Jet Pump

Diunggah oleh

dewidar1234Deskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Jet Pump

Diunggah oleh

dewidar1234Hak Cipta:

Format Tersedia

Hydraulic Jet Pumps

1.0 General

Jet Pumps are very important members in family of hydraulic pumps.

Production and power fluid rates in Jet Pumps are controlled by a nozzle/venturi

arrangement. Different geometry configurations are used for controlling the

clearance between the nozzle and mixing tube orifices, as specified by a

computer, to attain proper production rates.

2.0 Advantages

Jet Pumps have no moving parts, they are especially attractive because of

low maintenance costs, long runs, and either high or low volumes. Usually,

the main point of failure will be either a nozzle or mixing tube, either of which

may be easily replaced, even at the well site.

Jet Pumps are available in 2-inch, 2.5-inch, 3-inch and 4-inch sizes, in

standard materials or premium materials to fit almost every competitive

bottom-hole assembly.

Jet Pumps are of the free-pump concept, which incorporate all the

advantages previously listed for free pumps.

Capable of handling extremely high volumes.

Adjustable to varying production rates.

Low maintenance costs.

Pressure and temperature recording devices may be used as an integral

addition to the pump

Suitable for low gravity and high-pour-point crude oils.

Adaptable for use with a sliding sleeve.

Can be run in crooked holes.

Handles gassy production

Handles solids and corrosive fluids

3.0 Limitations

Producing Rate Relative to Bottomhole Pressure

Some Require Specific Bottomhole Assemblies

Lower Horsepower Efficiency

4.0 How it works

1. Power fluid is pumped at a given rate (Q

N

) to the down-hole jet pump

where it reaches a nozzle with a total pressure, designated as P

N

. This

high-pressure fluid (high potential energy) is then directed through the

nozzle, which converts the fluid stream to a high velocity (high kinetic

energy) and low static pressure.

2. The low pressure (P

S

) allows well fluids to flow into the well bore and

pump at the desired production rate (Q

S

). The high-momentum power fluid

is then mixed with the low-momentum production in a constant area

mixing tube. It is in this mixing process that energy is transferred from the

power fluid to the production. When the combined fluids reach the end of

the mixing tube, they are at a low pressure and high velocity.

3. The fluid then exits the pump through a diffuser section which converts the

fluid to a high-static-pressure, low velocity state. This high discharge

pressure (P

D

) must be sufficient to lift the combined fluid rate (Q

D

) to the

surface.

4. The key components of the jet pump are the nozzle and mixing tube

(throat). The area of the openings in these parts determines the

performance characteristics of the pump. These areas are designated as

A

N

and A

T

.

5. The ratio of these areas, A

N

/A

T

, is referred to as the area ratio. Pumps

with the same area ratio have the same performance curve.

6. The volume of power fluid used will be proportional to the size of the

nozzle.

7. The sizes of nozzles and throats determine the flow rate while the ratio of

their flow areas determines tradeoff between produced head and flow rate.

8. If, for example, a throat is selected such that the area of the nozzle is 60%

of the throat area, a relatively high head, low flow will result. There is a

small area around the jet for well fluids to enter, leading to low production

rates.

9.

10. If, on the other hand, a throat is selected such that the area of the nozzle

is 20% of the throat area, more production flow is possible, but, since the

nozzle energy is being transferred to a large amount of production, lower

head will be developed.

11. The cavitation characteristics of the pump must be considered, cavitation

will occur when the velocity of the produced fluids entering the throat

around the power fluid jet is high enough that static pressure in the fluid

falls to its vapor pressure. This will choke the flow and damage the throat.

5.0 Selecting a Pump

The Jet Pump selected to produce a well must have a capacity large enough to

obtain the rate of production the well is capable of producing. At the same time,

the required surface horsepower must be kept at a reasonable level.

The task of selecting the proper jet pump involves finding a pump geometry

capable of achieving the production rate, but capable of operating within given

horsepower requirements, or at an optimum horsepower.

The calculations on the following pages will provide the information necessary

to select the correct pump for any application.

6.0 Jet pump design step by step

1. From well data for production, Q

S

, and pump intake pressure, P

S

and GOR,

calculate the minimum annular area to avoid cavitations.

2. From the table of annular area, select nozzle and throat combination which

has an annular area greater than A

SM

3. Calculate the pressure at the nozzle, P

N

, which is the sum of the operating

pressure (known from the available Pump [triplex or horizontal pump]) plus

the hydrostatic pressure in the tubing minus friction losses in the tubing.

4. The friction in the annular or tubing can be determined from.

Annular flow Tubing flow

D

1

Casing I.D Tubing I.D

D

2

Tubing O.D 0

5. Determine the power fluid rate, Q

N

from,

6. Determine the returned flow rate, Q

D,

7. Determine the production gradient (pump suction),

8. Determine the returned flow fluid gradient, G

D,

from,

9. Calculate the returned flow WC, WC

D

10. Calculate the returned flow gas liquid ratio, GLR,

11. Determine the returned flow liquid viscosity for calculating friction loss,

D

from,

12. Calculate the pump discharge pressur P

D

pressur which is the sum of

hydrostatic pressure in the reurn conduit, the friction losses, and the well

head back pressure,

13. Calculate N (dimensionless pressure recover ratio) from,

14. Calculate M (dimensionless mass flow ratio) from,

15. Calculate N (dimensionless pressure recover ratio), for the value of R

selected, using of M from step 11

16. Compare the current value of N with the N value from step 13. if the

difference is less than 0.5%, iteration is completed go to step 19 otherwise

go to step 17.

