Aluminum Filler Metal Selection Chart

Diunggah oleh

Rama Krishna Reddy DonthireddyHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Aluminum Filler Metal Selection Chart

Diunggah oleh

Rama Krishna Reddy DonthireddyHak Cipta:

Format Tersedia

7005, 7021

7039, 7046

7146

710.0, 711.0

413.0, 443.0

444.0, 356.0

A356.0, 357.0

359.0

319.0, 333.0

354.0, 355.0

C355.0, 380.0

319.0, 333.0

354.0, 355.0

C355.0, 380.0

2014, 2036

1100, 1060,

1070, 1080,

1350

1100, 1060, 1070,

1080, 1350

2014, 2036

2219

3003,

Alclad 3003

3004

Alclad 3004

5005, 5050

5052, 5652

5086,

5083,

5456, 5383

511.0, 512.0

513.0, 514.0

535.0

5154, 5254

5454

6061,6005

6063,6070

6151,6201

6351,6951,6082

2319

4043/4943**

4145

A356.0

A357.0

5356

4145

4043/4943**

4145

4043/4943**

5183

5356

5554

5556

5654

4145

4043**

4943**

5183

5356

5554

5556

5654

5554

1100

4043/4943**

4145

5183

5356

5556

1100

4043/4943**

4145

2319

4043/4943**

4145

2319

4043/4943**

4145

1188

1100

4043/4943**

4043/4943**

5183

5356

5554

5556

5654

5183

5356

5554

5556

5654

5183

5356

5554

5556

5654

5183

5356

5554

5556

5654

5005, 5050

5052, 5652

5086,

5083,

5456, 5383

511.0, 512.0

513.0, 514.0

535.0

5154, 5254

5454

7005, 7021

7039, 7046

7146

710.0, 711.0

413.0, 443.0

444.0, 356.0

A356.0, 357.0

359.0

6061,6005

6063,6070

6151,6201

6351,6951,6082

2219

3003,

Alclad 3003

3004,

Alclad 3004

319.0, 333.0

354.0, 355.0

C355.0, 380.0

2319

4043/4943**

4145

413.0, 443.0

444.0, 356.0

A356.0, 357.0

359.0

7005, 7021

7039, 7046

7146

710.0, 711.0

6061,6005

6063,6070

6151,6201

6351,6951,

6082

5454

A356.0

A357.0

5356

4145

4043/4943**

4145

4043/4943**

5183

5356

5554

5556

5654

4145

4043**

4943**

5183

5356

5554

5556

5654

5183

5356

5554

5556

5654

511.0, 512.0

513.0, 514.0

535.0

5154, 5254

5183

5356

5554

5556

5654

5086,

5083,

5456, 5383

5183

5356

5554

5556

5654

5005, 5050

5052, 5652

1188

1100

4043/4943**

2319

4043/4943**

4145

2319

4043/4943**

4145

1100

4043/4943**

4145

1100,1060,1070,

1080,1350

2014, 2036

2219

3003,

Alclad 3003

5554

1100

4043/4943**

4145

5183

5356

5556

4043/4943**

5183

5356

5554

5556

5654

3004,

Alclad 3004

B A A A A

A A A A B

B B A A A A

A A A A B

B

A

A A A A A A

A

A A A A A A A A A A A B

B B A B A

B C B A D

A B A

A A B A

A

B A A A

A A A B

C

A

A

A

A

B C A A A

A A A B

A A A B

A B A A

A

A

A

A

A B A A A A

A

A A

A A B

B

B

C

C

C C

A

B

A

A

C

D

A B A A A A

A A A A A B

C

D

A A A A A A

A A A B B

C

D

C

B

B

B

B

B

A D A A

A

B A A A

A A

A A A

D

B

A

B

B

A D A A

A C A

A

B

A

A

A

A

A

B

B B

B

B B

C

D

C

D

A C A A C C

B

A

B

B

C

A

A A A A

A

A

A

B

B B

B B B

C

B B A

A

B

A

B

B

A

B

C

A

C

A

A

A

A

A

A

A

A

A

B B B

B

B B B

B

C

C

B

B

A

B

B

B

A

A

A

A A

B A

A A

A

A

A B

B

A

B

B

A

A A

A A

B

A

A

A

D

B

B

B

A

C

A B B

D

B

B

A

B

B

B

D

C

C

C

C

A A A A

A C A A

C A

A

B

A

D

B B

B

B

B

D

D

D

C

B

B

A

B B

B

B C

A A A A

A A A A

A A A

A

D

D

A A

B A A A

A A B

B D

D

A A

B A A A

A A B

B D

D

B A A

A

A A A

A A

B

A A

A

B B

C

A

A

D

B A A A A

A A A A B

B B

A

C

D

B A A A

A A A A B

B C

D

B A A A

A A A A B

B C

D

B A A A

A A A A B

B C

D

B A A A

A A A A B

B C

D

A B A A A A

A

A A

A A B

B

B

C

C

C C C

D

A A

B

A

B A A A A

A A A A B

B C

D

B

A

A A

A A A A

A A B

B D

D A A

A A A A

A A B

B D

D

A A A A A A

A

A A

B

B

B

B

C C

C

D

D

B

A

A A B

B B

B B

A A A A A

A

A A

C

C

C D

D

A

B

A

