

1

5

V

-

1

5

V

I

r

e

d

M

A

T

s

e

n

s

e

0

V

M

0

V

M

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

1 2 3 4 5 6 7 8 9 10

FrontanTDM13

Busbars

Bus terminal X1

Programming module MOD with rating plate

Plug-in terminals

1 2 3 4

A

S

1

A

S

2

A

S

Q

A

S

Q

X9

1 2 3 4

Contr.: TDM 1.3-100-300-W1

Motor: MAC 112D-.-FD-.-C

Current (A): peak/cont.: 100/75

Operating rpm: 2000 MA: 0,05 V/A

MOD 1/1X077-002

Input rpm/V

E1/E2 2000/10

E3 2000/10

E4 2000/10

OPERATING PARAMETER: PROGRAMMING MODULE

ATTENTION: MOTORAND CONTROLLER-TYPE INDICATED ON THE MODULE MUSTAGREE

WITH THE DEVISES IN USE. OTHERWISE LACK OF PERFORMANCE

AND DANGER OF DAMAGE MAY OCCUR

Betriebsdaten-Programmierungsmodul

Achtung: Motor- und Verstrkertypenangaben mssen mit der

Installation bereinstimmen, sonst Schdigungsgefahr.

AS

1 2 3 4 5 6 7 8 9 10

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

ATTENTION!

NEVER REMOVE OR INSTALL THIS

PLUG WHILE VOLTAGE IS APPLIED.

BLACK CABLE ON THE BOTTOM!

Verbindung nie unter Spannung

lsen bzw. stecken.

Schwarze Leitung immer unten!

Figure 6: Front view of TDM 1.3

4. Controller types and related plans

23 TDM Starting Lockout 9.555.012.4-05 4/94

Figure 7: Front view of TDM 3.3

ZERO ADJ

RESET

S1

X8

L+

L-

A3

A2

A1

P

O

S

I

T

I

O

N

F

O

R

O

P

E

R

A

T

I

N

G

P

A

R

A

M

E

T

E

R

P

R

O

G

R

A

M

M

I

N

G

M

O

D

U

L

E

,

P

L

U

G

I

N

C

O

R

R

E

C

T

M

O

D

U

L

E

,

B

E

F

O

R

E

S

T

A

R

T

U

P

P

la

t

z

f

r

B

e

t

r

ie

b

s

d

a

t

e

n

-

P

r

o

g

r

a

m

m

ie

r

u

n

g

s

-

m

o

d

u

l.

V

o

r

d

e

m

E

in

s

c

h

a

lt

e

n

k

o

r

r

e

k

t

e

s

M

o

d

u

l

e

in

s

t

e

c

k

e

n

.

