str-x6729 Ds en

Diunggah oleh

perro sDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

str-x6729 Ds en

Diunggah oleh

perro sHak Cipta:

Format Tersedia

SANKEN ELECTRIC CO., LTD.

http://www.sanken-ele.co.jp

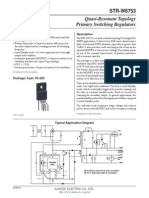

STR-X6729

Description

The STR-X6729 is a quasi-resonant topology IC designed for

SMPS applications. It shows lower EMI noise characteristics

than conventional PWM solutions, especially at greater than

2 MHz. It also provides a soft-switching mode to turn on the

internal MOSFET at close to zero voltage (V

DS

bottom point)

by use of the resonant characteristic of primary inductance

and a resonant capacitor.

The package is a fully molded TO-3P, which contains the

controller chip (MIC) and MOSFET, enabling output

power up to 360 W at 120 VAC input. The bottom-skip

mode skips the first bottom of V

DS

and turns on the MOSFET

at the second bottom point, to minimize an increase of

operating frequency at light output load, improving system-

level efficiency over the entire load range.

A standby mode is executed by clamping the secondary output.

In general applications, standby mode reduces input power.

The soft-start mode minimizes surge voltage and reduces power

stress to the MOSFET and to the secondary rectifying diodes

during the start-up sequence.

Various protections such as overvoltage, overload, overcurrent,

maximum on-time protections and avalanche-energy guaranteed

MOSFET secure good system-level reliability.

Features and Benefits

Quasi-resonant topology IC Low EMI noise and soft

switching

Bottom-skip mode Improved system efficiency over

the entire output load by avoiding increase of switching

frequency

Standby mode Lowers input power at very light output

load condition

Avalanche-guaranteed MOSFET Improves system-level

reliability and does not require V

DSS

derating

450 V

DSS

/ 0.189 R

DS(on)

Various protections Improved system-level reliability

Pulse-by-pulse drain overcurrent limiting

Overvoltage Protection (bias winding voltage sensing),

with latch

Overload Protection with latch

Maximum on-time limit

Off-Line Quasi-Resonant Switching Regulators

Typical Application

Not to scale

Package: 7-Pin TO-3P

Continued on the next page

STRX6729DS

2

SANKEN ELECTRIC CO., LTD.

Off-Line Quasi-Resonant Switching Regulators STR-X6729

STRX6729DS

All performance characteristics given are typical values for circuit or

system baseline design only and are at the nominal operating voltage and

an ambient temperature, T

A

, of 25C, unless oth er wise stated.

Absolute Maximum Ratings at T

A

= 25C

Parameter Symbol Conditions Rating Unit

Drain Current

1

I

D

peak Single pulse 22 A

Maximum Switching Current

2

I

Dmax

T

A

= 20C to 125C 22 A

Single Pulse Avalanche Energy

3

E

AS

Single pulse, V

DD

= 30 V, L = 50 mH, I

Lpeak

= 4.2 A 472 mJ

Input Voltage for Controller (MIC) V

CC

35 V

SS/OLP Terminal Voltage V

SSOLP

0.5 to 6.0 V

FB Terminal Inflow Current I

FB

10 mA

FB Terminal Voltage V

FB

I

FB

within the limits of I

FB

0.5 to 9.0 V

OCP/BD Terminal Voltage V

OCPBD

1.5 to 5.0 V

MOSFET Power Dissipation

4

P

D1

With infinite heatsink 46 W

Without heatsink 2.8 W

Controller (MIC) Power Dissipation P

D2

V

CC

I

CC

0.8 W

Operating Internal Leadframe Temperature T

F

Recommended operation temperature, see cautions 20 to 125 C

Operating Ambient Temperature T

OP

20 to 125 C

Storage Temperature T

stg

40 to 125 C

Channel Temperature T

ch

150 C

1

Refer to MOSFET ASO curve

2

I

DMAX

is the drain current determined by the drive voltage of the IC and the threshold voltage, V

th

, of the MOSFET

3

Refer to Avalanche Energy Derating curve

4

Refer to MOSFET Ta-PD1 curve

Selection Guide

Part Number Package

STR-X6729 TO-3P

Applications include the following:

Set Top Box

LCD PC monitor, LCD TV

Printer, Scanner

SMPS power supplies

Description (continued)

3

SANKEN ELECTRIC CO., LTD.

