Production and Operations Management: A Life Cyde Approadi

Diunggah oleh

diegoacunabJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Production and Operations Management: A Life Cyde Approadi

Diunggah oleh

diegoacunabHak Cipta:

Format Tersedia

PRODUCTION

AND OPERATIONS

MANAGEMENT

A Life Cyde Approadi

Richard B. Chase

University of Soutiiern California

Nicholas J. Aquilano

University of Arizona

.

GIFT OF

THE ASIA FOUNDATION

NOT FOR RE-SALE

Fifth Edition

1989

OAI HOC QU6'C GIA HA N O

T R UN GT A N UH^ ^

IRWIN

Ho me wood, IL 60430

Boston. MA 02116

s

Contents

SECTION I

THE NATURE AND CONTEXT OF OPERATIONS

MANAGEMENT 2

Chapter 1

Introduction and Overview 4

Specific Objectives of the Book.

Operations Management Defined.

The Operations Function and Its Environment.

Operations Objectives.

Production Systems.

The Life Cycle Approach.

Operations Management and Other Business Specialties.

Historical Development of OM.

Conclusion: Current Issues in Operations Management.

Chapter 2

Productivity and Competitiveness 26

Competitiveness Defined.

Productivity Measurement and Trends.

General Causes and Solutions to the Competitiveness Problem.

Productivity and Competitiveness.

Competitive Priorities,

Manufacturing's Role in Corporate Strategy.

Case: Splash-N-Wipe Manufacturing.

SECTION II

PRODUCT DESIGN AND PROCESS SELECTION 46

Chapter 3

Product Design and Process SelectionManufacturing 48

Product Design and Development Sequence.

Product Design and Selection.

Process Selection.

Automation.

Process Flow Design.

Case: The W. C. Adams Company.

XI

Xfi Contents

Supplement

Computer-Integrated Manufacturing 75

Computer-Integrated Manufacturing.

Benefits of CIM.

Examples of CIM.

Reading: MAP Pilot Pays Off for Lockheed.

Chapter 4

Product Design and Process SelectionServices 92

The Nature and Importance of Services.

An Operational Classification of Services.

A Systems View of High-Contact Services.

Service-System Design Matrix.

Service Blueprinting.

Identifying Sales Opportunities.

Three System Design Options.

Case: Kinko's Copier Stores.

Tutorial 1

Waiting Line Theory 120

Economics of the Waiting Line Problem.

Waiting Line Characteristics.

Seven Typical Waiting Line Situations.

Computer Simulation of Waiting Lines.

Chapter 5

Design of the Quality Control System 162

Organization and Role of the Quality Control Function.

Meaning and Measurement of Quality.

Cost of Quality.

Statistical Quality Control (SQC).

Acceptance Sampling.

Process Control Procedures.

Taguchi Methods.

Personnel Considerations.

Quality Measurement in Service Industries.

Reading: Making Quality Control Theories Workable.

SECTION III

DESIGN OF FACILITIES AND JOBS 212

Chapter 6

Forecasting 214

Demand Management.

Types of Forecasting.

Contents xiii

Components of Demand.

Casual Relationships.

Time Series Analysis.

Forecast Errors.

Focus Forecasting.

Computer Programs.

Chapter 7

Capacitv Planning and Location 270

Importance of Capacity Decisions.

Important Capacity Concepts.

Capacity Planning.

Facility Location.

Locating Service FaciHties.

Case: Community Hospital.

Case: Zepf Technologies Inc. (B).

Tutorial 2

Linear Programming 308

The Linear Programming Model.

Graphical Linear Programming.

The Simplex Method.

Transportation Method.

Assignment Method.

Karmarkar's Algorithm for Solving Linear Programming Problems.

General Algebraic ModeHng System (GAMS).

Chapter 8

Facility Layout 356

Basic Layout Formats.

Process Layout.

Product Layout.

Assembly Lines.

Assembly Line Balancing.

Mixed-Model Line Balancing.

The Contemporary Approach to Lines.

Group Technology (Cellular) Layout.

Tutorial 3

Simulation 386

Definition of Simulation.

Simulation Methodology.

