Correlation of Evaporative Heat Transfer Coefficients For Refrige

Diunggah oleh

Hai LeJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Correlation of Evaporative Heat Transfer Coefficients For Refrige

Diunggah oleh

Hai LeHak Cipta:

Format Tersedia

Purdue University

Purdue e-Pubs

International Refrigeration and Air Conditioning

Conference

School of Mechanical Engineering

1996

Correlation of Evaporative Heat Transfer

Coefcients for Refrigerant Mixtures

J. Y. Shin

Seoul National University

M. S. Kim

Seoul National University

S. T. Ro

Seoul National University

Follow this and additional works at: htp://docs.lib.purdue.edu/iracc

Tis document has been made available through Purdue e-Pubs, a service of the Purdue University Libraries. Please contact epubs@purdue.edu for

additional information.

Complete proceedings may be acquired in print and on CD-ROM directly from the Ray W. Herrick Laboratories at htps://engineering.purdue.edu/

Herrick/Events/orderlit.html

Shin, J. Y.; Kim, M. S.; and Ro, S. T., "Correlation of Evaporative Heat Transfer Coefcients for Refrigerant Mixtures" (1996).

International Refigeration and Air Conditioning Conference. Paper 316.

htp://docs.lib.purdue.edu/iracc/316

CORRELATION OF EVAPORATIVE HEAT TRANSFER COEFFICIENTS

FOR REFRIGERANT MIXTURES

lee Young Shin, Min Soo Kim, and Sung Tack Ro

Department ofMechanical Engineering

Seoul National University

SeoullSI-742, Korea

ABSTRACT

On the basis of the measured evaporative heat transfer coefficients for pure refrigerants (R22, R32,

Rl25, Rl34a, R290, and R600a) and refrigerant mixtures (R32/R134a and R290/R600a) in a horizontal

tube, a correlation of evaporative heat transfer coefficients for refrigerant mixtures is developed. An

analysis of evaporative heat transfer is performed for an annular flow of refrigerant mixtures. Mass transfer

effect due to composition difference between liquid and vapor phases, which is considered as a driving

force for mass transfer at the interface, is included in this analysis. Correction factor CF is introduced to the

correlation for refrigerant mixtures. The evaporative heat transfer coefficients are calculated using the

correlation considering nucleate boiling effect in the low quality region and mass transfer effect for zeotropic

refrigerant mixtures.

INTRODUCTION

New alternative refrigerants are in production and the application techniques are being developed. As

higher efficiency of the system is constantly required, a new technique for performance enhancement is

pursued and the use of refrigerant mixtures is thought to be a solution. Some refrigerant mixtures show

temperature glide during evaporation and condensation (i.e., zeotrope), and this temperature glide can be

utilized to reduce the mean temperature difference between the secondary heat transfer fluid and refrigerant,

which is known to increase the cycle efficiency from the basic principles of thermodynamics.

It has been known by many researchers that the heat transfer coefficient (HTC) of zeotropic refrigerant

mixtures is smaller than linearly interpolated HTC based on those of pure constitutive refrigerants. This

phenomenon is attributed to non-linear behavior of thermodynamic properties of refrigerant mixtures and

mass transfer effect caused by composition change during the evaporation of zeotropic refrigerant mixtures.<

1

4

l

For mixtures, mass transfer resistance is introduced to the correlation that is obtained by regression of

experimental data. However, since the coefficients in the correlation are determined based on the experimental

data, the use of such correlations becomes limited when they are applied to other fluids. Therefore, simple

and physically meaningful correlations that can be used to many fluids are required. Furthermore, it is

desired that the correlations can be applied for mixtures.

In this study, a correlation which can predict the HTCs of zeotropic refrigerant mixtures will be

presented. To consider the different characteristics between pure refrigerants and refrigerant mixtures, a

factor for the mass transfer resistance caused by composition difference of liquid and vapor phases during

the evaporation will be introduced. Correlations and experimental data of evaporative heat transfer will be

compared.