Off-Line Quasi-Resonant Switching Regulators STR-X6729

STRX6729DS

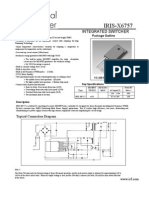

Terminal List Table

Number Name Description Functions

1 D Drain MOSFET drain

2 S Source MOSFET source

3 GND Ground terminal Ground

4 VCC Power supply terminal Input of power supply for control circuit

5 SS/OLP Soft Start/Overload Protection terminal Input to set delay for Overload Protection and Soft Start operation

6 FB Feedback terminal

Input for Constant Voltage Control and Burst (intermittent) Mode

oscillation control signals

7 OCP/BD Overcurrent Protection/Bottom Detection Input for Overcurrent Detection and Bottom Detection signals

Functional

Block Diagram

4

SANKEN ELECTRIC CO., LTD.

Off-Line Quasi-Resonant Switching Regulators STR-X6729

STRX6729DS

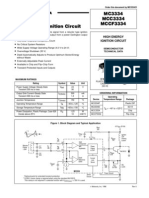

0

20

40

60

80

100

0 20 40 60 80 100 120

A

.

S

.

O

.

t

e

m

p

e

r

a

t

u

r

e

d

e

r

a

t

i

n

g

c

o

e

f

f

i

c

i

e

n

t

(

%

)

Internal frame temperature T

F

[]

STR-X6729

A.S.O. temperature derating coefficient curve

0.1

1

10

100

1 10 100 1000

I

D

[

A

]

D

r

a

i

n

C

u

r

r

e

n

t

V

DS

[V]

Drain-to-Source Voltage

STR-X6729

MOS FET A.S.O. Curve

Apply ASO temperature

derating coefficient from the

left graph to this curve for

evaluating actual operations

safety

Determined by On-

Resistance

1ms

100s

Ta=25Single Pulse

0

20

40

60

80

100

25 50 75 100 125 150

[

E

A

S

t

e

m

p

e

r

a

t

u

r

e

d

e

r

a

t

i

n

g

c

o

e

f

f

i

c

i

e

n

t

(

%

)

Tch[]

Channel temperature

STR-X6729

Avalanche energy derating curve

5

SANKEN ELECTRIC CO., LTD.

Off-Line Quasi-Resonant Switching Regulators STR-X6729

STRX6729DS

0

10

20

30

40

50

60

0 20 40 60 80 100 120 140 160

P

D

1

[

]

P

o

w

e

r

d

i

s

s

i

p

a

t

i

o

n

Ta []

Ambient temperature

STR-X6729

MOSFET Ta-PD1 Curve

With infinite heatsink

PD1=46[W]

PD1=2.8[W]

Without heatsink

0

0.2

0.4

0.6

0.8

1

0 20 40 60 80 100 120 140

P

D

2

[

]

P

o

w

e

r

d

i

s

s

i

p

a

t

i

o

n

T

F

[]

Internal frame temperature

STR-X6729

MIC T

F

-P

D2

Curve

0.001

0.01

0.1

1

c

h

-

c

[

/

W

]

T

r

a

n

s

i

e

n

t

t

h

e

r

m

a

l

r

e

s

i

s

t

a

n

c

e

[sec]

Tim e

STR-X6729

Transient thermal resistance curve

6

SANKEN ELECTRIC CO., LTD.