Computerization of the Fish Market Example.

Simulating Waiting Lines.

Simulation Programs and Languages.

Advantages and Disadvantages of Simulation.

xfv OofKcnts

Chapter 9

Job Design and Work Measurement 42^

Job Design.

Behavioral Considerations in lob Desit^n.

Physical Considerations in Job Design.

Methods, Measurement, and Payment.

SECTION IV

STARTUP OF THE SYSTEM 470

Chapter 10

Project Planning and Control 472

Definition of Project Management.

Organizational Forms.

Project Control.

Critical Path Scheduling.

Time-Oriented Techniques.

Time-Cost Models.

Computer Programs for Project Scheduling.

Criticisms of PERT and CPM.

Tutorial 4

Experience Curves 514

Predicting Startup Progress: Experience Curves.

Simple Exponential Curve.

Time-Constant Learning Curve Model.

SECTION V

THE SYSTEM IN STEADY STATE 542

Chapter 11

Aggregate Planning 544

Overview of Manufacturing Planning Activities.

Hierarchical Production Planning.

Aggregate Production Planning.

Aggregate Planning Techniques.

Chapter 12

Inventory Systems for Independent Demand 576

Independent versus Dependent Demand.

Definition of Inventory.

Purpose of Inventory.

Inventory Costs.

Inventory Systems.

Contents xv

Basic Model Types.

A Major Problem: Determining ReaHstic Costs.

Chapter 13

Inventory Systems for Dependent Demand:

Materials Requirements Planning

A Simple MRP Example. ^^^

Material Requirements Planning (MRP) Systems.

Material Requirements Planning Systems Structure.

An Example Using MRP.

MRP in Services.

Capacity Requirements Planning.

Manufacturing Resource Planning (MRP II).

Miscellaneous MRP Issues.

Instalhng an MRP System.

Case: Nichols Company.

Chapter 14

Operations Planning and Control 672

Job Shop Defined.

Scheduling and Control in the Job Shop.

Elements of the Job-Shop Scheduling Problem.

Priority Rules and Techniques.

Shop-Floor Control.

Example of a Total System: H. P.'s Production Management/3000.

Personnel Scheduling in Services.

Case: McCall Diesel Motor Works.

Chapter 15

Materials Management and Purchasing "02

Overview of the Materials-Flow Process.

Organizational Placement of Materials Management.

Purchasing.

Materials Management and Manufacturing.

Marketing and Distribution.

Case: Thomas Manufacturing Company.

Case: Ohio Tool Company.

SECTION VI 732

IMPROVING THE SYSTEM

Chapter 16 734

lust-in-Time Production Systems

The Japanese Approach to Productivity

How to Accomplish JIT Production.

KV^ Oot^eaa

Some Technical Issues about Kanban.

Company Experiences with JIT.

Case: XYZ Products Company.

Case: McCall Diesel Motor Works Revisited.

Supplement

JIT for Services 774

JIT: Not Just for the Factory.

Midway Airlines Problem-Solving Groups Apply Analytical Tools to

Departure Delays.

Japanese Management and the 100 Yen Sushi House.

Chapter 17

Synchronized Manufacturing 790

Hockey-Stick Phenomenon.

Goal of the Firm.

Performance Measurements.

Attempts to Balance Capacity.

Bottlenecks, Nonbottlenecks, and Capacity-Constrained Resources.

Basic Manufacturing Building Blocks.

Comparing Synchronized Manufacturing to MRP and JIT.

Methods for Control in Synchronized Manufacturing.

VAT Classification of Firms.

Relationship with Other Functional Areas.

Estabhshing a Process of Ongoing Improvement.

Chapter 18

Revising Operations Strategy 840

Manufacturing's Role in Corporate Strategy.

Developing and Implementing a Manufacturing Strategy.

Operations Strategy in Services.

The Service Factory.

Case: Memphis Toy Company.

Case: Big Jim's Gym.