A

C

C

C

C

A A A A A

A

A A

B B

B B

D

D

A

B

A

A

C

D

A A A A A A D

A C A A D

B B A

B A B A

A

B A A B

A

A

A

D

B

A

B

A C A A D

A D B A C

B B A A

B A A B

B B A A

C

D

B

A

B

B A A B

B A B

C A A C A

B

B B B A

A

A

A

A

B

A

B

B

B B A B

B A B

C A C A

B

B B B

C A C A

A

A

A

A

A

B

B

B

A

B

B

A C A A

B A B

D

B A B

B B A

A

A

A

D

B

A

B

C A A A

A A A C C

B D B A

C C A B

C

C B C B

A

A

A

C B C A

C

D

D

B

A

B

B

A B

A B

A A A A

A

A A

A

C

A

A

D

D

A C A A D

B C A B

B A C

C A B C A

B

B

A

B

B A B C B

C C A B A

A B A B

A A B

C A A C A

B

A B B

B B C A

A

A

A

A

A

B

B

A

B

B

B

A A A B

A A A

C C A

B

A B A

B B C A

A

A

A

A

A

A

B

A

B

B

B

A B A B

A A B

C A C A

B

A B B

B A C A

A

B

A

B

B

A

C

D

D

A C B A D

B B A

B A B A

A

C A A A

B A A B

C

A

A

A

A

C C A A B

D

B

A

B

B

B

A C A A D

B D B A C

B B A A

B A A B

B B A A

C

D

B

A

B

B B A B

B A B

C A A C A

B

B B B A

A

A

A

A

B

A

B

B

B B A B

B A B

C A C A

B

B B B

C A C A

A

A

A

A

A

B

B

A

B

B

B

A A A B

A A A B

A B A A

A

A

A

B

A

B

A C A A

B A B

D

B A B

B B A

A

A

A

B

D

A

B

A A A D D

B C A C

B B C

C A B C A

B

A

A

A

B A C C A

B

D

A

B

B

A A A B

A A A

C A C A

B

A B A

B B C A

A

A

A

A

A

A

B

A

B

B

B

B

A

B

A B D C A

A

A B A

A A B A

A

A A A B

A

A

A

A B A

A A B A

A

B A A

A A A B

C

A

A

A

A

B C A A A

B C A B

B A C

C B C A

B

A

A

A

B A B C A

C C A B A

A B A B

A A B

B A C A

B

A B B

B A C A

A

A

A

A

A

B

B

A

B

B

B

A B A B

A A B

B A C A

B

A B B

B A C A

A

B

A

B

A

A

B

A

B

B

B

B

A

B

A A A B

A A A

B A C A

B

A

A

A

A A B A A

B C A A B

B

A

B

B

B

A B A B

A A B

B A C A

B

A B B A

A

A

A

A

B

A

B

B

A A A B

A A A

B A C A

B

A B A

B A C A

A

A

A

A

A

B

B

A

B

B

B

A A * B

A A A *

A B A *

A

A

A

B

A

B

D

D

A

D

B

A

B

B

B

D

A C A A C C A C A A C A C A A C C D

B

A

B

B

B

A

B

B

B

D

B A A A A

A A A A B

B

A

B A A A A

A A A A B

B

A

A A A A A B

B B A A A

B A A A A D

B B A A C

A A B A A

A A A A D

B B A A C

A A A A A

A A A A A

B C B A D

A B A

A A B A

A

B A A A

A A A B

C

A

A

A

A

B C A A A

A B A

A A B A

A

B A A A

A A A B

C

A

A

A

A

B C A A A

A C B A D

A B A

A A B A

A

B A A A

A A A B

C

A

A

A

A

B C A A A

A B A A D

A B A A

B C A A

C

B A C

C B B C A

B

A

A

A

B A A C A

C C A B B

B A A A A

A A A A B

B

A

C

D

C

D

C

D

D

B

A

B

B

B

C

D

C

D

D

B

A

B

B

A

B

A

B

B

B

B C A B

B A C

C A A C A

B

A

A

A

B A B C A

C C A B B

D

B

B

B

B

A B A B

A A B

B A A C A

B

A B B

B B C A

A

A

A

A

A

B

B

A

B

B

B

B

A

B

B

B

B

A

B

B

B

B

A

B

B

D

A

D

B

B

C

C

C

C

C

C

B A A A A

A A B

A

B C A

A

B

A

A

C

C

C

C

D A

A A

C

D

A

B

5454

5454

5454

5183

5356

5554

5556

5654

A B A B

A A B

B A A C A

B

A B B

B B C A

A

A

A

A

A

B

B

A

B

B

B

TOUGHNESS This rating applies to the ability of an aluminum weldment to deform plastically

in the presence of stress raisers without low-energy initiation and propagation of cracks. The

most useful test data is from tear resistance testing expressed in unit propagation energy of

measured crack lengths. In structural design, notch toughness is becoming more emphasized

by designers to facilitate the ability to inspect highly stressed structures and nd cracks in

weldments before catastrophic failure occurs. It may also be a design consideration if fatigue

and impact loading are factors directly associated with a weldment.

