APP1008 - Understanding SCR Power Controllers

Diunggah oleh

Raj Hakani0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

97 tayangan4 halamanfa

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen Inifa

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

97 tayangan4 halamanAPP1008 - Understanding SCR Power Controllers

Diunggah oleh

Raj Hakanifa

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 4

Application Note 1008

Understanding SCR Power Controls

Author - George A. Sites, AMETEK HDR Power Systems

Copyright 2003, Republished Dec 2012 Toll Free: 1-888-PWR-CNTL

1 1-614-308-5500 Fax: 1-614-308-5506

www.hdrpower.com

INTRODUCTION

SCR Power Controls were first developed in the late 1950s. Originally available with ratings of only a

few hundred amps and low voltage, the SCR Power Control has steadily increased in ratings. As the

controls capabilities increased, the number of potential applications has increased as well. In fact,

nearly every industrial process that uses process-heating equipment can now employ SCR Power

Controllers.

ADVANTAGES

Clearly, the advantages of SCR Power Controls outweigh the disadvantages. The biggest advantages

are high reliability and low maintenance requirements. Because the SCR is a solid-state device, there

are no moving parts to wear out. Simply keeping it clean and cool provides users with many years of

reliable service. Another advantage is control options. Compared with an on/off electro-mechanical

contactor, an SCR provides fast response and high resolution as well as the ability to limit current and

regulate load voltage, current or power. Disadvantages to using an SCR Power Control can include low

power factor, high harmonic currents and radio frequency interference (RFI) when using phase-fired

power controllers.

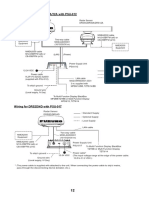

UNDERSTANDING THE SCR POWER CONTROL

To fully understand how an SCR Power Controller operates, it is important to understand how a silicon-

controlled rectifier (SCR) works. The SCR is the power-handling electronic device in an SCR Power

Control. Because an SCR conducts current in only one direction, two SCRs are connected in an

inverse parallel, or back-to-back, configuration when used as the power control (see figure 1).

LOAD LINE

G

SCR1

SCR2

G

Figure 1 - Two SCRs are connected in a back-to-back configuration to form an AC switch

When power is applied to the line side of the SCR, a timed pulse is applied alternately to the gates of

SCR 1 and 2. When SCR 1 is gated on, it conducts the positive half-cycle of the AC power; alternately,

when SCR 2 is gated on, it conducts the negative half-cycle. The SCR pair is commonly called an AC

switch.

1

Application Note 1008 Toll Free: 1-888-PWR-CNTL

Copyright 2003, Republished Dec 2012 2 1-614-308-5500 Fax: 1-614-308-5506

www.hdrpower.com

Understanding SCR Power Controls

An SCR Power Controller consists of one, two or three AC switches, depending on how many phases

are being controlled. A single AC switch is used to control a single-phase load. When two AC switches

are used, the load must be three-phase, three-wire connected. Three AC switches are used on three-

phase loads that are three- or four-wire connected.

CONTROL MODES

There are three basic control modes: on/off, zero-firing and phase-firing. On/off control is the simplest

method it merely duplicates the action of an electromechanical contactor. When a command signal is

applied, the control turns on and conducts current. When the command signal is removed, the control

turns off.

0%

25%

75%

50%

100%

Figure 2 - Zero-firing provides proportional control

by varying the number of cycles the SCR is on or off.

Zero-firing control switches the SCRs on and off much like on/off control but this method

incorporates proportional control. With this control mode, the number of on or off AC cycles is varied

to maintain as steady a voltage to the load as possible while turning the power on and off. Figure 2

shows the on and off AC cycles associated with a zero-fired SCR Power Control.