APPENDIXES 869

A: Financial Analysis in Production and Operations

Management 870

B: Uniforrnly Distributed Random Digits 890

C: Normally Distributed Random Digits 891

D: Areas of the Standard Normal Distribudon 892

E: Areas of the Cumulative Standard Normal Distribudon 893

F: Negadve Exponential Distribudon: Values of e"^ 899

G: Cumulative Poisson Disinbution 901

H- !ntrft Tables 907

! Answers to Selected Problems 913

QIC

T H E MC G R A W- H I L L / I R WI N SER?

Operations and Decision Sciences

OPERATIONS MANAGEMENT

Bowersox and Closs

Logistical Management: The Integrated Supply Chain Process

First Edition

Chase, Aquilano, and Jacobs

Operations Management tor Competitive Advantage

Ninth Edition

Chu, Hottenstein, and Greenlaw

PROSIM for Windows

Third Edition

Cohen and Apte

Manufacturing Automation

First Edition

Davis, Aquilano, and Chase

Fundamentals of Operations Management

Third Edition

Dobler and Burt

Purchasing and Supply Management

Sixth Edition

Flaherty

Global Operations Management i

First Edition

Fitzsimmons and Fitzsimmons

Service Management: Operations, Strategy, Information Technology

Third Edition

Gray and Larson

Project Management: The Managerial Process

First Edition

Hill

Manufacturing Strategy: Text & Cases

Third Edition ,

Hopp and Spearman

Factory Physics

Second Edition

Jacobs and Whybark

Why ERP: A Primer on SAP Implementaion

First Edition

Lambert and Stock

Strategic Logistics Management

Third Edition

Leenders and Fearon

Purchasing and Supply Chain Management

Eleventh Edition

Moses, Seshadri, and Yakir

HOM Operations Management Software for Windows

First Edition

Nahmias

Production and Opeiotions Analysis

Fourth Edition

Nicholas

Competitive Manufacturing Management

First Edition

Olson

Introduction to Information Systems Project Ma-

First Edition

Pinedo and Chao

Operations Scheduling

First Edition

Sanderson and IJ/umeri

Managing Product Families

First Edition

Schroeder

Operations Management: Contemporary Concepts and Cases

First Edition

Schonberger and Knod

Operations Management

Seventh Edition

Simchi-Levi, Kaminsky, and Simchi-Levi

Designing and Managing the Supply Chain: Concepts, Strategies,

and Case Studies

First Edition

Sterman

Business Dynamics: Systems Thmknig and Modeling for a Complex World

First Edition

Stevenson

Production/Operations Management

Sixth Edition

Vollmann, Berry, and Whybark

Manufacturing Planning & Control Systems

Fourth Edition

Zipkin

Foundations of Inventory Management

First Edition

QUANTITATIVE METHODS AND MANAGEMENT SCIENCE

Alwan

Statistical Process Analysis

First Edition

Bodily, Carraway, Frey, Pfeifer

Quantitative Business Analysis: Casebook

First Edition

Bodily, Carraway, Frey, Pfeifer

Quantitative Business Analysis: Text and Cases

I It St Edition

Bonini, Hausman, and Bierman

Quantitative Analysis for Business Decisions

Ninth Edition

Hesse

Managerial Spreadsheet Modeling and Analysis

First Edition

Hillier, Hillier, Liebemian

Intrt)duction to Management Science: A Modeling and Case Studies

Approach with Spreadsheets

First Edition

C O N T E N T S I N B R I E F

S E C T I O N O N E

OPERATIONS STRATEGY AND MANAGI NG

CHANGE

1 I nt r oduct i on t o t he Fi el d 4

2 Oper at i ons Strategy and

Compet i t i veness 22

Technical Note 2 Learning Curves 40

3 Proj ect Managennent 56

S E C T I O N T w o

PRODUCT DESIGN AND PROCESS SELECTION

4 Process Anal ysi s 90

Technical Note 4 Job Design and Work

Measurement 113

5 Product Design and Process

Sel ect i on Manuf act ur i ng 142

Technical Note 5 Facility Layout 174

6 Product Design and Process

Sel ect i onServi ces 206

Technical Note 6 Waiting Line Management

230

7 Qual i t y Managennent 258

Technical Note 7 Process Capability and

Statistical Quality Control 290

S E C T I O N T H R E E

SUPPLY CHAI N DESI GN

Managerial Briefing Electronic Commerce

and E-Ops" 316

8 Suppl y Chain Strategy 330

9 Strategi c Capaci t y Management 352

Technical Note 9 Facility Location 373

10 Just-i n-Ti me and Lean Systems 392

S E C T I O N F O U R

PLANNI NG AND CONTROLLI NG THE SUPPLY

CHAI N

Managerial Briefing Enterprise Resource

Planning Systems 420

11 F^-^--sting 432

'^~ Aggregate Piannsrig 460

"^3 I f uci i t L . oncroi -:

14 Mau. Requirerrients f-

15 v^,'peratior!S Sc?

Technical No'.

SE

REVISING J^C- SVS^

16 Oper at i ons Co-is

Reengi neeri ng 640

17 Synchronous Manuf act ur i ng a

Theor y of Const rai nt s 662

SUPPLEMENTS

A Linear Programmi ng wi t h t he Excel

Sol ver 694

B Fi nanci al Anal ysi s 703

C Oper at i ons Technol ogy 720

APPENDICES

A Answers t o Sel ect ed Problems 729

B Uni forml y Di stri buted Random Digits 734

C Normal l y Di st ri but ed Random Digits 735

D Areas of t he Standard Normal

Di st r i but i on 736

E

F

G

Areas of t he Cumul at i ve Standard

Nor mal Di st r i but i on 737

Negat i ve Exponenti a

Value of e~' 738

I nt erest Tables 739

1 Di st r i but i on:

PHOTO CREDITS 743

NAME INDEX 745

C i i D i c / " T l M r \ c v r7C: i

Anda mungkin juga menyukai

- Statistical Methods For Machine LearningDokumen291 halamanStatistical Methods For Machine Learninggiby jose100% (1)

- Fundamentals of Financial ManagementDokumen131 halamanFundamentals of Financial ManagementDhanraj MoreBelum ada peringkat

- Dynamics of Financial System: A System Dynamics ApproachDokumen14 halamanDynamics of Financial System: A System Dynamics ApproachAbraham SuarezBelum ada peringkat

- (Catherine M. Price (Auth.) ) Welfare Economics PDFDokumen179 halaman(Catherine M. Price (Auth.) ) Welfare Economics PDFNino PapachashviliBelum ada peringkat

- Samples of Solution Manual For Capital Investment Analysis For Engineering and Management 3rd Edition by John R. CanadaDokumen15 halamanSamples of Solution Manual For Capital Investment Analysis For Engineering and Management 3rd Edition by John R. CanadaIMZN0% (1)

- Organizational life cycle A Complete Guide - 2019 EditionDari EverandOrganizational life cycle A Complete Guide - 2019 EditionBelum ada peringkat

- 02-Instrument Types and Performance Characteristics PDFDokumen28 halaman02-Instrument Types and Performance Characteristics PDFPao Castillon100% (2)

- Principles of Project FinanceDokumen10 halamanPrinciples of Project FinanceEdgar Diaz NietoBelum ada peringkat

- 2020: Achieving Supply Chain Visibility & Operational EfficiencyDokumen35 halaman2020: Achieving Supply Chain Visibility & Operational EfficiencyAaron BoatengBelum ada peringkat

- Exam Style Answers 3 Asal Physics CBDokumen2 halamanExam Style Answers 3 Asal Physics CBAnshul ShahBelum ada peringkat

- 03 Lean Accounting - A Connection To Strategic Partnership & CollaborDokumen105 halaman03 Lean Accounting - A Connection To Strategic Partnership & CollaborAndrey SidorovBelum ada peringkat

- Lean Accounting, Costs of Quality & Target Costing: Oleh: Suyanto, MBA., Dipl. ResDokumen47 halamanLean Accounting, Costs of Quality & Target Costing: Oleh: Suyanto, MBA., Dipl. ResrikiBelum ada peringkat

- Authors BookDokumen176 halamanAuthors BookOliwiaBelum ada peringkat

- Process Management: ISBN 978-953-307-085-8Dokumen356 halamanProcess Management: ISBN 978-953-307-085-8RAUL EDUARDO GUTIERREZ COITIÑOBelum ada peringkat

