Blind List

Diunggah oleh

thmaraishriDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Blind List

Diunggah oleh

thmaraishriHak Cipta:

Format Tersedia

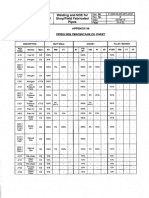

Temporary Slip Blind Thickness Calculation for Hydro Test

(For Low Carbon steel A283 Grade C)

Norminal Pipe Size

1

10

12

14

16

18

6

8

10

12

16

19

22

25

28

30

32

35

38

40

42

44

45

50

55

60

65

70

75

80

90

100

105

110

115

120

125

540.00

960.00

1500.00

135.00

240.00

375.00

540.00

960.00

1353.75

60.00

106.67

166.67

240.00

426.67

601.67

806.67

1041.67

33.75

60.00

93.75

135.00

240.00

338.44

453.75

585.94

735.00

843.75

960.00

1148.44

15.00

26.67

41.67

60.00

106.67

150.42

201.67

260.42

326.67

375.00

426.67

510.42

601.67

666.67

735.00

806.67

843.75

8.44

15.00

23.44

33.75

60.00

84.61

113.44

146.48

183.75

210.94

240.00

287.11

338.44

375.00

413.44

453.75

474.61

585.94

708.98

843.75

990.23

1148.44

5.40

9.60

15.00

21.60

38.40

54.15

72.60

93.75

117.60

135.00

153.60

183.75

216.60

240.00

264.60

290.40

303.75

375.00

453.75

540.00

633.75

735.00

843.75

960.00

1215.00

3.75

6.67

10.42

15.00

26.67

37.60

50.42

65.10

81.67

93.75

106.67

127.60

150.42

166.67

183.75

201.67

210.94

260.42

315.10

375.00

440.10

510.42

585.94

666.67

843.75

1041.67

2.76

4.90

7.65

11.02

19.59

27.63

37.04

47.83

60.00

68.88

78.37

93.75

110.51

122.45

135.00

148.16

154.97

191.33

231.51

275.51

323.34

375.00

430.48

489.80

619.90

765.31

843.75

926.02

1012.12

2.11

3.75

5.86

8.44

15.00

21.15

28.36

36.62

45.94

52.73

60.00

71.78

84.61

93.75

103.36

113.44

118.65

146.48

177.25

210.94

247.56

287.11

329.59

375.00

474.61

585.94

646.00

708.98

843.75

915.53

1.67

2.96

4.63

6.67

11.85

16.71

22.41

28.94

36.30

41.67

47.41

56.71

66.85

74.07

81.67

89.63

93.75

115.74

140.05

166.67

195.60

226.85

260.42

296.30

375.00

462.96

510.42

560.19

612.27

666.67

723.38

Test Pressure

Plate Thickness

p=Testing Pressure (Kg/Cm)

t=Thickness of Temporary Blind Plate (mm)

d=Inside Diameter of Gasket(Inch)

S=Maximum Allowable stress (Kg/cm)

E=Quality factor

Prepared By

Reviewed By

Safety Factor = 1.15

w=Welding Joint Strength Reduction factor

c=Sum of Allowance define in para ASME B31.3,304.1.1

Approved By

20

1.35

2.40

3.75

5.40

9.60

13.54

18.15

23.44

29.40

33.75

38.40

45.94

54.15

60.00

66.15

72.60

75.94

93.75

113.44

135.00

158.44

183.75

210.94

240.00

303.75

375.00

413.44

453.75

495.94

540.00

585.94

24

0.94

1.67

0.60

3.75

6.67

9.40

12.60

16.28

20.42

23.44

26.67

31.90

37.60

41.67

45.94

50.42

52.73

65.10

78.78

93.75

110.03

127.60

146.48

166.67

210.94

260.42

287.11

315.10

344.40

375.00

406.90

Temporary Slip Blind Thickness Calculation for Hydro Test

(For Low Carbon steel A283 Grade C)