POST WELD HEAT TREATMENT This rating applies to the ability of a weld to respond to

post-weld heat treatment in the form of solution heat treatment and articial aging. An A

rating indicates that the ller metal is heat treatable and will therefore respond to post weld heat

treatment even without dilution of the base metal. A B rating indicates that the ller metal is

not heat treatable. However, it may be used for applications requiring post weld heat treatment

but with the understanding that the weld may or may not acquire substantial increase in

strength dependent on the joint design, welding procedure, and resultant amount of dilution of

base metal obtained during welding. A C rating requires consultation with MAXAL. No

rating indicates that the ller metal is not heat treatable and that it should not be used for

applications requiring post weld heat treatment as it may result in substantial reduction in weld

performance.

COLOR MATCH AFTER ANODIZING Base metal and ller metal color match after post-weld

anodizing can be of major concern in cosmetic applications. Some ller metals closely match

the base metal color after anodizing and others will react to the anodizing process by changing

to a color very different to that of the base metal.

ELEVATED TEMPERATURE SERVICE This rating is based on the reaction of some ller

metals when exposed to sustained elevated temperature: 150F to 350F (66C to 180C). If

5xxx series base metal or ller metal with more than 3% magnesium content are subjected to

prolonged exposure to these temperatures, precipitate can form within them that is highly

anodic to the aluminum-magnesium matrix. It is this continuous grain boundary network of

precipitate that produces susceptibility to stress corrosion cracking (SCC) and the potential for

premature component failure.

CORROSION RESISTANCE This variable may be a consideration for some environmental

conditions. The rating is based on exposure to fresh and salt water environments and is not

associated with a specic chemical exposure. It gives an indication as to the possibility of

galvanic corrosion due to the difference in the electrode potential between the base metal and

the ller metal. For consideration for other environmental and chemical exposures contact

MAXAL.

DUCTILITY This characteristic of the completed weld may be of consideration if forming

operations are to be used on a completed weldment during fabrication.

Note: Testing procedure requirements for guided bend tests may need to be adjusted to

accommodate the varying ductility of ller metals (AWS D1.2).

CRACK SENSITIVITY The Probability of Hot Cracking - this rating is established through use

of crack sensitivity curves (Developed by Alcoa) and the consideration of ller metal and base

metal chemistry combinations. There are levels of various alloying elements within aluminum

that have been identied as seriously affecting hot cracking susceptibility during weld solidi-

cation. This rating is primarily based on the probability of producing a weld outside these crack

sensitive chemistry ranges.

STRENGTH Ratings are for llet weld and groove weld strength in the as welded condition.

Groove welds Any specied ller metal with a rating can provide minimum transverse tensile

strength in groove welds that will meet the as-welded strength of the base material.

Fillet welds Ratings provided are for llet weld shear strength.

Explanation of Relative Rating A, B, C, & D

Filler metal property ratings A, B, C and D

are relative values for welding base metals

indicated in a specic box. An A rating is

the best t for the weldment property and

D rating is the least t. A blank rating

indicates that the ller metal is not recom-

mended for that specic weldment property

application. All ratings listed are in the as

welded condition. For post weld heat

treatment (PWHT) ratings, refer to the table

on the right.

C

R

A

C

K

I

N

G

S

T

R

E

N

G

T

H

D

U

C

T

I

L

I

T

Y

C

O

R

R

O

S

I

O

N

T

E

M

P

E

R

A

T

U

R

E

C

O

L

O

R

P

W

H

T

T

O

U

G

H

N

E

S

S

ALUMINUM FILLER

METAL SELECTION CHART

Explanation of Ratings A, B, C, & D -

Comparison Between Boxes Ratings have

comparative meaning within a single box

only. For example, an A rating in one box

does not have any comparative value to an

A rating in another box.

**Special Filler Metal Considerations

Filler Metal 4943

4943 will provide substantially higher

strength with comparable weldability and

crack sensitivity when compared to 4043.

This ller metal has an addition of Mg which

provides it with higher as-welded strength

without dependence on dilution from base

material. It will also provide greater strength

in components that are subjected to post

weld heat treatment (solutionizing and/or

precipitation hardening).

Filler Metal 4047

4047 has a lower melting temperature,

slightly higher shear strength, higher uidity

and reduced sensitivity to termination

cracking when compared to 4043. It is often

selected for leak-tight joints and may also

make a good substitute for 4043 when

welding other types of thin sections.

