ASME Code Calculations For Companion Flanges

Diunggah oleh

Kamlesh DalavadiDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

ASME Code Calculations For Companion Flanges

Diunggah oleh

Kamlesh DalavadiHak Cipta:

Format Tersedia

PAGE 1 OF 9

ENGINEERING REFERENCE

REV DESCRIPTION REV EC DATE REV EC DATE

Page 6, was c > ..., now c > ... to correct error when

retyped on Rev 6.

4 014174 3-9-07

3 013100 1-27-06

2 011107 1-14-03 7 015809 3-17-09

1 ECN8755 5-4-01 6 015727 1-16-09

0 ECN8727 5-3-01 5 014743 11-2-07

ER-16.0.22 REV 7

7

ASME Code Calculations

for Companion Flanges

Ariel Part Numbers

C-3371, C-3374, C-5632

Drawing Numbers

C-3371, R10; C-3374, R6; C-5632, R0

ASME Boiler and Pressure Vessel Code

Section VIII, Division 1

2007 Edition, 2008 Addenda

Prepared by: Staci M. Friedlander

T

h

e

c

o

n

t

e

n

t

s

o

f

t

h

i

s

d

o

c

u

m

e

n

t

a

r

e

p

r

o

p

r

i

e

t

a

r

y

a

n

d

c

o

n

f

i

d

e

n

t

i

a

l

.

T

h

e

y

a

r

e

t

h

e

p

r

o

p

e

r

t

y

o

f

A

r

i

e

l

C

o

r

p

o

r

a

t

i

o

n

a

n

d

m

a

y

n

o

t

b

e

d

i

s

c

l

o

s

e

d

,

r

e

p

r

o

d

u

c

e

d

,

o

r

u

s

e

d

f

o

r

m

a

n

u

f

a

c

t

u

r

e

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

w

i

t

h

o

u

t

w

r

i

t

t

e

n

p

e

r

m

i

s

s

i

o

n

f

r

o

m

A

r

i

e

l

C

o

r

p

o

r

a

t

i

o

n

.

PAGE 2 OF 9 REV 7 ER-16.0.22

ENGINEERING REFERENCE

Scope

Design analysis of Ariel Corporation companion flanges with part numbers C-3371, C-3374, and

C-5632 assures compliance with requirements of the ASME Boiler and Pressure Vessel Code,

Section VIII, Division 1. Ariel supplies these flanges for customers to fabricate onto pressure vessels

so Ariel compressor cylinders may mount by bolting the companion flange directly onto cylinder

nozzle connections.

Stress Calculation Results

Companion flange design and calculated stresses meet requirements set forth in the 2007 Edition,

2008 Addenda of the ASME Boiler and Pressure Vessel Code, Section VIII, Division 1.

The flanges as designed and manufactured to drawings C-3371 Rev. 10, C-3374 Rev. 6, and

C-5632 Rev. 0 meet requirements of the code for use on pressure vessels built to Section VIII, Div. 1.

Resulting stresses are from worst case loading of bolting pre-stress. Operating stresses will be less

per Appendix 2, 2.5(e)(note 2).

Discussion of Analysis

The above companion flanges are identical except for distances between nozzle hole centerlines.

This similarity allows for a common calculation for a single Flange.

The calculations use Appendix 2 Rules for Bolted Flange Connections with Ring Type Gaskets.

The Flange was calculated as two single flanges because of the two independent gaskets and bolt

circles. The calculations are conservative because the connection between the two flanges

increases part strength.

The Flange was calculated as an Loose Type Flange, per 2-4(a)(1) using loadings and dimensions

per Appendix 2, Figure 2-4(3a). See Figure 1 on page 6 for dimensional definition of the weld. The

Flange is designed to use 8 schedule 80 pipe in conjunction with the plate supplied by Ariel to make

the complete flange analyzed in this report. Customers are responsible to procure the pipe and

fabricate it to the plate per the dimensions in Figure 1.

The Flange was analyzed with a corrosion allowance of 0.125 inch, but this calculation applies to any

vessel with a less than or equal corrosion allowance. The calculations assume a 0.125 inch

machining allowance for material removed to level the flange face after welding to facilitate

installation.

The Allowable Design Stress for SA-240, Grade 316L stainless steel plate is 11,700 psi maximum.

This is per table 1A of Section II, Materials, Part D- Properties for a maximum operating temperature

of 400F. The compressor cylinder is limited to a maximum of 350F, so the operating temperature

will not reach the maximum temperature rating of the Flange material for the allowable stress used.

Ariel supplies a special gasket with this flange, Ariel part number A-10411. The gasket is produced

by Flexitallic, Deer Park, Texas. The sealing spiral wound section is 9-5/8 inch ID by 10-3/8 inch OD

and the metallic inner and outer rings are 9-1/8 inch ID and 11 inch OD respectively. Per Flexitallic

literature, gasket factors for the LSI style gasket is a (m) factor of 3.00 and a (y) factor of 5,000 psi.

Discussion of Bolting

Ariel supplies special proprietary high endurance bolts to mount the companion flanges to Ariel

supplied compressor cylinder nozzles. These bolts are not within the scope of the ASME Code per

interpretation VIII-1-98-57, file number BC98-368. The code responsibility ends at the nozzle face of

the vessel when bolted to a non-code mechanical part.

Ariel supplied bolts for standard applications are manufactured using AISI 8640 or equivalent,

tempered to a hardness range of 37 ~ 43 HRC, and a minimum tensile strength limit of 180,000 psi.

T

h

e

c

o

n

t

e

n

t

s

o

f

t

h

i

s

d

o

c

u

m

e

n

t

a

r

e

p

r

o

p

r

i

e

t

a

r

y

a

n

d

c

o

n

f

i

d

e

n

t

i

a

l

.