EXPERIMENTS

Test Review and Data Reduction

The HTCs for pure refrigerants and refrigerant mixtures flowing in a horizontal tube have been

151

under heat flux condition by applying electric current directly to the tube. Heat transfer

coefficients at different mass fluxes and heat fluxes were measured and the dependence on the overall

compositions for mixtures has been investigated. (

5

l

In order to calculate the H!Cs, local heat flux and the temperatures of the refrigerant and the wall

should be measured. In our previous study, outer wall temperature was measured and inner wall temperature

was radial conduction. tips were fastened on the outer wall by

alummum tape at 4 pos1tlons around the tube and the lead w1re was attached on the wall alono- the axial

direction to avoid axial conduction through the wire from the surroundings. The refrigerant

was determined by measuring the saturation pressure.

Heat transferred to the refrigerant at the test section was measured by watt meter. The output signals

of the pressure_transducers were carried to the personal computer through multi-channel

recorder usmg the GPIB mterface mterface. Estimated error was about 0.2 C for the outer wall temperature

measurement and 0.5 oc for the measurement of saturation temperature of the refrigerant

Heat transfer coefficient is defined as in Equation ( 1 ).

(1)

where q" is heat flux and T,,, T, represent inner wall and saturation temperature, respectively. Subscript k

represents top, bottom, left, and right sides, respectively. For mixtures, thennodynamic quality which can

be determined by energy balance should be known to calculate saturation temperature. Local heat transfer

coefficient, h, at local positions is determined by averaging above mentioned 4 temperatures. Experimental

data for deducing the correlation ofthis study is listed in reference (5). The error in measuring heat transfer

coefficients is about 5.8% in our previous study.

Comparison of Existing Correlations for Pure Substances with Experimental Data

Root mean square (RMS) values of relative errors between existing correlations and experimental data

with respect to quality for pure refrigerants such as R22, R32, R125, R134a, R290, and R600a are

presented in Table L The numbers in parentheses represent the result with data for quality range over 0.2.

The fact that the error for the quality range over 0.2 becomes smaller implies that existing correlations can

not represent well the influence of nucleate boiling in the low quality region.

Among the existing correlations, the convective boiling term in the Chen's correlation is in good

agreement with the experimental data except for the early period of evaporation (for the quality range over

0.2). This implies that the convective boiling could be represented quite well with Chen's convective

boiling term. This will be considered in developing new correlation for refrigerant mixtures.

Table 1 Root mean square error (%) between predicted and experimental heat transfer coefficients (numbers

in parenthesis represent RMS error for the experimental data of quality over 0.2)

Refrigerants

ChenC

6

) Shah<

7

l Gungor & Winterton(

81

Kandlikar(

9

l

R22 32.0 (10.7) 17.2 (13.9) 29.9 (15.6) 22.8 (18.9)

R32 43.2 ( 8.6) 13.4 (10.8) 39.4 (13.2) 29.5 (25.2)

R134a 77.8 (13.6) 19.4 (15.7) 72.8 (17.2) 23.8 (20.9)

R125 35.0 (12.5) 12.4 (10.9) 31.2 (14.2) 18.0 (18.2)

R290

34.8 (16.4) 19.3 (13.8) 32.3 (14.1) 30.8 (30.8)

R600a 34.8 (15.6) 35.2 (24.4) 38.1 (28.0) 38.5 (38.5)

152

ANNULAR FLOW ANALYSIS

In modeling the evaporative heat transfer in an annular flow regime, constant heat flux condition is

assumed. The influence of nucleate boiling in the low quality region is neglected and the thickness of liquid

layer is assumed to be constant in the circumferential direction. The entrainment to vapor phase or the

deposition to liquid phase are not considered in this analysis. In Fig. I, X and Y represent liquid and vapor

compositions of more volatile component and T represents temperature, J, mass flux, and Q, heat transfer

rate, respectively. Subscripts l, v, i, b, and w i imply liquid phase, vapor phase, interface, bulk, and inner

wall, respectively. Mass conservation for more volatile component at the interface is represented as in

Equation (2) and shown in Fig. I.

