2 CNC

Diunggah oleh

Anvit TiwariJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

2 CNC

Diunggah oleh

Anvit TiwariHak Cipta:

Format Tersedia

CNC PROGRAMMING

1

Basic Concepts of Part Programming

Different Types of Format

Fixed Sequential Format

Tab Sequential Format

Word Address Format (EIA RS-274-D standard)

2

Address

Word

Function

A Rotation about the X-axis

B Rotation about the Y-axis

C Rotation about the Z-axis

F Feedrate commands

G Preparatory commands

I Circular interpolation X-axis offset

J Circular interpolation Y-axis offset

K Circular interpolation Z-axis offset

M Miscellaneous commands

N Sequence number

R Arc radius

S Spindle speed

T Tool number

X X-axis data

Y Y-axis data

Z Z-axis data

3

4

Basic Concept of Part Programming

Part programming contains geometric data about the part and motion

information to move the cutting tool with respect to the work piece.

Basically, the machine receives instructions as a sequence of blocks

containing commands to set machine parameters; speed, feed and other

relevant information.

A block is equivalent to a line of codes in a part program. Character

N135 G01 X1.0 Y1.0 Z0.125 T01 F5.0

Coordinates

Special function

Block number

G-code

Tool number

NC Coordinate Systems

To program the NC processing equipment, a standard axis system must be

defined by which the position of the workhead relative to the workpart can be

specified.

There are two axis systems used in NC, one for flat and prismatic parts and the

other for rotational parts.

Both axis systems are based on the Cartesian Coordinate System.

5

The axis system for flat and prismatic parts consists of:

1. Three linear axes (X, Y, Z) in Cartesian coordinate system.

2. Three rotational axes (A, B, C)

In most machine tool applications, the x-axes and y-axes are used to move and

position the worktable to which the part is attached, and the z-axis is used to

control the vertical position of the cutting tool

NC Coordinate Systems

6

The axis system for rotational parts is shown below

The path of the cutting tool relative to the rotating workpiece is defined in the

x-z plane.

The x-axis is the radial location of the tool.

The z-axis is parallel to the axis of rotation of the part.

NC Coordinate Systems

7

The Right-hand rule of

Coordinates

8

CNC Turning Machines

9

CNC Milling Machines

Vertical

Horizontal

In the area of milling systems, three most common machine

tools are available:

CNC Vertical Machining Center VMC

CNC Horizontal Machining Center HMC

10

Three Major Phases of A CNC Program

The following shows the three major phases of a CNC program.

%

: 1001

N5 G90 G20

N10 M06 T2

N15 M03 S1200

N20 G00 X1.00 Y1.00

N25 Z0.125

N30 G01 Z-0.125 F5.0

N35 G01 X2.0 Y2.0

N40 G00 Z1.0

N45 X0 Y0

N50 M05

N55 M30

Program set up

Material removal

System shutdown

11

Three Major Phases of A CNC Program:

1. Program Setup

The program setup contains all the instructions that prepare the machine for

operation.

% Program start flag

: 1001 Four-digit program number

N5 G90 G20 Use absolute units and inch programming

N10 M06 T2 Stop for tool change, use tool #2

N15 M03 S1200 Turn the spindle on CW to 1200 rpm

12

Three Major Phases of A CNC Program:

2. Material Removal

The material removal phase deals exclusively with the actual cutting feed moves.

N20 G00 X1.0 Y1.0 Rapid move to (X1, Y1) from origin

N25 Z0.1 Rapid down to Z1.0 just above the part

N30 G01 Z-0.125 F5.0 Feed down to Z-0.125 at 5 ipm

N35 X2.0 Y2.0 Feed diagonally to X2 and Y2

N40 G00 Z1.0 Rapid up to Z1 (clear the part)

N45 X0 Y0 Rapid back home X0 Y0

3. System shutdown

The system shutdown phase contains the G- and M-codes that turn off all the

options that were turned on in the setup phase.

N50 M05 Turn the spindle off

N55 M30 End of program

13

14

Basic Guidelines for Programming

The sequence of words (address characters plus

parameters) in an NC block must appear in the

following order when more than one address character

is used per block:

N, G, X, Y, Z, I,J, K, F, S, T, M, ;

Only one of each address character can be used per

block, except some G codes. For instance, you can

place one G code from the Interpolation Group and

one G code from the Programming Mode Group in the

same block. However, you can not place two codes

from one group in the same block.

15

Some codes don't have to be repeated in

every block. The mill will use the same value

until you change it.

Example: N3 G01 X.5 Y2 F1

N4 Y3.5

The first block in a program should move the

tool away from the workpiece to a safe point

(where the tool is not touching the workpiece)

to turn on the spindle.

Example:- NO G00 G9O Z.1

N1 M3

16

The third instruction in a program, after the spindle is

turned on, should move the tool to the start point, the

point where machining begins.

Example:- N2 G00 G90 X.5 Y.5

The end of a part program should move the tool back to

the start point so the tool will be ready to cut the next part.

Example: N5 G00 Z.1

N6 X.5 Y.5 M5

N7 M2

you can leave out extra zero's as long as they have no affect

on the value. For instance you can write

N6 G00 X0.500 Y1.500

as N6 G0 X.5 Y1.5 saving six characters.

17

Example 1: Write a part program to obtain the model shown below from the

profile of given size. FACE MILL TO REDUCE THICKNESS BY 2mm USING 50mm DIA.

MILL TOOL.

100

75

18

0001

G00 G28 G21 G91 X0 Y0 Z0

M06 T05

M03 S1000

G90 G00 X-30 Y20 Z5

G00 Z-2

G01 X130 Y20 F40

G00 Y55

G01 X-30

G00 Z5

G91 G28 X0 Y0 Z0

M05 M09

M30

19

Example 2 : Write a part program to perform

the linear slotting operation with 3mm depth

on the component as shown in the figure.