T

h

e

y

a

r

e

t

h

e

p

r

o

p

e

r

t

y

o

f

A

r

i

e

l

C

o

r

p

o

r

a

t

i

o

n

a

n

d

m

a

y

n

o

t

b

e

d

i

s

c

l

o

s

e

d

,

r

e

p

r

o

d

u

c

e

d

,

o

r

u

s

e

d

f

o

r

m

a

n

u

f

a

c

t

u

r

e

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

w

i

t

h

o

u

t

w

r

i

t

t

e

n

p

e

r

m

i

s

s

i

o

n

f

r

o

m

A

r

i

e

l

C

o

r

p

o

r

a

t

i

o

n

.

PAGE 3 OF 9 REV 7 ER-16.0.22

ENGINEERING REFERENCE

Upon request or for NACE applications, Ariel furnishes 17-4PH double age heat treated to H1150

stainless steel bolts with a minimum tensile strength of 135,000 psi and maximum hardness of 33

HRC. Both bolt materials have a reduced, shot peened shank area and special form rolled threads.

The shank diameter was used to calculate the minimum cross-sectional area of the bolts. The shank

diameter is 0.390 inches for steel bolting and 0.400 inches for stainless steel bolting. Calculation

results from both bolting options are listed on page 4 and page 5. The STL heading denotes AISI

8620 bolting and the SST heading denotes the 17-4PH bolting. Where not specified the calculation

was not affected by bolt material.

Ariel design practice specifies the allowable bolt stress as 1/5 of minimum tensile stress for flange

bolting. Based on this guideline, the maximum allowable tensile stress for steel bolts is 180,000 psi /

5.0 = 36,000 psi, and 135,000 psi / 5.0 = 27,000 psi for stainless steel bolts.

NOTE: When using 17-4PH stainless steel bolting, maximum allowable working pressure of

the flange is limited to 355 psig for the bolting to meet the above guidelines for maximum ten-

sile stress during operation.

Ariel Service Manuals call for a torque of 40 ft-lb (pre-stress of 45,000 psi) for bolts used to attach

companion flanges with self-energized gaskets. The addition of a spiral-wound Flexitallic gasket,

requires a torque increase to 53 ft-lb to allow for gasket crush on top of pressure containment. This

increase produces a pre-stress of 60,000 psi in the thread root area of the 1/2-13 UNRC-3A bolts.

Impact Testing and MDMT

Section UHA-51 exempts austenitic chromium-nickel stainless steel of type 316L in paragraph UHA-

51(d)(1)(a) from impact testing for MDMT of -320F and warmer. Since Ariel limits its cylinder

minimum design temperature to -50F, impact testing is not required.

Flange Rigidity

Per Appendix 2, section 2-14(c), the rigidity index (J) must be less than or equal to 1.0 for sufficient

flange rigidity to control leakage. The flange thickness is 2.125 inches with a machining allowance of

0.125 inches to flatten the flange at installation. A rigidity factor (K

L

) of 0.20 was used per 2-14. The

elastic modulus (E) at design temperature is 26.4 x 10

6

psi per Section II, part D for a Group G

material. The equation in Table 2-14 for loose type flanges without hubs was used for calculation.

T

h

e

c

o

n

t

e

n

t

s

o

f

t

h

i

s

d

o

c

u

m

e

n

t

a

r

e

p

r

o

p

r

i

e

t

a

r

y

a

n

d

c

o

n

f

i

d

e

n

t

i

a

l

.

T

h

e

y

a

r

e

t

h

e

p

r

o

p

e

r

t

y

o

f

A

r

i

e

l

C

o

r

p

o

r

a

t

i

o

n

a

n

d

m

a

y

n

o

t

b

e

d

i

s

c

l

o

s

e

d

,

r

e

p

r

o

d

u

c

e

d

,

o

r

u

s

e

d

f

o

r

m

a

n

u

f

a

c

t

u

r

e

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

w

i

t

h

o

u

t

w

r

i

t

t

e

n

p

e

r

m

i

s

s

i

o

n

f

r

o

m

A

r

i

e

l

C

o

r

p

o

r

a

t

i

o

n

.

PAGE 4 OF 9 REV 7 ER-16.0.22

ENGINEERING REFERENCE

Design Limits

Flange Inputs

Gasket Inputs/Calculations

K Factors

Bolting Inputs/Calculations

Limit Steel Stainless Steel

Design Pressure (P) 445 psi 355 psi

Maximum Operating Temperature 350F

Minimum Operating Temperature -50F

Input Steel Stainless Steel

Outside Diameter (A) 12.688 in.

Inside Diameter (B) 8.750 in.

Bolt Circle Diameter (C) 11.625 in.

Minimum Thickness (t) 2.000 in.

Corrosion Allowance (c) 0.125 in.

Allowable Design Stress of Material (S

a

) 11,700 psi

Input/Calculation Steel Stainless Steel

Inner Ring Inside Diameter (GSKT ID) 9.125 in.

Outer Ring Outside Diameter (GSKT OD) 11.000 in.

Seal Inside Diameter (SEAL ID) 9.625 in.

Seal Outside Diameter (SEAL OD) 10.375 in.

Material Factor (m) 3.000

Material Factor (y) 5,000 psi

Reaction Diameter, Entire Gasket: [G

m

= (GSKT OD + GSKT ID) / 2] 10.063 in.

Reaction Diameter, Seal Only: [G

s

= (SEAL OD + SEAL ID) / 2] 10.000 in.

Effective Seating Width (b

0

) 0.188 in.

Factor Steel Stainless Steel

K = [A / (B + 2c)] / 2 1.410

Y = 1/(K-1) x [0.66845 + 5.71690 x (K

2

x logK/(K

2

-1)]

5.820

Input/Calculation Steel Stainless Steel

Minimum Diameter of Bolts Used (d

b

) 0.390 in. 0.400 in.

Number of Bolts Used (NB) 12

Allowable Bolt Stress (S

a

) 36,000 psi 27,000 psi

Stress Area of Bolt [A = pi/4 x d

b

2

] 0.119 in.