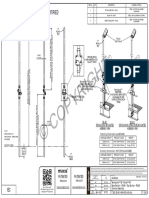

WELD METAL PROPERTIES

1. As the welded component is operating at tempera-

ture above 150F (66C). Elevated TEMPERATURE is

the most important weld metal property.

2. Left hand column 5454 (fifth fromtop), and top row

5454 (fifth fromright).

3. See insert picture of intersecting row and column

(On Right).

4. There is only one row that has a rating for elevated

temperature.

5. For this particular application we only have one filler

metal that is suitable for this application, and that is

filler metal 5554. All the other filler metals within the

box have a blank rating for elevated temperature which

indicates that they are not suitable for this particular

welding application.

5086

5083

5456, 5383

5183

5556

5556

5556

5183

5356

A

C

B

A

A

B

5356

5183

5356

2

How to use the Chart

Filler Metal Selection for AluminumWelding

This chart is a tool that is designed to help you select the most

appropriate filler metal, taking into consideration base metal, the

application, and the desired weld metal properties.

1. Determine which of the weld metal properties are most important for your

application. (Table located on far left)

2. Locate the base metal to be welded in the blue left hand column and in the blue

row across the top of the chart.

3. Locate the white box where the base metal row and column intersect.

4. Examine the data in the white box and select the row that provides the best match

for your application based on the weld metal properties. (There may be more than

one filler metal that is acceptable.)

5. Once you identify the row that gives you the properties you need, follow that row to

the left or right until you come to a gray box. The filler metal located in that row in the

gray box is the most suitable match.

6. Economic Considerations:

If there is more than one filler metal that meets the design criteria requirements,

choose the most economical product. More than 85% of all aluminumfiller metal

that is used is 5356 or 4043. These two products are easily acquired and, because of

their production volume the cost of these products is generally less than others.

