A7 Multi

Diunggah oleh

Thân KhaDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

A7 Multi

Diunggah oleh

Thân KhaHak Cipta:

Format Tersedia

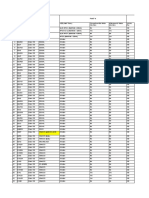

A7 03/03

Page 1 of 6

1

CERTIFICATION SCHEME FOR WELDING AND INSPECTION PERSONNEL

PHASE 6 : WELDING INSPECTORS 3-1

CANDIDATE: NAME:

EXAMINATION TIME : 30 MINUTES

MULTIPLE CHOICE PAPER A7 ALL 30 QUESTIONS

TO BE ATTEMPTED

ONLY ONE ANSWER IS TO BE TICKED ()

1. Which of the following MMA electrode types would you more likely expect to

be limited to PA position use only

a) a Basic type a.________

b) a Cellulosic type b.________

c) a Rutile type c.________

d) an Iron Powder type d.________

2. Which Polarity is normally required for TIG welding stainless steel

a) AC electrode autogenous a.________

b) DC electrode negative b.________

c) DC electrode positive c.________

d) It would make little difference which were used d.________

3. For 10mm material, which of the following welding processes would you

expect to give the highest heat input when using typically required parameters

a) Shielded metal arc welding a.________

b) Manual metal arc welding b.________

c) Submerged arc welding c.________

d) Oxy Acetylene d.________

4. A mitre/even leg length Fillet weld has a design throat thickness of 14mm.

What is its leg length?

a) 20 mm a.________

b) 14 mm b.________

c) 21 mm c.________

d) It cannot be determined from the information given d.________

A7 03/03

Page 2 of 6

2

5. At the end of a weld symbol reference line, in the tail, is the number 111.

This number indicates:

a) The type of process a.________

b) The type of electrode b.________

c) The welding position c.________

d) The WPS number d.________

6. Which of the following elements in a steel has the greatest effect on the

Formation of segregation bands?

a) Chromium a.________

b) Hydrogen b.________

c) Sulphur c.________

d) Carbon d.________

7. In MIG/MAG welding wire feed speed is proportional to:

a) Travel speed a.________

b) Polarity b.________

c) Arc length c.________

d) Welding Current d.________

8. An approximate temperature for the normalising of a carbon manganese

weldment is:

a) 200

0

C a.________

b) 600

0

C b.________

c) 900

0

C c.________

d) 1200

0

C d.________

9. A brittle failure can be identified visually by :

a) The presence of Beach Marks a.________

b) Plastic deformation b.________

c) Being Rough and Torn c.________

d) None of the above d.________

10. Which of the following terms differs from the three others given:

a) Linear misalignment a.________

b) Hi/Lo b.________

c) Mismatch c.________

d) Angular misalignment d.________

A7 03/03

Page 3 of 6

3

11. An electrode is classified as E 35 3 1Ni B to BSEN 499 specification

The B part of the classification means:

a) Manufactured to a British standard a.________

b) To be used in PB position b.________

c) The coating is a Basic type c.________

d) To be used for weld bead application d.________

12. A pipeline is to be laid across country. Which of the following would normally

be used to detect root defects :

a) Eddy current testing a.________

b) Radiography b.________

c) Hydrostatic testing c.________

d) Liquid penetrant Inspection d.________

13. The main purpose of Preheating steels is to :

a) Reduce the risk of hydrogen cracking a.________

b) Reduce residual stresses in the joint b.________

c) Reduce distortion c.________

d) Drive the moisture out of the plate d.________

14. A short transverse tensile test will give:

a) The tensile strength of the weld a.________

b) Indication of susceptibility to lamellar tearing b.________

c) The stress/ stain characteristics of the weld c.________

d) Indication of susceptibility to hydrogen cracking d.________

15. Weldments in carbon manganese steels using a higher than specified Heat

Input, may show:

a) Higher integrity a.________

b) Higher distortion b.________

c) Higher toughness c.________

d) Higher hardness d.________

16. When monitoring voltage in a welding operation, the check should be made:

a) Using a meter across the terminals on the welding set a.________

b) Using a meter as near as possible to and bridging the Arc. b.________

c) Using a meter around the cable near to the electrode

holder/ gun c.________

d) Using a meter around the cable anywhere in the circuit d.________

A7 03/03

Page 4 of 6

4

17. A drawing with symbols to BSEN 22553 will show a 7mm leg length fillet weld

with the fillet symbol prefixed as:

a) Z 7 a.________

b) S 7 b.________

c) A 7 c.________

d) None of the above as the size should follow the weld symbol d.________

18. Hard stamping pressure vessels materials may give rise to:

a) Corrosion problems a.________

b) Work hardening b.________

c) Stress concentrations c.________

d) All of the above d.________

19. Plasma cutting can be applied to:

a) Aluminium Alloys a.________

b) Carbon Steels b.________

c) Austenitic Stainless Steels c.________

d) All of the above d.________

20. Which of the following defect types will not be detected by penetrant testing

a) Surface breaking Planar flaws a.________

b) Undercut b.________

c) Buried Planar types c.________

d) Non-planar surface defects. d.________

21. Welding processes utilising fluxes are sometimes considered to be superior to

those that dont because:

a) Ease of possible variance of weld metal composition a.________

b) Greater tolerance of surface contaminants b.________

c) They can produce superior weld metal properties c.________

d) All of the above d.________

22. The output characteristics of a typical GTAW set are:

a) Constant Voltage a.________

b) Constant Current b.________

c) Flat c.________

d) Pulsing d.________

A7 03/03

Page 5 of 6

5

23. Which of the following standards is concerned with Welding procedure

approval:

a) BS EN 499 a.________

b) BS EN 288 b.________

c) BS EN 22554 c.________

d) BS EN 287 d.________

24. According to BS 499 a weld symbol below the reference line refers to:

a) A weld on the other side a.________

b) A weld on the root of the joint b.________

c) A weld on the arrow side c.________

d) None of the above as this should be shown on a dotted line d.________

25. A steel has laminations ,which of the following statements is correct

a) It has poor short transverse properties a.________

b) It has undergone high through thickness loading b.________

c) It has had a special heat-treatment c.________

d) It has been welded with excessive restraint d.________

26. What is the abbreviation for a welding procedure that has yet to be tested:

a) WPS a.________

b) pWPS b.________

c) uWPS c.________

d) WPStbt d.________

27. A typical bevel angle used for MMA welding 15mm t carbon steel could be:

a) 35 a.________

b) 120 b.________

c) 70 c.________

d) 90 d.________

28. Which of the following is a fusion welding process:

a) Friction Welding a.________

b) Manual metallic arc welding b.________

c) Forge welding c.________

d) Explosive welding d.________

A7 03/03

Page 6 of 6

6

29. The tungsten electrode used in TIG welding carbon steel may contain a small

percentage of:

a) Thoria a.________

b) Chromium b.________

c) Iridia c.________

d) Titania d.________

30. What element typically causes a carbon steel to suffer from hot shortness :

a) Silicon a.________

b) Martensite b.________

c) Manganese c.________

d) Sulphur d.________

Anda mungkin juga menyukai

- Corrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsDari EverandCorrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsBelum ada peringkat

- Final Assesment Multiple Choice Question Cswip Welding Inspector Course Mfy Oo4 All Question To Be AttemptedDokumen4 halamanFinal Assesment Multiple Choice Question Cswip Welding Inspector Course Mfy Oo4 All Question To Be AttemptedLe TuanBelum ada peringkat

- Non-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingDari EverandNon-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingRaman SinghBelum ada peringkat

- CSWIPDokumen3 halamanCSWIPBox Empty100% (2)

- Question Paper For Snr. WeldingDokumen3 halamanQuestion Paper For Snr. WeldingThulasi Ram100% (1)

- Painting Inspector: Passbooks Study GuideDari EverandPainting Inspector: Passbooks Study GuideBelum ada peringkat

- 187 RewDokumen32 halaman187 Rewdhasdj100% (5)

- Cswip Paper 2Dokumen5 halamanCswip Paper 2Vinu Raveendran100% (1)

- General MCQ's Paper 4 AnsDokumen4 halamanGeneral MCQ's Paper 4 AnsJawed AkhterBelum ada peringkat

- Welding QADokumen40 halamanWelding QAsskiitbBelum ada peringkat

- Cswip QuestioDokumen15 halamanCswip Questioniminkp123100% (1)

- 3 2Dokumen3 halaman3 2jayaarnav100% (1)

- 3.2.2 RI Sup. - Training Booklet 000521Dokumen28 halaman3.2.2 RI Sup. - Training Booklet 000521Mathew KurianBelum ada peringkat