1

Application Note 1008 Toll Free: 1-888-PWR-CNTL

Copyright 2003, Republished Dec 2012 3 1-614-308-5500 Fax: 1-614-308-5506

www.hdrpower.com

Understanding SCR Power Controls

While effective, zero-firing is not suited for every application. Because zero-firing turns the SCR either

completely on or off, the voltage applied to the load is either zero or full. This is not acceptable with an

exotic load element such as molybdenum disilicide. Molybdenum disilicides resistance is nearly zero

when cold, but increases with temperature. Ohms law shows that if zero-firing were used to control a

molybdenum disilicide load element, large current surges would result each time the SCR was turned

on when the element was cold. These current surges can damage SCRs and cause nuisance fuse

blowing. This application would be better suited to phase-firing.

Phase-firing provides infinitely variable control of voltage to the load much like a light dimmer. Similar

to zero-firing, with phase-firing, timed gate pulses are fed to the SCRs. But with this control mode,

each of the two SCRs in an AC switch is turned on only for a portion of the half-cycle it is controlling

(Figure 3).

25%

50%

100%

75%

0%

Figure 3 - Zero-firing provides proportional control

by varying the number of cycles the SCR is on or off.

1

Application Note 1008 Toll Free: 1-888-PWR-CNTL

Copyright 2003, Republished Dec 2012 4 1-614-308-5500 Fax: 1-614-308-5506

www.hdrpower.com

Understanding SCR Power Controls

TYPES OF CONNECTED LOADS

Two basic types of loads typically are connected to SCR Power Controls: resistive and inductive. A

resistive load is purely resistive in nature: its resistance varies little (less than +/-20%) with time and

temperature. Or, the resistance changes can be large greater than +/-20%.

If the load resistance change is small, a zero-fired controller is the right choice. By contrast, if the load

resistance change is large as with molybdenum disilicide or silicon carbide elements a phase-fired

SCR Power Controller is the correct choice.

Inductive loads such as a transformer-coupled load can cause high in-rush currents when used with

zero-firing. In this case, using a phase-fired controller allows the load voltage to ramp up and avoids

large current surges.

When selecting an SCR Power Controller, take the following 4 steps:

1. Determine the type of load element and whether on/off, zero or phase-firing is required.

2. Determine the line voltage and the number of phases to be controlled.

3. If the load is three-phase, determine whether it is three-or four-wire connected.

4. Calculate the maximum load current required at full output voltage, regardless of the

desired load voltage. (SCRs can turn full on when not expected or, if the SCR fails

shorted, full line voltage would be applied to the load.)

Use the following formulas when calculating load current.

1-Phase

3-Phase

Phase-firing can be used with nearly any load type; on/off and zero-fired control should only be used

with resistive loads.

One caution: The lower power factor, higher harmonic currents and radio frequency interference

generated by the high rising waveforms associated with phase-firing can be a problem. Using zero-

firing, if the load type allows, can eliminate these problems.

CONCLUSION

Most electrical heat control devices do not offer the flexibility, available with SCR Power Controls. Its

flexibility, ease of application and reliability account for its popularity.

Anda mungkin juga menyukai

- SCR Phase Control Lab ReportDokumen8 halamanSCR Phase Control Lab ReportFe BaltazarBelum ada peringkat

- Manabat - SCR APPLICATIONSDokumen11 halamanManabat - SCR APPLICATIONSCj SoferBelum ada peringkat

- Special Devices or Breakdown DevicesDokumen13 halamanSpecial Devices or Breakdown DevicesMuhammad Arif Rattar100% (1)

- SCR Silicon Controlled Rectifier: Time (TQ)Dokumen4 halamanSCR Silicon Controlled Rectifier: Time (TQ)Daniela Cardenas LuboBelum ada peringkat

- SCR NotesDokumen4 halamanSCR Notesmathew_john0077393100% (1)

- Oltc 2Dokumen4 halamanOltc 2Saravana Prakash PBelum ada peringkat

- Modeling and Simulation of Reverse PowerDokumen6 halamanModeling and Simulation of Reverse PowergusgifBelum ada peringkat

- Current Mode Voltage Mode ?: by Dr. Ray RidleyDokumen3 halamanCurrent Mode Voltage Mode ?: by Dr. Ray RidleyPhạm Văn TưởngBelum ada peringkat