WELD METAL

PROPERTIES

T

O

U

G

H

N

E

S

S

P

W

H

T

C

O

L

O

R

T

E

M

P

E

R

A

T

U

R

E

C

O

R

R

O

S

I

O

N

D

U

C

T

I

L

I

T

Y

S

T

R

E

N

G

T

H

C

R

A

C

K

I

N

G

T

O

U

G

H

N

E

S

S

P

W

H

T

C

O

L

O

R

T

E

M

P

E

R

A

T

U

R

E

C

O

R

R

O

S

I

O

N

D

U

C

T

I

L

I

T

Y

S

T

R

E

N

G

T

H

C

R

A

C

K

I

N

G

T

O

U

G

H

N

E

S

S

P

W

H

T

C

O

L

O

R

T

E

M

P

E

R

A

T

U

R

E

C

O

R

R

O

S

I

O

N

D

U

C

T

I

L

I

T

Y

S

T

R

E

N

G

T

H

C

R

A

C

K

I

N

G

T

O

U

G

H

N

E

S

S

P

W

H

T

C

O

L

O

R

T

E

M

P

E

R

A

T

U

R

E

C

O

R

R

O

S

I

O

N

D

U

C

T

I

L

I

T

Y

S

T

R

E

N

G

T

H

C

R

A

C

K

I

N

G

T

O

U

G

H

N

E

S

S

P

W

H

T

C

O

L

O

R

T

E

M

P

E

R

A

T

U

R

E

C

O

R

R

O

S

I

O

N

D

U

C

T

I

L

I

T

Y

S

T

R

E

N

G

T

H

C

R

A

C

K

I

N

G

T

O

U

G

H

N

E

S

S

P

W

H

T

C

O

L

O

R

T

E

M

P

E

R

A

T

U

R

E

C

O

R

R

O

S

I

O

N

D

U

C

T

I

L

I

T

Y

S

T

R

E

N

G

T

H

C

R

A

C

K

I

N

G

T

O

U

G

H

N

E

S

S

P

W

H

T

C

O

L

O

R

T

E

M

P

E

R

A

T

U

R

E

C

O

R

R

O

S

I

O

N

D

U

C

T

I

L

I

T

Y

S

T

R

E

N

G

T

H

C

R

A

C

K

I

N

G

T

O

U

G

H

N

E

S

S

P

W

H

T

C

O

L

O

R

T

E

M

P

E

R

A

T

U

R

E

C

O

R

R

O

S

I

O

N

D

U

C

T

I

L

I

T

Y

S

T

R

E

N

G

T

H

C

R

A

C

K

I

N

G

T

O

U

G

H

N

E

S

S

P

W

H

T

C

O

L

O

R

T

E

M

P

E

R

A

T

U

R

E

C

O

R

R

O

S

I

O

N

D

U

C

T

I

L

I

T

Y

S

T

R

E

N

G

T

H

C

R

A

C

K

I

N

G

T

O

U

G

H

N

E

S

S

P

W

H

T

C

O

L

O

R

T

E

M

P

E

R

A

T

U

R

E

C

O

R

R

O

S

I

O

N

D

U

C

T

I

L

I

T

Y

S

T

R

E

N

G

T

H

C

R

A

C

K

I

N

G

T

O

U

G

H

N

E

S

S

P

W

H

T

C

O

L

O

R

T

E

M

P

E

R

A

T

U

R

E

C

O

R

R

O

S

I

O

N

D

U

C

T

I

L

I

T

Y

S

T

R

E

N

G

T

H

C

R

A

C

K

I

N

G

T

O

U

G

H

N

E

S

S

P

W

H

T

C

O

L

O

R

T

E

M

P

E

R

A

T

U

R

E

C

O

R

R

O

S

I

O

N

D

U

C

T

I

L

I

T

Y

S

T

R

E

N

G

T

H

C

R

A

C

K

I

N

G

T

O

U

G

H

N

E

S

S

P

W

H

T

C

O

L

O

R

T

E

M

P

E

R

A

T

U

R

E

C

O

R

R

O

S

I

O

N

D

U

C

T

I

L

I

T

Y

S

T

R

E

N

G

T

H

C

R

A

C

K

I

N

G

T

O

U

G

H

N

E

S

S

P

W

H

T

T

E

M

P

E

R

A

T

U

R

E

C

O

L

O

R

C

O

R

R

O

S

I

O

N

D

U

C

T

I

L

I

T

Y

S

T

R

E

N

G

T

H

C

R

A

C

K

I

N

G

Example:

Welding 5454 base material that will be used as a

support bracket for an industrial heater This

weldment will be subjected to sustained elevated

temperature of 250 to 300F (121 to 149C).

METAL GROUPS

Pure

Aluminum

Aluminum- Copper

Aluminum-

Manganese

Aluminum- Magnesium AL-Mg Si AL - Zinc AL - Castings METAL GROUPS

BASE

METAL

FILLER

METAL

BASE

METAL

FILLER

METAL

WELD METAL

PROPERTIES

*5XXX Series Strength Ratings

Base Metal Filler Metal Strength Rating

Note: Any strength rating will meet the minimumtransverse tensile

strength requirements of AWS D1.2, a blank rating typically will not.

Anda mungkin juga menyukai

- 2015 KOBELCO Defect PDFDokumen25 halaman2015 KOBELCO Defect PDFayushBelum ada peringkat

- Filler Metal SelectionDokumen7 halamanFiller Metal SelectionMidhun K ChandraboseBelum ada peringkat

- Service Manual PerkinsDokumen130 halamanService Manual Perkinsgelu2003home100% (12)

- Aluminum Selection ChartDokumen1 halamanAluminum Selection ChartFahri Risfa ZulfiBelum ada peringkat

- Effect of Different Metalurgical Phases On The Welding Residual Stresses of Base MetalDokumen71 halamanEffect of Different Metalurgical Phases On The Welding Residual Stresses of Base Metalsalmanzafar_37304938Belum ada peringkat

- Dexta Onerw ManualDokumen54 halamanDexta Onerw Manualfogdart100% (1)

- Welding Metallurgy of Stainless Steels 12363Dokumen12 halamanWelding Metallurgy of Stainless Steels 12363claude.bouillot3566100% (1)

- Drive Rider&Pushmower PartsDokumen36 halamanDrive Rider&Pushmower Partsfogdart100% (2)

- Welding of Nonferrous Metal and Their AlloysDokumen62 halamanWelding of Nonferrous Metal and Their AlloysKhin Aung ShweBelum ada peringkat

- The "Michell" Crankless Engine - Why Was It Not A Commercial Success?Dokumen25 halamanThe "Michell" Crankless Engine - Why Was It Not A Commercial Success?fogdartBelum ada peringkat

- AWS 5.11 Thermal Expansion DataDokumen13 halamanAWS 5.11 Thermal Expansion DataS GoudaBelum ada peringkat

- AsmDokumen2 halamanAsmVictor Daniel WaasBelum ada peringkat

- Pipe and Tube SizeDokumen32 halamanPipe and Tube Sizehothanhdung2002Belum ada peringkat

- Building A SmokehouseDokumen6 halamanBuilding A Smokehouseleecad77Belum ada peringkat

- Building A SmokehouseDokumen6 halamanBuilding A Smokehouseleecad77Belum ada peringkat

- STD-INSP-0125 IGC Phases Practice - A - (ASTM A923) DUPLEXDokumen2 halamanSTD-INSP-0125 IGC Phases Practice - A - (ASTM A923) DUPLEXAkshay KalraBelum ada peringkat

- Perkins DieselDokumen31 halamanPerkins Dieselfogdart100% (6)

- Construction materials price list from local suppliersDokumen6 halamanConstruction materials price list from local suppliersicBelum ada peringkat

- A 304 - 04Dokumen50 halamanA 304 - 04Sasi KumarBelum ada peringkat

- SST (GMAW) Welding Process PDFDokumen4 halamanSST (GMAW) Welding Process PDFmudrijasm100% (1)