- Technology Multiple Choice 3Dokumen10 halamanTechnology Multiple Choice 3Alex KullehBelum ada peringkat

- CSWIP 3.1 Quiz: Multi-Choice QuestionsDokumen5 halamanCSWIP 3.1 Quiz: Multi-Choice QuestionsSaif UllahBelum ada peringkat

- Paper 10Dokumen8 halamanPaper 10Kani Al BazirBelum ada peringkat

- 400 Q PDFDokumen91 halaman400 Q PDFAhmed FoudaBelum ada peringkat

- Question Excerpt From CSWIP 3Dokumen4 halamanQuestion Excerpt From CSWIP 3Ekor JohnBelum ada peringkat

- MCQ'ScswipDokumen29 halamanMCQ'ScswipAkhilesh KumarBelum ada peringkat

- Cswip 3.1 QU MSR WI 3 05Dokumen8 halamanCswip 3.1 QU MSR WI 3 05Luan Nguyen100% (1)

- Model - 5Dokumen26 halamanModel - 5PrabuBelum ada peringkat

- Cswip Question and Answers: ResponsibilitiesDokumen11 halamanCswip Question and Answers: Responsibilitiesfery0% (1)

- Welding Inspection Questions WisDokumen5 halamanWelding Inspection Questions WisBhavani PrasadBelum ada peringkat

- Cswip 3.1 QU MSR WI 4 05Dokumen8 halamanCswip 3.1 QU MSR WI 4 05Luan Nguyen100% (3)

- CSWIP QuestionaireDokumen158 halamanCSWIP QuestionaireUmaibalanBelum ada peringkat

- Welding Inspection: Multi-Choice Questions Paper 1 Please Return This Paper UnmarkedDokumen16 halamanWelding Inspection: Multi-Choice Questions Paper 1 Please Return This Paper UnmarkedRobert MichaelrajBelum ada peringkat

- Test No 5Dokumen3 halamanTest No 5Muhammad AsimBelum ada peringkat

- Cswip Multi Choice Questions With AnswersDokumen19 halamanCswip Multi Choice Questions With AnswersNeel Mukherjee0% (1)

- Cswip Question PaperDokumen3 halamanCswip Question Paperantonyfernandof100% (1)

- Questions Cswip 3.11.1Dokumen11 halamanQuestions Cswip 3.11.1Ralph Laurence Parungao100% (1)

- (D) Basic: Cswip 3.1 (Welding Inspector) Multiple Choice QuestionsDokumen31 halaman(D) Basic: Cswip 3.1 (Welding Inspector) Multiple Choice QuestionsJigar Prajapati100% (1)

- CSWIP Plate Tr5. WPK Rev2Dokumen4 halamanCSWIP Plate Tr5. WPK Rev2razormeback100% (1)

- Cswip 3 1-300 - Multiple Choice QuestionDokumen43 halamanCswip 3 1-300 - Multiple Choice QuestionTrương Ngọc SơnBelum ada peringkat

- WISS CSWIP Technology Multiple Choice Exam 1 Version A 18 August 2014Dokumen10 halamanWISS CSWIP Technology Multiple Choice Exam 1 Version A 18 August 2014rinhycraBelum ada peringkat

- Multi - Choice Question Paper (MSR-WI-1)Dokumen8 halamanMulti - Choice Question Paper (MSR-WI-1)Karit Hawichit100% (1)

- CSWIP Set QuestionDokumen13 halamanCSWIP Set QuestionMuhammad Hannan100% (2)

- CSWIP QuizDokumen12 halamanCSWIP Quizmushruff100% (1)

- Cswip 3.1 Practice QuestionDokumen22 halamanCswip 3.1 Practice QuestionKoya ThangalBelum ada peringkat

- Cswip Qa 1 - 300 QaDokumen64 halamanCswip Qa 1 - 300 QaIyappan BaluBelum ada peringkat

- Cswip3.1 Exam QuestionDokumen4 halamanCswip3.1 Exam QuestionMOHAMMAD SAJIDALAM100% (2)

- General 2Dokumen4 halamanGeneral 2Sobia KalsoomBelum ada peringkat

- In General, The MIG/MAG Mode of Transfer Best Suited For Welding Thick Sheet Is Spray TransferDokumen4 halamanIn General, The MIG/MAG Mode of Transfer Best Suited For Welding Thick Sheet Is Spray TransferLe TuanBelum ada peringkat