-m;x; - }

1

= -m;r; + J,. ,

(2)

where m/represents evaporated mass flux. For zeotropic refrigerant mixtures, the vapor phase temperature

in two phase flow is calculated by using equation of state. Interface temperature is determined so as to

satisfy the condition that the mass flux in Equation (2) is the same as the mass flux calculated from the

overall energy and mass balance equations. Once interface temperature is determined, the wall temperature

is automatically determined from the heat transfer relation in the liquid layer.

Based on the above analysis, a new modification coefficient CF as shown in Equation (3) was defined

to consider the degradation of HTCs due to the temperature difference between interface and vapor phase

during the evaporative heat transfer process of zeotropic refrigerant mixtures.

!lT = 1- C

!lT + !11; F '

where !lT = T.., -I;, and !1.7; =I;- T...

DEVELOPMENT OF HEAT TRANSFER CORRELATION

FOR REFRIGERANT MIXTURES

Evaporative Heat Transfer Correlations for Pure Refrigerants

(3)

In this study, the Chen correlation shown in Equation (4) is chosen to be the basic model for

evaporative heat transfer correlation.

I

I

I

I ...

I

I

I:.

T,.our

(

I Y,UI

t

Two

Qw

Fig. 1 Control volume for the annular flow analysis in this study.

153

h =Sh +Fh

TP NcB con

(4)

Measured heat transfer coefficient, hmeas can be expressed as a combination of h . , the influence of

nucleate boiling and hce, that of convective boiling, as shown in Equation (5). .vs

=Sh +Fh

pool com ,

(5)

where S and F represent the suppression and enhancement factors. Once convective boiling term is

determined, nucleate boiling term can be calculated by subtracting hce from hmea_,. Important factors in

nucleate boiling are the flow condition and heat flux condition. Therefore, Sin Equation (5) is set as a

function of Martinelli parameter (X,J and non-dimensional boiling number (BJ as shown in Equation (6).

The correlation of Cooperr

1

OJ is used to obtain hpool in the nucleate boiling region. The coefficients a, a

1

and a

1

are determined by least square fitting as 0.0592, 0.668, and 1.38, respectively.

S

- X alB ~

- ao " o .

(6)

Fig. 2 shows the deviations of heat transfer coefficients calculated from modified correlation equation with

experiment data. Modified correlation equation is expressed as in Equation (5) with Sin Equation ( 6). It

predicts experiment data within 18.9% error bound for every condition of heat flux, mass flux, and

operation pressure in this study. Satisfied results are obtained for pure refrigerants with modified correlation

equation. Since complicated correlation equation is difficult to use and the coefficients are sometimes hard

to determine, the correlation equation of simple form is chosen in this study and this modified equation

represents the experimental data pretty well. The main reason to introduce the correlation equation for pure

refrigerants is that the same form of equation will be used for mixtures by modifying the factor F according

to the annular flow analysis.

10000

0

0

0

I:!.

X

+

X

0

+

1 0 0 0 ~ ~ - - - - - - - - - - - - - - - - ~

1000

10000

h

pred

Fig. 2 Comparison between predicted and experimental heat transfer coefficients for pure refrigerants

154

Correlation of Evaporative Heat Transfer Coefficient for Zeotropic Refrigerant Mixtures

Cr in Equation (3) has been curve-fitted based on the annular flow analysis in the form of Equation (7)

by introducing /Y- X/, which is the composition difference between vapor and liquid phases. Curve-fitted

coefficients, A, n for zeotropic refrigerant mixture, R32/134a are 0.569, 0.860; for R290/600a, A, n are

0.533, 0.828, respectively

Cr = A/Y -X/" .