CONTROLLER AC SERVO

X1

Servo drive module

Electrical connecting accessories

and programming module

TDM 3.3-020-300-W0

236226 K39/91

SN240060-02029 A01

D

A

N

G

E

R

H

I

G

H

V

O

L

T

A

G

E

D

O

N

O

T

O

P

E

R

A

T

E

W

I

T

H

O

U

T

P

O

W

E

R

Spannungs- und

isolationsgeprft

nach DIN VDE 0160

+24V

15V

BLC1

BLC2

BLC3

Tacho

PWR

RF

Bb

TS

BS

Offset

adjust

FrontanTDM33

Inputs and outputs

Feedback

Inputs and outputs

1 2 3 4 5 6 7 8 9

1 2 3 4 5 6 7 8 9 10

1 2 3 4 5 6 7 8 9 10 11 12 13

E

1

E

2

E

3

E

4

+

1

5

V

M

+

1

5

V

M

I

r

e

d

0

V

M

F

B

M

A

I

i

s

t

T

T

s

e

n

s

e

1 2 3 4 5 6 7 8 9 10

B

b

-

1

5

V

M

0

V

M

R

F

B

b

+

2

4

V

L

0

V

L

1 2 3 4 5 6 7 8 9

+

1

5

V

M

-

1

5

V

M

0

V

M

0

V

M

B

L

C

2

B

L

C

1

B

L

C

3

T

a

c

h

o

X

4

1

X

4

2

X

4

3

Contr.: TDM 3.3-020-300-W0

Motor: MAC 090A-.-ZD-.-C

Current (A): peak/cont.: 20/15

Operating rpm: 2000 MA: 0,375 V/A

Input rpm/V: E1/E2: 2000/10

E3: 3000/10 E4: 1500/10

MOD 13/1X012-002

OPERATING PARAMETER: PROGRAMMING MODULE

ATTENTION: MOTORAND CONTROLLER-TYPE INDICATED ON THE

MODULE MUSTAGREE

WITH THE DEVISES IN USE. OTHERWISE LACK OF PERFORMANCE

AND DANGER OF DAMAGE MAY OCCUR

Betriebsdaten-Programmierungsmodul

Achtung: Motor- und Verstrkertypenangaben mssen mit der

Installation bereinstimmen, sonst Schdigungsgefahr.

M

O

T

O

R

P

O

W

E

R

M

o

t

o

r

a

n

s

c

h

l

u

3

0

0

V

D

C

I

N

P

U

T

D

I

S

C

H

A

R

G

E

T

I

M

E

E

n

t

l

a

d

e

z

e

i

t

>

1

M

i

n

.

AS

Busbars

Bus terminal X1

Programming module MOD with rating plate

Plug-in terminals

1 2 3 4 5 6 7 8 9 10 11 12 13

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

A

S

Q

A

S

Q

A

S

2

A

S

1

f

r

e

i

T

M

O

T

M

O

B

R

I

+

B

R

I

-

B

R

O

-

B

R

O

+

T

M

I

T

M

I

Plug-in terminals

ATTENTION!

NEVER REMOVE OR INSTALL THIS

PLUG WHILE VOLTAGE IS APPLIED.

BLACK CABLE ON THE BOTTOM!

Verbindung nie unter Spannung

lsen bzw. stecken.

Schwarze Leitung immer unten!

4. Controller types and related plans

24 TDM Starting Lockout 9.555.012.4-05 4/94

Figure 8: Front view of TDM 4.3

ZERO ADJ

RESET

S1

X8

L+

L-

A3

A2

A1

P

O

S

I

T

I

O

N

F

O

R

O

P

E

R

A

T

I

N

G

P

A

R

A

M

E

T

E

R

P

R

O

G

R

A

M

M

I

N

G

M

O

D

U

L

E

,

P

L

U

G

I

N

C

O

R

R

E

C

T

M

O

D

U

L

E

,

B

E

F

O

R

E

S

T

A

R

T

U

P

P

la

t

z

f

r

B

e

t

r

ie

b

s

d

a

t

e

n

-

P

r

o

g

r

a

m

m

ie

r

u

n

g

s

-

m

o

d

u

l.

V

o

r

d

e

m

E

in

s

c

h

a

lt

e

n

k

o

r

r

e

k

t

e

s

M

o

d

u

l

e

in

s

t

e

c

k

e

n

.

CONTROLLER AC SERVO

X1

Servo drive module

Electrical connection accessories

and programming module

TDM 4.3-020-300-W0

236226 K39/91

SN241060-02030 A01

D

A

N

G

E

R

H

I

G

H

V

O

L

T

A

G

E

D

O

N

O

T

O

P

E

R

A

T

E

W

I

T

H

O

U

T

P

O

W

E

R

Spannungs- und

isolationsgeprft

nach DIN VDE 0160

+24V

15V

BLC1

BLC2

BLC3

Tacho

PWR

RF

Bb

TS

BS

Offset

adjust

FrontanTDM43

Inputs and outputs

Feedback

Inputs and outputs

1 2 3 4 5 6 7 8 9 10 11 12 13

E

1

E

2

E

3

E

4

+

1

5

V

M

+

1

5

V

M

I

r

e

d

0

V

M

F

B

M

A

I

i

s

t

T

T

s

e

n

s

e

1 2 3 4 5 6 7 8 9

B

b

-

1

5

V

M

0

V

M

R

F

B

b

2

4

V

L

0

V

L

1 2 3 4 5 6 7 8 9 10

T

0

T

2

T

1

0

V

M

H

S

2

H

S

1

H

S

3

X

4

8

X

5

0

X

4

9

M

O

T

O

R

P

O

W

E

R

M

o

t

o

r

a

n

s

c

h

l

u

3

0

0

V

D

C

I

N

P

U

T

D

I

S

C

H

A

R

G

E

T

I

M

E

E

n

t

l

a

d

e

z

e

i

t

>

1

M

i

n

.