- Click Icon To Add PictureDokumen22 halamanClick Icon To Add PictureAbdul wahedBelum ada peringkat

- SCR Phase Control ExperimentDokumen22 halamanSCR Phase Control ExperimentJomel CanalesBelum ada peringkat

- Slua 143Dokumen15 halamanSlua 143Tonia KataBelum ada peringkat

- AppNote03 Uc3842Dokumen14 halamanAppNote03 Uc3842Heriberto Flores AmpieBelum ada peringkat

- Aplicacion Uc3842Dokumen15 halamanAplicacion Uc3842Gian Mejia100% (1)

- Silicon Controlled RectifierDokumen1 halamanSilicon Controlled RectifierJazzel Avila ParadiseBelum ada peringkat

- Soft Start: Reducing Excess Current During Motor StartupDokumen5 halamanSoft Start: Reducing Excess Current During Motor Startupnicko_octaveroBelum ada peringkat

- Process Control Lab ManualDokumen32 halamanProcess Control Lab ManualRakesh Kumar Patnaik50% (2)

- Trigged Current Limiters ApplicationsDokumen6 halamanTrigged Current Limiters ApplicationsVíctor RojasBelum ada peringkat

- SCR Control of Electric HeatersDokumen3 halamanSCR Control of Electric HeatersHayden Lovett100% (2)

- Sensorless Current Mode Control-An Observer-Based Technique For DC-DC ConvertersDokumen5 halamanSensorless Current Mode Control-An Observer-Based Technique For DC-DC ConvertersDipanjan DasBelum ada peringkat

- Troubleshooting SCR IPSDokumen14 halamanTroubleshooting SCR IPSRené Galvis Oliveira75% (4)

- Static Voltage Regulator SynopsisDokumen4 halamanStatic Voltage Regulator SynopsisShravan JadhavBelum ada peringkat

- Synchronizing and Synchronizing EquipmentDokumen10 halamanSynchronizing and Synchronizing EquipmentLog in 2007Belum ada peringkat

- AUTO CONTROLLER FOR PETROL (Revised)Dokumen25 halamanAUTO CONTROLLER FOR PETROL (Revised)Hamed RazaBelum ada peringkat

- AN1060 Flyback L6561Dokumen12 halamanAN1060 Flyback L6561Armando SánchezBelum ada peringkat

- Pci Lab ManualDokumen32 halamanPci Lab ManualrkshpatnaikBelum ada peringkat

- Jara Exp-1Dokumen9 halamanJara Exp-1diannesanjuan29Belum ada peringkat

- Sincronizing of Two SourceDokumen5 halamanSincronizing of Two SourceMonjur Morshed AhmedBelum ada peringkat

- Banao Lab 1Dokumen9 halamanBanao Lab 1diannesanjuan29Belum ada peringkat

- Load Power Control by Using SCRDokumen40 halamanLoad Power Control by Using SCRalthaf hussainBelum ada peringkat

- GE Power Relay Application GuideDokumen24 halamanGE Power Relay Application GuidehajianamirBelum ada peringkat

- 1mrk508002-Ben B en Time Relays RXKL 1 and RXKM 2hDokumen8 halaman1mrk508002-Ben B en Time Relays RXKL 1 and RXKM 2hDave ChaudhuryBelum ada peringkat

- UC3845 Technical ExplanationDokumen15 halamanUC3845 Technical ExplanationankurmalviyaBelum ada peringkat

- Flyback Converters With The L6561 PFC Controller: AN1060 Application NoteDokumen11 halamanFlyback Converters With The L6561 PFC Controller: AN1060 Application NotegrittinjamesBelum ada peringkat

- AC-AC Converters Chapter Explains Voltage RegulationDokumen22 halamanAC-AC Converters Chapter Explains Voltage RegulationGebremichael Teklay GebretsadikBelum ada peringkat

- SCR Power Control Circuit ExplainedDokumen6 halamanSCR Power Control Circuit ExplainedEric BiscochoBelum ada peringkat