- Weld DefectsDokumen45 halamanWeld Defectsanon_256154377Belum ada peringkat

- Material Conversion Chart: Steel Grades and StandardsDokumen8 halamanMaterial Conversion Chart: Steel Grades and StandardsChuan SwtsBelum ada peringkat

- The Lincoln Procedure Handbook of Arc WeldingDokumen742 halamanThe Lincoln Procedure Handbook of Arc Weldingmario fisgaBelum ada peringkat

- Weld Duplex Ss SteelDokumen12 halamanWeld Duplex Ss SteelSan JaBelum ada peringkat

- Building A Earthbag HouseDokumen5 halamanBuilding A Earthbag HouseAndrzej GutowiecBelum ada peringkat

- WeldPulse - Welding Software BrochureDokumen13 halamanWeldPulse - Welding Software BrochureWeldPulse100% (1)

- Fabricating Techniques: Welding Aluminum: Different But Not DifficultDokumen5 halamanFabricating Techniques: Welding Aluminum: Different But Not DifficultDee Dee0% (1)

- Jublie Church - Precast Building Case StudyDokumen1 halamanJublie Church - Precast Building Case Studypriyadharshini0% (1)

- Mechanical Testing 01B: Part 2 Charpy Impact TestingDokumen25 halamanMechanical Testing 01B: Part 2 Charpy Impact Testingsamurai7_77100% (1)

- Astm B32 PDFDokumen9 halamanAstm B32 PDFRodolfo MontoyaBelum ada peringkat

- A5 32-A5 32M-97Dokumen5 halamanA5 32-A5 32M-97mon3embo7Belum ada peringkat

- Bill of Quantities of RasuwagadhiDokumen6 halamanBill of Quantities of RasuwagadhiIndra DhakalBelum ada peringkat

- Tig and Plasma Welding: Process Techniques, Recommended Practices and ApplicationsDari EverandTig and Plasma Welding: Process Techniques, Recommended Practices and ApplicationsPenilaian: 5 dari 5 bintang5/5 (1)

- Atlas of Time-Temperature Diagrams For Irons and Steels PDFDokumen39 halamanAtlas of Time-Temperature Diagrams For Irons and Steels PDFVeronica Martinez100% (1)

- General Specification - Roads and BridgesDokumen165 halamanGeneral Specification - Roads and BridgesEnea BogdanBelum ada peringkat

- AnnealingDokumen9 halamanAnnealingRathne AbeynayakeBelum ada peringkat

- Time Temperature Transformation (TTT) Diagrams PDFDokumen108 halamanTime Temperature Transformation (TTT) Diagrams PDFSerkan Apay100% (1)

- Estimation and EstimatesDokumen61 halamanEstimation and EstimatesShaheryar AhmadBelum ada peringkat

- Bohler Welding Guide PDFDokumen515 halamanBohler Welding Guide PDFParveen (Atam Valves)100% (1)

- Aws Filler Metal PDFDokumen19 halamanAws Filler Metal PDFEngr100% (1)

- Metallic Materials Spec PDFDokumen842 halamanMetallic Materials Spec PDFlisaBelum ada peringkat

- Selection of Welding ConsumablesDokumen13 halamanSelection of Welding ConsumablesbassemaeBelum ada peringkat

- Arcelor High Yield IfDokumen4 halamanArcelor High Yield IfJayDadrassBelum ada peringkat

- Welders Hand BookDokumen23 halamanWelders Hand Booksamyqatar100% (2)

- WJ 2013 05Dokumen128 halamanWJ 2013 05Matija BušićBelum ada peringkat

- Testing of WeldsDokumen44 halamanTesting of Weldspkn_pnt9950Belum ada peringkat

- Factors in Selection of Filler Metals in WeldingDokumen2 halamanFactors in Selection of Filler Metals in WeldingBalakumarBelum ada peringkat

- The Welding Metallurgy of HASTELLOY Alloys C-4, C-22, and C-276Dokumen2 halamanThe Welding Metallurgy of HASTELLOY Alloys C-4, C-22, and C-276Ivan GarzonBelum ada peringkat

- Schaeffler Diagram PDFDokumen16 halamanSchaeffler Diagram PDFrajesh_14Belum ada peringkat

- Thermanit MTS 3 - GTAWDokumen1 halamanThermanit MTS 3 - GTAWdnageshm4n244Belum ada peringkat

- Stainless Steel Electrode Comparison ChartDokumen7 halamanStainless Steel Electrode Comparison Chartmiker100Belum ada peringkat

- Kobe Welding Handbook 2004Dokumen183 halamanKobe Welding Handbook 2004Nasywafi AlyaBelum ada peringkat

- Electrogas WeldingDokumen11 halamanElectrogas WeldingDarryl007100% (1)

- ASTM Welding Tips A410 To A643Dokumen20 halamanASTM Welding Tips A410 To A643MARIO HUAMANBelum ada peringkat