2

0.126 in.

2

Total Bolt Cross-Section: Available [A

b

= A x NB]

1.434 in.

2

1.508 in.

2

Total Bolt Cross-Section: Required [A

m

= W

m1

/ S

a

]

1.408 in.

2

1.497 in.

2

T

h

e

c

o

n

t

e

n

t

s

o

f

t

h

i

s

d

o

c

u

m

e

n

t

a

r

e

p

r

o

p

r

i

e

t

a

r

y

a

n

d

c

o

n

f

i

d

e

n

t

i

a

l

.

T

h

e

y

a

r

e

t

h

e

p

r

o

p

e

r

t

y

o

f

A

r

i

e

l

C

o

r

p

o

r

a

t

i

o

n

a

n

d

m

a

y

n

o

t

b

e

d

i

s

c

l

o

s

e

d

,

r

e

p

r

o

d

u

c

e

d

,

o

r

u

s

e

d

f

o

r

m

a

n

u

f

a

c

t

u

r

e

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

w

i

t

h

o

u

t

w

r

i

t

t

e

n

p

e

r

m

i

s

s

i

o

n

f

r

o

m

A

r

i

e

l

C

o

r

p

o

r

a

t

i

o

n

.

PAGE 5 OF 9 REV 7 ER-16.0.22

ENGINEERING REFERENCE

Loading Calculations

Rigidity Requirements

Stress Calculations Results

Calculation Steel Stainless Steel

h

D

= [C - (B + 2c)] / 2 1.313 in.

h

G

= (C - G

s

) / 2 0.813 in.

h

T

= (h

D

+ h

G

) / 2 1.063 in.

H = 0.785 x G

s

2

x P 34,950 lb. 27,882 lb.

H

P

= 2pi x b

0

x m x G

s

x P 15,728 lb. 12,547 lb.

Flange Design Bolt Load: Operating [W

m1

= H + H

P

] 50,678 lb. 40,428 lb.

Flange Design Bolt Load: Gasket Seating [W

m2

= pi x b

0

x G

s

x y] 29,452 lb. 29,452 lb.

H

G

= W H 15,728 lb. 12,547 lb.

H

D

= 0.785 x (B + 2c)

2

x P 28,310 lb. 22,584 lb.

H

T

= H H

D

6,641 lb. 5,298 lb.

Flange Design Bolt Load: Operating [W

op

= W

m1

] 50,678 psi 40,428 psi

Flange Design Bolt Load: Bolt Load Only [W

b

= S

p

x (A

b

+ A

m

) / 2] 51,142 psi 40,572 psi

M

D

= H

D

x h

D

37,156 in-lb 29,642 in-lb

M

G

= h

G

x H

G

12,779 in-lb 10,194 in-lb

M

T

= H

T

x h

T

7,056 in-lb 5,629 in-lb

Total Flange Moment: Operating Conditions [M

op

= M

D

+ M

G

+ M

T

] 56,991 in-lb 45,464 in-lb

Total Flange Moment: Bolt Load Only [M

bolt

= W x (C - G

m

) / 2] 39,955 in-lb 31,697 in-lb

Requirement Steel Stainless Steel

Flange Elastic Modulus @ Design Temperature (E)

6.4x10

6

psi

Rigidity Factor for Loose Type Flange (K

L

) 0.200

Rigidity Index [J = (109.4 x M

op

)/(E x t

3

x ln(K)(K

L

)] 0.430 0.343

Calculation Steel Stainless Steel

Longitudinal Hub Stress (S

H

) 0 psi

Maximum Longitudinal Hub Stress Allowable 17550 psi

Radial Stress (S

R

) 0 psi

Maximum Radial Stress Allowable 11700 psi

Tangential Stress (S

T

) 9,477 psi 7,560 psi

Maximum Tangential Stress Allowable 11700 psi

T

h

e

c

o

n

t

e

n

t

s

o

f

t

h

i

s

d

o

c

u

m

e

n

t

a

r

e

p

r

o

p

r

i

e

t

a

r

y

a

n

d

c

o

n

f

i

d

e

n

t

i

a

l

.

T

h

e

y

a

r

e

t

h

e

p

r

o

p

e

r

t

y

o

f

A

r

i

e

l

C

o

r

p

o

r

a

t

i

o

n

a

n

d

m

a

y

n

o

t

b

e

d

i

s

c

l

o

s

e

d

,

r

e

p

r

o

d

u

c

e

d

,

o

r

u

s

e

d

f

o

r

m

a

n

u

f

a

c

t

u

r

e

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

w

i

t

h

o

u

t

w

r

i

t

t

e

n

p

e

r

m

i

s

s

i

o

n

f

r

o

m

A

r

i

e

l

C

o

r

p

o

r

a

t

i

o

n

.

PAGE 6 OF 9 REV 7 ER-16.0.22

ENGINEERING REFERENCE

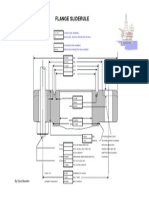

Where:

t

n

= Pipe thickness

t

p

= Calculated nozzle shell thickness required

due to pressure, not less than 0.250

t

x

= 2 X t

p

c > lesser of t

n

or t

x

FIGURE 1 Definition of Weld Dimensions

T

h

e

c

o

n

t

e

n

t

s

o

f

t

h

i

s

d

o

c

u

m

e

n

t

a

r

e

p

r

o

p

r

i

e

t

a

r

y

a

n

d

c

o

n

f

i

d

e

n

t

i

a

l

.