20

0002

N01 G21

N02 G91 G28 Z0

N03 G28 X0 Y0

N04 G90

N05 M06 T01

N06 M03 S1000

N07G00 Z2

N08 G00 X10 Y10

N09 G01 Z-3 F50

N10 X10 Y90

N11 X90 Y90

N12 X90 Y10

N13 X10 Y10

N14 G00 Z5

N15 G91 G28 Z0

N16 G28 X0 Y0

N17 M05

N 18 M30

21

7

5

Mill circular slot using slot mill of 4 mm

Example 3: Write a part program to obtain the model shown below from the

workpiece of given size.

100

15

2

49

37.5

50

22

0003

N01 G21 G91 G28 Z0

N02 G28 X0 Y0

N03 G90

N04 M06 T01

N05 M03 S1000

N06 G00 X50 Y13

N07 G01 Z-2 F20

N07 G02 X50 Y62 R24.5 F50

N08 G02 X50 Y13 R24.5 F50

N09 G00 Z2

N10 G91 G28 Z0

N11 G28 X0 Y0

N12 M05

N13 M30

23

Example 4: Write a part program to perform slotting operation as shown below

from the profile of given size. Take Radius as 25 mm and Depth of cut 10mm

(-50, 0) (0, 0) (50, 0)

(50,20)

(25,45) (-25,45)

(-50,20)

N01 G21 G91 G28 X0 Y0 Z0

N02 M06 T04

N03 M03 S1000

N04 G90

N04 G00 X50 Y0 Z5

N05 G01 Z-10 F50

N06 G01 X100 Y0

N07 G01 X100 Y20

N08 G02 X75 Y45 R25

N09 G03 X25 Y45 R25

N10 G02 X0 Y20 R25

N11 G01 X0 Y0

N13 G01 X50 Y0

N12 G00 X0 Y0 Z0

N13 M05

N14 M30

Write a part program to obtain the model shown

below from the profile of given size. Operation: Slot

mill of dia. 4mm. Take Billet size of 100 X 100mm,

Radius of circular slot 25mm and Depth of cut

10mm

26

(80, 80)

N01 G21 G94

N02 G91 G28 X0 Y0 Z0

N03 G90

N04 M06 T01

N05 M03 S1000

N06 G00 X50 Y37.5

N07 G01 Z-10 F50

N08 G02 X50 Y62.5 Z-10 R12.5 F50

N09 G02 X50 Y37.5 Z-10 R12.5

N10 G00 Z10

N11 G00 X10 Y10

N12 G01 X10 Y10 Z-10

N13 G01 X80 Y10

N14 G01 X80 Y80

N15 G01 X10 Y80

N16 G01 X10 Y10

N17 G00 Z10

N18 G28 X0 Y0 Z0

N19 M05 M09

N20 M30

27

(80, 80)

Example 5: Write a part program to obtain the model shown below from the

profile of given size. CONTOUR MILL USING 20mm DIA.

G00 G28 G91 X0 Y0 Z0

M06 T02

M03 S1000

G90 G00 X-15 Y15 Z5

G00 Z-3

G01 G41 X4 F40

G01 X4 Y60

G01 X15 Y71

G01 X85 Y71

G01 X96 Y60

G01 X96 Y15

G01 X85 Y4

G01 X15 Y4

G01 X4 Y15

G40 X-15

G00 Z5

G91 G28 X0 Y0 Z0

M05 M09

M30

30

Example 6: Write a part program to obtain the model shown below from the

profile of given size.

Drill 4 holes at the corners using drill bit of 5 mm

33

Canned Cycle

34

A sequence of machine operations initiated by a single G code.

Canned cycles act as shortcuts that simplify the program.

The five operations in a canned cycle:

Positioning of the X and Y axes

Rapid traverse to the R plane

Drill, boring & tapping

Operation at the bottom of hole

Retraction to the R

G00 G91 G28 Z0

G28 X0 Y0

M06 T5

M03 S1200

G90 G00 X6 Y6 Z5

G81 G99 G90 Z-20 R2 F50

X94

Y69

X6

G80

G91 G28 X0 Y0 Z0

M05

M30

36

7

5

Mill circular pocket using slot mill of 12 mm

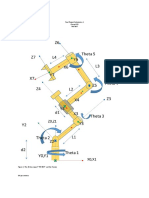

Example 7) Write a part program to obtain the model shown below from the workpiece

of given size.

100

15

2

30

37.5

50

38

G170 R0 P0 Q3 X10 Y10 Z - 5 I0 J0 K24

G171 P75 S1000 R50 F45 B1500 J15

R - Position of tool to start cycle

P - Roughing (0) / finishing (1)

Q - Peck increment for each cut

X,Y & Z - Coordinates of bottom center of the circular pocket.

I & J - Finishing allowance for side and pocket base

K - Radius of circular pocket

P - Cutter movement percentage for next step

S - Roughing spindle speed

R - Roughing feed in Z direction

F - Roughing feed in XY directions

B - Finishing spindle speed

J - Finishing feed

G21 G94

G91 G28 Z0

G28 X0 Y0

G90

M06 T01

M03 S1000

G00 X50 Y37.5 Z5

G01 Z0 F20

G91

G170 R0 P0 Q1 X0 Y0 Z-2 I0 J0 K-15

G171 P45 S1200 R25 F50 B1300 J40

G28 Z0

G28 X0 Y0

M05

M30

40

Example 8 ) Write a part program to obtain the model shown below from the workpiece

of given size.