Off-Line Quasi-Resonant Switching Regulators STR-X6729

STRX6729DS

ELECTRICAL CHARACTERISTICS

Characteristic Symbol Test Conditions Min. Typ. Max. Units

ELECTRICAL CHARACTERISTICS for Controller (MIC)

1

, valid at T

A

= 25C, V

CC

= 20 V, unless otherwise specified

Power Supply Start-up Operation

Operation Start Voltage V

CC(ON)

V

CC

= 020 V 16.3 18.2 19.9 V

Operation Stop Voltage V

CC(OFF)

V

CC

= 208.8 V 8.8 9.7 10.6 V

Circuit Current In Operation I

CC(ON)

6 mA

Circuit Current In Non-Operation I

CC(OFF)

V

CC

= 15 V 100 A

Oscillation Frequency f

osc

19 22 25 kHz

Soft Start Operation Stop Voltage V

SSOLP(SS)

V

SS/OLP

increasing 1.1 1.2 1.4 V

Soft Start Operation Charging Current I

SSOLP(SS)

V

SS/OLP

= 0 V 710 550 390 A

Normal Operation

Bottom-Skip Operation Threshold Voltage 1 V

OCPBD(BS1)

0.720 0.665 0.605 V

Bottom-Skip Operation Threshold Voltage 2 V

OCPBD(BS2)

0.485 0.435 0.385 V

Overcurrent Detection Threshold Voltage V

OCPBD(LIM)

V

OCP/BD

falling 0.995 0.940 0.895 V

OCP/BD Terminal Outflow Current I

OCPBD

V

OCP/BD

= 0.95 V 250 100 40 A

Quasi-Resonant Operation Threshold Voltage 1 V

OCPBD(TH1)

V

OCP/BD

falling 0.28 0.40 0.52 V

Quasi-Resonant Operation Threshold Voltage 2 V

OCPBD(TH2)

V

OCP/BD

rising 0.67 0.80 0.93 V

FB Terminal Threshold Voltage V

FB(OFF)

V

FB

rising 1.32 1.45 1.58 V

FB Terminal Inflow Current (Normal Operation) I

FB(ON)

V

FB

= 1.6 V 600 1000 1400 A

Standby Operation

Standby Operation Start Voltage V

CC(S)

V

CC

= 015 V, V

FB

= 1.6 V 10.3 11.2 12.1 V

Standby Operation Start Voltage Interval V

CC(SK)

V

CC(SK)

= V

CC(S)

V

CC(OFF) 1.10 1.35 1.65 V

Standby Non-Operation Circuit Current I

CC(S)

V

CC

= 10.2 V, V

FB

= 1.6 V 20 56 A

FB Terminal Inflow Current, Standby Operation I

FB(S)

V

CC

= 10.2 V, V

FB

= 1.6 V 4 14 A

FB Terminal Threshold Voltage, Standby Operation V

FB(S)

V

CC

= 15 V, V

FB

rising 0.55 1.10 1.50 V

Minimum On Time t

ON(MIN)

0.75 1.15 1.55 s

Protection Operation

Maximum On Time t

ON(MAX)

27.5 32.5 39.0 s

Overload Protection Operation Threshold Voltage V

SSOLP(OLP)

4.0 4.9 5.8 V

Overload Protection Operation Charging Current I

SSOLP(OLP)

V

SS/OLP

= 2.5 V 16 11 6 A

Overvoltage Protection Operation Voltage V

CC(OVP)

V

CC

= 030 V 25.5 27.7 29.9 V

Latch Circuit Holding Current

2

I

CC(H)

V

CC(OFF)

0.3 V 45 140 A

Latch Circuit Release Voltage

2

V

CC(La.OFF)

V

CC

= 306 V, OVP operating 6.0 7.2 8.5 V

ELECTRICAL CHARACTERISTICS for MOSFET, valid at T

A

= 25C, unless otherwise specified

Drain-to-Source Breakdown Voltage V

DSS

I

DSS

= 300 A 450 V

Drain Leakage Current I

DSS

V

DSSS

= 450 V 300 A

On Resistance R

DS(on)

I

DS

= 4.0 A 0.189

Switching Time t

f

700 ns

Thermal Resistance R

ch-F

Channel to internal frame 0.99 C/W

1

Current polarity with respect to the IC: positive current indicates current sink at the terminal named, negative current indicates source at the

terminal named.

2

The latch circuit means a circuit operated OVP and OLP.

7

SANKEN ELECTRIC CO., LTD.

Off-Line Quasi-Resonant Switching Regulators STR-X6729

STRX6729DS

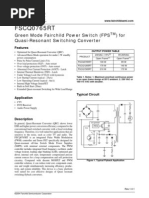

3

.