Norminal Pipe Size

26

28

30

32

34

36

38

40

42

44

46

48

50

52

54

56

58

60

72

78

6

8

10

12

16

19

22

25

28

30

32

35

38

40

42

44

45

50

55

60

65

70

75

80

90

100

105

110

115

120

125

150

0.80

1.42

2.22

3.20

5.68

8.01

10.74

13.87

17.40

19.97

22.72

27.18

32.04

35.50

39.14

42.96

44.93

55.47

67.12

79.88

93.75

108.73

124.82

142.01

179.73

221.89

244.64

268.49

293.45

319.53

346.71

499.26

0.69

1.22

1.91

2.76

4.90

6.91

9.26

11.96

15.00

17.22

19.59

23.44

27.63

30.61

33.75

37.04

38.74

47.83

57.88

68.88

80.84

93.75

107.62

122.45

154.97

191.33

210.94

231.51

253.03

275.51

298.95

430.48

0.60

1.07

1.67

2.40

4.27

6.02

8.07

10.42

13.07

15.00

17.07

20.42

24.07

26.67

29.40

32.27

33.75

41.67

50.42

60.00

70.42

81.67

93.75

106.67

135.00

166.67

183.75

201.67

220.42

240.00

260.42

375.00

0.53

0.94

1.46

2.11

3.75

5.29

7.09

9.16

11.48

13.18

15.00

17.94

21.15

23.44

25.84

28.36

29.66

36.62

44.31

52.73

61.89

71.78

82.40

93.75

118.65

146.48

161.50

177.25

193.73

210.94

228.88

329.00

0.47

0.83

1.30

1.87

3.32

4.68

6.28

8.11

10.17

11.68

13.29

15.90

18.74

20.76

22.89

25.12

26.28

32.44

39.25

46.71

54.82

63.58

72.99

83.04

105.10

129.76

143.06

157.01

171.60

186.85

202.75

291.96

0.42

0.74

1.16

1.67

2.96

4.18

5.60

7.23

9.07

10.42

11.85

14.18

16.71

18.52

20.42

22.41

23.44

28.94

35.01

41.67

48.90

56.71

65.10

74.07

93.75

115.74

127.60

140.05

153.07

166.67

180.84

260.42

0.37

0.66

1.04

1.50

2.66

3.75

5.03

6.49

8.14

9.35

10.64

12.73

15.00

16.62

18.32

20.11

21.04

25.97

31.42

37.40

43.89

50.90

58.43

66.48

84.14

103.88

114.53

125.69

137.38

149.58

162.31

233.73

0.34

0.60

0.94

1.35

2.40

3.38

4.54

5.86

7.35

8.44

9.60

11.48

13.54

15.00

16.64

18.15

18.98

23.44

28.36

33.75

39.61

45.94

52.73

60.00

75.94

93.75

103.36

113.44

123.98

135.00

146.48

210.94

0.31

0.54

0.85

1.22

2.18

3.07

4.12

5.31

6.67

7.65

8.71

10.42

12.28

13.61

15.00

16.46

17.22

21.26

25.72

30.61

35.93

41.67

47.83

54.42

68.88

85.03

93.75

102.89

112.46

122.45

132.87

191.33

0.28

0.50

0.77

1.12

1.98

2.80

3.75

4.84

6.07

6.97

7.93

9.49

11.19

12.40

13.67

15.00

15.69

19.37

23.44

27.89

32.74

37.96

43.58

49.59

62.76

77.48

85.42

93.75

102.47

111.57

121.06

174.33

0.26

0.45

0.71

1.02

1.81

2.56

3.43

4.43

5.56

6.38

7.26

8.68

10.24

11.34

12.50

13.72

14.35

17.72

21.44

25.52

29.95

34.74

39.87

45.37

57.42

70.89

78.15

85.78

93.75

102.08

110.76

159.50

0.23

0.42

0.65

0.94

1.67

2.35

3.15

4.07

5.10

5.86

6.67

7.98

9.40

10.42

11.48

12.60

13.18

16.28

16.69

23.44

27.51

31.90

36.62

41.67

52.73

65.10

71.78

78.78

86.10

93.75

101.73

146.48

0.22

0.38

0.60

0.86

1.54

2.17

2.90

3.75

4.70

5.40

6.14

7.35

8.66

9.60

10.58

11.62

12.15

15.00

18.15

21.60

25.35

29.40

33.75

38.40

48.60

60.00

66.15

72.60

79.35

86.40

193.75

135.00

0.20

0.36

0.55

0.80

1.42