G0 G91 G28 Z0 M39

G28 X0 Y0

M06 T1

M03 S1000

G90 G00 X-30 Y20 Z5

Z-1

G01 X130 Y20 F40

G0 Y55

G01 X-30

G0 Z5

G91 G28 X0 Y0 Z0

M05

M06 T2

M03 S1300

G90 G00 X-15 Y15 Z5

Z-4

G01 G41 X4 F40

Y60

X15 Y71

X85

X96 Y60

Y15

X85 Y4

X15

X4 Y15

G40 X-15

G00 Z5

G91 G28 X0 Y0 Z0

M5

M06 T3

M03 S1200

G90 Z5 M08

G0 X50 Y13

G01 Z-3 F20

G02 X50 Y62 R24.5 F50

G02 X50 Y13 R24.5

G0 Z0

G28 G91 G0 Z0 X0 Y0

M05

M06 T4

M03 S1000

G90 G0 X50 Y37.5Z5

G1 Z-1 F20

G91

G170 R0 P0 Q1 X0 Y0 Z-2 I0 J0 K-15

G171 P45 S1200 R25 F50 B1300 J40

G00 G28 Z0 X0 Y0

M5

M06 T5

M03 S1200

G90 G00 X6 Y6 Z5

G81 G99 G90 Z-20 R3 F50

G90 X94

Y69

X6

G80

G91 G28 X0 Y0 Z0

M05 M30

Mirroring

42

M70 Mirror along X

ON

M71 Mirror along Y

ON

M80 Mirror along X

OFF

M81 Mirror along Y

OFF

M98 subprogram Call

M99 Subprogram End

43

Note:

Width of slot = 4 mm and Depth of Cut= 1mm

44

G21 G94

G91 G28 Z0

G28 X0 Y0

G90

M06 T01

M03 S1000

G00 X0 Y0 Z5

M98 P0015000

M70

M98 P0015000

M80

M70

M71

M98 P0015000

M80

M81

M71

M98 P0015000

M81

G00 Z5

G91 G28 Z0

G28 X0 Y0

M05

M30

Subprogram

:5000

G00 X10 Y10 Z5

G01 Z-1 F20

X40

X10 Y40

Y10

G01 Z5

G00 X0 Y0

M99

45

G51 Scaling Function

G50

Scaling Function Cancel

Scaling

46

G21 G94

G91 G28 Z0

G28 X0 Y0

G90

M06 T01

M03 S1500

G00 X0 Y0

M98 P0012424

G00 X0 Y0

M98 P0012425

G91 G28 Z0

G28 X0 Y0

M05

M30

Subprogram 2:

:2424

G90 G00 X-40 Y-40 Z5

G01 Z-1 F40

X-40 Y40

X40 Y40

X40 Y-40

X-40 Y-40

G01 Z5

M99

Subprogram 1:

:2425

G51 P0.5

M98 P0012424

G50

M99

47

G68 X.. Y.. R.. (Coordinate system rotation )

X, Y Hole Center

R Rotation Angle

G69 (Coordinate system rotation Cancel )

G73 High speed Peck Drilling Cycle

Rotation

48

G21 G94

G91 G28 Z0

G28 X0 Y0

G90

M06 T01

M03 S1500

G00 X25 Y25 Z5

G68 X0 Y0 R0

M98 P0012323

G68 X0 Y0 R45

M98 P0012323

G68 X0 Y0 R90

M98 P0012323

G68 X0 Y0 R135

M98 P0012323

G68 X0 Y0 R180

M98 P0012323

G68 X0 Y0 R225

M98 P0012323

G68 X0 Y0 R270

M98 P0012323

G68 X0 Y0 R315

M98 P001 2323

G69

G91 G28 Z0

G28 X0 Y0

M05

M30

Subprogram:

:2323

G99 G90G73 X25 Y25 Z-5 Q1 R3 F80

G00 Z5

G80

M99

49

CNC PROGRAMMING TURNING OPERATIONS

Exercise 1: Facing cycle (G94)

G99 G28 U0 W0 (TAKING THE TOOL TO HOME POSITION INCREMENTALLY,)

M06 T1 (TOOL CHANGE,TO TOOL NO 1)

M39

G97 M03 S1100 (SPINDLE ON, GAURD CLOSE)

G00 X34 Z2 (INITIAL POSITIONING CLOSE TO THE WORKPIECE)

G99 G94 X0 Z-0.5 F0.1 (FACING, WIDTH 0.5 MM, FEED RATE IN MM/REV)

Z-1

Z-1.5

Z-2

G28 U0 W0 (HOMING)

M05 (SPINDLE STOP)

M38 (GAURD OPEN)

M30 (PROGRAM END)

Exercise 2: Turning cycle (G90)

G99 G28 U0 W0

M06 T1

G97 M03 S1100

G00 X32 Z2

G90 X31 Z-45 F.1

X30

X29 Z-30

X28

X27

X26

X25 Z-15

X24

X23

X22

G28 U0 W0

M05

M30

Exercise 3: Taper turning cycle (G90 R-)

G99 G28 U0 W0

M06 T1

G97 M03 S1000

G0 X32 Z2

G90 X31 Z-45 F0.1

X30

G90 X31 Z-44 R-0.5

X31 R-1

X31 R-1.5

X31 R-2

X31 R-2.5

X31 R-3

X31 R-3.5

X31 R-4

X31 R-4.5

X31 R-5

X31 R-5.5

X31 R-5.75

G28 U0 W0

M05

M09 M38

M30

Exercise 4: Stock removal Turning cycle (G71)