AS

Busbars

Bus terminal X1

Programming module MOD with rating plate

Plug-in terminals

T

3

+

1

5

V

M

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

A

S

Q

A

S

Q

A

S

2

A

S

1

f

r

e

i

T

M

O

T

M

O

B

R

I

+

B

R

I

-

B

R

O

-

B

R

O

+

T

M

I

T

M

I

Plug-in terminals

1 2 3 4 5 6 7 8 9

1 2 3 4 5 6 7 8 9 10

1 2 3 4 5 6 7 8 9 10 11 12 13

Contr.: TDM 4.3-020-300-W0

Motor: MAC 025C-.-QS-.-E

Current (A): peak/cont.: 14/7

Operating rpm: 10000 MA: 0,375 V/A

Input rpm/V: E1/E2: 10000/10

E3: 10000/10 E4: ----------

MOD 17/1X001-193

OPERATING PARAMETER: PROGRAMMING MODULE

ATTENTION: MOTORAND CONTROLLER-TYPE INDICATED ON THE

MODULE MUSTAGREE

WITH THE DEVISES IN USE. OTHERWISE LACK OF PERFORMANCE

AND DANGER OF DAMAGE MAY OCCUR

Betriebsdaten-Programmierungsmodul

Achtung: Motor- und Verstrkertypenangaben mssen mit der

Installation bereinstimmen, sonst Schdigungsgefahr.

ATTENTION!

NEVER REMOVE OR INSTALL THIS

PLUG WHILE VOLTAGE IS APPLIED.

BLACK CABLE ON THE BOTTOM!

Verbindung nie unter Spannung

lsen bzw. stecken.

Schwarze Leitung immer unten!

4. Controller types and related plans

25 TDM Starting Lockout 9.555.012.4-05 4/94

Figure 9: Front view of TDM 6.1

ZERO ADJ

RESET

S1

X8

L+

L-

A3

A2

A1

P

O

S

I

T

I

O

N

F

O

R

O

P

E

R

A

T

I

N

G

P

A

R

A

M

E

T

E

R

P

R

O

G

R

A

M

M

I

N

G

M

O

D

U

L

E

,

P

L

U

G

I

N

C

O

R

R

E

C

T

M

O

D

U

L

E

,

B

E

F

O

R

E

S

T

A

R

T

U

P

P

la

t

z

f

r

B

e

t

r

ie

b

s

d

a

t

e

n

-

P

r

o

g

r

a

m

m

ie

r

u

n

g

s

-

m

o

d

u

l.

V

o

r

d

e

m

E

in

s

c

h

a

lt

e

n

k

o

r

r

e

k

t

e

s

M

o

d

u

l

e

in

s

t

e

c

k

e

n

.