(7)

HTCs of refrigerant mixtures can be calculated considering the mixture effect with the F factor in

Chen's correlation as in Equation (8).

h=F h .

m <om (Sa)

F = (I - Cr) F . m . (Sb)

F is the Chen's F factor and F"' is a modified factor to predict the HTCs of zeotropic refrigerant mixtures

considering the heat transfer degradation due to mass transfer. h,.m" is the heat transfer coefficient of

Dittus-Boelter type. The HTCs of zeotropic refrigerant mixtures can be calculated by defining F"' as in

Equation (Sb ).

When mass transfer effect due to composition difference is introduced and the influence of nucleate

boiling is considered, the RMS ofrelative errors are 8.9% for R32/134a and 14.6% for R290/600a. Fig. 3

shows the comparison of experimental data with heat transfer coefficients calculated from the correlation

equation for mixtures in this study. The experimental data for R32/Rl34a and R290/R600a are obtained for

the reduced pressure of 0.15 and mass flux of 424 kg/rn

2

s. The correlative equation for refrigerant mixtures

includes the heat transfer enhancement effect caused by nucleate boiling in the low quality region and the

heat transfer degradation effect due to mass transfer due to composition change between liquid and vapor

phases.

I..

0

I..

I..

w

5 0 . - - - - - - - r - - - - - - r - - - . - - - - ~ - - - - -

25

0

-25

75/25%

50!50%

25/75%

. 50 L---_.,1_---L--..L-----L..-----'

0.0 0.2 0.4 X 0.6 0.8 1.0

(a) R32/R134a

;,.;'

0

I..

I..

w

(b) R290/R600a

Fig. 3 Relative error between predicted and experimental heat transfer coefficients for refrigerant mixtures

155

CONCLUDING REMARKS

In order to predict the evaporative heat transfer coefficients for zeotropic refrigerant mixtures in a

tube, fl?7" a?alysis has been done which is the most dominant flow in the evaporator of

refngeratwn and a1r-cond1t10nmg system. Influence of mass transfer during the evaporative heat transfer

process for zeotropic refrigerant mixtures was considered in the analysis. Based on experimental results

with several refrigerants, a correlation is developed to predict evaporative heat transfer coefficients for

refrigerant mixtures. The correlation equation predicts experiment data for pure refrigerants within 18.9%

error bound for all conditions of heat flux, mass flux, and operation pressure in this study.

Based on Chen's correlation, the modification factor, CP> is introduced by considering the composition

difference between liquid and vapor phases for zeotropic refrigerant mixtures. Predicted results show that

RMS values of relative errors are 8.9% for R32/134a and 14.6% for R290/600a. The correlation equation

in this study is simple to use and predicts the HTCs of refrigerant mixtures quite well. This equation

includes the heat transfer enhancement effect caused by nucleate boiling in the low quality region and the

heat transfer degradation effect due to the mass transfer resistance because of the composinon difference

between liquid and vapor phases.

ACKNOWLEDGMENT

This work has been supported by Korea Science and Engineering Foundation (KOSEF). The authors

thank Dr. M. H. Kim and Mr. Y. S. Park of living system R&D center of Samsung Electronics, Co., Ltd.

for their guidance and financial support. The assistance of Mr. T. Choi in preparing the manuscript is

greatly appreciated.

REFERENCES

(1) Ross, H., Radermacher, R., DiMarzo, M., and Didion, D., 1987, "Horizontal Flow Boiling of Pure

and Mixed Refrigerants", Int. J. Heat Mass Transfer, Vol. 30, No. 5., pp. 979-992.

(2) Jung, D. S., McLinden, M., and Radermacher, R., and Didion, D., 1989, "Horizontal Flow Boiling

Heat Transfer Experiments with a Mixture ofR22/R114", Int. J. Heat Mass Transfer, Vol. 32, No.

1, pp. 131-145.

(3) Murata, K. and Hashizume, K., 1993, "Forced Convective Boiling of Nonazeotropic Refrigerant

Mixtures inside Tubes", Trans. ASME J Heat Transfer, Vol. 115, pp. 680-688.