2.00

2.68

3.47

4.35

4.99

5.68

6.80

8.01

8.88

9.79

10.74

11.23

13.87

16.78

19.97

23.44

27.18

31.20

35.50

44.93

55.47

61.16

67.12

73.36

79.88

86.68

124.82

0.19

0.33

0.51

0.74

1.32

1.86

2.49

3.22

4.03

4.63

5.27

6.30

7.43

8.23

9.07

9.96

10.42

12.86

15.56

18.52

21.73

25.21

28.94

32.92

41.67

51.44

56.71

62.24

68.03

74.07

80.38

115.74

0.17

0.31

0.48

0.69

1.22

1.73

2.32

2.99

3.75

4.30

4.90

5.86

6.91

7.65

8.44

9.26

9.69

11.96

14.47

17.22

20.21

23.44

26.91

30.61

38.74

47.83

52.73

57.88

63.26

68.88

74.74

107.62

0.16

0.29

0.45

0.64

1.14

1.61

2.16

2.79

3.50

4.01

4.57

5.46

6.44

7.13

7.87

8.63

9.03

11.15

13.49

16.05

18.84

21.85

25.08

28.54

36.12

44.59

59.16

53.95

58.97

64.21

69.67

100.33

0.15

0.27

0.42

0.60

1.07

1.50

2.02

2.60

3.27

3.75

4.27

5.10

6.02

6.67

7.35

8.07

8.44

10.42

12.60

15.00

17.60

20.42

23.44

26.67

33.75

41.64

45.94

50.42

55.10

60.00

65.10

93.75

0.10

0.19

0.29

0.42

0.74

1.04

1.40

1.81

2.27

2.60

2.96

3.54

4.18

4.63

5.10

5.60

5.86

7.23

8.75

10.42

12.23

14.18

16.28

18.52

23.44

28.94

31.90

35.01

38.27

41.67

45.21

65.10

0.09

0.16

0.25

0.36

0.63

0.89

1.19

1.54

1.93

2.22

2.52

3.02

3.56

3.94

4.35

4.77

4.99

6.16

7.46

8.88

10.42

12.08

13.87

15.78

19.97

24.65

27.18

29.83

32.61

35.50

38.52

55.47

Test Pressure

Plate Thickness

p=Testing Pressure (Kg/Cm)

t=Thickness of Temporary Blind Plate (mm)

d=Inside Diameter of Gasket(Inch)

S=Maximum Allowable stress (Kg/cm)

E=Quality factor

Safety Factor = 1.15

w=Welding Joint Strength Reduction factor

c=Sum of Allowance define in para ASME B31.3,304.1.1

Approved By

Prepared By

Reviewed By

Temporary Slip Blind Thickness Calculation for Hydro Test

(For Low Carbon steel A283 Grade C)

p=Testing Pressure (Kg/Cm)

t=Thickness of Temporary Blind Plate (mm)

d=Inside Diameter of Gasket(Inch)

E=Quality factor (1.0)

S=90% Maximum Allowable stress (Kg/cm)

=0.9 x 30 Ksi = 1836 Kg/cm

Safety Factor = 1.15 (Not required to consider)

w=Welding Joint Strength Reduction factor

c=Sum of Allowance define in para ASME B31.3,304.1.1

(Not required to consider)

Example:

According to above formula;

P = (t/d) x 15.17

P = (90/60) x 15.17

P = 33.75 Kg/cm

Therefore 90 mm thick slip blind can be used for NPS 60" with test pressure 33.75 Kg/cm

Anda mungkin juga menyukai

- PipesDokumen37 halamanPipesGautam BhardwajBelum ada peringkat

- Spec Grade Number Symbol Number Symbol Asme (Astm) KS JISDokumen50 halamanSpec Grade Number Symbol Number Symbol Asme (Astm) KS JISVinay TrivediBelum ada peringkat

- Valves Kvc07Dokumen25 halamanValves Kvc07Dimas Anugrah MahardikaBelum ada peringkat

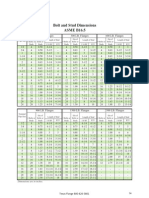

- Bolt and Stud DimentionDokumen1 halamanBolt and Stud DimentionwhngomjBelum ada peringkat

- WEP Standard For Reference OnlyDokumen37 halamanWEP Standard For Reference OnlyKiran NikateBelum ada peringkat

- Grating Weight - CalculationDokumen1 halamanGrating Weight - CalculationMuthuram NBelum ada peringkat