CONTROLLER AC SERVO

X1

Servo drive module

Electrical connection accessories

and programming module

TDM 6.1-020-300-W0

236226 K39/91

SN240060-02029 A01

D

A

N

G

E

R

H

I

G

H

V

O

L

T

A

G

E

D

O

N

O

T

O

P

E

R

A

T

E

W

I

T

H

O

U

T

P

O

W

E

R

Spannungs- und

isolationsgeprft

nach DIN VDE 0160

+24V

15V

BLC1

BLC2

BLC3

Tacho

PWR

RF

Bb

TS

BS

Offset

adjust

FrontanTDM6

Inputs and outputs

Feedback

Inputs and outputs

1 2 3 4 5 6 7 8 9

1 2 3 4 5 6 7 8 9 10

1 2 3 4 5 6 7 8 9 10 11 12 13

E

1

E

2

E

3

E

4

+

1

5

V

M

+

1

5

V

M

I

r

e

d

0

V

M

F

B

M

A

I

i

s

t

T

T

s

e

n

s

e

1 2 3 4 5 6 7 8 9 10

B

b

-

1

5

V

M

0

V

M

R

F

B

b

+

2

4

V

L

0

V

L

1 2 3 4 5 6 7 8 9

+

1

5

V

M

-

1

5

V

M

0

V

M

0

V

M

B

L

C

2

B

L

C

1

B

L

C

3

T

a

c

h

o

X

4

1

X

4

2

X

4

3

Contr.: TDM 6.1-020-300-W0

Motor: MAC 090A-.-ZD-.-C

Current (A): peak/cont.: 20/15

Operating rpm: 2000 MA: 0,375 V/A

Input rpm/V: E1/E2: 2000/10

E3: 3000/10 E4: 1500/10

MOD 19/1X012-002

OPERATING PARAMETER: PROGRAMMING MODULE

ATTENTION: MOTORAND CONTROLLER-TYPE INDICATED ON THE

MODULE MUSTAGREE

WITH THE DEVISES IN USE. OTHERWISE LACK OF PERFORMANCE

AND DANGER OF DAMAGE MAY OCCUR

Betriebsdaten-Programmierungsmodul

Achtung: Motor- und Verstrkertypenangaben mssen mit der

Installation bereinstimmen, sonst Schdigungsgefahr.

M

O

T

O

R

P

O

W

E

R

M

o

t

o

r

a

n

s

c

h

l

u

3

0

0

V

D

C

I

N

P

U

T

D

I

S

C

H

A

R

G

E

T

I

M

E

E

n

t

l

a

d

e

z

e

i

t

>

1

M

i

n

.

AS

Busbars

Bus terminal X1

Programming module MOD with rating plate

Plug-in terminals

1 2 3 4 5 6 7 8 9 10 11 12 13

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

A

S

Q

A

S

Q

A

S

2

A

S

1

f

r

e

i

T

M

O

T

M

O

B

R

I

+

B

R

I

-

B

R

O

-

B

R

O

+

T

M

I

T

M

I

Plug-in terminals

ATTENTION!

NEVER REMOVE OR INSTALL THIS

PLUG WHILE VOLTAGE IS APPLIED.

BLACK CABLE ON THE BOTTOM!

Verbindung nie unter Spannung

lsen bzw. stecken.

Schwarze Leitung immer unten!

4. Controller types and related plans

26 TDM Starting Lockout 9.555.012.4-05 4/94

Figure 10: Front view of TDM 7.1

ZERO ADJ

RESET

S1

X8

L+

L-

A3

A2

A1

P

O

S

I

T

I

O

N

F

O

R

O

P

E

R

A

T

I

N

G

P

A

R

A

M

E

T

E

R

P

R

O

G

R

A

M

M

I

N

G

M

O

D

U

L

E

,

P

L

U

G

I

N

C

O

R

R

E

C

T

M

O

D

U

L

E

,

B

E

F

O

R

E

S

T

A

R

T

U

P

P

la

t

z

f

r

B

e

t

r

ie

b

s

d

a

t

e

n

-

P

r

o

g

r

a

m

m

ie

r

u

n

g

s

-

m

o

d

u

l.

V

o

r

d

e

m

E

in

s

c

h

a

lt

e

n

k

o

r

r

e

k

t

e

s

M

o

d

u

l

e

in

s

t

e

c

k

e

n

.

CONTROLLER AC SERVO

X1

Servo drive module

Electrical connecting accessories

and programming module

TDM 7.1-020-300-W0

236226 K39/91

SN241060-02030 A01

D

A

N

G

E

R

H

I

G

H

V

O

L

T

A

G

E

D

O

N

O

T

O

P

E

R

A

T

E

W

I

T

H

O

U

T

P

O

W

E

R

Spannungs- und

isolationsgeprft

nach DIN VDE 0160

+24V

15V

BLC1

BLC2

BLC3

Tacho

PWR

RF

Bb

TS

BS

Offset

adjust

FrontanTDM7

Inputs and outputs

Feedback

Inputs and outputs

1 2 3 4 5 6 7 8 9 10 11 12 13

E

1

E

2

E

3

E

4

+

1

5

V

M

+

1

5

V

M

I

r

e

d

0

V

M

F

B

M

A

I

i

s

t

T

T

s

e

n

s

e

1 2 3 4 5 6 7 8 9

B

b

-

1

5

V

M

0

V

M

R

F

B

b

2

4

V

L

0

V

L

1 2 3 4 5 6 7 8 9 10

T

0

T

2

T

1

0

V

M

H

S

2

H

S

1

H

S

3

X

4

8

X

5

0

X

4

9

M

O

T

O

R

P

O

W

E

R

M

o

t

o

r

a

n

s

c

h

l

u

3

0

0

V

D

C

I

N

P

U

T

D

I

S

C

H

A

R

G

E

T

I

M

E

E

n

t

l

a

d

e

z

e

i

t

>

1

M

i

n

.