(4) Torikoshi, K. and Ebisu, T., 1993, "Heat Transfer and Pressure Drop Characteristics of R-134a,

R-32, and a Mixture ofR-32/R-134a inside a Horizontal Tube", ASHRAE Trans., Vol. 99, Part 2,

pp. 90-96.

.

. . . .

(5) Shin, J. Y., Kim, M. S., and Ro, S. T., 1996, "Expenmental Study on Convective B01lmg Heat

Transfer for Pure Refrigerants and Refrigerant Mixtures in a Horizontal Tube", Trans. Kor. Soc.

Mech. Eng. (KSME), VoL 20, No.2, pp. 730-740.

(6) Chen, J. C., 1966, "Correlation for Boiling Heat Transfer to Saturated Fluids in Convective Flow",

I&EC Process Design and Development, Vol. 5, No.3, pp. 322-329.

(7) Shah, M. M., 1982, "Chart Correlation for Saturated Boiling Heat Transfer Equations and Further

Study", ASHRAE Trans., Vol. 88, Part 2, pp. 66-86.

(8) Gungor, K. E. and Winterton, R. H. S., 1986, "A General Correlation for Flow Boiling in Tubes and

Annuli", Int. J Heat Mass Transfer, Vol. 29, No.3, pp. 351-358.

(9) Kandlikar, S. G., 1990, "A General Correlation for Saturated Two-Phase Flow Boiling Heat Transfer

inside Horizontal and Vertical Tubes", Trans. ASME J Heat Transfer, Vol. 112, pp. 219-228.

(10) Cooper, M. G., 1984, "Heat Flow Rates in Saturated Nucleate Pool Wide-Ranging

Examination Using Reduced Properties", Advances in Heat Transfer, Vol. 16, pp. 157-239.

156

Anda mungkin juga menyukai

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Air Balancing - AgDokumen8 halamanAir Balancing - AgHai Le100% (2)

- Heat Exchangers Design NotesDokumen75 halamanHeat Exchangers Design NotesHai Le100% (1)

- Part Load DehumidificationDokumen8 halamanPart Load DehumidificationHai LeBelum ada peringkat

- Transformer and Inductor Design Handbook (PDFDrive)Dokumen669 halamanTransformer and Inductor Design Handbook (PDFDrive)nirwana84Belum ada peringkat

- ASHRAE Standard 62 and LEED CertificationDokumen41 halamanASHRAE Standard 62 and LEED CertificationAndreAPLBelum ada peringkat

- Duct Work Method StatementDokumen5 halamanDuct Work Method StatementHai LeBelum ada peringkat

- Pump CalculationDokumen4 halamanPump CalculationHai LeBelum ada peringkat

- Pump CalculationDokumen4 halamanPump CalculationHai LeBelum ada peringkat

- 11KV Kiosk Panel DrawingDokumen12 halaman11KV Kiosk Panel Drawingerkamlakar223483% (6)

- Generator Set and System Spec Review - 05!12!2016Dokumen38 halamanGenerator Set and System Spec Review - 05!12!2016Hai LeBelum ada peringkat

- Advance in Energy Research 2011Dokumen421 halamanAdvance in Energy Research 2011Hai Le100% (1)

- New NRB Air Cooled Chiller and Heat Pump Multi-Scroll Compressors and Micro-Channel CoilDokumen37 halamanNew NRB Air Cooled Chiller and Heat Pump Multi-Scroll Compressors and Micro-Channel CoilHai LeBelum ada peringkat

- CEN LSC G Using GAMP Methods To Validate CMS Software B211370EN A PDFDokumen11 halamanCEN LSC G Using GAMP Methods To Validate CMS Software B211370EN A PDFHassan HoudoudBelum ada peringkat

- Bsb-Cat009 E5 Ed1Dokumen53 halamanBsb-Cat009 E5 Ed1TienNguyenBelum ada peringkat

- APN Series: Propeller FansDokumen2 halamanAPN Series: Propeller FansHANDOYO RBelum ada peringkat