- Productivity and Reliability-Based Maintenance Management, Second EditionDari EverandProductivity and Reliability-Based Maintenance Management, Second EditionBelum ada peringkat

- (Ray Proctor, Nigel Burton, Adrian Pierce, Gary BuDokumen642 halaman(Ray Proctor, Nigel Burton, Adrian Pierce, Gary BuMohammed BENMESSAOUDBelum ada peringkat

- Note LogisticsDokumen24 halamanNote LogisticsMohammad Halis AzhanBelum ada peringkat

- Chapter One (Operations Management)Dokumen46 halamanChapter One (Operations Management)sam.geneneBelum ada peringkat

- Fba 311 (March 2021) Lecture - Managing Emerging TechnologiesDokumen17 halamanFba 311 (March 2021) Lecture - Managing Emerging Technologiesfaith ola100% (1)

- ME LM SyllabusDokumen5 halamanME LM SyllabusSiddharth Narayanan ChidambareswaranBelum ada peringkat

- Peter S. H. Leeflang Dick R. Wittink Mi PDFDokumen642 halamanPeter S. H. Leeflang Dick R. Wittink Mi PDFGabriela Ioana IonitaBelum ada peringkat

- 1898 Ford Operations ManagementDokumen8 halaman1898 Ford Operations ManagementSanthoshAnvekarBelum ada peringkat

- Syllabus MacroeconomicsDokumen2 halamanSyllabus Macroeconomicspuliyanam100% (1)

- Case AnalysisDokumen18 halamanCase AnalysisShazeeb SalimBelum ada peringkat

- 1 Statistical Quality Control, 7th Edition by Douglas C. MontgomeryDokumen76 halaman1 Statistical Quality Control, 7th Edition by Douglas C. Montgomeryehab kamal100% (1)

- Dea PDFDokumen149 halamanDea PDFErizal SutartoBelum ada peringkat

- OM - QAB-Unit 1Dokumen33 halamanOM - QAB-Unit 1GOVINDASAMY PBelum ada peringkat

- Financing Technology Entrepreneurs in Developing CountriesDokumen103 halamanFinancing Technology Entrepreneurs in Developing CountriesNgoan TranBelum ada peringkat

- Introduction To Optimization: MIT and James Orlin ©2003 1Dokumen39 halamanIntroduction To Optimization: MIT and James Orlin ©2003 1john tylerBelum ada peringkat

- Accounting For ManagementDokumen225 halamanAccounting For ManagementHanan QureshiBelum ada peringkat

- IE-L1-Presentation New - Work Study and Job DesignDokumen93 halamanIE-L1-Presentation New - Work Study and Job Designsanjeewa herathBelum ada peringkat

- Absolute Essentials of Operatio - Andrew GreasleyDokumen125 halamanAbsolute Essentials of Operatio - Andrew GreasleyBhavya RastogiBelum ada peringkat

- Jacobs - 2e Prefácio PDFDokumen33 halamanJacobs - 2e Prefácio PDFNum ToukaBelum ada peringkat

- Finance and Marketing: Masters Engineering RoutesDokumen44 halamanFinance and Marketing: Masters Engineering RoutesHoàngAnhBelum ada peringkat

- Management and Cost Accounting: Colin DruryDokumen14 halamanManagement and Cost Accounting: Colin DruryUmar SulemanBelum ada peringkat

- Chap 009Dokumen40 halamanChap 009Fatma AlmheiriBelum ada peringkat

- Aputo-The Effect of Procurement Functions On Project Performance in Non Governmental Organizations in Nairobi County, KenyaDokumen72 halamanAputo-The Effect of Procurement Functions On Project Performance in Non Governmental Organizations in Nairobi County, KenyahajiBelum ada peringkat

- Operations Management, 3rd Canadian Edition Samplech01Dokumen29 halamanOperations Management, 3rd Canadian Edition Samplech01Erik LeeBelum ada peringkat

- Management Information Assignment 2Dokumen23 halamanManagement Information Assignment 2clintonblouw100% (1)