- SEO Optimized Product Data Sheet for OK Tigrod 316L TIG Welding RodDokumen2 halamanSEO Optimized Product Data Sheet for OK Tigrod 316L TIG Welding Rodsoft4gsmBelum ada peringkat

- WJ 2007 12 PDFDokumen124 halamanWJ 2007 12 PDFAhmed GomaaBelum ada peringkat

- Purging While WeldingDokumen16 halamanPurging While WeldingchapulincoloradoBelum ada peringkat

- Wire Cast and HelixDokumen1 halamanWire Cast and Helixmpptanks100% (1)

- Bitumastic 300 MDokumen2 halamanBitumastic 300 MANIBALLOPEZVEGA100% (1)

- Shallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceDari EverandShallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceBelum ada peringkat

- The Physical Metallurgy of Fracture: Fourth International Conference on Fracture, June 1977, University of Waterloo, CanadaDari EverandThe Physical Metallurgy of Fracture: Fourth International Conference on Fracture, June 1977, University of Waterloo, CanadaD M R TaplinBelum ada peringkat

- Aluminum Filler Metal Selection ChartDokumen1 halamanAluminum Filler Metal Selection ChartbrrrrzzzzBelum ada peringkat

- Aluminum Selecti TTQVGDokumen1 halamanAluminum Selecti TTQVGa.kamyabiBelum ada peringkat

- 1 No. Ver Bracing Required As Drawn MKD' - 1Vb-47: Bolt List For Assembly MKD' 1Vb-47 X 1 Dia. Qty. Bolt GradeDokumen1 halaman1 No. Ver Bracing Required As Drawn MKD' - 1Vb-47: Bolt List For Assembly MKD' 1Vb-47 X 1 Dia. Qty. Bolt Grademo3azBelum ada peringkat

- Petrol Chemical Onshore Structure ModuleDokumen18 halamanPetrol Chemical Onshore Structure ModulehavutaBelum ada peringkat

- C IEC S3 M1 4040 003 (HG AL) Rev 3Dokumen1 halamanC IEC S3 M1 4040 003 (HG AL) Rev 3John Bell Rey SarsabaBelum ada peringkat

- Alum A Beam Product SheetDokumen2 halamanAlum A Beam Product SheetatiBelum ada peringkat

- Light pole aluminum notesDokumen7 halamanLight pole aluminum notesSuhas AnilBelum ada peringkat

- Schedule of Finishes for Building MaterialsDokumen1 halamanSchedule of Finishes for Building MaterialsMBelum ada peringkat

- S-1.1 Proposed Filling Station (Caltex Station) : Typical Column-Footing (C1-F1) DetailDokumen1 halamanS-1.1 Proposed Filling Station (Caltex Station) : Typical Column-Footing (C1-F1) DetailCarmela Andrea BuenafeBelum ada peringkat

- Armor Chapter Xii ADokumen8 halamanArmor Chapter Xii AfogdartBelum ada peringkat

- Heating and AC Mobile HomeDokumen26 halamanHeating and AC Mobile HomefogdartBelum ada peringkat

- Build Your Own SmokehouDokumen53 halamanBuild Your Own SmokehoufogdartBelum ada peringkat

- MN 110 Pi Ovra Limpet Mine OkDokumen2 halamanMN 110 Pi Ovra Limpet Mine OkfogdartBelum ada peringkat

- Comparison of Blast Pressures and Effects Methodologies (2009)Dokumen58 halamanComparison of Blast Pressures and Effects Methodologies (2009)fogdartBelum ada peringkat

- ScalmalloyDokumen8 halamanScalmalloyfogdartBelum ada peringkat

- Deprten: Ofmealurica RsercDokumen22 halamanDeprten: Ofmealurica RsercfogdartBelum ada peringkat

- Rocketry R&D Jan2000Dokumen22 halamanRocketry R&D Jan2000fogdartBelum ada peringkat

- 1943 US Army WWII US Sniper Rifle W Sight .30 Cal M1903A4Dokumen17 halaman1943 US Army WWII US Sniper Rifle W Sight .30 Cal M1903A4PlainNormalGuy2100% (1)

- UN-SCETDG-34-InF38e Abuse Testing of Supercapacitors and Related ItemsDokumen12 halamanUN-SCETDG-34-InF38e Abuse Testing of Supercapacitors and Related ItemsfogdartBelum ada peringkat

- Pyrotechnics (1972)Dokumen251 halamanPyrotechnics (1972)fogdartBelum ada peringkat

- 2009 Parts SectionDokumen60 halaman2009 Parts SectionfogdartBelum ada peringkat

- Lawn-Boy F Series DriveDokumen13 halamanLawn-Boy F Series DrivefogdartBelum ada peringkat

- Atrix Ug Att 68xxxxx468a FinalDokumen90 halamanAtrix Ug Att 68xxxxx468a FinalYoshi SwedeBelum ada peringkat

- Watts 500800 User-Manual PDFDokumen8 halamanWatts 500800 User-Manual PDFfogdartBelum ada peringkat