T

h

e

y

a

r

e

t

h

e

p

r

o

p

e

r

t

y

o

f

A

r

i

e

l

C

o

r

p

o

r

a

t

i

o

n

a

n

d

m

a

y

n

o

t

b

e

d

i

s

c

l

o

s

e

d

,

r

e

p

r

o

d

u

c

e

d

,

o

r

u

s

e

d

f

o

r

m

a

n

u

f

a

c

t

u

r

e

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

w

i

t

h

o

u

t

w

r

i

t

t

e

n

p

e

r

m

i

s

s

i

o

n

f

r

o

m

A

r

i

e

l

C

o

r

p

o

r

a

t

i

o

n

.

PAGE 7 OF 9 REV 7 ER-16.0.22

ENGINEERING REFERENCE

T

h

e

c

o

n

t

e

n

t

s

o

f

t

h

i

s

d

o

c

u

m

e

n

t

a

r

e

p

r

o

p

r

i

e

t

a

r

y

a

n

d

c

o

n

f

i

d

e

n

t

i

a

l

.

T

h

e

y

a

r

e

t

h

e

p

r

o

p

e

r

t

y

o

f

A

r

i

e

l

C

o

r

p

o

r

a

t

i

o

n

a

n

d

m

a

y

n

o

t

b

e

d

i

s

c

l

o

s

e

d

,

r

e

p

r

o

d

u

c

e

d

,

o

r

u

s

e

d

f

o

r

m

a

n

u

f

a

c

t

u

r

e

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

w

i

t

h

o

u

t

w

r

i

t

t

e

n

p

e

r

m

i

s

s

i

o

n

f

r

o

m

A

r

i

e

l

C

o

r

p

o

r

a

t

i

o

n

.

PAGE 8 OF 9 REV 7 ER-16.0.22

ENGINEERING REFERENCE

T

h

e

c

o

n

t

e

n

t

s

o

f

t

h

i

s

d

o

c

u

m

e

n

t

a

r

e

p

r

o

p

r

i

e

t

a

r

y

a

n

d

c

o

n

f

i

d

e

n

t

i

a

l

.

T

h

e

y

a

r

e

t

h

e

p

r

o

p

e

r

t

y

o

f

A

r

i

e

l

C

o

r

p

o

r

a

t

i

o

n

a

n

d

m

a

y

n

o

t

b

e

d

i

s

c

l

o

s

e

d

,

r

e

p

r

o

d

u

c

e

d

,

o

r

u

s

e

d

f

o

r

m

a

n

u

f

a

c

t

u

r

e

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

w

i

t

h

o

u

t

w

r

i

t

t

e

n

p

e

r

m

i

s

s

i

o

n

f

r

o

m

A

r

i

e

l

C

o

r

p

o

r

a

t

i

o

n

.

PAGE 9 OF 9 REV 7 ER-16.0.22

ENGINEERING REFERENCE

A

1

B

2

3

C D

1

2

3

A

R

I

E

L

C

O

R

P

O

R

A

T

I

O

N

M

O

U

N

T

V

E

R

N

O

N

,

O

H

I

O

4

3

0

5

0

3

5

B

L

A

C

K

J

A

C

K

R

O

A

D

4

R

E

V

E

C

N

T

H

IR

D

A

N

G

L

E

P

R

O

J

E

C

T

IO

N

5

D

R

A

W

N

:

C

H

E

C

K

E

D

:

S

C

A

L

E

:

M

A

T

E

R

IA

L

:

6

R

.S

. N

o

:

P

A

R

T

N

o

:

D

W

G

. N

o

:

T

IT

L

E

:

A B

4

5

C

6

D

T

H

IS

D

O

C

U

M

E

N

T

A

N

D

C

O

N

T

E

N

T

S

T

H

E

R

E

IN

A

R

E

P

R

O

P

R

IE

T

A

R

Y

T

O

A

R

IE

L

C

O

R

P

O

R

A

T

IO

N

. O

N

L

Y

B

Y

W

R

IT

T

E

N

C

O

N

S

E

N

T

A

N

D

A

G

R

E

E

D

T

E

R

M

S

B

Y

A

R

IE

L

C

O

R

P

O

R

A

T

IO

N

G

IV

E

S

T

H

E

R

IG

H

T

T

O

M

A

N

U

F

A

C

T

U

R

E

, B

U

T

D

O

E

S

N

O

T

G

R

A

N

T

T

H

E

R

IG

H

T

T

O

D

IS

C

L

O

S

E

O

R

U

S

E

IN

P

A

R

T

O

R

IN

W

H

O

L

E

IN

F

O

R

M

A

T

IO

N

C

O

N

T

A

IN

E

D

IN

D

O

C

U

M

E

N

T

.

D

IM

E

N

S

IO

N

S

A

R

E

IN

IN

C

H

E

S

U

N

L

E

S

S

O

T

H

E

R

W

IS

E

S

P

E

C

IF

IE

D

.

--- D

O

N

O

T

S

C

A

L

E

D

R

A

W

IN

G

---

C

O

M

P

A

N

I

O

N

F

L

A

N

G

E

,

D

U

A

L

S

S

T

,

2

6

-

1

/

2

J

G

K

:

T

:

C

:

D

N

O

Z

Z

L

E

,

F

I

L

L

E

T

-

W

E

L

D

E

D

,

S

H

T

1

O

F

1

C

-

5

6

3

2

C

-

5

6

3

2

C

C

-

5

6

3

2

S

E

E

N

O

T

E

#

4

N

O

N

E

K

S

L

0

1

/

1

4

/

0

9

M

L

B

0

1

/

1

5

/

0

9

0

1

5

7

2

7

R

E

V

D

E

S

C

R

IP

T

IO

N

IN

IT

/D

A

T

E

A

A

S

E

C

T

I

O

N

A

-

A

1

/

4

1

-

1

/

2

3

6

.

2

.

1

3

0

2

.

1

2

0

F

I

N

I

S

H

E

D

D

I

M

.

O

8

.

7

5

0

8

.

7

6

0

O

8

.

7

5

0

8

.

7

6

0

1

3

.

0

0

5

1

2

.