17. If the required is power fluid pressure, calculate new nozzle pressure from

equation,

Then go to step 5

18. If the required is PIP, calculate it from the equation,

Then go to step 3

19. Determine the new surface operating pressure (triples) from equation,

20. Calculate the maximum non-cavitating flow from equation,

21. Calculate triplex HP assuming 90% efficiency from the equation,

7.0 Glossary

A

N

= Nozzle flow area in2

A

S

= Throat annulus area (A

T

-A

N

) in2

A

SM

= Minimum throat annulus area to avoid cavitation in2

A

T

= Throat flow area in

2

D = Vertical depth of well ft

D

1

= ID of tubing or casing in

D

2

= OD of inner tubing in annular flow in

G

D

= Gradient of returned mixed power fluid and producing fluid psi/ft

GLR = Returned flow gas liquid ratio scf/bbl

G

N

= Power fluid gradient at nozzle psi/ft

G

O

= Produced oil gradient psi/ft

GOR = Gas oil ratio scf/bbl

G

S

= Water gradient psi/ft

KN = Nozzle loss coefficient

KTD = Throat-diffuser loss coefficient

L = Tubing length ft

M = Dimensionless mass flow rate

N = Dimensionless pressure recovery ratio

P

D

= Pump discharge pressure psi

P

F

= Friction loss in tubing psi/ft

P

FN

= friction loss in power fluid tubing psi/ft

P

FD

= Friction loss in returned conduit psi/ft

P

N

= pressure at nozzle interance psi

P

S

= pump suction pressure (Pwf) psi

P

T

= Surface operating pressure (triplex pressure) psi

P

WH

= Well head pressure psi

Q

D

= Flow rate from pump discharge bpd

Q

G

= Flow rate of gas through pump bpd

Q

N

= Flow rate through the nozzle bpd

Q

S

= Producing flow rate bpd

Q

SC

= Minimum non-cavitating pump suction flow rate bpd

R = Nozzle throat areas ration (A

N

/A

T

)

WC = Water cut (decimal)

W

CD

= Returned flow water cut

D

= Returned fluid viscosity cp

O

= Viscosity of oil cp

W

= Viscosity of water cp

Guiberson A

N

, A

T

, A

S

, and R as Example:

Nozzle

A

Throat 1 2 3

1

R 0.38 0.29 0.23

AS 0.0088 0.0134 0.0186

A+

Throat 1 2 3 4 5

2

R 0.52 0.4 0.31 0.24 0.2

AS 0.0068 0.0114 0.0166 0.0239 0.0305

B

Throat 1 2 3 4 5 6

3

R 0.66 0.5 0.39 0.3 0.25 0.21

AS 0.0048 0.0094 0.0146 0.0219 0.0285 0.0357

B+

Throat 1 2 3 4 5 6 7

0.04

R 0.76 0.58 0.45 0.35 0.29 0.24 0.21

AS 0.0034 0.008 0.0132 0.0205 0.0271 0.0343 0.0422

C

Throat 1 2 3 4 5 6 7

5

R 0.86 0.65 0.51 0.39 0.32 0.27 0.23

AS 0.002 0.0066 0.0118 0.0191 0.0257 0.0329 0.0408

C+

Throat 2 3 4 0.05 6 7 8

6

R 0.79 0.62 0.48 0.39 0.33 0.28 0.23

AS 0.0039 0.0091 0.0164 0.023 0.0302 0.0381 0.0511

D

Throat 3 4 5 6 7 8 9

7

R 0.73 0.56 0.47 0.39 0.33 0.27 0.22

AS 0.0064 0.0137 0.0203 0.0275 0.0354 0.0484 0.0627

E

Throat 4 5 6 7 8 9 10 11

8 R 0.77 0.63 0.53 0.45 0.36 0.3 0.25 0.2

AS 0.0073 0.0139 0.0211 0.029 0.042 0.0563 0.0721 0.0954

F

Throat 6 7 8 9 10 11 12

9

R 0.69 0.59 0.48 0.39 0.33 0.26 0.22

AS 0.0138 0.0217 0.0347 0.049 0.0648 0.0881 0.1138

G

Throat 8 9 10 11 12 13 14

10

R 0.68 0.56 0.47 0.38 0.31 0.26 0.21

AS 0.0209 0.0352 0.051 0.0743 0.1 0.132 0.1713

H

Throat 10 11 12 13 14 15 16

11

R 0.69 0.55 0.46 0.37 0.31 0.25 0.21

AS 0.0301 0.0534 0.0791 0.1111 0.1504 0.1945 0.2466

I

Throat 11 12 13 14 15 16 17

12

R 0.72 0.59 0.48 0.39 0.33 0.27 0.23

AS 0.034 0.0597 0.0917 0.131 0.1751 0.2272 0.2895

J

Throat 13 14 15 16 17 18 19

13

R 0.71 0.58 0.48 0.4 0.34 0.28 0.23

AS 0.0515 0.0908 0.1349 0.187 0.2493 0.3256 0.4167

K

Throat 15 16 17 18 19 20

14

R 0.61 0.51 0.42 0.35 0.29 0.24

AS 0.1016 0.1537 0.216 0.2923 0.3834 0.4928

L

Throat 16 17 18 19 20

15

R 0.63 0.52 0.43 0.36 0.3

AS 0.1164 0.1787 0.255 0.3461 0.4555

M

Throat 17 18 19 20

16

R 0.66 0.55 0.45 0.38

AS 0.1287 0.205 0.2961 0.4055

N

Throat 18 19 20

17

R 0.69 0.57 0.48

AS 0.1396 0.2307 0.3401

P

Throat 19 20

18

R 0.71 0.59

AS 0.1576 0.267

Throat Nozzle

No. Area Nom. Area

1 0.0143 A 0.0055

2 0.0189 A+ 0.0075

3 0.0241 B 0.0095

4 0.0314 B+ 0.0109

5 0.038 C 0.0123

6 0.0452 C+ 0.015

7 0.0531 D 0.0177

8 0.0661 E 0.0241

9 0.0804 F 0.0314

10 0.0962 G 0.0452

11 0.1195 H 0.0661

12 0.1452 I 0.0855

13 0.1772 J 0.1257

14 0.2165 K 0.159

15 0.2606 L 0.1963

16 0.3127 M 0.2463

17 0.375 N 0.3117

18 0.4513 P 0.3848

19 0.5424

20 0.6518

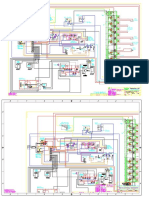

8.0 Surface equipment package for hydraulic pumping applications.

It provides complete fluid conditioning as well as a surface pump to provide

pressurized power fluid to the down-hole pump.

It is designed for continuous operation and will perform satisfactorily when properly

set, adjusted and maintained. Periodic inspections and repairs will be required.

The end-user of the equipment must determine the intervals of inspections.

System Description

The fluid and gas Check Valve received from the producing well are fluids from the

formation and fluids that have been used to power the down-hole hydraulic pump

which have been co-mingled down hole.

Check valve

The fluids first enter the package through a check valve normally furnished by

the user of the equipment.

Accumulator Surge Vessel

The first entrance of fluids into the unit itself will be at the accumulator surge

vessel (25) (vertical separator). See the drawing below.

The purpose of the accumulator surge vessel (25) is to prevent excess gas

from entering the cyclone desander (9) causing cyclone desander inefficiency.

The vertical separator also serves as a surge chamber should the vessel be

subjected to a high-pressure kick from the well. It prevents the surge from

being transmitted to the cyclone desander and the conditioning vessel.

Surge Control Valve

The surge control valve (13) is set to open whenever a high-pressure surge is

sensed at the valve inlet (i.e. at the accumulation surge vessel). The valve is

normally set to open at a differential pressure of 40 psi. It can be adjusted to

sense other differentials if required.

If too much fluid is being by-passed in front of the cyclone desander (9) with

the surge valve (13) set to open at 40 psi differential, the surge valve (13) may

be set for a higher differential pressure (up to 45 psi). This will by-pass less

fluid through valve (13) and direct more fluid through the cyclone desander (9).

If no fluid or gas is being by-passed with the surge valve (13) is set to open at

a differential of 40 psi, the surge valve (13) may be set to open at a lower

differential pressure (35 psi minimum) so that gas and some liquid will by-

pass the cyclone desander.

The surge control valve can be converted to a back-pressure regulator by

isolating the pressure source to the top of the valve diaphragm and loosening

the adjusting screw sealing nut. When a back pressure greater than 60 psi is

required, a stronger spring must be installed.

Cyclone Desander

The cyclone desander is considered to be the very heart of the 9Unit. Without

excellent solids separation, unnecessarily short pump runs and excessive

multiplex maintenance will result.

The cyclone desander(s) (9) must be sized to effect maximum solid particle

separation and furnish essentially clean fluid for the surface power fluid pump

(29) and the down-hole hydraulic pump.

The solids separated by cyclone desander (9) are discharged downward

through the cyclone desander underflow and can be viewed through visual

sight glass (22).

The clean power fluid passes from the top (overflow) of the cyclone desander

(9), through the cyclone desander outlet valve (20) and on into the fluid

conditioning vessel (24) for further separation of gas, oil, and water.

Fluid Conditioning Vessel

The retention time of the power fluid in the conditioning vessel is not really

long enough for any appreciable settling of solids particles from the fluids, so

most solids separation must be done by the cyclone desander. This is what

makes proper installation, sizing, monitoring and operation of the cyclone

desander so important to the entire system operation.

Once the hydraulic system is operating, fluid in excess of that required by the

surface and subsurface pumps is discharged from fluid conditioning vessel

(24) through manual selector valve (3) (high outlet) for oil discharge, or

through valve (4) (low outlet) for primarily water discharge.

The amount of fluid discharge from conditioning vessel (24) is controlled by

the pressure differential between conditioning vessel (24) and flow line

pressure.

The level of liquids in the conditioning vessel is maintained at a high enough

level to supply the multiplex with adequate clean fluid.

Safety Valves

The Unit is equipped with two safety valves. There is a conditioning vessel

safety valve (10) and an accumulator safety valve (14). Each valve is set to

provide over-pressure protection for the vessels.

CAUTIONS

Never pipe the safety relief outlets back

into the flow line. If a downstream valve is

closed or the flow line plugs the whole

system will be over pressured, possibly

resulting in a ruptured vessel.