G99 G28 U0 W0

M06 T1

G97 S1500 M03 M39

G00 X32 Z2

G71 U0.5 R0.5

G71 P07 Q14 U0.1 W0.1 F0.1

N07 G00 X10

G1 Z-12

G02 X16 Z-15 R3

G1 X22 Z-30

G02 X26 Z-32 R2

G03 X30 Z-34 R2

G01 Z-44

N14 X32

G70 P07 Q14

G28 U0 W0

M05 M09

M30

54

G99 G28 U0 W0

M06 T1

G97 S1500 M03 M39

G00 X34 Z2

G72 W0.5 R0.5

G72 P07 Q13 U0.1 W0.1 F0.1

N07 G00 Z-17

G1 X32

X26 Z-14

X20

G02 X12 Z-10 R4

G1 X8 Z0

N13 Z2

G70 P07 Q13

G28 U0 W0

M05 M09

M30

Exercise 5: Stock removal Facing cycle (G72)

Exercise 6: Threading cycle (G76)

G99 G28 U0 W0

M06 T1

G97 S110 M13 M39

G00 X32 Z2

G90 X31 Z-40 F0.1

X30

X29

X28

X27

X26

X25

X24

X23

X22

X21

X20

G00 X14

G01 X22 Z-2

M05 M09

G28 U0W0

M06 T02

G97 S250 M13

G00 X22 Z2

G76 P034560 Q100 R0.06

G76 X18.08 Z-30 P960 Q150 F1.5

G28 U0 W0 M05 M09

M30

56

The portion at the end of a threaded shank which is not cut or

rolled to full depth, but which provides a transition between full

depth threads and the fastener shank or head.

Thread Runout

Screw Thread terminology

Pitch

Crest

Root

Flank

Thread

Angle

Pitch line

Axis of thread

Axial thickness

Addendum

Dedendum

Flank

angle

Major dia

Pitch dia Minor dia

EXTERNAL THREAD TERMINOLOGY

Tool Nose Radius Compensation

58

59

60

61

Computer-Assisted Part Programming

Write machine instructions using natural language type

statements

Statements translated into machine code of the MCU

APT (Automatically Programmed Tool) Language

COMPUTER ASSISTED PART PROGRAMMING

There are various programming languages developed in the recent past, such

as,

APT (Automatically Programmed Tools),

ADAPT, EXAPT, VNIAPT

AUTOSPOT,

COMPAT-II,

PROMPT,

ROMANCE,

SPLIT

- are used for writing a computer programme, which has English like

statements. A translator known as compiler program is used to translate it in a

form acceptable to MCU.

Computer assisted part programming

APT (Automatically Programmed Tool)

- Machining instructions are written in English-like statements that are

translated by the computer into the low-level

- It is used for more complex jobs.

machine code of the MCU.

The various tasks in computer-assisted part programming are divided

between;

The human part

The computer.

programmer

Sequence of activities in computer-assisted part programming

Part Programmer's Job :

Two main tasks of the programmer:

1- Define the part geometry

2- Specify the tool path and Operation Sequence

1- Define the part geometry

Underlying assumption: no matter how complex the part geometry, it is composed of

basic geometric elements and mathematically defined surfaces

Geometry elements are sometimes defined only for use in specifying tool path

Examples of part geometry definitions:

P4 = POINT/35, 90,0

L1 = LINE/P1, P2

C1 = CIRCLE/CENTER, P8, RADIUS, 30.0

2- Specify the tool path and Operation Sequence

Tool path consists of a sequence of points or connected line and arc segments, using previously

defined geometry elements

Point-to-Point command: GOTO/P0

Continuous path command: GOLFT/L2, TANTO, C1

Other Functions in Computer-Assisted Part Programming

Specifying cutting speeds and feed rates

Designating cutter size (for tool offset calculations)

Specifying tolerances in circular interpolation

Naming the program

Identifying the machine tool

Computer Tasks in Computer-Assisted part programming

1. Input translation converts the coded instructions in the part program into

computer usable form.

2. Arithmetic and cutter offset computations performs the mathematical

computations to define the part surface and generate the tool path, including cutter

offset compensation (CLFILE)

3. Editing Provides readable data on cutter locations and machine tool operating

commands (CLDATA).

4. Postprocessing Converts into low level code that can be interpreted by the

MCU

There are four basic types of statements in the APT language:

Geometry statements, also called definition statements; are used to define the

geometry elements that comprise the part.

1.

2. Motion commands; are used to specify the tool path.

3. Postprocessor statements; control the machine tool operation, for example, to

specify speeds and feeds, set tolerance values for circular interpolation, and

actuate other capabilities of the machine tool.

4. Auxiliary statements; a group of miscellaneous statements used to name the part

program, insert comments in the program and accomplish similar functions.

APT vocabulary words consist of six or fewer characters. The characters are

almost always letters of the alphabet.

Geometry statements:

The points, lines, and surfaces must be defined in the program prior to

specifying the motion statements. The general form of an APT geometry statement is

the following

SYMBOL = GEOMETRY TYPE/descriptive data

as an example; P1 = POINT/20.0, 40.0, 60.0

A symbol can be any combination of six or fewer alphabetical and numerical

characters, at-least one of which must be alphabetical. Also symbol cannot be APT

vocabulary word.

Symbol Permissible or Not and Why

P1 Permissible

PZL Permissible

ABCDEF Permissible

PABCDEF Not Permissible, Too many Characters (Maximum 6 characters)

POINT Not Permissible, APT vocabulary word

P1.5 Not Permissible, only alphabet and numerical characters allowed

Points: Specification of a point can be accomplished by the following:

1)

Designating its x-, y-, and z-coordinates;

P1 = POINT/15.0, 10.0, 25.0

2)

As the intersection of two intersecting lines;

P2 = POINT/INTOF, L1, L2

L1 and L2 are two previously defined lines.

Lines: A line in APT is considered to be of infinite length in both directions.