- Multi PDFDokumen6 halamanMulti PDFrimpiBelum ada peringkat

- SA-2 9b (BEPMS)Dokumen4 halamanSA-2 9b (BEPMS)bhargavBelum ada peringkat

- Cswip Wi-5Dokumen10 halamanCswip Wi-5Thirumalesu ChowdamBelum ada peringkat

- Tech 6 (Solved)Dokumen7 halamanTech 6 (Solved)Saif Ullah100% (3)

- Welding Insp QuestionsDokumen10 halamanWelding Insp QuestionsdselvakuuBelum ada peringkat

- Multichoice Paper FiveDokumen4 halamanMultichoice Paper FiveAhmed ShakirBelum ada peringkat

- Practice 1Dokumen7 halamanPractice 1ravichandran0506Belum ada peringkat

- Paper 12Dokumen5 halamanPaper 12Kani Al Bazir100% (1)

- MP1 Quiz 4Dokumen3 halamanMP1 Quiz 4Veerakumar SBelum ada peringkat

- Weld QuestionsDokumen9 halamanWeld QuestionsdselvakuuBelum ada peringkat

- WISS CSWIP General Multiple Choice Exam 3 Version A 18 August 2014Dokumen5 halamanWISS CSWIP General Multiple Choice Exam 3 Version A 18 August 2014rinhycra100% (1)

- General All SolvedDokumen25 halamanGeneral All SolvedAndiappan Pillai100% (2)

- Question BankDokumen27 halamanQuestion BankselvaBelum ada peringkat

- Nonferrous MetallurgyDokumen6 halamanNonferrous MetallurgyThangapandian NBelum ada peringkat

- Compre 15-16 Sem1 With Soln (Charsichoco)Dokumen4 halamanCompre 15-16 Sem1 With Soln (Charsichoco)Jasdeep SinghBelum ada peringkat

- Soalan Cswip 3.1 Set 3 GeneralDokumen3 halamanSoalan Cswip 3.1 Set 3 GeneralShamsul Affendi25% (4)

- Tech 1Dokumen9 halamanTech 1PraviBeetlesBelum ada peringkat

- SmileDokumen1 halamanSmileThân KhaBelum ada peringkat

- QPF 01-01 Coded Marking Control Log Rev0Dokumen2 halamanQPF 01-01 Coded Marking Control Log Rev0Thân KhaBelum ada peringkat

- QPF 03-01 Physical Examination Record Rev0Dokumen2 halamanQPF 03-01 Physical Examination Record Rev0Thân KhaBelum ada peringkat

- QPF 02-01 Welding Material Baking and Holding RecordDokumen6 halamanQPF 02-01 Welding Material Baking and Holding RecordThân KhaBelum ada peringkat

- Processing: Hot Forming Heat Treatments MachiningDokumen32 halamanProcessing: Hot Forming Heat Treatments MachiningThân KhaBelum ada peringkat

- 12 MT ProcedureDokumen17 halaman12 MT ProcedureThân KhaBelum ada peringkat

- Line Class - NDT RateDokumen24 halamanLine Class - NDT RateThân KhaBelum ada peringkat

- 13 PT ProcedureDokumen14 halaman13 PT ProcedureThân KhaBelum ada peringkat

- NDT Procedure ChemicalDokumen52 halamanNDT Procedure ChemicalThân Kha100% (2)

- An Dam Kieu Nhat-Tsutsumi ChiharuDokumen154 halamanAn Dam Kieu Nhat-Tsutsumi ChiharuThân KhaBelum ada peringkat

- Dell Inspiron 16 5000 (5625) Laptop - Dell IndiaDokumen5 halamanDell Inspiron 16 5000 (5625) Laptop - Dell IndiamubbunBelum ada peringkat

- Be Project Presentation SuspensionDokumen17 halamanBe Project Presentation SuspensionGabrielBelum ada peringkat

- E2788-11 Standard Specification For Use of Expanded Shale, Clay and Slate (ESCS) As A Mineral Component in The Growing Media and The Drainage Layer For Vegetative (Green) Roof SystemsDokumen3 halamanE2788-11 Standard Specification For Use of Expanded Shale, Clay and Slate (ESCS) As A Mineral Component in The Growing Media and The Drainage Layer For Vegetative (Green) Roof SystemsSatya kaliprasad vangaraBelum ada peringkat