The safety valves are factory set to meet

vessel specifications and are sealed. They

are not to be adjusted in the field.

Power Fluid Pump

Fluid from the conditioning vessel is supplied to the surface power fluid pump

(29) (multiplex pump) which provides pressurized liquid to operate the

subsurface hydraulic pump. The power fluid pump is powered by an electric

motor, diesel, or gas engine.

Pulsation Dampener

A pulsation dampener (32) is installed near the multiplex discharge to

dissipate "fluid hammer" in the system which can develop due to the pulsating

multiplex output.

If the pressure fluctuations from the multiplex are not damped out, the fluid

hammer can become severe enough to actually break the wellhead

connections.

As the pulsating shock waves travel farther from the pump, the reflecting

shock wave becomes amplified. These amplified pulsations, if not damped

out, will also reflect back into the fluid power pump destroying the pump. For

this reason the pulsation dampener must be located as close as possible to

the multiplex discharge.

Manual By-pass Valve

The power fluid manual by-pass valve (15) regulates the volume of power fluid

which is diverted from the down-hole pump and circulated back into the Unit

as excess power fluid.

Since the multiplex displacement is greater than the volume required to

operate the subsurface hydraulic pump, some fluid must be by-passed. The

amount by-passed fluid must be adjustable so that the volume of injected

power fluid can be varied to regulate the hydraulic pumping speed.

Control Panel

The control panel is a standard oil-field type Murphy panel with indicators and

limit controls for safety, start up, operation, and shut down.

Component Description

Accumulator Surge Vessel

The accumulator surge vessel (25) provides ample storage capacity in the event

the well "heads-up" with gas. It separates the gas and cushions abnormally

high pressure surges.

Surge Control Valve

The surge control valve (13) will open when the valve inlet receives a high surge

of pressure.

When the volume of fluid processed is great enough to cause a 40 psi pressure

loss across the cyclone desander (9) the surge valve (13) will open and excess

gas and fluid will be removed from the accumulator surge vessel (25). This

results in a fluid level near the vessel top.

The valve may also be set for other differential pressures.

Cyclone Desander

The cyclone desander (9) cleans the fluid so it can be used in the pumps. The

fluid must be cleaned sufficiently to prevent excessive wear to the surface

multiplex pump and the sub-surface hydraulic pump.

Fluid Conditioning Vessel

The fluid conditioning vessel is a storage container which separates the oil,

water and gas.

Fluid in excess of that required by the surface and sub-surface pumps is

discharged from the vessel through valve (3) for oil discharge or valve (4) for

water discharge.

When the pre-set fluid level reaches approximately 5 inches from top of the fluid

conditioning vessel, the fluid is passed into an over-flow line outside the vessel.

The overflow is routed to a pipe leading to the flow line and lease tank battery.

Vessel Safety Valves

The fluid conditioning vessel safety valves (10 & 14) prevent excessive pressure

inside each of the vessels.

Throttle Valve

The manual throttle valve (21) beneath the cyclone desander underflow will

control the fluid flow when properly adjusted. If the underflow fluid is very dirty it

tends to plug the opening, therefore the valve must be opened as fully as

possible.

If too much fluid is lost from the system the valve must be partly closed.

Caution must be exercised to prevent complete plugging which will cause the

dirty fluid to go into the remainder of the system and contaminate the system.

By-pass Valve

Manual by-pass valve (15) allows high-pressure fluid to be bypassed and

returned to the low-pressure system. This valve controls the volume of fluid

from the multiplex pump to the subsurface hydraulic pump.

The manual by-pass valve (flow control valve) is a manually-variable, orifice-

type valve. The orifice consists of slots formed in a tungsten carbide sleeve with

openings controlled by moving an integral carbide plug inside the sleeve to the

desired position. The integral plug uncovers or covers the orifice slots allowing

a greater or lesser volume of fluid to exit the by-pass valve (15) into the by-pass

line.

As more power fluid is by-passed, less fluid is injected down hole, slowing the

pump strokes on a piston pump and reducing the operating pressure on a jet

pump.

The flow control valve (15) is a simple device which gives few problems in

actual operation. The volume of by-passed fluid will remain very stable as long

as there are no great pressure fluctuations in the system.

Safety Valve

The safety valve (11) prevents excessive pressure in the power fluid line

connected to the well head and protects the pump and motor from excessive

overload.

Motor

The motor (gas, diesel, or electric powered) provides power to the multiplex

pump. Operation and maintenance manuals for the motor are provided by the

motor manufacturer.

Multiplex Pump

The surface power fluid multiplex pump (29) provides pressurized fluid to the

subsurface hydraulic pump.

The pump shaft is properly aligned with the motor shaft and connected through

a flexible coupling at the factory. However, it is necessary to check the gap and

angular alignment after final installation on the job site.

Control Panel

The control panel (12) is a standard oil-field type Murphy indicating and limit

control for safe start-up, operation and shut-down.

The control panel is mounted off of the unit skid to prevent vibrations from

causing control panel malfunctions.

The limit controls must be properly set, adjusted and maintained to assure

adequate protection of personnel, equipment, and property.