- DSC3705 Study Guide 2016Dokumen108 halamanDSC3705 Study Guide 2016Georg100% (1)

- Publicações Com DEADokumen648 halamanPublicações Com DEAAnonymous b0cKPzDMqfBelum ada peringkat

- Week 1 Workshops Learning Activity: RequiredDokumen3 halamanWeek 1 Workshops Learning Activity: RequiredRegina AtkinsBelum ada peringkat

- Sri Sairam Institute of Technology Department of Management StudiesDokumen11 halamanSri Sairam Institute of Technology Department of Management StudiesAbhinayaa SBelum ada peringkat

- Syllabus - Lean and Agile ManufacturingDokumen2 halamanSyllabus - Lean and Agile ManufacturingjvanandhBelum ada peringkat

- Full Text PDFDokumen332 halamanFull Text PDFManish Singh100% (1)

- Introduction Operational ManagementDokumen16 halamanIntroduction Operational Managementpalak32Belum ada peringkat

- DEA2013 Proceedings PDFDokumen443 halamanDEA2013 Proceedings PDFГалина Йорданова-ЧавговаBelum ada peringkat

- Business Research Methods Lecutre Notes ALL UNITSDokumen75 halamanBusiness Research Methods Lecutre Notes ALL UNITSshahnilaBelum ada peringkat

- Financial Cash Flow Determinants of Company Failure in The Construction Industry (PDFDrive) PDFDokumen222 halamanFinancial Cash Flow Determinants of Company Failure in The Construction Industry (PDFDrive) PDFAnonymous 94TBTBRksBelum ada peringkat

- Data Mining: Sabiha Kanwal 2012003214Dokumen11 halamanData Mining: Sabiha Kanwal 2012003214StyloKuriBelum ada peringkat

- Inventory Models: Single Quantity: 1.purchase Model Without ShortagesDokumen6 halamanInventory Models: Single Quantity: 1.purchase Model Without ShortagesmunotmanasBelum ada peringkat

- FM Notes PDFDokumen311 halamanFM Notes PDFhitmaaaccountBelum ada peringkat

- Student Handbook HETAC MBADokumen13 halamanStudent Handbook HETAC MBAfinalversionBelum ada peringkat

- Activity Based CostingDokumen19 halamanActivity Based CostingChristine Mae MataBelum ada peringkat

- Business Improvement Districts: An Introduction to 3 P CitizenshipDari EverandBusiness Improvement Districts: An Introduction to 3 P CitizenshipBelum ada peringkat

- Real Estate Management Strategies & Tactics - How to Lead Agents and Managers to Peak PerformanceDari EverandReal Estate Management Strategies & Tactics - How to Lead Agents and Managers to Peak PerformanceBelum ada peringkat

- Project Production Management A Complete Guide - 2020 EditionDari EverandProject Production Management A Complete Guide - 2020 EditionBelum ada peringkat

- Value Chain Management Capability A Complete Guide - 2020 EditionDari EverandValue Chain Management Capability A Complete Guide - 2020 EditionBelum ada peringkat

- 1) Management Information SystemsDokumen13 halaman1) Management Information Systemssagar09100% (1)

- Operation ManagementDokumen10 halamanOperation ManagementPritam RoyBelum ada peringkat

- 20MBA21 SyllabusDokumen4 halaman20MBA21 SyllabusBheemeswar ReddyBelum ada peringkat

- Spyros@isye - Gatech.edu WWW - Isye.gatech - Edu/ SpyrosDokumen3 halamanSpyros@isye - Gatech.edu WWW - Isye.gatech - Edu/ SpyrosVinay KumarBelum ada peringkat

- Enterprise Ai in The Cloud A Practical Guide To Deploying End To End Machine Learning and Chatgpt Solutions Rabi Jay Download 2024 Full ChapterDokumen48 halamanEnterprise Ai in The Cloud A Practical Guide To Deploying End To End Machine Learning and Chatgpt Solutions Rabi Jay Download 2024 Full Chapterlucy.federico457100% (9)

- Stratego AlgorithmsDokumen74 halamanStratego AlgorithmsbobertstokesBelum ada peringkat