Specification of a line can be accomplished by the following:

Two points through which it passes;

L1 = LINE/P3, P4

P3 and P4 are two previously defined points.

1)

2) Passes through point (P5) and parallel to another line (L3) that has been

previously defined;

L2 = LINE/P5, PARLEL,L3

Planes: In APT, a plane extends indefinitely. A plane can be defined by the

following:

1) Three points through which it passes;

PL1 = PLANE/P1, P2, P3

P1, P2 and P3 must be non-collinear.

2) Passes through point (P2) and parallel to another plane (PL1) that has been

previously defined;

PL2 = PLANE/P2, PARLEL, PL1

Circles: In APT, a circle is considered to be a cylindrical surface that is

perpendicular to the plane and extends to infinitely in the z-direction.

A circle can be defined by the following;

Its center and radius;

C1 = CIRCLE/CENTER, P1, RADIUS, 25.0

1)

2) Three points through which it passes;

C2 = CIRCLE/P4, P5, P6

The three points must not be collinear.

2. MOTION STATEMENTS

APT motion statements have a general format:

motion command / descriptive data

e.g. GOTO / P1

At the beginning of the motion statements tool must be given a starting

point

FROM / P0

Or FROM / -2, -2, 0

In APT there are two basic types of motion statements:

a) Point to Point motion

b) Contouring motion

POINT TO POINT MOTION

There are only two basic point to point motion commands

GOTO:

The GOTO statement instructs the tool to go to a particular point location

specified in the descriptive data.

e.g. GOTO / P2

GOTO / 2, 7, 0

GODLTA:

The GODLTA command specifies an incremental move for the tool.

e,g, GODLTA / 2, 7, 0

EXAMPLE OF POINT TO POINT MOTION

Drill three through holes of 0.5 diameter at P1, P2, P3. The part is 0.5 thick.

EXAMPLE OF POINT TO POINT MOTION

P1=POINT/1,2,0.5

P2=POINT/1,1,0.5

P3=POINT/3.5,1.5,0.5

P0=POINT/-1,3,2

FROM/P0

GOTO/P1

GODLTA/0,0,-0.5

GODLTA/0,0,0.5

GOTO/P2

GODLTA/0,0,-0.5

GODLTA/0,0,0.5

GOTO/P3

GODLTA/0,0,-0.5

GODLTA/0,0,0.5

GOTO/P0

CONTOURING MOTION

How to approach the check surface

Modifier words, such as TO, ON, PAST or TANTO, are used to govern the

position of the tool in relation to the check surface.

How to use the drive surface

Motion statements, GOLFT (go to the left), GOFWD (go forward) and

GORGT(go to the right), are also used to control the cutter motion.

EXAMPLE OF CONTOURING MOTION STATEMENTS

EXAMPLE OF CONTOURING MOTION STATEMENTS

FROM/P0

GO/TO,L1,TO,PL1,TO,L5

GORGT/L1,PAST,L2

GOLFT/L2,TO,L3

GORGT/L3,TANTO,C1

GOFWD/C1,PAST,L4

GOLFT/L5,PAST,L1

GOTO/P0

83

POST PROCESSOR STATEMENTS :

To write complete program, statements must be written that controls operations of the spindle,

feed and other features of the machine tools.

Post processor statement are,

COOLANT/ MACHIN/

END RAPID

FEDRAT/ SPINDL/

AUXILLIARY STATEMENTS :

A group of miscellaneous statements used to name the part program, cutter size, part

identification, insert comments in the program and accomplish similar functions.

Auxiliary statement are,

CLPRNT/ INTOL/

CUTTER / OUTOL/

FINI PARTNO

86

MACRO STATEMENTS :

Symbol = MACRO/ Parameter definition(s)

TERMAC

Activating MACRO subroutine

CALL/symbol, parameter specification

Example

DRI LL =MACRO/PX

GOTO/PX

GODLTA/0,0,-2.5

GODLTA/0,0,2.5

TERMAC

CALL/DRILL,PX=P1

CALL/DRILL,PX=P2

y

x

EXAMPLE 1 DRILLING & MILLING OPERATION

Write the APT program to generate the given profile.

EX 1.1 The drill will be operated at a feed of 0.05mm/rev and a spindle speed of 1000 rev/min.

At the beginning of the job, the drill point will be positioned at a target point located at

X=0, Y=-50, and Z=10 (in mm).

EX 1.2 For milling operation : Feed = 50 mm/min., Speed = 1000 rev/min.,

Cutter diam. = 20 mm.

PARTNO SAMPLE PART DRILLING OPERATION

MACHIN/DRILL,02

CLPRNT

UNITS/MM

REMARK Part geometry, Points are defined 10 mm above part surface.

P0 = POINT/0, -50.0, 10.0

P5 = POINT/70.0, 30.0, 10.0

P6 = POINT/120.0, 30.0, 10.0

P7 = POINT/70.0, 60.0, 10.0

REMARK Drill bit motion statements.

FROM/P0

RAPID

GOTO/P5

SPINDL/1000, CLW

FEDRAT/MMPR,0.05

GODLTA/0, 0, -25.0

GODLTA/0, 0, 25.0

RAPID GOTO/P6

GODLTA/0, 0, -25.0

GODLTA/0, 0, 25.0

RAPID GOTO/P7

GODLTA/0, 0, -25.0

GODLTA/0, 0, 25.0

RAPID GOTO/P0

SPINDL/OFF

FINI

PARTNO SAMPLE PART MILLING OPERATION

MACHIN/MILLING,01

CLPRNT

UNITS/MM

CUTTER/20.0

REMARK Part geometry, Points and Lines are defined 25 mm below part top surface.

