Extrusion Compounding and Boron Nitride

Diunggah oleh

Victor CastrejonDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Extrusion Compounding and Boron Nitride

Diunggah oleh

Victor CastrejonHak Cipta:

Format Tersedia

SpecialChem S.A.

, Socit Anonyme au capital de 113 793 enregistre au RCS Paris B 432 249 126 - # TVA: FR77432249126

100 rue Petit, 75 019 Paris Tel: +33 1 72 76 39 00 Fax: +33 1 72 76 39 01

web: www.specialchem.com email: info@specialchem.com

Page 1 of 3

Extrusion Compounding and Boron Nitride

SpecialChem | Donal McNally - Sep 26, 2013

Extrusion has been known as an industrial process for centuries. It is the forcing of a malleable material through a

shaping orifice or die, originally by mechanical and later by hydraulic means. These processes were limited to unit

production, i.e., one extruded form was made in each actuating stroke. It was not until the 1870's that continuous

extrusion processes emerged in the rubber industry with the use of screw extruders. In such machines, the rubber

mixture was heated and conveyed forward on an Archimedean screw and then pumped out through a die. A sketch of

such a screw is shown in Figure 1 below. The pressure needed to force the material through the die is obtained either

by decreasing the flight depth as shown in the figure, or by decreasing the screw pitch (the distance between the

flights).

These early rubber extruder screws had low length to diameter

(L/D) ratios, as low as 4 to 1 in some cases. Perhaps 60 years

after its use in the rubber industry, screw extrusion technology

was employed for thermoplastics, initially for materials such as

cellulosics and polyvinyl chloride. With the later development of

nylon, screw profiles required a transition region to

accommodate the rapid shift from solid to melt typical of semi-crystalline polymers, so that such screws had three

distinct zones.

Feed or solids conveying zone. Here, resin is fed into the extruder. Channel depth is usually the same

throughout the zone.

Melting, transition or compression zone. Most of the resin is melted in this section, and the channel depth gets

progressively smaller.

Metering or melt conveying zone. Channel depth is the same throughout the zone, which melts the last

particles and mixes to a uniform temperature and composition.

To provide for these zones, screw L/D ratios increased to a range around 16:1, and as extruders were called on to

provide more functions, L/D ratios continued to increase, now reaching as high as 36:1 in some instances, such as

two-stage (vented) screws. A vented screw incorporates a decompression zone for vacuum venting and a second

metering zone to re-pressurize the melt to get it through the resistance of the

screws and the die.

As the plastics industry grew, a wide range of compounds was developed both by

polymer manufacturers and custom compounders. Initially these compounds were

made by dry-blending the components and feeding the mixture at the feed throat

of the extruder. As it became apparent, especially in the case of fiberglass-

reinforced materials, that better properties could be obtained by feeding fillers

and reinforcements directly into the polymer melt, screw profiles became more

and more complicated, with provision for side-feeders and the addition of (often

proprietary) mixing and shearing elements into the design.

At some point, there is only so much that can be achieved with a single screw.

The more specialized the design is, the less flexible the extrusion process

becomes. Nevertheless, for economic reasons, single screw extruders remain the

workhorses of the industry, particularly for large volume processing of a single

material or group of similar materials.

Figure 1: Simple Extruder Screw

SpecialChem S.A., Socit Anonyme au capital de 113 793 enregistre au RCS Paris B 432 249 126 - # TVA: FR77432249126

100 rue Petit, 75 019 Paris Tel: +33 1 72 76 39 00 Fax: +33 1 72 76 39 01

web: www.specialchem.com email: info@specialchem.com

Page 2 of 3

Twin screw extrusion of plastics also appeared in the early part

of the 20th century. Continuing evolution of this process led to

the development of machines with both counter-rotating and co-

rotating, and intermeshing and non-intermeshing screws. Co-

rotating intermeshing screw (CRIS) extruders are most

commonly used in plastics compounding applications. As shown

in Figure 2, in such machines, the root of one screw is wiped by

the crests of the adjacent screw flights so that they are often

described as self-wiping machines. Material flows along the

screws following a spiral figure eight pattern until reaching the

breaker plates and strand extrusion die.