- GDL External LouvreDokumen4 halamanGDL External LouvreHai LeBelum ada peringkat

- New NSM Air Cooled Chiller With Screw Compressors and Micro-Channel CoilDokumen38 halamanNew NSM Air Cooled Chiller With Screw Compressors and Micro-Channel CoilHai LeBelum ada peringkat

- BAS Digital Direct Control: FunctionDokumen1 halamanBAS Digital Direct Control: FunctionHai Le0% (1)

- Appendices: © 2003 by CRC Press LLCDokumen25 halamanAppendices: © 2003 by CRC Press LLCHai LeBelum ada peringkat

- Standards For Corrosion RatesDokumen2 halamanStandards For Corrosion RatesHai LeBelum ada peringkat

- Data Center TiersDokumen2 halamanData Center TiersHai LeBelum ada peringkat

- Solahart CatalogueDokumen8 halamanSolahart CatalogueHai LeBelum ada peringkat

- Ashrae D 23127 20041201Dokumen6 halamanAshrae D 23127 20041201Hai LeBelum ada peringkat

- Analysis of Segmental and Helical Baffle in Shell and Tube Heat ExchangerDokumen4 halamanAnalysis of Segmental and Helical Baffle in Shell and Tube Heat ExchangerHai LeBelum ada peringkat

- TCVN 5866-1995 - Thang May - Co Cau An Toan Co KhiDokumen3 halamanTCVN 5866-1995 - Thang May - Co Cau An Toan Co Khiwww.diendandien.comBelum ada peringkat

- TCVN 2287 - 1978 He Thong Tieu Chuan An Toan Lao Dong - Quy Dinh Co BanDokumen2 halamanTCVN 2287 - 1978 He Thong Tieu Chuan An Toan Lao Dong - Quy Dinh Co BanHai LeBelum ada peringkat

- TCVN 2291 - 1978 Phuong Tien Bao Ve Nguoi Lao Dong - Phan LoaiDokumen6 halamanTCVN 2291 - 1978 Phuong Tien Bao Ve Nguoi Lao Dong - Phan LoaiHai LeBelum ada peringkat

- TCVN 2291 - 1978 Phuong Tien Bao Ve Nguoi Lao Dong - Phan LoaiDokumen6 halamanTCVN 2291 - 1978 Phuong Tien Bao Ve Nguoi Lao Dong - Phan LoaiHai LeBelum ada peringkat

- TCVN 2292 - 1978 Cong Viec Son - Yeu Cau Chung Ve An ToanDokumen5 halamanTCVN 2292 - 1978 Cong Viec Son - Yeu Cau Chung Ve An ToanHai LeBelum ada peringkat

- TCVN 2287 - 1978 He Thong Tieu Chuan An Toan Lao Dong - Quy Dinh Co BanDokumen2 halamanTCVN 2287 - 1978 He Thong Tieu Chuan An Toan Lao Dong - Quy Dinh Co BanHai LeBelum ada peringkat

- TCVN 2291 - 1978 Phuong Tien Bao Ve Nguoi Lao Dong - Phan LoaiDokumen6 halamanTCVN 2291 - 1978 Phuong Tien Bao Ve Nguoi Lao Dong - Phan LoaiHai LeBelum ada peringkat

- MMP-II, Course Outline Spring 2019Dokumen3 halamanMMP-II, Course Outline Spring 2019Ehsan AdeebBelum ada peringkat

- ArXiVEuler L. - On Magic Squares (1776)Dokumen11 halamanArXiVEuler L. - On Magic Squares (1776)griffingrip1443Belum ada peringkat

- Structure Plasma Membrane: of TheDokumen4 halamanStructure Plasma Membrane: of TheYaserhaidar AlgotaryBelum ada peringkat

- Samples 2 Final - ExamDokumen6 halamanSamples 2 Final - ExamNam Anh Nguyễn HữuBelum ada peringkat

- Theory of Structures FormulaDokumen1 halamanTheory of Structures FormulaArjay AlibinBelum ada peringkat