P0 = POINT/0, -50.0, 10.0

P1 = POINT/0, 0, -25.0

P2 = POINT/160.0, 0, -25.0

P3 = POINT/160.0, 60.0, -25.0

P4 = POINT/35.0, 90.0, -25.0

P8 = POINT/130.0, 60.0, -25.0

L1 = LINE/P1, P2

L2 = LINE/P2, P3

C1 = CIRCLE/CENTER, P8, RADIUS, 30.0

L3 = LINE/P4, LEFT, TANTO, C1

L4 = LINE/P4, P1

PL1 = PLANE/P1, P2, P4

REMARK Milling cutter motion statements.

FROM/P0

SPINDL/1000, CLW

FEDRAT/50

GO/TO, L1, TO, PL1, TO, L4

GORGT/L1, PAST, L2

GOLFT/L2, TANTO, C1

GOFWD/C1, PAST, L3

GOFWD/L3, PAST, L4

GOLFT/L4, PAST, L1

RAPID GOTO/P0

SPINDL/OFF

FINI

90

Example 2:

A profile milling operation is to be performed to generate the outline of the

part in the figure shown below. Disregard the two holes in the part. They have

already been drilled and will be used to clamp the part to the machine table .

Write the complete APT program

PARTNO EXAMPLE 2

MACHIN/MILLING,04

CLPRNT

INTOL/0.0001

UNITS/MM CUTTER/20.0

P0 = POINT/0, -1, 0

P1 = POINT/0, 0, 0

P2 = POINT/6, 0, 0

P3 = POINT/6, 1.88, 0

P4 = POINT/2.0, 3.75, 0

P5=POINT/0, 3.75, 0

L1 = LINE/P1, P2

L2=LINE/P2, P3

L3=LINE/P1, P5

L4=LINE/P5, P4

P6=POINT/3, 2.88, 0

C1 = CIRCLE/CENTER, P6, RADIUS, 1

L5 = LINE/P3, LEFT, TANTO, C1

L6 = LINE/P4, RIGHT, TANTO, C1

PL1 = PLANE/P1, P2, P3

SPINDL/573, CLW

FEEDRAT/2.29 COOLNT/ON

FROM/P0

GO/TO, L1, TO, PL1, TO, L3

GOFWD/L1, PAST, L2

GOLFT/L2, PAST, L5

GOLFT/L5, TANTO, C1

GOFWD/C1, PAST, L6

GOFWD/L4, PAST, L3

GOLFT/L3, PAST, L1

RAPID

GOTO/P0

SPINDL/OFF

FINI

EXAMPLE 2

Graphic based software using menu driven technique improves the user

friendliness.

The part programmer can create the geometrical model in the CAM package or

directly extract the geometrical model from the CAD/CAM database.

Built in tool motion commands can assist the part programmer to calculate the

tool paths automatically.

The programmer can verify the tool paths through the graphic display using the

animation function of the CAM system.

CNC programming with Interactive Graphic System

NC Part Programming Using CAD/CAM

AUTOMATED INSPECTION

METHODS OF AUTOMATED INSPECTION

Offline Inspection

On-line/in-process,

On-line/post process inspection.

1. Off-line Inspection Methods

In off-line inspection, the inspection equipment is usually dedicated and does not

make any physical contact with machine tools. There is always a time delay between

production and inspection.

Manual inspection is common that tend to promote the use of offline inspection that

include:

1. Variability of the process is well within the design tolerance,

2. Processing conditions are stable and the risk of significant deviation in the process

is small, and

3. Cost incurred during inspection is high in comparison to the cost of few defective

parts.

2. On-line/In-process and On-line/Post-process Inspection Methods

If the task of inspection is done as the parts are manufactured, then it is called as

online inspection.

There are two variations of on-line inspection -

If the inspection is performed during the manufacturing operation, it is called on-

line/in-process inspection.

If the inspection is performed immediately following the production process, it is

called on-line/post-process inspection.

COORDINATE MEASURING MACHINE

A coordinate measuring machine is an electromechanical system designed to perform

coordinate metrology.

In three-dimensional coordinate system, a basic CMM is composed of the following

components.

Probe head and probe,

Mechanical structure and displacement transducer,

Drive system and control units, and

Digital computer system with application software.

99

Horizontal Structure Gantry Structure

Column Structure Bridge Structure Cantilever Structure

CMM Controls

On the basis of operating and controlling of CMM, it can be classified in the four

following ways :

1. Manual drive,

2. Manual drive with computer-assisted data processing, (CADP)

3. Motor drive with computer-assisted data processing,

4. Direct Computer Control (DCC) with computer-assisted data processing.

The probe is physically moved by human operator along the machines axes for making

contact with the part and the measurements are recorded in manual drive CMM.

The three orthogonal slides are designed to be nearly frictionless to permit the

probe to be free floating in the x, y, and z-directions.

A digital readout provides the measurements that the operator can record either

manually or with paper printout.

Only operator is allowed to carry out calculations on the data that includes the

enumeration of the centre and hole diameter.

1. Manual drive

Data processing and computational capability for performing the calculations that are

required to evaluate a given part feature are provided by a CMM with manual drive

CMM with computer-assisted data processing.

The different types of data processing and computations are ranging from simple

conversions of metric units to more complicated geometry calculations, such as

determining the angle between two planes.

The probe is free floating and permits the operator to bring it into contact with the

desired part surfaces.

2. Manual drive with computer-assisted data processing

Electric motors are used in a motor driven CMM with the computer-assisted data

processing to drive the probe along the machine axes under the operator control.

The motion is controlled by joystick or similar devices.

The collisions between the probe and the part are reduced by low-power stepping

motor and friction clutches.

3. Motor drive with computer-assisted data processing

CMM with direct computer control (DCC) operates just like a CNC machine tool.