- Motorola ATRIX HD PDFDokumen107 halamanMotorola ATRIX HD PDFjajanayaBelum ada peringkat

- My Passport: Essential Ultra-Portable Hard DriveDokumen77 halamanMy Passport: Essential Ultra-Portable Hard DrivefogdartBelum ada peringkat

- 42" Snow Blade: Operator's ManualDokumen20 halaman42" Snow Blade: Operator's ManualfogdartBelum ada peringkat

- Gcv160a N5aDokumen26 halamanGcv160a N5afogdartBelum ada peringkat

- Bridgestone Firestone Supplemental Details 05-12-17Dokumen19 halamanBridgestone Firestone Supplemental Details 05-12-17fogdartBelum ada peringkat

- Desktop PC Users Guide 8512780Dokumen96 halamanDesktop PC Users Guide 8512780fogdartBelum ada peringkat

- Operator's Manual Model 560 Series (770-10163b)Dokumen24 halamanOperator's Manual Model 560 Series (770-10163b)fogdartBelum ada peringkat

- Operator's Manual Model 568 (770-10163d)Dokumen20 halamanOperator's Manual Model 568 (770-10163d)fogdartBelum ada peringkat

- GTC CivilDokumen1 halamanGTC CivilRadulescu AndreiBelum ada peringkat

- 45° Brick House: Sunrise Society, Vadodara, GujaratDokumen21 halaman45° Brick House: Sunrise Society, Vadodara, GujaratSneha PatilBelum ada peringkat

- A Simple Horizontal Mill Steam Engine With Slide Valve by H.Muncaster. General Arangement, Bill of Materials, Notes, Isometric ViewDokumen1 halamanA Simple Horizontal Mill Steam Engine With Slide Valve by H.Muncaster. General Arangement, Bill of Materials, Notes, Isometric ViewMD26Belum ada peringkat

- 20Ft Flat Pack Container House BOM ListDokumen2 halaman20Ft Flat Pack Container House BOM List陌陌100% (1)

- Effect of Superplasticizer Type On The PerformanceDokumen14 halamanEffect of Superplasticizer Type On The PerformanceKevin ChumánBelum ada peringkat

- CLASS 11450: DEP 31.38.01.15-Gen Class 11450, Rev. I Page 1 of 13Dokumen13 halamanCLASS 11450: DEP 31.38.01.15-Gen Class 11450, Rev. I Page 1 of 13SaguesoBelum ada peringkat

- Masonry, Stucco & Brick Paints: Z - Xghiiify06991Tz)Dokumen2 halamanMasonry, Stucco & Brick Paints: Z - Xghiiify06991Tz)DGWBelum ada peringkat

- Portland Cement Plaster - SpecDokumen7 halamanPortland Cement Plaster - Speclinga2014Belum ada peringkat

- Alltek: An Internal Finish For Walls & Ceilings, Designed To Replace Gypsum Based PlasterDokumen3 halamanAlltek: An Internal Finish For Walls & Ceilings, Designed To Replace Gypsum Based PlasterTinasheBelum ada peringkat

- Heavy Hex Bolts and Nuts Spec SheetDokumen2 halamanHeavy Hex Bolts and Nuts Spec Sheetrusli bahtiarBelum ada peringkat

- Bedauli BoqDokumen15 halamanBedauli BoqFaquruddin AliBelum ada peringkat

- SikaTop-Armatec 110 PDFDokumen4 halamanSikaTop-Armatec 110 PDFNick BesterBelum ada peringkat

- Notes of CH 6 Physical and Chemical Changes Class 7th ScienceDokumen3 halamanNotes of CH 6 Physical and Chemical Changes Class 7th ScienceVicky SharmaBelum ada peringkat

- Portland Cement ConcreteDokumen15 halamanPortland Cement ConcreteIm ChinithBelum ada peringkat

- Henry Waterproofing BrochureDokumen7 halamanHenry Waterproofing BrochureOgbedande Awo OrunmilaBelum ada peringkat

- 9 Oprema-OrdinacijeDokumen10 halaman9 Oprema-OrdinacijeAleksandar TanasijevicBelum ada peringkat

- AASHTO Pot BearingsDokumen4 halamanAASHTO Pot BearingsJithesh.k.sBelum ada peringkat

- Cold Rooms Amp Insulated Panels TSSCDokumen32 halamanCold Rooms Amp Insulated Panels TSSCZar KhariBelum ada peringkat

- WOOD As A BUILDING MATERIAL 2Dokumen9 halamanWOOD As A BUILDING MATERIAL 2Jays Tioxon IIIBelum ada peringkat

- As 1Dokumen9 halamanAs 1Gnana BetsyBelum ada peringkat

- Bar Bending Schedule For Footings Estimation of Reinforcement in FootingsDokumen17 halamanBar Bending Schedule For Footings Estimation of Reinforcement in Footingsဒုကၡ သစၥာBelum ada peringkat