- Peter Maandag 3047121 Solving 3-Sat PDFDokumen37 halamanPeter Maandag 3047121 Solving 3-Sat PDFVibhav JoshiBelum ada peringkat

- CSLABMANUALDokumen99 halamanCSLABMANUALGOKUL RBelum ada peringkat

- ABSTRACTDokumen41 halamanABSTRACTSaidhaBelum ada peringkat

- 1 ShaftDokumen20 halaman1 ShaftAJ BantayBelum ada peringkat

- Pseudo 1Dokumen1 halamanPseudo 1Chamari JayawanthiBelum ada peringkat

- The Journal of Space Syntax (JOSS)Dokumen9 halamanThe Journal of Space Syntax (JOSS)Luma DaradkehBelum ada peringkat

- Watermarking For Video AuthenticationDokumen29 halamanWatermarking For Video Authenticationhirenbhalala708Belum ada peringkat

- Experiment 1: Output and Delay Thayja Rae O. Magana: Display (LED) Binary Decimal HexadecimalDokumen2 halamanExperiment 1: Output and Delay Thayja Rae O. Magana: Display (LED) Binary Decimal HexadecimalThayja Rae Opiana MaganaBelum ada peringkat

- Tutorial 1Dokumen3 halamanTutorial 1Manvendra TomarBelum ada peringkat

- CBSE Class 12 Physics Alternating Current NotesDokumen84 halamanCBSE Class 12 Physics Alternating Current NotesSanikaa MadhuBelum ada peringkat

- Cambridge Espresso - 42 - Division - and - MultiplicationDokumen2 halamanCambridge Espresso - 42 - Division - and - Multiplicationilonka kolevaBelum ada peringkat

- C4 Vectors - Vector Lines PDFDokumen33 halamanC4 Vectors - Vector Lines PDFMohsin NaveedBelum ada peringkat

- Digital SAT Tests MATH Explanation (Mr. Amr Mustafa)Dokumen196 halamanDigital SAT Tests MATH Explanation (Mr. Amr Mustafa)mr.samirjon.07Belum ada peringkat

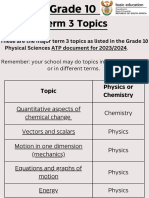

- Grade 10 Term 3 TopicsDokumen10 halamanGrade 10 Term 3 TopicsOwamiirh RsaBelum ada peringkat

- Vedic MathsDokumen8 halamanVedic Mathsnithin s gowda100% (1)

- Essbase MDXDokumen23 halamanEssbase MDXapi-26942036Belum ada peringkat

- 09 Energy&Aeronautics&AuronauticsDokumen211 halaman09 Energy&Aeronautics&AuronauticsDorisman Feriandi SimorangkirBelum ada peringkat

- Chetan PrakashDokumen48 halamanChetan PrakashpatrickBelum ada peringkat

- MCQ in Computer Fundamentals Part 1 ECE Board ExamDokumen18 halamanMCQ in Computer Fundamentals Part 1 ECE Board ExamLuelson CordovaBelum ada peringkat

- Mark Scheme (Results) January 2019: Pearson Edexcel International GCSE Mathematics A (4MA0) Foundation Tier Paper 2FRDokumen14 halamanMark Scheme (Results) January 2019: Pearson Edexcel International GCSE Mathematics A (4MA0) Foundation Tier Paper 2FRLIN YANBelum ada peringkat

- Sigma Plot UserguideDokumen526 halamanSigma Plot UserguideCleber JadoskiBelum ada peringkat

- Etap - Key Points For Load Summary, Part 4: Lumped Load ApplicationsDokumen2 halamanEtap - Key Points For Load Summary, Part 4: Lumped Load ApplicationsMarcelBelum ada peringkat

- Mit SyllabusDokumen2 halamanMit SyllabusKarnan ArjunBelum ada peringkat

- Process ControlDokumen57 halamanProcess Controlneerajtrip123Belum ada peringkat

- Polygon ClippingDokumen25 halamanPolygon ClippingSahil Gupta50% (2)

- Lecture 3 Bilinear TFDokumen32 halamanLecture 3 Bilinear TFNathan KingoriBelum ada peringkat