9

9

5

F

I

N

I

S

H

E

D

D

I

M

.

1

3

.

0

0

5

1

2

.

9

9

5

F

I

N

I

S

H

E

D

D

I

M

.

O

1

2

-

1

1

/

1

6

R

1

(

4

)

P

L

A

C

E

S

9

-

1

/

2

4

-

3

/

4

O

2

D

R

I

L

L

T

H

R

U

O

7

-

3

/

8

B

U

R

N

O

U

T

(

2

)

P

L

A

C

E

S

O

9

/

1

6

D

R

I

L

L

T

H

R

U

(

1

2

)

H

O

L

E

S

E

Q

.

S

P

A

C

E

D

L

O

C

.

O

N

1

1

-

5

/

8

B

.

C

.

(

2

4

)

H

O

L

E

S

T

O

T

A

L

1

5

T

Y

P

.

3

0

T

Y

P

.

O

2

7

/

6

4

D

R

I

L

L

,

1

-

3

/

1

6

D

E

E

P

1

/

2

-

1

3

U

N

C

S

E

M

I

-

B

O

T

T

.

T

A

P

(

1

)

H

O

L

E

A

S

S

H

O

W

N

L

O

C

.

O

N

1

1

-

5

/

8

B

.

C

.

(

2

)

H

O

L

E

S

T

O

T

A

L

N

O

T

E

S

1

.

-

F

I

N

I

S

H

U

N

L

E

S

S

N

O

T

E

D

O

T

H

E

R

W

I

S

E

.

2

.

-

B

R

E

A

K

A

L

L

S

H

A

R

P

E

D

G

E

S

.

3

.

-

D

I

M

E

N

S

I

O

N

I

N

G

A

N

D

T

O

L

E

R

A

N

C

I

N

G

P

E

R

A

R

I

E

L

S

P

E

C

I

F

I

C

A

T

I

O

N

E

R

-

1

7

.

0

.

1

.

4

.

-

M

A

T

E

R

I

A

L

:

A

S

M

E

S

A

-

2

4

0

,

G

R

,

3

1

6

L

S

T

A

I

N

L

E

S

S

S

T

E

E

L

.

5

.

-

M

A

T

E

R

I

A

L

C

E

R

T

I

F

I

C

A

T

E

S

A

R

E

R

E

Q

U

I

R

E

D

A

N

D

M

U

S

T

I

N

C

L

U

D

E

T

H

E

A

S

M

E

S

P

E

C

I

F

I

C

A

T

I

O

N

.

1

2

5

S

T

A

M

P

I

N

A

R

E

A

I

N

D

I

C

A

T

E

D

W

I

T

H

3

/

1

6

H

I

G

H

L

E

T

T

E

R

S

:

A

R

I

E

L

C

-

5

6

3

2

W

I

T

H

G

R

A

D

E

8

B

O

L

T

S

:

4

4

5

P

S

I

D

E

S

I

G

N

W

I

T

H

1

7

-

4

P

H

B

O

L

T

S

:

3

5

5

P

S

I

D

E

S

I

G

N

A

S

M

E

S

A

-

2

4

0

,

G

R

.

3

1

6

L

H

T

#

_

_

_

_

_

_

_

(

H

T

#

I

S

P

R

O

V

I

D

E

D

W

I

T

H

M

A

T

E

R

I

A

L

C

E

R

T

I

F

I

C

A

T

I

O

N

S

U

P

P

L

I

E

D

B

Y

V

E

N

D

O

R

O

F

B

U

R

N

O

U

T

C

C

-

5

6

3

2

.

)

S

E

E

E

R

-

1

6

.

0

.

2

2

F

O

R

A

S

M

E

S

E

C

.

V

I

I

I

,

D

I

V

.

1

C

O

D

E

C

A

L

C

U

L

A

T

I

O

N

.

7

.

-

L

I

Q

U

I

D

D

Y

E

P

E

N

E

T

R

A

N

T

I

N

S

P

E

C

T

.

O

P

E

N

I

N

D

I

C

A

T

I

O

N

S

I

N

T

H

E

B

O

R

E

S

A

N

D

T

H

E

F

A

C

E

S

F

R

O

M

T

H

E

B

O

R

E

T

O

1

"

L

A

R

G

E

R

T

H

A

N

T

H

E

D

I

A

.

O

F

T

H

E

B

O

R

E

A

R

E

T

O

B

E

R

E

M

O

V

E

D

B

Y

D

I

M

P

L

I

N

G

.

I

F

T

H

E

D

I

M

P

L

E

S

A

R

E

D

E

E

P

E

R

T

H

A

N

1

/

8

I

N

.

T

H

E

Y

A

R

E

T

O

B

E

A

R

C

W

E

L

D

E

D

F

U

L

L

W

I

T

H

A

N

"

E

3

1

8

-

1

6

"

O

R

B

E

T

T

E

R

R

O

D

.

6

.

l

.

0

0

5

3

8

-

1

1

/

1

6

R

E

F

.

T

h

e

c

o

n

t

e

n

t

s

o

f

t

h

i

s

d

o

c

u

m

e

n

t

a

r

e

p

r

o

p

r

i

e

t

a

r

y

a

n

d

c

o

n

f

i

d

e

n

t

i

a

l

.

T

h

e

y

a

r

e

t

h

e

p

r

o

p

e

r

t

y

o

f

A

r

i

e

l

C

o

r

p

o

r

a

t

i

o

n

a

n

d

m

a

y

n

o

t

b

e

d

i

s

c

l

o

s

e

d

,

r

e

p

r

o

d

u

c

e

d

,

o

r

u

s

e

d

f

o

r

m

a

n

u

f

a

c

t

u

r

e

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

w

i

t

h

o

u

t

w

r

i

t

t

e

n

p

e

r

m

i

s

s

i

o

n

f

r

o

m

A

r

i

e

l

C

o

r

p

o

r

a

t

i

o

n

.