2

0

.

2

3.450.2

3.350.1

5.50.2

5

.

5

0

.

2

Terminal dimension at lead tip

Terminal dimension at lead tip

0.55

+0.2

0.1

5X 0.65

+0.2

0.1

2

3

0

.

3 Branding

Area

XXXXXXXX

XXXXXXXX

XXXXXXXX

2X 2.540.1 4X 1.270.1

6

15.6 0.2

1.89

+0.2

0.1

1.33

+0.2

0.1

2X 0.83

+0.2

0.1

5X 0.75

+0.2

0.1

2

0

.

2

Gate Burr

Gate burr: 0.3 mm (max.)

Terminal core material: Cu

Terminal treatment: Ni plating and Pb-free solder dip

Leadform: 1902

Approximate weight: 6 g

Dimensions in millimeters

Drawing for reference only

Branding codes (exact appearance at manufacturer discretion):

1st line, type: STR

2nd line, subtype: X6729

3rd line, lot: YM DD

Where: Y is the last digit of the year of manufacture

M is the month (1 to 9, O, N, D)

DD is the 2-digit date

Enlargement View A

5

.

5

R

E

F

4.5 0.7 4.5 0.7

7

.

0

0

.

5

3

.

3

0

.

5

3

.

3

3

1

2

.

5

0

.

5

View A

1

2

5 7

6

3

4

0.7

Front View (Plan View) Side View

0.7 0.7 0.7

Package Outline Drawing, TO-3P

Leadframe plating Pb-free. Device composition

includes high-temperature solder (Pb >85%),

which is exempted from the RoHS directive.

8

SANKEN ELECTRIC CO., LTD.

Off-Line Quasi-Resonant Switching Regulators STR-X6729

STRX6729DS

Because reliability can be affected adversely by improper

storage environments and handling methods, please observe

the following cautions.

Cautions for Storage

Ensure that storage conditions comply with the standard

temperature (5C to 35C) and the standard relative

humidity (around 40% to 75%); avoid storage locations

that experience extreme changes in temperature or

humidity.

Avoid locations where dust or harmful gases are present

and avoid direct sunlight.

Reinspect for rust on leads and solderability of the

products that have been stored for a long time.

Cautions for Testing and Handling

When tests are carried out during inspection testing and

other standard test periods, protect the products from

power surges from the testing device, shorts between

the product pins, and wrong connections. Ensure all test

parameters are within the ratings specified by Sanken for

the products.

Remarks About Using Silicone Grease with a Heatsink

When silicone grease is used in mounting the products on

a heatsink, it shall be applied evenly and thinly. If more

silicone grease than required is applied, it may produce

excess stress.

Volatile-type silicone greases may crack after long periods

of time, resulting in reduced heat radiation effect. Silicone

greases with low consistency (hard grease) may cause

cracks in the mold resin when screwing the products to a

heatsink.

Our recommended silicone greases for heat radiation

purposes, which will not cause any adverse effect on the

product life, are indicated below:

Type Suppliers

G746 Shin-Etsu Chemical Co., Ltd.

YG6260 Momentive Performance Materials Inc.

SC102 Dow Corning Toray Co., Ltd.

Cautions for Mounting to a Heatsink

When the flatness around the screw hole is insufficient, such

as when mounting the products to a heatsink that has an

extruded (burred) screw hole, the products can be damaged,

even with a lower than recommended screw torque. For

mounting the products, the mounting surface flatness should

be 0.05 mm or less.

Please select suitable screws for the product shape. Do not

use a flat-head machine screw because of the stress to the

products. Self-tapping screws are not recommended. When

using self-tapping screws, the screw may enter the hole

diagonally, not vertically, depending on the conditions of hole

before threading or the work situation. That may stress the

products and may cause failures.

Recommended screw torque: 0.588 to 0.785 Nm (6 to 8

kgfcm).

For tightening screws, if a tightening tool (such as a driver)

hits the products, the package may crack, and internal

stress fractures may occur, which shorten the lifetime of

the electrical elements and can cause catastrophic failure.

Tightening with an air driver makes a substantial impact.