- Morning in Nagrebcan - Manuel E. ArguillaDokumen8 halamanMorning in Nagrebcan - Manuel E. ArguillaClara Buenconsejo75% (16)

- Ambitious Academy Lahore: Annual Revision Test SystemDokumen2 halamanAmbitious Academy Lahore: Annual Revision Test SystemAmir HabibBelum ada peringkat

- Cleavage in MammalsDokumen51 halamanCleavage in MammalsIrfan Azram100% (4)

- Haruki Murakami - MirrorDokumen5 halamanHaruki Murakami - Mirrorhhellakoski25% (4)

- Project Final PDFDokumen98 halamanProject Final PDFNgonidzashe MhukaBelum ada peringkat

- Classification of Tooth StainingDokumen4 halamanClassification of Tooth StainingYAMUNA M.D.S. PAEDODONTICS & PREVENTIVE DENTISTRYBelum ada peringkat

- A Lightweight True Random Number Generator For Root of Trust ApplicationsDokumen11 halamanA Lightweight True Random Number Generator For Root of Trust ApplicationsMADDULURI JAYASRIBelum ada peringkat

- Psychological Factors Influencing Technology Adoption A Case S - 2021 - TechnovDokumen17 halamanPsychological Factors Influencing Technology Adoption A Case S - 2021 - Technov6helmi6nauval6Belum ada peringkat

- Inventory of Flood Bund PunjabDokumen26 halamanInventory of Flood Bund PunjabguildkeyBelum ada peringkat

- Notes On Peck&Coyle Practical CriticismDokumen10 halamanNotes On Peck&Coyle Practical CriticismLily DameBelum ada peringkat

- Material Control Procedure - TemplateDokumen5 halamanMaterial Control Procedure - TemplateHernandito Rahmat KusumaBelum ada peringkat

- PerthDokumen21 halamanPerthjohn_wlmns3929Belum ada peringkat

- Sales Training Deck Updated July 2022Dokumen40 halamanSales Training Deck Updated July 2022Thanh MinhBelum ada peringkat

- A Lesson About SpringDokumen7 halamanA Lesson About SpringKatjaBelum ada peringkat

- 03 Soil Classification Numerical PDFDokumen5 halaman03 Soil Classification Numerical PDFabishrantBelum ada peringkat

- Chapter Eight - Vapour Compression CycleDokumen37 halamanChapter Eight - Vapour Compression Cyclealhusseny100% (1)

- IBH Link UA Manual PDFDokumen302 halamanIBH Link UA Manual PDFjavixl1Belum ada peringkat

- BookDokumen28 halamanBookFebrian Wardoyo100% (1)

- An Analytical Study of Foreign Direct InvestmentDokumen19 halamanAn Analytical Study of Foreign Direct InvestmentNeha SachdevaBelum ada peringkat

- Brochure - Citadines Flatiron Phnom Penh - EnglishDokumen4 halamanBrochure - Citadines Flatiron Phnom Penh - EnglishTix VirakBelum ada peringkat

- CF1900SS-DF Example Spec - Rev1Dokumen1 halamanCF1900SS-DF Example Spec - Rev1parsiti unnesBelum ada peringkat

- 11 Physical Fitness Assessment 1Dokumen40 halaman11 Physical Fitness Assessment 1Danilo Sare IIIBelum ada peringkat

- Nukote Aegis SubmittalDokumen112 halamanNukote Aegis SubmittalMarco Dos Santos NevesBelum ada peringkat

- Deutz Fahr Rear Axle T 7100 Workshop ManualDokumen22 halamanDeutz Fahr Rear Axle T 7100 Workshop Manualcindybennettmd040595jbw100% (133)

- 365-M - City Bus Route & Timings, Bangalore (BMTC) Map, First & Last BusDokumen10 halaman365-M - City Bus Route & Timings, Bangalore (BMTC) Map, First & Last BusER Aditya DasBelum ada peringkat

- Harrington SOAP NoteDokumen5 halamanHarrington SOAP NoteDanielle100% (4)

- 6.m.tech-Ece-Vlsi, Vlsi Systems, Vlsi System Design (Vlsi, Vlsis, Vlsisd) r17 Course Structure & SyllabiDokumen35 halaman6.m.tech-Ece-Vlsi, Vlsi Systems, Vlsi System Design (Vlsi, Vlsis, Vlsisd) r17 Course Structure & SyllabiravibabukancharlaBelum ada peringkat