CRIS compounding extruders typically employ modular screws and barrels and thus can be configured to manufacture

a wide variety of compositions. Their relatively higher cost compared with single screw machines is offset by their

much greater flexibility. Different process zones can be created for conveying, plasticizing, mixing and shearing,

homogenizing, devolatilizing and pressure build-up. Figure 3 shows a conveying section mated to a kneading section

on an assembled pair of screws.

Screw element design technology for CRIS-type compounders continues to advance and has generated highly

specialized screw elements for different processing stages including intake, melting, venting, mixing and metering.

Some of these designs have been patented by their manufacturers.

The proliferation of screw element components both enables process

optimization for various feed stocks and makes the overall screw

design choice more challenging. Equipment makers make

recommendations based on their compounding research with more

common materials, for instance polypropylene and talc, or polyamide

and glass fibers, but compounders may find it desirable to carry out

their own studies to get the best results in terms of throughput and

product mechanical properties.

Compounding boron nitride (BN) is a case in point. Boron nitride is a

remarkable material. It does not occur in nature, but is made in a high

temperature reaction from boron containing materials and nitrogen. It is

converted to a crystalline hexagonal form, h-BN, wherein hexagonal

platelets can slide on each other like graphite. This material has the

interesting property of being an excellent conductor of heat, while remaining an electrical insulator. h-BN has a very

high aspect ratio (~20:1), such that it has an in-plane thermal conductivity of about 600 W/m.K and a through-plane

conductivity of 30 W/m.K. The overall average conductivity is about 60 W/m.K.

The relatively low density of h-BN means it can be compounded into plastics without producing an overly dense final

resin. However, compounding expertise is needed to ensure good wet-out of the filler and achieve best physical

properties. Highly loaded h-BN compounds can provide thermal conductivities up to 10 W/m.K., far greater than the

values for conventional electrically insulating plastics (~0.2 W/mK on average). This enables these interesting

formulations to provide value in applications including consumer electronic devices, aerospace and vehicle cooling

systems, motor and battery housings, temperature sensors, heat exchangers and other systems where thermal

energy must be dissipated.

Manufacturing highly loaded h-BN compounds presents challenges, some typical of other materials and some rather

different. The key issues include achieving and consistently maintaining the correct filler loading at an acceptable

production rate, fully wetting out the h-BN particles and maintaining adequate temperature control of the strands

exiting the die.

Properly calibrated gravimetric feeders set to match the highest starve-fed throughput of the extruder (typically < 40%)

will help meet the first requirement. As h-BN is a light fluffy material, shovel elements are useful for getting it into the

extruder. However, while the concave flights of such elements can convey high volumes of the low bulk density h-BN,

they are not efficient at building pressure to move material forward against powder build up at the end of a side feeder.

Figure 2: Co-rotating Twin Screw Extruder

Figure 3: Co-rotating Screw Sections

SpecialChem S.A., Socit Anonyme au capital de 113 793 enregistre au RCS Paris B 432 249 126 - # TVA: FR77432249126

100 rue Petit, 75 019 Paris Tel: +33 1 72 76 39 00 Fax: +33 1 72 76 39 01

web: www.specialchem.com email: info@specialchem.com

Page 3 of 3

Good filler-particle wet-out is essential for proper stress transfer from polymer matrix to filler and to consistently obtain

the best mechanical properties in the resulting composite. This can be facilitated by use of surface treatments such as

silanes, but efficient mixing in the extruder also plays a role. There is evidence that including fractional mixing element

blocks in the screw design enables better results at higher throughputs than with conventional kneading blocks and

also improves the balance between in-plane and through-plane thermal. To get in touch with the exclusive

manufacturer of fractional mixing element blocks for your equipment, please ask Momentive for contact details.