In addition, a screw torque higher than the set torque can

be applied and the package may be damaged. Therefore, an

electric driver is recommended.

When the package is tightened at two or more places, first

pre-tighten with a lower torque at all places, then tighten

with the specified torque. When using a power driver, torque

control is mandatory.

Soldering

When soldering the products, please be sure to minimize

the working time, within the following limits:

2605C 101 s (Flow, 2 times)

38010C 3.50.5 s (Soldering iron, 1 time)

Soldering should be at a distance of at least 2.0 mm from

the body of the products.

Electrostatic Discharge

When handling the products, the operator must be

grounded. Grounded wrist straps worn should have at

least 1 M of resistance from the operator to ground to

prevent shock hazard, and it should be placed near the

operator.

Workbenches where the products are handled should be

grounded and be provided with conductive table and floor

mats.

When using measuring equipment such as a curve tracer,

the equipment should be grounded.

When soldering the products, the head of soldering irons

or the solder bath must be grounded in order to prevent

leak voltages generated by them from being applied to the

products.

The products should always be stored and transported in

Sanken shipping containers or conductive containers, or

be wrapped in aluminum foil.

9

SANKEN ELECTRIC CO., LTD.

Off-Line Quasi-Resonant Switching Regulators STR-X6729

STRX6729DS

The contents in this document are subject to changes, for improvement and other purposes, without notice. Make sure that this is the

latest revision of the document before use.

Application and operation examples described in this document are quoted for the sole purpose of reference for the use of the prod-

ucts herein and Sanken can assume no responsibility for any infringement of industrial property rights, intellectual property rights or

any other rights of Sanken or any third party which may result from its use.

Although Sanken undertakes to enhance the quality and reliability of its products, the occurrence of failure and defect of semicon-

ductor products at a certain rate is inevitable. Users of Sanken products are requested to take, at their own risk, preventative measures

including safety design of the equipment or systems against any possible injury, death, fires or damages to the society due to device

failure or malfunction.

Sanken products listed in this document are designed and intended for the use as components in general purpose electronic equip-

ment or apparatus (home appliances, office equipment, telecommunication equipment, measuring equipment, etc.).

When considering the use of Sanken products in the applications where higher reliability is required (transportation equipment and

its control systems, traffic signal control systems or equipment, fire/crime alarm systems, various safety devices, etc.), and whenever

long life expectancy is required even in general purpose electronic equipment or apparatus, please contact your nearest Sanken sales

representative to discuss, prior to the use of the products herein.

The use of Sanken products without the written consent of Sanken in the applications where extremely high reliability is required

(aerospace equipment, nuclear power control systems, life support systems, etc.) is strictly prohibited.

In the case that you use Sanken products or design your products by using Sanken products, the reliability largely depends on the

degree of derating to be made to the rated values. Derating may be interpreted as a case that an operation range is set by derating the

load from each rated value or surge voltage or noise is considered for derating in order to assure or improve the reliability. In general,

derating factors include electric stresses such as electric voltage, electric current, electric power etc., environmental stresses such

as ambient temperature, humidity etc. and thermal stress caused due to self-heating of semiconductor products. For these stresses,

instantaneous values, maximum values and minimum values must be taken into consideration.

In addition, it should be noted that since power devices or IC's including power devices have large self-heating value, the degree of

derating of junction temperature affects the reliability significantly.

When using the products specified herein by either (i) combining other products or materials therewith or (ii) physically, chemically

or otherwise processing or treating the products, please duly consider all possible risks that may result from all such uses in advance

and proceed therewith at your own responsibility.

Anti radioactive ray design is not considered for the products listed herein.

Sanken assumes no responsibility for any troubles, such as dropping products caused during transportation out of Sanken's distribu-

tion network.

The contents in this document must not be transcribed or copied without Sanken's written consent.