Major Component Identification

1. Multiplex pump high level suction valve.

2. Multiplex pump low level suction valve.

3. Conditioning vessel high level outlet valve.

4. Conditioning vessel low level outlet valve.

9. Cyclone desander.

10. Conditioning vessel safety relief valve.

11. Multiplex pump discharge safety relief valve.

12. Control panel.

13. Well surge control valve.

14. Accumulator surge vessel safety relief valve.

15. Power fluid manual by-pass control valve.

16. Manual valve.

18. Manual valve.

19. Desander inlet manual valve.

20. Desander outlet manual valve.

21. Desander underflow manual valve.

22. Desander underflow visual flow sight glass.

23. Conditioning vessel drain manual valve.

24. Conditioning vessel.

25. Accumulator surge vessel.

26. Accumulator surge vessel pressure gauge.

27. Conditioning vessel pressure gauge.

29. Power fluid pump (multiplex).

30. Electric motor, diesel, or gas engine.

31. Chemical injection pump.

32. Multiplex pump discharge pulsation dampener

9.0 Power oil Tank and Accessories.

A typical power oil treating system which has proven adequate for most open

power oil systems when "stock tank" quality oil is supplied, is illustrated in Figure

below.

The following paragraphs cover the functions of important components and

recommended piping instructions for the power oil treating system.

9.1 Tank Construction

The power oil settling tank in this system is usually a 24-foot high, three-

ring, bolted steel tank. A tank of this height generally wi ll provide adequate

head for gravity flow of oil from the tank to the intake of the charge pump.

If more than one plunger pump is required for this system, individual power

oil tanks can be set for each pump, or a single large tank can be used;

whichever is most economical and best meets the operating requirements.

Ideal tank size would be large enough to allow for 24 hours settling time.

This means that oil entering the tank would arrive at the suction or the

multiplex pump 24 hours later.

The tank should be positioned between the heater treater and the stock

tanks, so that total lease production comes across the power oil tank,

ensuring that the power oil tank is full at all times.

There should be two suction connections in the tank, one high and one low.

High suction, the cleanest oil in the tank, is for normal operation. Low

suction is for emergency.

At the time of construction, a bypass line should be installed directly

between the treater and the stock tanks by-passing the power oil tank for

use in emergencies.

Standard Power Oil Facility

Always check sizes and capacities of lease treaters. Over-loaded treaters

will not do a thorough job of separating oil from water. This condition will

show up in the power oil tank.

Also check operation of water dump leg on treaters. These have been

known to malfunction dumping everything to the pit, thereby pumping power

oil tank dry.

9.2 Gas Boot

The gas boot is essentially a part of the power oil tank. The purpose of the

boot is to provide final gas-oil separation so that the oil will be stable at

atmospheric pressure.

If the gas is not sufficiently separated from the oil, entrained free gas can

enter the settling tank and destroy the settling process by causing the fluid

in the tank to roll.

The following piping specifications for the gas boot are necessary to insure

undisturbed settling.

o The gas boot inlet height should be 4 feet above the top of the settling

tank. This will allow the incoming fluid to fall. The resulting agitation will

encourage gas-oil separation.

o The top section of the gas boot should be at least 3 feet in diameter and

8 feet higher than the top of the settling tank. These two factors will

provide a reservoir that should absorb the surges.

o The gas line out of the top of the boot should be tied into the settling tank

and stock tank vent line. Should the gas boot become overloaded,

thereby kicking fluid over through the gas line, this arrangement will

prevent the raw or settled fluid from being dumped in the top of the

settling tank. If this occurs, it may contaminate the oil drawn off to the

multiplex.

o The line connecting the gas boot to the settling tank should be at least 4

inches in diameter. This is necessary to minimize restrictions to flow

during surge loadings of the boot.

9.3 Spreader

Oil entering a large tank at the bottom and rising to be drawn off the top

tends to channel from the tank inlet to the outlet. This is true because the

channeling fluid moves more rapidly than the rest of the fluid in the tank

which remains relatively undisturbed.

The purpose of the spreader is to reduce the velocity of the incoming fluid

by distributing the incoming volume over a large area. This allows the fluid

to rise upward at a more even rate.

The type of spreader recommended consists of a round flat plate,

approximately a half of the diameter of the tank. (See Figure 5-4) It should

have a 4-inch skirt, which has 60-degree, triangular "saw-tooth" slots cut in

it. The slots provide automatic opening adjustment for varying amounts of

flow. It is essential that the slots be cut to a uniform depth to obtain an even

distribution of flow.

This type spreader must be installed with the tops of all the slots in a level

plane to prevent fluid from dumping out under a high side.

The spreader should be mounted about 2 feet above the bottom rim of the

tank.

Although this type spreader is relatively expensive, it will give satisfactory

spreading of flow with a minimum of trouble and maintenance.

9.4 Stock Oil Take-off and Level Control

The location of the stock tank take-off and level control is important in that it

establishes the effective settling interval of the settling tank and controls the

fluid level in the power oil tank.

All fluid coming from the spreader rises to the stock tanks. Fluid rising

above this level is only that amount required to replace the fluid withdrawn

by the plunger pump.

The stock take-off point should be located within six feet of the spreader.

The height to which the stock oil must rise in the piping to overflow into the

stock tank determines the fluid level in the settling tank. For this reason, the

level control should be placed a minimum of 18 inches from the top of the

settling tank. The diameter of piping used should be sufficient to provide

negligible resistance for the required volume of flow.

The extension at the top of the level control is connected to the gas line to

provide a vent which keeps oil in the settling tank from being siphoned down

to the level of the top of the stock tank.