AS

Busbars

Bus terminal X1

Programming module MOD with rating plate

Plug-in terminals

T

3

+

1

5

V

M

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

A

S

Q

A

S

Q

A

S

2

A

S

1

f

r

e

i

T

M

O

T

M

O

B

R

I

+

B

R

I

-

B

R

O

-

B

R

O

+

T

M

I

T

M

I

Plug-in terminals

1 2 3 4 5 6 7 8 9

1 2 3 4 5 6 7 8 9 10

1 2 3 4 5 6 7 8 9 10 11 12 13

Contr.: TDM 7.1-020-300-W0

Motor: MAC 025C-.-QS-.-E

Current (A): peak/cont.: 14 / 7

Operating rpm: 10000 MA: 0,375 V/A

Input rpm/V: E1/E2: 10000/10

E3: 10000/10 E4: ----------

MOD 21/1X005-123

OPERATING PARAMETER: PROGRAMMING MODULE

ATTENTION: MOTORAND CONTROLLER-TYPE INDICATED ON THE

MODULE MUSTAGREE

WITH THE DEVISES IN USE. OTHERWISE LACK OF PERFORMANCE

AND DANGER OF DAMAGE MAY OCCUR

Betriebsdaten-Programmierungsmodul

Achtung: Motor- und Verstrkertypenangaben mssen mit der

Installation bereinstimmen, sonst Schdigungsgefahr.

ATTENTION!

NEVER REMOVE OR INSTALL THIS

PLUG WHILE VOLTAGE IS APPLIED.

BLACK CABLE ON THE BOTTOM!

Verbindung nie unter Spannung

lsen bzw. stecken.

Schwarze Leitung immer unten!

4. Controller types and related plans

27 TDM Starting Lockout 9.555.012.4-05 4/94

3

2

5

O

u

t

l

e

t

f

o

r

c

o

o

l

i

n

g

a

i

r

m

i

n

.

8

0

m

m

f

o

r

c

o

o

l

i

n

g

a

i

r

o

u

t

l

e

t

3 5 5

m

i

n

.

8

0

m

m

f

o

r

c

o

o

l

i

n

g

a

i

r

i

n

l

e

t

A

c

c

e

s

s

f

o

r

c

o

o

l

i

n

g

a

i

r

T

i

g

h

t

e

n

i

n

g

t

o

r

q

u

e

M

(

N

m

)

f

o

r

t

e

r

m

i

n

a

l

b

o

l

t

:

M

6

=

5

N

m

T

i

g

h

t

e

n

i

n

g

t

o

r

q

u

e

M

(

N

m

)

f

o

r

t

e

r

m

i

n

a

l

b

o

l

t

:

M

5

=

3

N

m

T

i

g

h

t

e

n

i

n

g

t

o

r

q

u

e

M

(

N

m

)

f

o

r

t

e

r

m

i

n

a

l

b

o

l

t

:

M

5

=

1

,

5

N

m

AA

7

3 7 3

3 9 0

6

0

9

Mablatt TDM13

2 0

O

n

l

y

a

p

p

l

i

e

s

t

o

d

e

s

i

g

n

w

i

t

h

f

a

n

1

2

X

2

7

1 7

1

0

5

A

S

a

f

e

t

y

g

u

a

r

d

X

9

X

6

X

5

Figure 11: Dimension sheet for TDM 1.3

4. Controller types and related plans

28 TDM Starting Lockout 9.555.012.4-05 4/94

Figure 12: Dimension sheets for TDM 3.3, TDM 4.3, TDM 6.1 and TDM 7.1

3

2

5

O

u

t

l

e

t

f

o

r

c

o

o

l

i

n

g

a

i

r

H

e

a

t

s

i

n

k

m

i

n

.

8

0

m

m

f

o

r

c

o

o

l

i

n

g

a

i

r

o

u

t

l

e

t

3 5 5

S

a

f

e

t

y

g

u

a

r

d

m

i

n

.