Anda mungkin juga menyukai

- Flange Leakage L&TDokumen48 halamanFlange Leakage L&Tmidnightcowboy100% (1)

- Project 2x660MW Shree Singaji TPP, Malwa BFP Interconnecting Piping System Design CheckDokumen54 halamanProject 2x660MW Shree Singaji TPP, Malwa BFP Interconnecting Piping System Design CheckNixonBelum ada peringkat

- Design of Compact Flange JointsDokumen15 halamanDesign of Compact Flange JointsAkhil JoseBelum ada peringkat

- Ancor Flanges Asme ViiiDokumen3 halamanAncor Flanges Asme ViiiAnjani PrabhakarBelum ada peringkat

- Flange CalculationDokumen48 halamanFlange CalculationAndi SuntoroBelum ada peringkat

- Flange Leakage Check Calculation - Updated On 27-09-2009Dokumen24 halamanFlange Leakage Check Calculation - Updated On 27-09-2009SamBelum ada peringkat

- Sec. VIII Div 1 Apen 1Dokumen16 halamanSec. VIII Div 1 Apen 1ADRIANBelum ada peringkat

- Modification Thickness of A FlangeDokumen3 halamanModification Thickness of A FlangePeter PerezBelum ada peringkat

- Design Calculation of Nozzle Junction Based On ASME Pressure Vessel Design CodeDokumen8 halamanDesign Calculation of Nozzle Junction Based On ASME Pressure Vessel Design CodeAndres Rodriguez HerreraBelum ada peringkat

- Flange DesignDokumen23 halamanFlange DesignNirmalkumarBelum ada peringkat

- EN1591 Flange DesignDokumen9 halamanEN1591 Flange DesignmadodandembeBelum ada peringkat

- Bolt Torque Calculation - Apr19Dokumen69 halamanBolt Torque Calculation - Apr19Raj SBelum ada peringkat

- Flange Calculation Sheet..Dokumen2 halamanFlange Calculation Sheet..nguyenquoc198850% (2)

- Gasket ParametersDokumen9 halamanGasket Parametersttr_1947Belum ada peringkat

- Design and Analysis of Flange Gasket and Bolt Assembly For Leak Tightness 05-07-2016Dokumen13 halamanDesign and Analysis of Flange Gasket and Bolt Assembly For Leak Tightness 05-07-2016renu rani100% (1)

- Loads On FlangesDokumen16 halamanLoads On Flangesccoollest100% (3)

- 6.5.3 Calculation of The Reaction ForceDokumen3 halaman6.5.3 Calculation of The Reaction Forcesammar_10Belum ada peringkat

- Assembly Bolt Stress As Per Asme Pcc-1 2013Dokumen12 halamanAssembly Bolt Stress As Per Asme Pcc-1 2013Anonymous RytT6uvX1Belum ada peringkat

- Flange Leakage Evaluation Based On NC 3658 PDFDokumen3 halamanFlange Leakage Evaluation Based On NC 3658 PDFkaruna346Belum ada peringkat

- Design of Flanges - Loose Hub Type 2010Dokumen58 halamanDesign of Flanges - Loose Hub Type 2010bakellyBelum ada peringkat

- ASME V111 Div2 APP 3 Flanges Stress Calculation in ExcelDokumen16 halamanASME V111 Div2 APP 3 Flanges Stress Calculation in ExcelPanya Purahong100% (1)

- Bolt Torque ASME B16.5 Flanges - Spiral Wound GasketsDokumen31 halamanBolt Torque ASME B16.5 Flanges - Spiral Wound Gasketsbakelly100% (5)

- Blind Flange DesignDokumen1 halamanBlind Flange DesignSachin5586Belum ada peringkat

- Flange DesignDokumen6 halamanFlange DesignDinesh VaghelaBelum ada peringkat

- Platform Weight Calculator (Vertical Vessel)Dokumen11 halamanPlatform Weight Calculator (Vertical Vessel)Sky LarksBelum ada peringkat

- Structural TrunnionDokumen4 halamanStructural TrunnionecsalomBelum ada peringkat

- Flange Leakage CheckingDokumen25 halamanFlange Leakage CheckingAMRUTA PATIL100% (1)

- Calculating bolt torque for sealing a 30Dokumen4 halamanCalculating bolt torque for sealing a 30souren1975Belum ada peringkat

- Flange Leakage Check SheetDokumen1 halamanFlange Leakage Check SheetEhtisham AndrAbiBelum ada peringkat

- Clamped Cover Plate DesignDokumen7 halamanClamped Cover Plate DesignChiedu OkonduBelum ada peringkat

- What Is An Appendix-2 Flange? - Key Design Engineering BlogDokumen1 halamanWhat Is An Appendix-2 Flange? - Key Design Engineering Blogsurefooted1100% (1)

- Check 18Dokumen6 halamanCheck 18Anonymous qBwHKusBelum ada peringkat

- FLANGEDokumen1 halamanFLANGEscrbdgharavi50% (2)

- Datasheet Anchor FlangeDokumen1 halamanDatasheet Anchor FlangeHafiz Ashadi100% (1)

- Understanding the Kellogg Equivalent Pressure MethodDokumen4 halamanUnderstanding the Kellogg Equivalent Pressure MethodLucky Jaswal0% (1)

- Expansion Joint in CAESARDokumen5 halamanExpansion Joint in CAESARkaruna346Belum ada peringkat

- Bolt Torque As Per ASME PCC-1 - MDokumen31 halamanBolt Torque As Per ASME PCC-1 - Mmechengg01100% (2)

- Allowable External Forces on Vessel NozzlesDokumen3 halamanAllowable External Forces on Vessel Nozzlesvenkatrangan2003Belum ada peringkat

- Local Stress Analysis by Chris HinnantDokumen52 halamanLocal Stress Analysis by Chris Hinnantjohnnyr_5100% (4)