9.5 Power Oil Outlets

The power oil outlet should be located on the opposite side of the settling

tank from the stock take-off outlet to balance the flow distribution within the

tank.

Since the fluid level in the tank is maintained approximately 18 inches from

the top of the tank, the upper outlet should be located 3 feet below the top of

the tank. This will ensure the oil level will be above the outlet at all times.

The second, or emergency, power oil outlet should be located below the

upper outlet for use in starting up or filling tubing strings. The location of

this outlet will depend on estimated emergency requirements and the

capacity per foot of tank. A distance of 7 feet from the top of the tank is

usually sufficient.

This lower outlet line contains a shut-off valve which is to be kept closed

during normal operations in order that the full settling interval will be used.

10.0 Different Configurations of jet pump completion

Standard Configuration Reverse Configuration Offshore Configuration

Example of Lock mandrel assembly

Example of Jet pump with lower seal (Reverse)

Example of SSD Assembly

Anda mungkin juga menyukai

- Flowing Well PerformanceDokumen57 halamanFlowing Well PerformancemkwendeBelum ada peringkat

- Sandstone AcidizingDokumen24 halamanSandstone AcidizingDarya Khan BhuttoBelum ada peringkat

- Jet Pump NewDokumen42 halamanJet Pump NewShagun DevshaliBelum ada peringkat

- Petrowiki Pressure Drop EquationsDokumen14 halamanPetrowiki Pressure Drop Equationsrasnowmah2012Belum ada peringkat

- WST - Perforation Part 2Dokumen27 halamanWST - Perforation Part 2NorBelum ada peringkat

- Chapter 06 Pressure Losses in The Circulating SystemDokumen22 halamanChapter 06 Pressure Losses in The Circulating SystemAbrar HassanBelum ada peringkat

- Halliburton - Real Time Production Optimization & Reservoir Management PDFDokumen21 halamanHalliburton - Real Time Production Optimization & Reservoir Management PDFFernandoEnriqueCalveteGonzálezBelum ada peringkat

- Gas Well Deliverability Fetkovich PDFDokumen33 halamanGas Well Deliverability Fetkovich PDFBarbara_LFCBelum ada peringkat

- Foss & Gaul PDFDokumen17 halamanFoss & Gaul PDFnicolasbelliniBelum ada peringkat

- Tugas 3Dokumen4 halamanTugas 3rarahahaBelum ada peringkat

- Plunger Fall Velocity Model 164495lDokumen16 halamanPlunger Fall Velocity Model 164495lJonathan AvilaBelum ada peringkat

- Tubing DesignDokumen12 halamanTubing Designakshitppe11Belum ada peringkat

- Artificial Lift AssignDokumen3 halamanArtificial Lift AssignShahrukh09021Belum ada peringkat

- Velocity StringsDokumen2 halamanVelocity StringsDedy DayatBelum ada peringkat

- Well Control FdreDokumen27 halamanWell Control FdreKhairi OmarBelum ada peringkat

- Hole Cleaning StuffDokumen33 halamanHole Cleaning StuffABelum ada peringkat

- SPE-115526-MS-P Fracture Ballooning in Naturally Fractured Formations - Mechanism and Controlling FactorsDokumen9 halamanSPE-115526-MS-P Fracture Ballooning in Naturally Fractured Formations - Mechanism and Controlling Factorszouke2002100% (1)

- Choke Calculation (Sizing)Dokumen19 halamanChoke Calculation (Sizing)sddrlBelum ada peringkat

- Eaton EquationDokumen6 halamanEaton EquationYusuf MaringgaBelum ada peringkat

- Fluid Planning - Field Applications & Brine MaintenanceDokumen38 halamanFluid Planning - Field Applications & Brine MaintenanceKolawole AdisaBelum ada peringkat

- Pressure Drop TheoryDokumen5 halamanPressure Drop Theorykaruna346100% (1)

- GL - 5days ManualDokumen252 halamanGL - 5days ManualWael FaragBelum ada peringkat

- Plunger Lift PumpDokumen39 halamanPlunger Lift PumpManuel Ch100% (1)

- PerforationsDokumen0 halamanPerforationsSikander MushtaqBelum ada peringkat

- 3 Hydrostatic PressureDokumen24 halaman3 Hydrostatic PressurealiBelum ada peringkat

- Pro Tech 1 CH 8Dokumen31 halamanPro Tech 1 CH 8weldsvBelum ada peringkat

- Gas Lift StarDokumen4 halamanGas Lift StarMikhaelrams RamsBelum ada peringkat

- Balanced Cement Plug CalculationDokumen7 halamanBalanced Cement Plug CalculationAlejandro ViscarraBelum ada peringkat

- Kick ToleranceDokumen3 halamanKick TolerancePunam KapoorBelum ada peringkat

- Pumps For Gassy WellsDokumen7 halamanPumps For Gassy WellsRichard More LeonBelum ada peringkat

- Well Control Preparation Class Final-Test: Name: Badge: DateDokumen16 halamanWell Control Preparation Class Final-Test: Name: Badge: DateBoedi SyafiqBelum ada peringkat

- How To Calculate The Balanced Plug 1Dokumen2 halamanHow To Calculate The Balanced Plug 1islam atifBelum ada peringkat

- CA Sand ManagementDokumen24 halamanCA Sand ManagementHemraj GaidhaniBelum ada peringkat