Depending on the system melt temperature, the high thermal conductivity of the composite may lead to uneven strand

cooling at the die. If this happens, varying strand stiffness can cause strand handling problems. This can be avoided

by ensuring uniform temperature across the die and particularly the die face. A further challenge is making sure the

extruded strands are not too cold, and hence overly brittle on arrival at the pelletizer or chopper. This concern may be

addressed either with a hot water bath or by allowing the strands to air-cool on a carrier belt.

Momentive Performance Materials Inc., the world's largest BN manufacturer, is launching new BN-based

formulations for creating thermally conductive and electrically insulating plastics at a potentially lower cost than

materials already in the market. These hybrid fillers are being marketed under the CoolFX trade name. These new

CoolFX hybrid filler formulations can be cost effective solutions for thermal management applications because they

achieve high thermal conductivities at lower BN loadings. They are now available for sampling as single powders,

offering more consistent feeding in compounding than traditional BN powder.

Compared with the neat base resins, compounds made from these new hybrid filler formulations may have faster in-

mold cooling and hence can potentially be molded on shorter cycles, yielding improved press utilization and

consequently higher productivity. The hybrid fillers also can deliver improved mechanical properties with reduced

anisotropy in molded parts.

During in-house testing of the new formulations in nylon 6, Momentive researchers have achieved tensile strengths

approaching 10,000 psi and notched Izod impact values of about 30 J/m while still delivering thermal conductivities in

excess of 5 W/m.K. Other compositions have shown thermal conductivities up to 10 W/m.K. Most significantly, it is

estimated that cost reductions from 10% to 30% over existing BN-only compounds can be obtained with the new

hybrid fillers.

From their own compounding studies, Momentive researchers can advise on twin screw compounding parameters for

various BN formulations, including recommendations on equipment, screw design, material handling and process

operating parameters. To discuss any of these issues, please contact Momentive through SpecialChem. Additional

information on Momentive Boron Nitride solutions including case studies and technical data sheets are available at

SpecialChem.

Anda mungkin juga menyukai

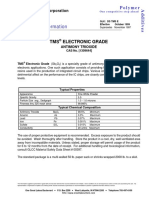

- Technical Information: TMS D Catalyst GradeDokumen1 halamanTechnical Information: TMS D Catalyst GradeVictor CastrejonBelum ada peringkat

- Technical Information: Pyrobloc® Sap2 and Sap5Dokumen2 halamanTechnical Information: Pyrobloc® Sap2 and Sap5Victor CastrejonBelum ada peringkat

- Technical Information: TMS - VHPDokumen1 halamanTechnical Information: TMS - VHPVictor CastrejonBelum ada peringkat

- Technical Information: Sodium Antimonate-EDokumen1 halamanTechnical Information: Sodium Antimonate-EVictor CastrejonBelum ada peringkat

- Pyrobloc SAP-2 PDFDokumen1 halamanPyrobloc SAP-2 PDFVictor CastrejonBelum ada peringkat

- Technical Information: TMS Catalyst Grade PHPDokumen1 halamanTechnical Information: TMS Catalyst Grade PHPVictor CastrejonBelum ada peringkat

- Suptms PDFDokumen1 halamanSuptms PDFVictor CastrejonBelum ada peringkat

- Atstemp PDFDokumen1 halamanAtstemp PDFVictor CastrejonBelum ada peringkat

- Atocg PDFDokumen1 halamanAtocg PDFVictor CastrejonBelum ada peringkat

- Tmse PDFDokumen1 halamanTmse PDFVictor CastrejonBelum ada peringkat

- Tms PDFDokumen2 halamanTms PDFVictor CastrejonBelum ada peringkat

- Ongard 2 PDFDokumen1 halamanOngard 2 PDFVictor CastrejonBelum ada peringkat

- Tmse PDFDokumen1 halamanTmse PDFVictor CastrejonBelum ada peringkat

- Technical Information: Antimony Trioxide Wetted GradesDokumen1 halamanTechnical Information: Antimony Trioxide Wetted GradesVictor CastrejonBelum ada peringkat