- Carbon Steel ASME B36.10M Stainless Steel ASME B36.19M Cu-Ni Brass Bronze Thermoplastic ThermosettingDokumen9 halamanCarbon Steel ASME B36.10M Stainless Steel ASME B36.19M Cu-Ni Brass Bronze Thermoplastic ThermosettingkaviramanBelum ada peringkat

- Piping Material EquivalentsDokumen1 halamanPiping Material EquivalentspejnorozyBelum ada peringkat

- Mild Steel Welding ElectrodeDokumen12 halamanMild Steel Welding ElectrodeVĩnh NguyễnBelum ada peringkat

- Carbon, Alloy and Stainless Steel Pipes - ASME/ANSI B36.10/19Dokumen5 halamanCarbon, Alloy and Stainless Steel Pipes - ASME/ANSI B36.10/19Ton PhichitBelum ada peringkat

- Material Selection Chart Based On Operating TemperatureDokumen1 halamanMaterial Selection Chart Based On Operating TemperatureVIVEK TIWARIBelum ada peringkat

- 07 Piping BOQDokumen54 halaman07 Piping BOQHRK65Belum ada peringkat

- L&T Aquaseal Butterfly Check Valves PDFDokumen28 halamanL&T Aquaseal Butterfly Check Valves PDFSanjay SahulBelum ada peringkat

- Pipe Fitting Weight ChartDokumen1 halamanPipe Fitting Weight Chartab5918590Belum ada peringkat

- Carbon Steel Pipe Weight ChartDokumen27 halamanCarbon Steel Pipe Weight ChartMaryam ArifBelum ada peringkat

- Belt Conveyor Draw FinishDokumen1 halamanBelt Conveyor Draw FinishRizki FauziBelum ada peringkat

- Tube Bundle DrawingDokumen1 halamanTube Bundle DrawingVeera ManiBelum ada peringkat

- A. For Welding Sa 210 Gra1 To Sa 210 GR A1Dokumen1 halamanA. For Welding Sa 210 Gra1 To Sa 210 GR A1911targa100% (1)

- FDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Dokumen15 halamanFDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Gisela ViskaBelum ada peringkat

- Pump Material SpecificationDokumen6 halamanPump Material SpecificationshripaddixitBelum ada peringkat

- S.NO. Description Unit QTY Remarks 1.0 Pipe: 1.1 A B: Total (Usd) Rate (USD /unit)Dokumen6 halamanS.NO. Description Unit QTY Remarks 1.0 Pipe: 1.1 A B: Total (Usd) Rate (USD /unit)Mavia KhanBelum ada peringkat

- Fitter ToolsDokumen7 halamanFitter ToolsSainadhReddy100% (1)

- Torque Values B7 Studs PDFDokumen1 halamanTorque Values B7 Studs PDFipsthethiBelum ada peringkat

- 127.study The Effect of Welding Parameters of Tig Welding of PlateDokumen43 halaman127.study The Effect of Welding Parameters of Tig Welding of PlatemoorthikumarBelum ada peringkat

- Instrumentation Pipe & Weld Fittings: 6000psig, 10000psig and Standard RatingDokumen5 halamanInstrumentation Pipe & Weld Fittings: 6000psig, 10000psig and Standard Ratinggohjh80Belum ada peringkat

- ASTM Comparison PDFDokumen1 halamanASTM Comparison PDFRaja HoneBelum ada peringkat

- Material Selection and SpecificationDokumen50 halamanMaterial Selection and SpecificationbashirBelum ada peringkat

- Arc Welding Filler Metal Selection ChartDokumen7 halamanArc Welding Filler Metal Selection Chartepriyono0% (1)

- HDPE Flange AdaptorDokumen1 halamanHDPE Flange Adaptorcld72Belum ada peringkat

- Short List of Applied Piping Standard PDFDokumen3 halamanShort List of Applied Piping Standard PDFmohamad3010Belum ada peringkat

- En 13121-3:2008+a1:2010 (E)Dokumen1 halamanEn 13121-3:2008+a1:2010 (E)TIME STAR COMPOSITEBelum ada peringkat

- Ladder Rung Calc.Dokumen1 halamanLadder Rung Calc.Azwan ShahBelum ada peringkat

- Materials Comparison DIN / EN / ASTM: Pipes / Tubes Flanges Buttwelding FittingsDokumen1 halamanMaterials Comparison DIN / EN / ASTM: Pipes / Tubes Flanges Buttwelding Fittingsnaseema1Belum ada peringkat