- Blind Flange Design Calculations - by Abdel Halim GalalaDokumen6 halamanBlind Flange Design Calculations - by Abdel Halim GalalaNirmalraj Manoharan67% (3)

- Steel Tapping Screws For Cold-Formed Steel Framing ConnectionsDokumen5 halamanSteel Tapping Screws For Cold-Formed Steel Framing ConnectionsAlvaro Alexis Mendoza PradaBelum ada peringkat

- ErmetoDokumen14 halamanErmetoJavier VespaBelum ada peringkat

- Water SystemDokumen9 halamanWater SystemArun GuptaBelum ada peringkat

- Guide to Strip Lining of Pressure VesselsDokumen6 halamanGuide to Strip Lining of Pressure VesselsaminBelum ada peringkat

- Pipe DesignDokumen6 halamanPipe DesignmaneeshmsanjagiriBelum ada peringkat

- rc61180 b09Dokumen9 halamanrc61180 b09eww08Belum ada peringkat

- Type 3510 1 and Type 3510 7 Pneumatic Control Valves Type 3510 Micro Flow ValveDokumen12 halamanType 3510 1 and Type 3510 7 Pneumatic Control Valves Type 3510 Micro Flow Valvepaulo cesar f machadoBelum ada peringkat

- Pipe FabricationDokumen42 halamanPipe FabricationJanani M Janani67% (6)

- Steel Drill Collars: Quality Control and Ultrasonic Inspection Precision BoringDokumen19 halamanSteel Drill Collars: Quality Control and Ultrasonic Inspection Precision BoringAshba13Belum ada peringkat

- A 814 - A 814m - 01 Qtgxnc9bode0ts1sruqDokumen7 halamanA 814 - A 814m - 01 Qtgxnc9bode0ts1sruqsachinguptachdBelum ada peringkat

- ICC-ES Evaluation Report ESR-3372 : - (800) 423-6587 - (562) 699-0543 A Subsidiary of The International Code CouncilDokumen16 halamanICC-ES Evaluation Report ESR-3372 : - (800) 423-6587 - (562) 699-0543 A Subsidiary of The International Code CouncilpabinupcBelum ada peringkat

- KVC 01Dokumen35 halamanKVC 01hamidreza_m85Belum ada peringkat

- 4100 1998 - A1 2012Dokumen30 halaman4100 1998 - A1 2012Farid TataBelum ada peringkat

- ASME B31.3 Tri-Clamp FEA Stress Analysis ReportDokumen18 halamanASME B31.3 Tri-Clamp FEA Stress Analysis ReportBertrandMezatioBelum ada peringkat

- EN6114Dokumen17 halamanEN6114Andrei Cozma67% (3)

- C100 Helium Vessel Code DocumentationDokumen6 halamanC100 Helium Vessel Code DocumentationSrinivasa Rao VenkumahanthiBelum ada peringkat

- C955 09Dokumen4 halamanC955 09jacr27Belum ada peringkat

- Steel Penstocks - 11 ManufactureDokumen10 halamanSteel Penstocks - 11 ManufactureRicardo MartinezBelum ada peringkat

- Flange Selection GuideDokumen11 halamanFlange Selection GuidebandithaguruBelum ada peringkat

- Hot Tapping Split Tee SpecificationDokumen19 halamanHot Tapping Split Tee SpecificationAli ClubistBelum ada peringkat

- Positive ThoughtsDokumen5 halamanPositive ThoughtsBalasubramaniam MuruganBelum ada peringkat

- Stainless - 304 Vs F593C ArticleDokumen2 halamanStainless - 304 Vs F593C ArticleOswaldo Leyva R100% (8)

- Pressure Rating of Steel PipeDokumen2 halamanPressure Rating of Steel PipeKamlesh DalavadiBelum ada peringkat

- Pressure Seal ValveDokumen5 halamanPressure Seal ValveWilson WongBelum ada peringkat

- Gambar 1Dokumen10 halamanGambar 1Mario HanamiciBelum ada peringkat

- Inconel Alloy 718Dokumen28 halamanInconel Alloy 718hosseinidokht86Belum ada peringkat

- Cci PDFDokumen4 halamanCci PDFKamlesh DalavadiBelum ada peringkat

- Motor Torque CalculationDokumen5 halamanMotor Torque CalculationSanjula Darshana WickramasingheBelum ada peringkat

- O-Ring (Metric Size)Dokumen63 halamanO-Ring (Metric Size)Kamlesh DalavadiBelum ada peringkat

- Pipeline Design Factor ReviewDokumen94 halamanPipeline Design Factor ReviewpiolinwallsBelum ada peringkat

- Viton Material - Dopont PDFDokumen1 halamanViton Material - Dopont PDFKamlesh DalavadiBelum ada peringkat

- CCI Choke ValveDokumen8 halamanCCI Choke ValveEssJayJoeBelum ada peringkat

- Material Selection & Design PDFDokumen9 halamanMaterial Selection & Design PDFKamlesh DalavadiBelum ada peringkat

- V 2 Chap 1Dokumen34 halamanV 2 Chap 1guruvashisthaBelum ada peringkat

- Ball Valve CalculationDokumen5 halamanBall Valve CalculationKamlesh Dalavadi50% (2)

- Calculation 2Dokumen5 halamanCalculation 2salhikarimBelum ada peringkat

- O-Ring (Metric Size)Dokumen63 halamanO-Ring (Metric Size)Kamlesh DalavadiBelum ada peringkat

- 3 ElectricArcWeldingDokumen34 halaman3 ElectricArcWeldingKamlesh DalavadiBelum ada peringkat

- Welding SymbolsDokumen60 halamanWelding Symbolskimboon_ngBelum ada peringkat

- Factors Affect SelectionDokumen4 halamanFactors Affect SelectionSajay SuryaBelum ada peringkat