Anda mungkin juga menyukai

- Off-Line Quasi-Resonant Switching Regulators: STR-X6769Dokumen9 halamanOff-Line Quasi-Resonant Switching Regulators: STR-X6769Alfredo Valencia RodriguezBelum ada peringkat

- Quasi-Resonant Topology Primary Switching Regulators: STR-W6756Dokumen8 halamanQuasi-Resonant Topology Primary Switching Regulators: STR-W6756perro sBelum ada peringkat

- STR W6753 DatasheetDokumen8 halamanSTR W6753 DatasheetjgerabmBelum ada peringkat

- Allegro STR-W6765 PDFDokumen15 halamanAllegro STR-W6765 PDFcomportBelum ada peringkat

- Datasheet STR 6757Dokumen11 halamanDatasheet STR 6757Walter CarreroBelum ada peringkat

- Quasi-Resonant Topology Primary Switching Regulators: STR-W6735Dokumen13 halamanQuasi-Resonant Topology Primary Switching Regulators: STR-W6735perro sBelum ada peringkat

- PWM Off-Line Switching Regulator Ics: Str-A6000H SeriesDokumen13 halamanPWM Off-Line Switching Regulator Ics: Str-A6000H SeriesAnonymous Lfgk6vygBelum ada peringkat

- STR W6735Dokumen14 halamanSTR W6735proctepBelum ada peringkat

- PDF Sanken 882276Dokumen13 halamanPDF Sanken 882276Moises CelosoBelum ada peringkat

- STR W6735 DatasheetDokumen13 halamanSTR W6735 DatasheetloagerBelum ada peringkat

- Off-Line Quasi-Resonant Switching Regulators Features and Benefits (39Dokumen9 halamanOff-Line Quasi-Resonant Switching Regulators Features and Benefits (39ch3o10836266Belum ada peringkat

- Tle6220gp DatasheetDokumen18 halamanTle6220gp Datasheetmaelo99999Belum ada peringkat

- DatasheetDokumen12 halamanDatasheetDjalma MoreiraBelum ada peringkat

- Switching IC for compact power supply STR-A6252Dokumen9 halamanSwitching IC for compact power supply STR-A6252Fernando ChingaBelum ada peringkat

- STR W6053SDokumen14 halamanSTR W6053SMarcos Rangel100% (1)

- Data SheetDokumen12 halamanData SheetMarcoAntonioCamanTraihuelBelum ada peringkat

- STR W6000S Series Application NoteDokumen20 halamanSTR W6000S Series Application NoteSutrisno OkBelum ada peringkat

- Str-x6759n Ds enDokumen9 halamanStr-x6759n Ds enCleiton SilvaBelum ada peringkat

- Iris-W 6754Dokumen8 halamanIris-W 6754Fatah MedAmineBelum ada peringkat

- Dse STR A6000mDokumen13 halamanDse STR A6000mAlanBelum ada peringkat

- High-Current LGA Power BlockDokumen10 halamanHigh-Current LGA Power BlockCengiz KayaBelum ada peringkat

- Go-iris-A6159 Fuente TV Samsung LCD 32"Dokumen7 halamanGo-iris-A6159 Fuente TV Samsung LCD 32"Daniel GómezBelum ada peringkat

- str-x6768n Ds en PDFDokumen9 halamanstr-x6768n Ds en PDFCarlBelum ada peringkat

- Document - SG3525A DDokumen10 halamanDocument - SG3525A Donlinerahul823405Belum ada peringkat

- Off-Line Quasi-Resonant Switching Regulators: STR-X6729Dokumen11 halamanOff-Line Quasi-Resonant Switching Regulators: STR-X6729Ossian Valera PinedaBelum ada peringkat

- Features Description: Ltc3633 Dual Channel 3A, 15V Monolithic Synchronous Step-Down RegulatorDokumen28 halamanFeatures Description: Ltc3633 Dual Channel 3A, 15V Monolithic Synchronous Step-Down RegulatorMichael LeeBelum ada peringkat

- Ane Str3a100Dokumen17 halamanAne Str3a100vietanh_askBelum ada peringkat

- DatasheetDokumen6 halamanDatasheetEktor CelaBelum ada peringkat

- L6208D To L6208PDDokumen16 halamanL6208D To L6208PDwtn2013Belum ada peringkat

- IRIS-X6757: FeaturesDokumen10 halamanIRIS-X6757: Featuresmiguel angel jaramilloBelum ada peringkat