- 12 - Horizontal Well CompletionDokumen21 halaman12 - Horizontal Well CompletionMaximiliano GonzalezBelum ada peringkat

- Methods To Improve The Efficiency of Rod-Drawn Subsurface PumpsDokumen16 halamanMethods To Improve The Efficiency of Rod-Drawn Subsurface PumpsRichard More LeonBelum ada peringkat

- Notes On Reservoir Engineering HB, Tarek Ahmed PDFDokumen28 halamanNotes On Reservoir Engineering HB, Tarek Ahmed PDFJParra100% (1)

- Cementing CalculationDokumen7 halamanCementing CalculationAngel NgoBelum ada peringkat

- Drilling HomeworkDokumen10 halamanDrilling HomeworkRaphael L Cotta MacedoBelum ada peringkat

- Petrobowl 2015 (1) Flashcards - QuizletDokumen29 halamanPetrobowl 2015 (1) Flashcards - Quizlethenry christian wontumiBelum ada peringkat

- High Perm FracturingDokumen34 halamanHigh Perm Fracturingkesavan.govinathanBelum ada peringkat

- Underground Gas Storage: ISO 9001: 2008 Certified CompanyDokumen6 halamanUnderground Gas Storage: ISO 9001: 2008 Certified CompanycuervohijoguachoBelum ada peringkat

- 2008 Workover and Completion Practice TestDokumen14 halaman2008 Workover and Completion Practice TestWaOne PrabowoBelum ada peringkat

- Cement Stinger Balanced PlugDokumen13 halamanCement Stinger Balanced Plugjsever1Belum ada peringkat

- Reservoir Laboratory: Exp Name: Bulk Volume MeasurementDokumen5 halamanReservoir Laboratory: Exp Name: Bulk Volume MeasurementAvericl H n v ejkeBelum ada peringkat

- Dynamic Flow Performance Modeling of A Gas-Lift ValveDokumen11 halamanDynamic Flow Performance Modeling of A Gas-Lift Valvemohamed fathyBelum ada peringkat

- TUTORIAL 1 Drilling EngineerDokumen4 halamanTUTORIAL 1 Drilling EngineerAnonymous AkV8maWxGNBelum ada peringkat

- WST - Formation Damage Part 1Dokumen31 halamanWST - Formation Damage Part 1NorBelum ada peringkat

- Drilling HomeworkDokumen14 halamanDrilling HomeworkRaphael L Cotta MacedoBelum ada peringkat

- Gas Well TestingDokumen84 halamanGas Well TestingTatiana Uribe CastilloBelum ada peringkat

- Tech Drilling CoilTubingDokumen45 halamanTech Drilling CoilTubingLawBelum ada peringkat

- 1.basic Formulas PDFDokumen30 halaman1.basic Formulas PDFKevin AtochaBelum ada peringkat

- Pump Intake Pressure Determined From Fluid Levels Dynamometers and Valve Test MeasurementsDokumen13 halamanPump Intake Pressure Determined From Fluid Levels Dynamometers and Valve Test Measurementsenriqueg_53Belum ada peringkat

- Case 1. Gas Lift System DesignDokumen10 halamanCase 1. Gas Lift System DesignDaniel ChiriacBelum ada peringkat

- Effect of Gas Injection Rate On Oil Production Rate: Details of Operating MechanismDokumen13 halamanEffect of Gas Injection Rate On Oil Production Rate: Details of Operating MechanismAsekhame Yadua100% (1)

- Gas Well Deliquification: Solutions to Gas Well Liquid Loading ProblemsDari EverandGas Well Deliquification: Solutions to Gas Well Liquid Loading ProblemsBelum ada peringkat

- Streamline Numerical Well Test Interpretation: Theory and MethodDari EverandStreamline Numerical Well Test Interpretation: Theory and MethodBelum ada peringkat

- Microbial Enhancement of Oil Recovery - Recent AdvancesDari EverandMicrobial Enhancement of Oil Recovery - Recent AdvancesBelum ada peringkat

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsDari EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsBelum ada peringkat

- Advanced Water Injection for Low Permeability Reservoirs: Theory and PracticeDari EverandAdvanced Water Injection for Low Permeability Reservoirs: Theory and PracticePenilaian: 4 dari 5 bintang4/5 (2)

- JP - Chapter 03Dokumen14 halamanJP - Chapter 03dewidar1234100% (1)

- JP - Chapter 01Dokumen9 halamanJP - Chapter 01dewidar1234100% (1)

- JP - Chapter 04Dokumen3 halamanJP - Chapter 04dewidar1234100% (4)

- JP - Chapter 02Dokumen11 halamanJP - Chapter 02dewidar1234Belum ada peringkat

- Chapter 11 EconomisDokumen9 halamanChapter 11 Economisdewidar1234100% (2)

- Chapter - 10 Recommended Practice For ESP Failure AnalysisDokumen64 halamanChapter - 10 Recommended Practice For ESP Failure Analysisdewidar123492% (12)

- Chapter - 08 Switchboard and VSDDokumen44 halamanChapter - 08 Switchboard and VSDdewidar1234100% (2)

- Chapter - 09 ESP Design ExamplesDokumen16 halamanChapter - 09 ESP Design Examplesdewidar1234100% (11)

- Chapter - 06 Power CableDokumen50 halamanChapter - 06 Power Cabledewidar1234100% (5)