- Tanky 53 KL Rev.1Dokumen187 halamanTanky 53 KL Rev.1Priyo Jati WahyonoBelum ada peringkat

- ASTM Cross Reference Material Specs.Dokumen2 halamanASTM Cross Reference Material Specs.septixBelum ada peringkat

- Input Parameter Valve and Flange: Fluid Density (KG/M) Insulation Density (KG/M)Dokumen12 halamanInput Parameter Valve and Flange: Fluid Density (KG/M) Insulation Density (KG/M)ibmsherBelum ada peringkat

- Closure Data PEDokumen2 halamanClosure Data PEjowarBelum ada peringkat

- 5 Units Separator BOQ Pipe, Flange and Fitting 25-8-15Dokumen24 halaman5 Units Separator BOQ Pipe, Flange and Fitting 25-8-15Engr Khurram Jaan RamayBelum ada peringkat

- Metal Chemical CompositionDokumen1 halamanMetal Chemical CompositionprathmeshBelum ada peringkat

- Pressure Vessel, Boiler, Storage Tanks and Heat Exchanger in Oil, Gas Project. Storage Tanks Heat ExchangerDokumen1 halamanPressure Vessel, Boiler, Storage Tanks and Heat Exchanger in Oil, Gas Project. Storage Tanks Heat ExchangerValli RajuBelum ada peringkat

- Made in Italy - EuropeDokumen8 halamanMade in Italy - EuropeenenickBelum ada peringkat

- Electode Equivalent China Standards (GB) Vs AWSDokumen1 halamanElectode Equivalent China Standards (GB) Vs AWSTariqBelum ada peringkat

- Knife Gate Valve Testing Procedure Rev. 2Dokumen2 halamanKnife Gate Valve Testing Procedure Rev. 2mehtahemalBelum ada peringkat

- ASTM A53 Vs A500 EquivalenceDokumen6 halamanASTM A53 Vs A500 Equivalenceemmanuilmoulos6339Belum ada peringkat

- Sight Glass Selection Guide PDFDokumen7 halamanSight Glass Selection Guide PDFani_datBelum ada peringkat

- ISO 15614-1 0 Bilfinger Salamis 19.11.2018. ISO 15614-1 N/A BIS-DK Form Number: BIS-DK-F 108Dokumen1 halamanISO 15614-1 0 Bilfinger Salamis 19.11.2018. ISO 15614-1 N/A BIS-DK Form Number: BIS-DK-F 108TomasPavlovicBelum ada peringkat

- Att 15 - Equipment Nozzle LoadsDokumen11 halamanAtt 15 - Equipment Nozzle LoadsahmedalishBelum ada peringkat

- MTH - Spec Cross-Ref Chartr1Dokumen1 halamanMTH - Spec Cross-Ref Chartr1RamuAlagappanBelum ada peringkat

- DCP Nde DV 297 HLT 01Dokumen7 halamanDCP Nde DV 297 HLT 01Chandrasekhar mishraBelum ada peringkat

- Steel StandardsDokumen53 halamanSteel StandardsSureshBelum ada peringkat

- AL-2208-6'' Pig Launcher Engineering and Fabrication - KNOCDokumen5 halamanAL-2208-6'' Pig Launcher Engineering and Fabrication - KNOCCaptainToniesBelum ada peringkat

- Material P NumberDokumen11 halamanMaterial P NumberChaitanya Sai TBelum ada peringkat

- Amine Stripper Column Crack 3501-1-T-004: PQR Test CouponDokumen2 halamanAmine Stripper Column Crack 3501-1-T-004: PQR Test Couponpstechnical_43312697100% (1)

- Testing Blind Plate TableDokumen5 halamanTesting Blind Plate TableKyaw Kyaw Aung77% (13)

- Spec25051 - Teck CableDokumen4 halamanSpec25051 - Teck Cablecrfg2003Belum ada peringkat

- 1200 1300Dokumen18 halaman1200 1300wyerengrBelum ada peringkat

- Test Start Date Test Finish Date: Respect To Total StressDokumen25 halamanTest Start Date Test Finish Date: Respect To Total StressapitgoodBelum ada peringkat

- DBR ChecklistDokumen9 halamanDBR ChecklistJai ThakkarBelum ada peringkat

- Aluminium Conductor Composite Core ACCCDokumen5 halamanAluminium Conductor Composite Core ACCCAmlanshankar Deb BarmaBelum ada peringkat