- Pyrobloc SAP-5 PDFDokumen1 halamanPyrobloc SAP-5 PDFVictor CastrejonBelum ada peringkat

- Technical Information: Atc-HclDokumen1 halamanTechnical Information: Atc-HclVictor CastrejonBelum ada peringkat

- Technical Information: Microfine VHPDokumen1 halamanTechnical Information: Microfine VHPVictor CastrejonBelum ada peringkat

- Technical Information: Antimony MetalDokumen1 halamanTechnical Information: Antimony MetalVictor CastrejonBelum ada peringkat

- Technical Information: Microfine Ao5 and Ao5-Hp Antimony TrioxideDokumen2 halamanTechnical Information: Microfine Ao5 and Ao5-Hp Antimony TrioxideVictor CastrejonBelum ada peringkat

- Technical Information: Microfine Catalyst Grade PHP Antimony TrioxideDokumen1 halamanTechnical Information: Microfine Catalyst Grade PHP Antimony TrioxideVictor CastrejonBelum ada peringkat

- Technical Information: Antimony TrichlorideDokumen1 halamanTechnical Information: Antimony TrichlorideVictor CastrejonBelum ada peringkat

- Technical Information: Microfine Ao5 and Ao5-Hp Antimony TrioxideDokumen2 halamanTechnical Information: Microfine Ao5 and Ao5-Hp Antimony TrioxideVictor CastrejonBelum ada peringkat

- Technical Information: Antimony Trioxide GG Antimony TrioxideDokumen1 halamanTechnical Information: Antimony Trioxide GG Antimony TrioxideVictor CastrejonBelum ada peringkat

- PolymerAdditives - Thanox 1076 - TDS - 2012-JuneDokumen1 halamanPolymerAdditives - Thanox 1076 - TDS - 2012-JuneVictor CastrejonBelum ada peringkat

- PolymerAdditives - Thanox 1035 - TDS - 2013-MayDokumen1 halamanPolymerAdditives - Thanox 1035 - TDS - 2013-MayVictor CastrejonBelum ada peringkat

- Atomao9 PDFDokumen2 halamanAtomao9 PDFVictor CastrejonBelum ada peringkat

- Atomeg PDFDokumen2 halamanAtomeg PDFVictor CastrejonBelum ada peringkat

- Technical Information: Microfine Catalyst Grade PVHP Antimony TrioxideDokumen1 halamanTechnical Information: Microfine Catalyst Grade PVHP Antimony TrioxideVictor CastrejonBelum ada peringkat

- PolymerAdditives - Thanox 1098 - TDS - April-2013Dokumen1 halamanPolymerAdditives - Thanox 1098 - TDS - April-2013Victor CastrejonBelum ada peringkat

- PolymerAdditives - Thanox 1010 - TDS - 2011-AugustDokumen1 halamanPolymerAdditives - Thanox 1010 - TDS - 2011-AugustVictor CastrejonBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Desmodure-Rfe-Tds CROSSLİNKİNG AGENTDokumen2 halamanDesmodure-Rfe-Tds CROSSLİNKİNG AGENTGİZEM DEMİRBelum ada peringkat

- MCAS - Some Potential MCAS Triggers Incl Hidden SulphitesDokumen1 halamanMCAS - Some Potential MCAS Triggers Incl Hidden SulphitesNu Spun SpunBelum ada peringkat

- AISC-342 Seismic Provisions For Evaluation and Retrofit of Existing Structural Steel Buildings Public ReviewDokumen149 halamanAISC-342 Seismic Provisions For Evaluation and Retrofit of Existing Structural Steel Buildings Public Reviewjackcan501Belum ada peringkat

- Pakistan India Trade Liberalization Sactoral Study On Glass IndustryDokumen21 halamanPakistan India Trade Liberalization Sactoral Study On Glass IndustrymuhammadumersermadBelum ada peringkat

- Chapter 3Dokumen51 halamanChapter 3Ngọc Hà NguyễnBelum ada peringkat

- Dao 1998-58 - PCLDokumen1 halamanDao 1998-58 - PCLPacific SpectrumBelum ada peringkat