- Chapter 07 TransformerDokumen48 halamanChapter 07 Transformerdewidar1234100% (3)

- Chapter 04 SealDokumen25 halamanChapter 04 Sealdewidar1234100% (1)

- Chapter - 02 Centrifugal PumpDokumen83 halamanChapter - 02 Centrifugal Pumpdewidar1234100% (4)

- Chapter 05 GSDokumen10 halamanChapter 05 GSdewidar1234Belum ada peringkat

- Chapter - 03 ESP MotorDokumen80 halamanChapter - 03 ESP Motordewidar1234100% (2)

- Chapter 01 IntroductionDokumen12 halamanChapter 01 Introductiondewidar1234100% (1)

- Hitachi ZX200-5G Breaker Installation-1Dokumen93 halamanHitachi ZX200-5G Breaker Installation-1Aung Ko ThantBelum ada peringkat

- Enerpac-Solenoid Valves CatalogDokumen2 halamanEnerpac-Solenoid Valves CatalogTitanplyBelum ada peringkat

- N.K En-Fab Technology, GUJARAT: M/S Solvent StripperDokumen1 halamanN.K En-Fab Technology, GUJARAT: M/S Solvent StripperRaol VarshabenBelum ada peringkat

- Farg 504Dokumen4 halamanFarg 504lols100.comBelum ada peringkat

- Comfort PU FlyerDokumen5 halamanComfort PU FlyeruginpBelum ada peringkat

- Piping Data - MetricDokumen250 halamanPiping Data - MetricSteve WanBelum ada peringkat

- Valves Barendsen PDFDokumen63 halamanValves Barendsen PDFidontlikeebooksBelum ada peringkat

- Fluid Mechanics & Machinery: Topic: Water Hammer in PipesDokumen12 halamanFluid Mechanics & Machinery: Topic: Water Hammer in PipesLoga MadishBelum ada peringkat

- Piping Spec Book 1Dokumen259 halamanPiping Spec Book 1interx00Belum ada peringkat

- Construction Estimates - Electrical and Plumbing Labor Cost and EstimatesDokumen4 halamanConstruction Estimates - Electrical and Plumbing Labor Cost and EstimatesLyn Garcia80% (30)

- Choke Manifold Procedures 3932324 01Dokumen4 halamanChoke Manifold Procedures 3932324 01Saïd Ben Abdallah100% (1)

- Appendix: Water Engineering With The SpreadsheetDokumen7 halamanAppendix: Water Engineering With The SpreadsheetT M MurshedBelum ada peringkat

- FMDUDokumen5 halamanFMDUJoão Vitor Apolinário FerreiraBelum ada peringkat

- Timberpro P/N 50690: Optional Auxiliary Cooler Return Logic Block Load Sense ValveDokumen2 halamanTimberpro P/N 50690: Optional Auxiliary Cooler Return Logic Block Load Sense ValveЕвгений МакаровBelum ada peringkat

- Air Vent YoshitakeDokumen13 halamanAir Vent Yoshitakeeng.ahrteknikBelum ada peringkat

- Lps and MpsDokumen14 halamanLps and MpsAkash Singh TomarBelum ada peringkat

- Pump Head CalculationDokumen12 halamanPump Head CalculationIrfan Siddiqui100% (1)

- 320D & 320D L Excavator Hydraulic System Schematic PDFDokumen2 halaman320D & 320D L Excavator Hydraulic System Schematic PDFchanlin100% (5)

- Differential Pressure Relief ValvesDokumen4 halamanDifferential Pressure Relief ValvesSlobodan HristovBelum ada peringkat

- FM 1311-Specification of Split Case Pumps For FIREDokumen1 halamanFM 1311-Specification of Split Case Pumps For FIREKeval ShahBelum ada peringkat

- Hydraulics HandbookDokumen242 halamanHydraulics Handbookshahjitu100% (3)

- KSB Selecting Centrifugal Pumps En, Property FileDokumen92 halamanKSB Selecting Centrifugal Pumps En, Property Filevisitabhinav100% (7)

- Valve Basic Concepts at HTTPDokumen8 halamanValve Basic Concepts at HTTPalone160162Belum ada peringkat

- Manual Instruction Watt Water - Part13Dokumen1 halamanManual Instruction Watt Water - Part13Irvan VatoniBelum ada peringkat

- Morton Water Softener Valve-Assembly ReplacementDokumen2 halamanMorton Water Softener Valve-Assembly ReplacementBenjamin DoverBelum ada peringkat

- 06-DG-Section 6 Standard and Typical Drawings-Version 5.0Dokumen6 halaman06-DG-Section 6 Standard and Typical Drawings-Version 5.0Jamshed AlamBelum ada peringkat

- OzLinc Product CatalogueDokumen192 halamanOzLinc Product CatalogueKarenBelum ada peringkat

- Problem Set #6: Name: Date: SectionDokumen3 halamanProblem Set #6: Name: Date: SectionMatt DienteBelum ada peringkat

- VADDL /VA 34 (100) : Pressure Relief ValvesDokumen2 halamanVADDL /VA 34 (100) : Pressure Relief ValvesSachin RamadasanBelum ada peringkat

- FP100 SCHEMATIC Rev.8Dokumen1 halamanFP100 SCHEMATIC Rev.8Siddharth SoniBelum ada peringkat