8

0

m

m

f

o

r

c

o

o

l

i

n

g

a

i

r

o

u

t

l

e

t

3

2

6

A

c

c

e

s

s

f

o

r

c

o

o

l

i

n

g

a

i

r

T

i

g

h

t

e

n

i

n

g

t

o

r

q

u

e

M

(

N

m

)

f

o

r

t

e

r

m

i

n

a

l

b

o

l

t

X

8

:

M

6

=

5

N

m

T

i

g

h

t

e

n

i

n

g

t

o

r

q

u

e

M

(

N

m

)

f

o

r

t

e

r

m

i

n

a

l

b

o

l

t

X

8

:

M

5

=

3

N

m

T

i

g

h

t

e

n

i

n

g

t

o

r

q

u

e

M

(

N

m

)

f

o

r

t

e

r

m

i

n

a

l

b

o

l

t

:

M

5

=

3

N

m

A

A

S

1

A

1

A

2

A

3

L

-

L

+

X

8

X

1

P

r

o

g

r

a

m

m

i

n

g

m

o

d

u

l

e

Z

E

R

O

-

A

D

J

7

1

2

3 7 3

3 9 0

7

0

7

9

+ 1

Z

e

r

o

a

d

j

.

s

p

e

e

d

c

o

n

t

r

o

l

S

e

t

p

o

i

n

t

m

a

x

.

1

.

5

m

m

R

e

a

d

y

t

o

o

p

e

r

a

t

e

a

n

d

c

o

n

t

r

o

l

l

e

r

v

o

l

t

a

g

e

s

m

a

x

.

1

.

5

m

m

F

e

e

d

b

a

c

k

m

a

x

.

1

.

5

m

m

C

o

n

t

r

o

l

l

e

r

v

o

l

t

a

g

e

s

u

p

p

l

y

L

o

a

d

-

d

i

r

e

c

t

v

o

l

t

a

g

e

(

2

x

M

5

)

L

E

D

D

i

s

p

l

a

y

R

E

S

E

T

M

5

M

o

t

o

r

c

o

n

n

e

c

t

i

o

n

(

3

x

M

6

)

V

i

e

w

w

i

t

h

o

u

t

s

a

f

e

t

y

g

u

a

r

d

Mablatt/TDM33/43/6/7

A

1 2 8

4 8

S

a

f

e

t

y

g

u

a

r

d

F

u

n

c

t

i

o

n

i

n

p

u

t

,

s

i

g

n

a

l

s

1

5

p

o

l

e

s

,

m

a

x

.

1

.

5

m

m

2

5

F

a

n

b

a

f

f

l

e

o

n

l

y

r

e

q

u

i

r

e

d

i

f

t

h

e

u

n

i

t

-

i

s

m

o

u

n

t

e

d

o

n

t

h

e

l

e

f

t

s

i

d

e

o

f

t

h

e

d

r

i

v

e

p

a

c

k

a

g

e

,

o

r

,

-

i

s

m

o

u

n

t

e

d

a

t

a

d

i

s

t

a

n

c

e

g

r

e

a

t

e

r

t

h

a

n

1

0

0

m

m

f

r

o

m

a

n

a

d

j

a

c

e

n

t

u

n

i

t

o

n

t

h

e

l

e

f

t

s

i

d

e

.

(

F

a

n

b

a

f

f

l

e

w

i

t

h

s

c

r

e

w

s

I

N

D

R

A

M

A

T

m

a

t

.

N

o

.

:

2

2

4

8

6

9

m

u

s

t

b

e

o

r

d

e

r

e

d

s

e

p

a

r

a

t

e

l

y

)

4. Controller types and related plans

29 TDM Starting Lockout 9.555.012.4-05 4/94

m

i

n

.

4

0

0

m

i

n

.

2

3

2

5

m i n . 8 0

3 5 5

C

o

m

p

l

e

t

e

l

y

c

l

o

s

e

d

h

o

u

s

i

n

g

o

r

c

a

b

i

n

e

t

T

V

M

T

D

M

T

D

M

T

D

M

T

D

M

1

0

5

m

i

n

.

8

0

m

i

n

.

8

0

1

0

5

T

D

M

1

/

E

i

n

b

a

u

m i n . 8 0

6

0

7

3 7 3

3 9 0

4. Controller types and related plans

Figure 13: Mounting dimensions for TDM 1.3

30 TDM Starting Lockout 9.555.012.4-05 4/94

m

i

n

.

4

0

0

m

i

n

.

2

3

2

5

m i n . 8 0

3 5 5

C

o

m

p

l

e

t

e

l

y

c

l

o

s

e

d

h

o

u

s

i

n

g

o

r

c

a

b

i

n

e

t

T

V

M

7

4

0

,

5

m

i

n

.