- SG3525A Pulse Width Modulator Control Circuit: 1% and The ErrorDokumen10 halamanSG3525A Pulse Width Modulator Control Circuit: 1% and The ErrorJayesh SuryavanshiBelum ada peringkat

- 5V-0.5A Very Low Drop Regulator With Reset: DescriptionDokumen6 halaman5V-0.5A Very Low Drop Regulator With Reset: DescriptionDan EsentherBelum ada peringkat

- 161 20551 0 FS7M0880Dokumen16 halaman161 20551 0 FS7M0880Edwin Vitovis TorresBelum ada peringkat

- 20 W 2-Channel BTL AF Power Amplifier For Car Stereos: SANYO Electric Co.,Ltd. Semiconductor Bussiness HeadquartersDokumen9 halaman20 W 2-Channel BTL AF Power Amplifier For Car Stereos: SANYO Electric Co.,Ltd. Semiconductor Bussiness Headquartersfernandes66Belum ada peringkat

- IC-ON-LINE - CN dm0365r 44840Dokumen20 halamanIC-ON-LINE - CN dm0365r 44840MoscandoBelum ada peringkat

- Microstepping DMOS Driver With Translator: Description Features and BenefitsDokumen18 halamanMicrostepping DMOS Driver With Translator: Description Features and BenefitsSaid BoubkerBelum ada peringkat

- Datasheet MC3334Dokumen6 halamanDatasheet MC3334odipasBelum ada peringkat

- Ncl30160 1.0A Constant-Current Buck Regulator For Driving High Power LedsDokumen10 halamanNcl30160 1.0A Constant-Current Buck Regulator For Driving High Power LedsKhúc Hành QuânBelum ada peringkat

- STRG6653Dokumen8 halamanSTRG6653perro sBelum ada peringkat

- Features Description: LTC3864 60V Low I Step-Down DC/DC Controller With 100% Duty Cycle CapabilityDokumen28 halamanFeatures Description: LTC3864 60V Low I Step-Down DC/DC Controller With 100% Duty Cycle CapabilityDolly Arthur SiregarBelum ada peringkat

- IC-ON-LINE - CN dm0465r 44841Dokumen20 halamanIC-ON-LINE - CN dm0465r 44841ubhagavanBelum ada peringkat

- DatasheetDokumen13 halamanDatasheetebertecnicoBelum ada peringkat

- 3685 FBDokumen24 halaman3685 FBPravin MevadaBelum ada peringkat

- STR-X6729 DatasheetDokumen24 halamanSTR-X6729 DatasheetJesus E Lopez BBelum ada peringkat

- 12 Volt Smps Circuit DiagramDokumen7 halaman12 Volt Smps Circuit DiagramAnura MaddumageBelum ada peringkat

- Green Mode PWM Controller Ap384XgDokumen13 halamanGreen Mode PWM Controller Ap384XgbaphometabaddonBelum ada peringkat

- DL 0165 RDokumen20 halamanDL 0165 Rledu035Belum ada peringkat

- Ltc1629/Ltc1629-Pg Polyphase, High Efficiency, Synchronous Step-Down Switching RegulatorsDokumen28 halamanLtc1629/Ltc1629-Pg Polyphase, High Efficiency, Synchronous Step-Down Switching Regulatorscatsoithahuong84Belum ada peringkat

- DM0265Dokumen19 halamanDM0265liberthBelum ada peringkat

- STRW6252Dokumen15 halamanSTRW6252miltoncgBelum ada peringkat

- Linear LT3590Dokumen16 halamanLinear LT3590CiobanuClaudiuBelum ada peringkat

- 60 W-Universal Input/90 W-230 Vac Input PWM Switching RegulatorsDokumen14 halaman60 W-Universal Input/90 W-230 Vac Input PWM Switching RegulatorsIBSDIALLO0% (1)

- SI 3010KM DatasheetDokumen9 halamanSI 3010KM DatasheetAndres GuioBelum ada peringkat

- Ln4890 e 1wattDokumen14 halamanLn4890 e 1wattrichie1479Belum ada peringkat

- Transition-Mode PFC Controller: 1 FeaturesDokumen17 halamanTransition-Mode PFC Controller: 1 Featuresadriancho66Belum ada peringkat