- Tabel Baja LengkapDokumen29 halamanTabel Baja LengkapAlexander Ignatius50% (4)

- Comparative Study Summary 07 2004 enDokumen32 halamanComparative Study Summary 07 2004 enthmaraishriBelum ada peringkat

- Testing Procedure - Gate Globe Check Valve-Signed - APPROVED WITH COMMENTSDokumen6 halamanTesting Procedure - Gate Globe Check Valve-Signed - APPROVED WITH COMMENTSthmaraishriBelum ada peringkat

- Tentative Date of E-Submission Approved Basis Demolitition Work Authority SubmissionDokumen1 halamanTentative Date of E-Submission Approved Basis Demolitition Work Authority SubmissionthmaraishriBelum ada peringkat

- Bullet West Mound - 20 DecDokumen36 halamanBullet West Mound - 20 DecthmaraishriBelum ada peringkat

- Interface REsponsibility MatrixDokumen2 halamanInterface REsponsibility Matrixthmaraishri0% (1)

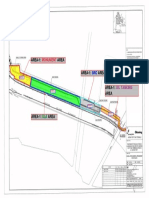

- Wayleave (Phase-1c) Divided Into 4 Area - Mark-Up Plot PlanDokumen1 halamanWayleave (Phase-1c) Divided Into 4 Area - Mark-Up Plot PlanthmaraishriBelum ada peringkat

- Base Oil 95 Solvent BrightstockDokumen1 halamanBase Oil 95 Solvent BrightstockthmaraishriBelum ada peringkat

- Tie inDokumen6 halamanTie inthmaraishriBelum ada peringkat

- Material Grade Comparison Chart PDFDokumen1 halamanMaterial Grade Comparison Chart PDFHelen Kate Saccuan100% (1)

- BOG CalDokumen6 halamanBOG CalSook Thiam LeeBelum ada peringkat

- 7hfkqlfdouhsruw Dvnhwvirusro/Hwk/Ohqh3 (SLSHFRQQHFWLRQV: A Technical Paper Presented by James Walker Australia Pty LTDDokumen16 halaman7hfkqlfdouhsruw Dvnhwvirusro/Hwk/Ohqh3 (SLSHFRQQHFWLRQV: A Technical Paper Presented by James Walker Australia Pty LTDthmaraishriBelum ada peringkat

- Pipe & Fittings Delivery Summary Sheet As On 2nd August 2014Dokumen15 halamanPipe & Fittings Delivery Summary Sheet As On 2nd August 2014thmaraishriBelum ada peringkat

- Test Blind ThicknessDokumen1 halamanTest Blind ThicknessthmaraishriBelum ada peringkat

- Sample For Pipe Welding NDE % ChartDokumen2 halamanSample For Pipe Welding NDE % ChartthmaraishriBelum ada peringkat

- Hot Work HES 205Dokumen20 halamanHot Work HES 205thmaraishriBelum ada peringkat

- Surface Preperation SSPCDokumen4 halamanSurface Preperation SSPCGTpianomanBelum ada peringkat

- SSPC ChartDokumen2 halamanSSPC ChartajuhaseenBelum ada peringkat

- 1000 11Dokumen4 halaman1000 11kamal_mdBelum ada peringkat

- HSB 58 ADokumen6 halamanHSB 58 AthmaraishriBelum ada peringkat

- bk101 Chapter3design Selection Criteria PDFDokumen30 halamanbk101 Chapter3design Selection Criteria PDFgalvigarciaBelum ada peringkat

- Welding Progress: Work Front of Pipe TrenchDokumen2 halamanWelding Progress: Work Front of Pipe TrenchthmaraishriBelum ada peringkat

- Temporary Bline List For Tank (Sheet-1 & Sheet-2)Dokumen2 halamanTemporary Bline List For Tank (Sheet-1 & Sheet-2)thmaraishriBelum ada peringkat

- CESCO Technical ProposalDokumen2 halamanCESCO Technical ProposalthmaraishriBelum ada peringkat

- Hot Work HES 205Dokumen20 halamanHot Work HES 205thmaraishriBelum ada peringkat