8

0

m

i

n

.

8

0

7

0

T

D

M

3

/

4

/

6

/

7

E

i

n

b

a

u

m i n . 8 0

7

3 7 3

3 9 0

T

D

M

T

D

M

T

D

M

T

D

M

T

D

M

9

2

0

,

5

1

0

5

6

0

4. Controller types and related plans

Figure 14: Mounting dimensions for TDM 3.3, TDM 4.3, TDM 6.1 and TDM 7.1

31 TDM Starting Lockout 9.555.012.4-05 4/94

290,5

m

i

n

.

2

0

0

61

65,5

X74

F7

X

7

3

290,5

m

i

n

.

2

0

0

61

65,5

8

0

8

0

Standard module

cooling unit LE 5-024 (24 volt fan)

Cooling unit LE 5 (115 volt or 220 volt fan)

LE5

TDM

24V-Connection

TDM

Standard type:

Obsolete type:

4. Controller types and related plans

Figure 15: Fan dimensions for TDM 3.3, TDM 4.3, TDM 6.1 and TDM 7.1

32 TDM Starting Lockout 9.555.012.4-05 4/94

Figure 16: Connection plan for TDM 1.3

1

1

2

A

1

A

2

A

3

X

8

M

b

l

a

c

k

X

1

M

A

C

2

2

0

V

X

1

3

S

p

e

c

i

a

l

3

-

p

o

l

e

c

a

b

l

e

(

1

)

M

3

M

A

C

S

e

r

v

o

M

o

t

o

r

F

G

H

E

A

B

C

D

>

B

l

o

c

k

i

n

g

b

r

a

k

e

T

h

e

r

m

o

s

t

a

t

c

o

n

t

a

c

t

M

o

t

o

r

f

e

e

d

b

a

c

k

+24VL

0VL

L

-

L

+

L

-

L

+

X

8

X

6

-15VM

0VM

+15VM

BLC 3

BLC 2

BLC 1

Tacho

0VM

1

U

D

2

B

B

3

+

1

5

V

M

4

,

5

,

6

,

7

0

V

M

8

,

9

-

1

5

V

M

1

0

0

V

L

1

1

+

2

4

V

L

1

2

X

8

X

1

4

A

C

2

2

0

V

A

C

2

2

0

V

E1

E2

E3

E4

Bb

Bb

RF

0VM

+15VM

0VM

-15VM

Ired

MA

Tsense

X

5

X

1

F

5

Anschlpl/TDM13

B

u

s

b

a

r

s

S

u

p

p

l

y

m

o

d

u

l

e

S

i

g

n

a

l

p

r

o

c

e

s

s

i

n

g

(

1

2

p

o

l

e

b

u

s

c

a

b

l

e

)

S

u

p

p

l

y

f

o

r

a

d

d

i

t

i

o

n

a

l

d

r

i

v

e

m

o

d

u

l

e

s

u

s

i

n

g

e

l

e

c

t

r

i

c

a

l

c

o

n

n

e

c

t

i

n

g

a

c

c

e

s

s

o

r

i

e

s

P

o

w

e

r

D

C

3

0

0

v

o

l

t

s

(

b

u

s

b

a

r

s

)

M

o

t

o

r

p

o

w

e

r

c

o

n

n

e

c

t

i

o

n

S

e

r

v

o

a

n

t

r

i

e

b

s

m

o

d

u

l

T

D

M

1

.

3

U

n

i

t

f

a

n

A

C

2

2

0

v

o

l

t

s

(

3

p

o

l

e

s

p

e

c

i

a

l

c

a

b

l

e

)

M

o

t

o

r

f

a

n

B

u

s

c

o

n

n

e

c

t

i

o

n

c

a

b

l

e

D

r

i

v

e

c

o

m

p

o

n

e

n

t

f

e

e

d

i

n

v

i

a

e

l

e

c

t

r

i

c

a

l

c

o

n

n

e

c

t

i

n

g

a

c

c

e

s

s

o

r

i

e

s

i

n

t

e

r

n

a

l

u

n

i

t

f

a

n

(

1

)

Programming

modules

MOD 1 / MOD 2

N

o

t

e

o

n

t

h

e

c

o

n

t

r

o

l

l

e

r

f

a

n

:

C