- NPT - National Pipe Thread: Laydown Threading InsertsDokumen1 halamanNPT - National Pipe Thread: Laydown Threading InsertsKamlesh DalavadiBelum ada peringkat

- Casting GradeDokumen2 halamanCasting GradeKamlesh DalavadiBelum ada peringkat

- Wind CalcDokumen4 halamanWind Calc06l01a0224100% (1)

- Delrin Mold Guide 11 06Dokumen48 halamanDelrin Mold Guide 11 06ibmufnman100% (2)

- Sheet Metal Design-Handbook-Rev3 PDFDokumen12 halamanSheet Metal Design-Handbook-Rev3 PDFtnchsg100% (1)

- Mild SteelDokumen4 halamanMild SteelKamlesh DalavadiBelum ada peringkat

- Frekote 55 NC PDFDokumen2 halamanFrekote 55 NC PDFKamlesh DalavadiBelum ada peringkat

- Basic Hydraulic Systems and ComponentsDokumen67 halamanBasic Hydraulic Systems and Componentsnareshkumaran100% (8)

- Composite ManufacturingDokumen45 halamanComposite ManufacturingKamlesh DalavadiBelum ada peringkat

- Experiences in Designing and Operating The Latest 1,050-MW Coal-Fired BoilerDokumen5 halamanExperiences in Designing and Operating The Latest 1,050-MW Coal-Fired BoilerswatkoolBelum ada peringkat

- Deha Halfen Kkt-EDokumen52 halamanDeha Halfen Kkt-ENandeesha RameshBelum ada peringkat

- Introduction To Plasma TechnologyDokumen82 halamanIntroduction To Plasma TechnologyjawsmBelum ada peringkat

- Green Catalogue PDFDokumen12 halamanGreen Catalogue PDFSumita JaiswalBelum ada peringkat

- Falcon C Concentrators Recover Down to 10 MicronsDokumen2 halamanFalcon C Concentrators Recover Down to 10 MicronsevalenciaBelum ada peringkat

- Dalian Hivolt Power System Co. Glass Insulator Test ReportDokumen5 halamanDalian Hivolt Power System Co. Glass Insulator Test ReportdiegoyyBelum ada peringkat

- Astm C78Dokumen3 halamanAstm C78avrajan100% (3)

- Certificate of Conformity: No. CLSAN 080567 0058 Rev. 00Dokumen2 halamanCertificate of Conformity: No. CLSAN 080567 0058 Rev. 00annamalaiBelum ada peringkat

- Hot and Cold Metalworking Processes ComparisonDokumen227 halamanHot and Cold Metalworking Processes ComparisonHardik ChhabraBelum ada peringkat

- Rollinson & Pease 2021 - Geochemical BookDokumen285 halamanRollinson & Pease 2021 - Geochemical BookLuciano SilvaBelum ada peringkat

- The Effect of Strain Rate On Mechanical PropertiesDokumen11 halamanThe Effect of Strain Rate On Mechanical Propertiesmechanicaltestinglab.acmsBelum ada peringkat

- Organic compound solubility behavior factorsDokumen19 halamanOrganic compound solubility behavior factorsAJBelum ada peringkat

- Vehicle Body Materials PDFDokumen5 halamanVehicle Body Materials PDFAghil BuddyBelum ada peringkat

- Structural Calculation MemoriesDokumen43 halamanStructural Calculation MemoriesScott Wade100% (1)

- Construction Tech II Door TypesDokumen105 halamanConstruction Tech II Door Typessydney augustBelum ada peringkat

- Module 8 Welding Metallurgy For The WIDokumen39 halamanModule 8 Welding Metallurgy For The WIRamesh R100% (1)

- Aff Ref Question Bank FullDokumen31 halamanAff Ref Question Bank Fullyash agrawalBelum ada peringkat

- Sop Magnesium Anode Installation - ThiessDokumen10 halamanSop Magnesium Anode Installation - ThiessbonnicoBelum ada peringkat

- Specifications: Rohs CompliantDokumen2 halamanSpecifications: Rohs Compliantkishore_bulli6666Belum ada peringkat

- Standard Test Methods For Conducting Creep, Creep-Rupture, and Stress-Rupture Tests of Metallic MaterialsDokumen14 halamanStandard Test Methods For Conducting Creep, Creep-Rupture, and Stress-Rupture Tests of Metallic MaterialsviverefeliceBelum ada peringkat

- Everest PEB Brochure - Leader in PEB StructuresDokumen28 halamanEverest PEB Brochure - Leader in PEB StructuresBikramdevPadhiBelum ada peringkat

- Aluminum Alloys For AerospaceDokumen2 halamanAluminum Alloys For AerospaceNicholas Featherston100% (1)

- Inorganic Salt Analysis Record WritingDokumen20 halamanInorganic Salt Analysis Record WritingDineshBelum ada peringkat

- Preliminary Technical Program HMnS2016Dokumen33 halamanPreliminary Technical Program HMnS2016manjumv27Belum ada peringkat

- Metal ExerciseDokumen3 halamanMetal ExercisemattyamaniBelum ada peringkat

- N2XSEBY cable specificationsDokumen5 halamanN2XSEBY cable specificationsKiki WidyaBelum ada peringkat

- Hook-Up Solutions Hanley Controls Compressed AirDokumen16 halamanHook-Up Solutions Hanley Controls Compressed AirAriel HughesBelum ada peringkat

- Water ChemDokumen11 halamanWater ChemAnjali KumbharBelum ada peringkat

- Surfactant Assisted Synthesis of Cuprous Oxide (Cu O) Nanoparticles Via Solvothermal ProcessDokumen7 halamanSurfactant Assisted Synthesis of Cuprous Oxide (Cu O) Nanoparticles Via Solvothermal ProcessNILTHON FRANCO POMA HUARINGABelum ada peringkat

- Lecture 2Dokumen74 halamanLecture 2афнан алиBelum ada peringkat