- Lecture 10 - HydrodynamicsDokumen10 halamanLecture 10 - HydrodynamicsPercival ArcherBelum ada peringkat

- Week 7 and 8 Performance of Single Phase Short Transmission LinesDokumen21 halamanWeek 7 and 8 Performance of Single Phase Short Transmission LinessensamedicBelum ada peringkat

- Standard Datasheets Portfolio enDokumen543 halamanStandard Datasheets Portfolio enTuna TaşkıntunaBelum ada peringkat

- 7300 ManualDokumen12 halaman7300 ManualDesmond Prince OmorogiuwaBelum ada peringkat

- 5 Spheres and ConesDokumen8 halaman5 Spheres and Conesstemtutor kakwongBelum ada peringkat

- Physics June 2000 p1Dokumen14 halamanPhysics June 2000 p1Dexter BBelum ada peringkat

- Pumps & Pumping Systems: Prof. Dr. Omar Badran Mechanical Engineering DepartmentDokumen39 halamanPumps & Pumping Systems: Prof. Dr. Omar Badran Mechanical Engineering Departmentمحمد القدوميBelum ada peringkat

- 3035-Article Text-3542-1-10-20200320Dokumen7 halaman3035-Article Text-3542-1-10-20200320gonzalez2678Belum ada peringkat

- GROUND OPERATIONAL CHECKS FOR AVIONICS EQUIPMENT Non ElectriDokumen6 halamanGROUND OPERATIONAL CHECKS FOR AVIONICS EQUIPMENT Non Electriadrian hBelum ada peringkat

- Boyle's Law Hand-Out.Dokumen3 halamanBoyle's Law Hand-Out.Rorisang MolotsiBelum ada peringkat

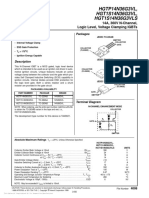

- Hgtp14N36G3Vl, Hgt1S14N36G3Vl, Hgt1S14N36G3Vls: 14A, 360V N-Channel, Logic Level, Voltage Clamping IgbtsDokumen6 halamanHgtp14N36G3Vl, Hgt1S14N36G3Vl, Hgt1S14N36G3Vls: 14A, 360V N-Channel, Logic Level, Voltage Clamping IgbtsDeiry Katherine Marquez RamirezBelum ada peringkat

- General Series Overhead Crane: User ManualDokumen30 halamanGeneral Series Overhead Crane: User ManualjokoBelum ada peringkat

- Data Sarana (21) Titl OcDokumen57 halamanData Sarana (21) Titl OcsunarioBelum ada peringkat

- 2021 CAC CatalogueDokumen100 halaman2021 CAC CatalogueRiyo SaputraBelum ada peringkat

- Motion in Straight LineDokumen13 halamanMotion in Straight LineKajol HBelum ada peringkat

- BYK Gardner USA Cert and Scope File 07 25 2022 - 1658779904Dokumen17 halamanBYK Gardner USA Cert and Scope File 07 25 2022 - 1658779904Raghunath DashBelum ada peringkat

- Types of IsomerismDokumen14 halamanTypes of IsomerismAbdullah MunawarBelum ada peringkat

- A Non-Isolated Onboard Charger For Electric VehicleDokumen6 halamanA Non-Isolated Onboard Charger For Electric VehicleTesfaye Utopia UtopiaBelum ada peringkat

- Paginas WebDokumen2 halamanPaginas Webesteban purillaBelum ada peringkat

- SM6 IAC 12.5ka - DM1A - DM1WDokumen4 halamanSM6 IAC 12.5ka - DM1A - DM1WpookeBelum ada peringkat

- Ladle NozzleDokumen6 halamanLadle Nozzlejagd.shresthaBelum ada peringkat

- Mil PRF 5606JDokumen13 halamanMil PRF 5606JDBelum ada peringkat

- Guided Review Exam 2Dokumen7 halamanGuided Review Exam 2mattBelum ada peringkat