- Yen Tiled RodDokumen5 halamanYen Tiled RodthmaraishriBelum ada peringkat

- HT1027 PDFDokumen4 halamanHT1027 PDFthmaraishriBelum ada peringkat

- Power CardDokumen6 halamanPower CardArun SBelum ada peringkat

- A-Level-Chemistry Edexcel FACER Sample-Chapter PDFDokumen36 halamanA-Level-Chemistry Edexcel FACER Sample-Chapter PDFahamedBelum ada peringkat

- PTQ (Petroleum Technology Quarterly) Vol 20 No 4 Q3 (Jul, Aug, Sep) 2015Dokumen148 halamanPTQ (Petroleum Technology Quarterly) Vol 20 No 4 Q3 (Jul, Aug, Sep) 2015Roo FaBelum ada peringkat

- Stireno 1Dokumen2 halamanStireno 1jhonBelum ada peringkat

- Plant Movement Bio ProjectDokumen16 halamanPlant Movement Bio ProjectShahab AkhtarBelum ada peringkat

- Bitumat TopsealDokumen5 halamanBitumat TopsealsathiyanBelum ada peringkat

- Lateral Deflection of Tall BuildingsDokumen4 halamanLateral Deflection of Tall BuildingsAshnaBeeslallBelum ada peringkat

- XJ (X350) Cooling System Drain Fill Bleed R&IDokumen4 halamanXJ (X350) Cooling System Drain Fill Bleed R&IMattBelum ada peringkat

- BPhO Round 1 2013 PRT 1Dokumen6 halamanBPhO Round 1 2013 PRT 1Karn KumarBelum ada peringkat

- Scale Up ArticleDokumen8 halamanScale Up ArticleAndrek QueckBelum ada peringkat

- Manual CAT4000Dokumen36 halamanManual CAT4000windrider56Belum ada peringkat

- ASTM A193: GradesDokumen1 halamanASTM A193: GradesRamon MendozaBelum ada peringkat

- Gate 1990Dokumen12 halamanGate 1990Akhil TiwariBelum ada peringkat

- Synthesis of Aspirin DataDokumen3 halamanSynthesis of Aspirin DataAnonymous orNHXM0f0Belum ada peringkat

- SSCF StainlessSteel Shell and TubeDokumen7 halamanSSCF StainlessSteel Shell and TubeTom GuyetteBelum ada peringkat

- DK7740A Wire CutDokumen45 halamanDK7740A Wire Cutdprdouglas100% (2)

- Level OrbitalDokumen2 halamanLevel OrbitalRizwan HaniffBelum ada peringkat

- Low Salinity EOR 2012Dokumen41 halamanLow Salinity EOR 2012Pondok Huda100% (2)

- Calculate The Mole ConceptDokumen1 halamanCalculate The Mole ConceptRajiv Shankar SinhaBelum ada peringkat

- Aspirin NewDokumen26 halamanAspirin NewsanasharBelum ada peringkat

- ASTM D 2513 04 Thermoplastic Gas Pressure Pipe Tubing and Fittings PDFDokumen25 halamanASTM D 2513 04 Thermoplastic Gas Pressure Pipe Tubing and Fittings PDFSunil Devdutt ThakoreBelum ada peringkat

- An-1009 Application Note On ASTM E313 WhitenessDokumen3 halamanAn-1009 Application Note On ASTM E313 WhitenesskcadavidBelum ada peringkat

- 6 Nutrition P3aDokumen9 halaman6 Nutrition P3aSharifah NurainBelum ada peringkat

- Performance Qualification and MaintenanceDokumen19 halamanPerformance Qualification and MaintenanceApoloTrevinoBelum ada peringkat

- Transparent WoodDokumen7 halamanTransparent WoodArnab BhattacharyaBelum ada peringkat

- Class 10 Chemistry Workbook PDFDokumen118 halamanClass 10 Chemistry Workbook PDFSayan Dutta100% (1)

- Diploma Thomas UehlingerDokumen75 halamanDiploma Thomas UehlingerTienTranBelum ada peringkat

- Generalized Guidelines For Structural Steel Welding InspectionDokumen19 halamanGeneralized Guidelines For Structural Steel Welding InspectionHariPrasath100% (1)

- Elastogran cellularPOLYURETHANEelastomerDokumen6 halamanElastogran cellularPOLYURETHANEelastomerAngelo NutiBelum ada peringkat

- IGSCE Reviewer Multiple Choice PDFDokumen52 halamanIGSCE Reviewer Multiple Choice PDFAlan Peter50% (2)