- Emergency Req NFPA 704Dokumen1 halamanEmergency Req NFPA 704Mike MidgettBelum ada peringkat

- 18ee2128 Waste To EnergyDokumen1 halaman18ee2128 Waste To Energys sBelum ada peringkat

- Scotchbond Uni Veneer TGDokumen6 halamanScotchbond Uni Veneer TGmaroun ghalebBelum ada peringkat

- Danfoss Compressor CatalogDokumen294 halamanDanfoss Compressor CatalogAnonymous uEOZ7raPkzBelum ada peringkat

- Fiberglass Gravity Sewer Pipe: Part 1: GeneralDokumen2 halamanFiberglass Gravity Sewer Pipe: Part 1: GeneralDaniel MoralesBelum ada peringkat

- Additives For Adhesives and Sealants Catalogue EuropeDokumen24 halamanAdditives For Adhesives and Sealants Catalogue EuropeAlexi WiedemannBelum ada peringkat

- Analysis of Sintered Copper Powder: Dana Emmellyne B. AgutoDokumen3 halamanAnalysis of Sintered Copper Powder: Dana Emmellyne B. AgutoDana Emmellyne AgutoBelum ada peringkat

- Design Calculation Anchor Flange ASME VIII Div 1Dokumen4 halamanDesign Calculation Anchor Flange ASME VIII Div 1Dhia SlamaBelum ada peringkat

- Indian Film Manufacturers Adding Capacities To Meet Growing Demand For Bopp and BopetDokumen8 halamanIndian Film Manufacturers Adding Capacities To Meet Growing Demand For Bopp and BopetSanjay Kumar ShahiBelum ada peringkat

- Marcegaglia Stainless-Steel en Ott12Dokumen37 halamanMarcegaglia Stainless-Steel en Ott12lucidbaseBelum ada peringkat

- Low Frequency Currents 1st BPT ChiragDokumen221 halamanLow Frequency Currents 1st BPT ChiragchiragBelum ada peringkat

- 1.2 Amount of SubstanceDokumen18 halaman1.2 Amount of SubstanceBhPO2023Belum ada peringkat

- Tegopren 5840 1020 en Oi AsDokumen2 halamanTegopren 5840 1020 en Oi AsmajidBelum ada peringkat

- Mat Forming Concepts For Particleboard MDF and OsbDokumen15 halamanMat Forming Concepts For Particleboard MDF and OsbJay-R NuestroBelum ada peringkat

- Rubber World HNBR Article - Therban AT PDFDokumen9 halamanRubber World HNBR Article - Therban AT PDFAnusha Rajagopalan100% (1)

- Direct Posterior Restoration PDFDokumen14 halamanDirect Posterior Restoration PDFياسر نادر حسين فليحBelum ada peringkat

- Powders and GranuleswhatDokumen47 halamanPowders and GranuleswhatJezreel JavierBelum ada peringkat

- Scott 2001Dokumen20 halamanScott 2001Mariana CatiniBelum ada peringkat

- Brochure of Marine Loading ArmDokumen22 halamanBrochure of Marine Loading ArmheriBelum ada peringkat

- Zhang L 2016 Removal of Heavy Metal Ions Using Chitosan and Modified Chitosan A ReviewDokumen17 halamanZhang L 2016 Removal of Heavy Metal Ions Using Chitosan and Modified Chitosan A ReviewWulan HumairahBelum ada peringkat

- Inorganic Chemistry Chem-318 Lec 3Dokumen24 halamanInorganic Chemistry Chem-318 Lec 3Mahnoor ShakeelBelum ada peringkat

- Delamination Repair ProcedureDokumen2 halamanDelamination Repair ProceduregnanasekarBelum ada peringkat

- The Preparation of Methylamine Hydrochloride From Acetamide by Means of Calcium HypochloriteDokumen3 halamanThe Preparation of Methylamine Hydrochloride From Acetamide by Means of Calcium Hypochloritegeovani2100% (1)