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Dari EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Belum ada peringkat

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDari EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsBelum ada peringkat

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Dari EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Penilaian: 2.5 dari 5 bintang2.5/5 (3)

- Power Amplifier Applications Driver Stage Amplifier ApplicationsDokumen3 halamanPower Amplifier Applications Driver Stage Amplifier Applicationsperro sBelum ada peringkat

- Power Amplifier Applications Driver Stage Amplifier ApplicationsDokumen3 halamanPower Amplifier Applications Driver Stage Amplifier Applicationsperro sBelum ada peringkat

- 2sa1015 TosDokumen3 halaman2sa1015 Tosmei jonieBelum ada peringkat

- str-w6754 Ds enDokumen8 halamanstr-w6754 Ds enAdah BumbonBelum ada peringkat

- CQ 0765RTDokumen24 halamanCQ 0765RTsonivitel100% (2)

- C3280 PDFDokumen2 halamanC3280 PDFperro sBelum ada peringkat

- C3280 PDFDokumen2 halamanC3280 PDFperro sBelum ada peringkat

- str-w6754 Ds enDokumen8 halamanstr-w6754 Ds enAdah BumbonBelum ada peringkat

- DST 2sa1943-Tde en 7673Dokumen5 halamanDST 2sa1943-Tde en 7673perro sBelum ada peringkat

- Old Company Name in Catalogs and Other DocumentsDokumen13 halamanOld Company Name in Catalogs and Other Documentsperro sBelum ada peringkat

- Upc 4558 PDFDokumen13 halamanUpc 4558 PDFperro sBelum ada peringkat

- str-w6754 Ds enDokumen8 halamanstr-w6754 Ds enAdah BumbonBelum ada peringkat

- Datasheet PDFDokumen15 halamanDatasheet PDFperro sBelum ada peringkat

- Datasheet Dh321Dokumen20 halamanDatasheet Dh32193082Belum ada peringkat

- 1-ICE2xxx Ver4.5Dokumen34 halaman1-ICE2xxx Ver4.5Lachlan NolanBelum ada peringkat

- STR G 6653Dokumen8 halamanSTR G 6653Saif RehmanBelum ada peringkat

- CQ 0765RTDokumen24 halamanCQ 0765RTsonivitel100% (2)

- Ffpf10up60s PDFDokumen5 halamanFfpf10up60s PDFperro sBelum ada peringkat

- STK4162IIDokumen9 halamanSTK4162IIFredy Reinaldo Rivera MartínezBelum ada peringkat

- Fa5501 PDFDokumen4 halamanFa5501 PDFperro sBelum ada peringkat

- STK4162IIDokumen9 halamanSTK4162IIFredy Reinaldo Rivera MartínezBelum ada peringkat

- FSFR-Series - : Fairchild Power Switch (FPS™) For Half-Bridge Resonant ConvertersDokumen18 halamanFSFR-Series - : Fairchild Power Switch (FPS™) For Half-Bridge Resonant ConvertersGioVoTamBelum ada peringkat

- STR G 6653Dokumen8 halamanSTR G 6653Saif RehmanBelum ada peringkat

- STK4162IIDokumen9 halamanSTK4162IIFredy Reinaldo Rivera MartínezBelum ada peringkat

- STRG6653Dokumen8 halamanSTRG6653perro sBelum ada peringkat

- HOT D1877 Datasheet PDFDokumen1 halamanHOT D1877 Datasheet PDFlaurentina52Belum ada peringkat

- STK4162IIDokumen9 halamanSTK4162IIFredy Reinaldo Rivera MartínezBelum ada peringkat

- DST 2sa1943-Tde en 7673Dokumen5 halamanDST 2sa1943-Tde en 7673perro sBelum ada peringkat

- ST 2SC1740: G S P Form A Is AvailableDokumen2 halamanST 2SC1740: G S P Form A Is Availableperro sBelum ada peringkat

- Off-Line Quasi-Resonant Switching Regulators: STR-X6729Dokumen9 halamanOff-Line Quasi-Resonant Switching Regulators: STR-X6729perro sBelum ada peringkat