It is power driven and the movements of the coordinate axes are controlled by a

dedicated computer under program control.

Various data processing is performed by the computer and it also keeps record of

the measurements made during inspection.

DCC CMM requires a part programming facility.

4. Direct Computer Control with computer-assisted data processing.

Anda mungkin juga menyukai

- MSC Lecture 6Dokumen28 halamanMSC Lecture 6Chán Chênh VênhBelum ada peringkat

- Lecture of CNC ProgramDokumen29 halamanLecture of CNC ProgramMargam Kiran KumarBelum ada peringkat

- NC ProgrammingDokumen54 halamanNC ProgrammingVed Vrat NuclearBelum ada peringkat

- CAD/CAM/CAE IntroductionDokumen149 halamanCAD/CAM/CAE IntroductionalexiskandarBelum ada peringkat

- CNC ProgrammingDokumen62 halamanCNC ProgrammingSanjog Maiti100% (1)

- 5 - G-CodeDokumen55 halaman5 - G-CodefamilyumaBelum ada peringkat

- U W CNC Lathe CNC Program ExamplesDokumen30 halamanU W CNC Lathe CNC Program ExamplesTrần Xuân Thanh100% (1)

- 11 Cad Cam CNC Programming MVVDokumen37 halaman11 Cad Cam CNC Programming MVVbassem smatiBelum ada peringkat

- UNIT 7 - CNC - Lecture 3 - ProgrammingDokumen33 halamanUNIT 7 - CNC - Lecture 3 - ProgrammingRakshithBelum ada peringkat

- CNC Programming (Manual Part Programming) Preparatory FunctionsDokumen8 halamanCNC Programming (Manual Part Programming) Preparatory Functionskirthi83Belum ada peringkat

- CNC ProgDokumen38 halamanCNC ProgPoornima JoshiBelum ada peringkat

- Programing Training Strung OKUMA-OSP100Dokumen42 halamanPrograming Training Strung OKUMA-OSP100IoanAlexandru Stoian80% (15)

- Programming 1Dokumen44 halamanProgramming 1shubhanshu kumarBelum ada peringkat

- CNC Part Program & DrawingDokumen21 halamanCNC Part Program & DrawingHairedinBelum ada peringkat

- CNC TRAINDokumen124 halamanCNC TRAINakshat naiduBelum ada peringkat

- CNC Turning (Bridgeport)Dokumen63 halamanCNC Turning (Bridgeport)Siti Idah TawhidBelum ada peringkat

- FanucDokumen10 halamanFanucgigofive66Belum ada peringkat

- CNC Programming CyclesDokumen8 halamanCNC Programming CyclesParveen KumarBelum ada peringkat

- Chapter 3.CNC Part ProgrammingDokumen61 halamanChapter 3.CNC Part ProgrammingDr. Vivek SrivastavaBelum ada peringkat

- 8 Fixed Canned Cycles (CNC Course CD) PDFDokumen24 halaman8 Fixed Canned Cycles (CNC Course CD) PDFVeerasamy SureshbabuBelum ada peringkat

- Cam Lab 12k708Dokumen37 halamanCam Lab 12k708Nithish Kumar K MBelum ada peringkat

- Chapter 3.Cnc Part ProgrammingDokumen61 halamanChapter 3.Cnc Part Programminghari0118Belum ada peringkat

- Mill Fanuc: Fanuc G68 Coordinate Rotation - Subprogram ExampleDokumen73 halamanMill Fanuc: Fanuc G68 Coordinate Rotation - Subprogram Exampleسليمان مصريBelum ada peringkat

- CNC ProgramsDokumen5 halamanCNC ProgramsBravo VermaBelum ada peringkat

- G-Code InstructionsDokumen55 halamanG-Code InstructionsSantiago LopezBelum ada peringkat

- CNC Programs ExamplesDokumen5 halamanCNC Programs ExamplesNemikumar GandhiBelum ada peringkat

- Cam Lab ManualDokumen29 halamanCam Lab ManualBalaji ManianBelum ada peringkat

- The Text Used On A Typical Detail Sheet Should Be - Placed HorizontallyDokumen30 halamanThe Text Used On A Typical Detail Sheet Should Be - Placed HorizontallyShalom HaileBelum ada peringkat

- CNC Programming BasicsDokumen53 halamanCNC Programming Basicspramod ChouguleBelum ada peringkat

- NC Part ProgrammingDokumen36 halamanNC Part Programmingabyzen0% (1)

- Lathe - Exercise 2014Dokumen8 halamanLathe - Exercise 2014Ramesh VajramBelum ada peringkat

- 5 - G-CodeDokumen55 halaman5 - G-CodeTan TeongShengBelum ada peringkat

- CNC Programming Turning GuideDokumen9 halamanCNC Programming Turning GuideG. Dancer GhBelum ada peringkat

- CNC Milling Program with G and M CodesDokumen20 halamanCNC Milling Program with G and M CodesSudeep Kumar SinghBelum ada peringkat

- FacingDokumen32 halamanFacingAdithyan GowthamBelum ada peringkat

- CNC ProgrammingDokumen27 halamanCNC ProgrammingAbhijit BiswasBelum ada peringkat

- Computer Aided Engineering: Assignment On CNC ProgrammingDokumen13 halamanComputer Aided Engineering: Assignment On CNC ProgrammingShaswata BoseBelum ada peringkat

- Module 2 Part 1Dokumen147 halamanModule 2 Part 1FRANCIS THOMASBelum ada peringkat

- ME 473 Unit 5Dokumen21 halamanME 473 Unit 5Ama Serwaa YeboahBelum ada peringkat

- Cam RecordDokumen39 halamanCam Recordryan saraBelum ada peringkat

- Turning Exercies - Ip710 - Dr.V.RameshDokumen8 halamanTurning Exercies - Ip710 - Dr.V.Rameshvajram1100% (1)

- ME8691 CNC Programming FundamentalsDokumen62 halamanME8691 CNC Programming FundamentalssamnztBelum ada peringkat

- Module 4Dokumen59 halamanModule 4Musadiq Ahmed100% (1)

- Debre Tabor University: Faculty of Technology Department of Electromechanical EngineeringDokumen25 halamanDebre Tabor University: Faculty of Technology Department of Electromechanical EngineeringBIRSHBelum ada peringkat

- CNC-Lab Mechanical ManualDokumen21 halamanCNC-Lab Mechanical ManualHaresh RaisinghaniBelum ada peringkat

- CNC Part ProgrammingDokumen61 halamanCNC Part ProgrammingrajaBelum ada peringkat

- Unit 4CADMDokumen62 halamanUnit 4CADMSurulivelrajantBelum ada peringkat

- CNC Programing ConceptDokumen11 halamanCNC Programing ConceptGatot PrasetyoBelum ada peringkat

- Syllabus Me0423 - Computer Aided Manufacturing Laboratory: PurposeDokumen10 halamanSyllabus Me0423 - Computer Aided Manufacturing Laboratory: PurposefamilyumaBelum ada peringkat

- Billet size: - φ 25 x 70 mm: Straight, Taper And Radius TurningDokumen16 halamanBillet size: - φ 25 x 70 mm: Straight, Taper And Radius TurningAnonymous NywZANxoBelum ada peringkat

- Circular Interpolation Programming Example 123456Dokumen14 halamanCircular Interpolation Programming Example 123456Kennaa GadaaBelum ada peringkat

- Training Programme On CNC LatheDokumen33 halamanTraining Programme On CNC Lathesharafudheen_sBelum ada peringkat

- Engineers Precision Data Pocket ReferenceDari EverandEngineers Precision Data Pocket ReferencePenilaian: 3 dari 5 bintang3/5 (1)

- Engineering Service Revenues World Summary: Market Values & Financials by CountryDari EverandEngineering Service Revenues World Summary: Market Values & Financials by CountryBelum ada peringkat

- E - Pressure Control ValveDokumen17 halamanE - Pressure Control ValveAnvit TiwariBelum ada peringkat

- CSD 1Dokumen15 halamanCSD 1Anvit TiwariBelum ada peringkat

- Manual IndexingDokumen41 halamanManual IndexingBasharat AhmadBelum ada peringkat

- Full Page PhotoDokumen1 halamanFull Page PhotoAnvit TiwariBelum ada peringkat

- CH 07Dokumen15 halamanCH 07Anvit TiwariBelum ada peringkat

- Hw1 MaterialsDokumen4 halamanHw1 MaterialsAnvit TiwariBelum ada peringkat

- Group 10 Submission 1Dokumen23 halamanGroup 10 Submission 1Anvit TiwariBelum ada peringkat

- HarryDokumen1 halamanHarryAnvit TiwariBelum ada peringkat

- Contents FinalDokumen9 halamanContents FinalAnvit TiwariBelum ada peringkat

- HarryDokumen1 halamanHarryAnvit TiwariBelum ada peringkat

- CHEMICAL EQUILIBRIUMDokumen254 halamanCHEMICAL EQUILIBRIUMYagnesh DBelum ada peringkat

- Prashant Jha 8134528984Dokumen1 halamanPrashant Jha 8134528984Anvit TiwariBelum ada peringkat

- CNC Hard Turning CenteDokumen13 halamanCNC Hard Turning CenteAnvit TiwariBelum ada peringkat

- Cricket 2008 File ListDokumen1 halamanCricket 2008 File ListHell DamBelum ada peringkat

- Me Web Module PDFDokumen104 halamanMe Web Module PDFAnvit TiwariBelum ada peringkat

- Voltage RegulatorsDokumen45 halamanVoltage RegulatorsAnvit TiwariBelum ada peringkat

- Input TemplatesDokumen7 halamanInput TemplatesSwkratis MourtzakisBelum ada peringkat

- CNCP Sessional 02 QP ToprintDokumen7 halamanCNCP Sessional 02 QP ToprintAnvit TiwariBelum ada peringkat

- CAPP Systems ExplainedDokumen23 halamanCAPP Systems ExplainedAnvit TiwariBelum ada peringkat

- Basic Electronics: Bipolar Junction TransistorDokumen68 halamanBasic Electronics: Bipolar Junction TransistorSanjana AnumoluBelum ada peringkat

- Banks Around USFDokumen3 halamanBanks Around USFAnvit TiwariBelum ada peringkat

- Magic LightsDokumen3 halamanMagic LightsBIBI MOHANANBelum ada peringkat

- Damping and Pole-Zero AnalysisDokumen10 halamanDamping and Pole-Zero AnalysisAnvit TiwariBelum ada peringkat

- CNC PROGRAMMING TITLEDokumen104 halamanCNC PROGRAMMING TITLEAnvit TiwariBelum ada peringkat

- Test SignalsDokumen31 halamanTest SignalsAnvit TiwariBelum ada peringkat

- Bessel - Legendre de 2 (Beamer)Dokumen41 halamanBessel - Legendre de 2 (Beamer)Anvit TiwariBelum ada peringkat

- Space Robotics: PreviewDokumen21 halamanSpace Robotics: PreviewAnvit TiwariBelum ada peringkat

- Bessel - Legendre de 1 (Beamer)Dokumen84 halamanBessel - Legendre de 1 (Beamer)Anvit TiwariBelum ada peringkat

- Bessel - Legendre D.EDokumen14 halamanBessel - Legendre D.EAnvit TiwariBelum ada peringkat