- Multi Channel IndicatorDokumen1 halamanMulti Channel IndicatorBala SingamBelum ada peringkat

- REducing ArcFlash Hazard-RELT Final-GEDokumen11 halamanREducing ArcFlash Hazard-RELT Final-GEmojsic6313Belum ada peringkat

- 4 (B) - IM Drives - AC Voltage ControllersDokumen71 halaman4 (B) - IM Drives - AC Voltage ControllersimdadamuBelum ada peringkat

- Motorola SCR Power Control FundamentalsDokumen6 halamanMotorola SCR Power Control FundamentalsSimon SimonBelum ada peringkat

- Midterm-PIT Written-Report Alaba Dano Kabingue Lacanaria-2Dokumen7 halamanMidterm-PIT Written-Report Alaba Dano Kabingue Lacanaria-2IvanAlabaBelum ada peringkat

- How Voltage Regulators OperateDokumen6 halamanHow Voltage Regulators Operateenriqueuno100% (1)

- Study For The Performance of High Speed Switchgear For Protection of In-House Generation SystemDokumen5 halamanStudy For The Performance of High Speed Switchgear For Protection of In-House Generation SystemDr Vijaya Kumar JBelum ada peringkat

- SCR Application and Converter Family IntroductionDokumen38 halamanSCR Application and Converter Family IntroductionFrancis GambolBelum ada peringkat

- What You Should KnowDokumen16 halamanWhat You Should Knowmohammad salehiBelum ada peringkat

- Single Phase Power SourceDokumen1 halamanSingle Phase Power Sourceippon_osotoBelum ada peringkat

- Triac ControlDokumen6 halamanTriac ControlSyaiful BakhriBelum ada peringkat

- Applications of Ac Ac Converters in Electric Power SystemsDokumen2 halamanApplications of Ac Ac Converters in Electric Power SystemsJesús CabezasBelum ada peringkat

- Technical University of Mombasa Controls Power Electronics Lab ReportDokumen14 halamanTechnical University of Mombasa Controls Power Electronics Lab ReportFaustin MailuBelum ada peringkat

- Subject (Reg198) - Improvement of Power QualityDokumen10 halamanSubject (Reg198) - Improvement of Power QualitysorrowarBelum ada peringkat

- IDAC Wheel Slip Control System Manual SectionDokumen6 halamanIDAC Wheel Slip Control System Manual SectionJustin Hernandez100% (1)

- 0100 DB 0501Dokumen62 halaman0100 DB 0501Husnain AssociatesBelum ada peringkat

- BuckConverter Design Jpe10Dokumen13 halamanBuckConverter Design Jpe10joviflocasBelum ada peringkat

- Analysis and Implementation of Solid-State Relays in Industrial Application For Instantaneous Current SupplyDokumen6 halamanAnalysis and Implementation of Solid-State Relays in Industrial Application For Instantaneous Current SupplyijmremBelum ada peringkat

- Load Shedding Philosophy ExplainedDokumen35 halamanLoad Shedding Philosophy Explainedchinnarao100% (1)

- Using PIC Microcontrollers to Control Triacs PhaseDokumen22 halamanUsing PIC Microcontrollers to Control Triacs PhaseMarko Lukic100% (1)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Dari EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Belum ada peringkat

- Simulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorDari EverandSimulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorBelum ada peringkat

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetDari EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetPenilaian: 2 dari 5 bintang2/5 (1)

- GNSS Augmentation Improves Positioning Accuracy for Airborne ApplicationsDokumen20 halamanGNSS Augmentation Improves Positioning Accuracy for Airborne ApplicationsRaj HakaniBelum ada peringkat

- Advance Vacuum Cleaner: ABSTRACT: Autonomous Cleaning Robot Will Perform Task LikeDokumen4 halamanAdvance Vacuum Cleaner: ABSTRACT: Autonomous Cleaning Robot Will Perform Task LikeRaj HakaniBelum ada peringkat

- Koyama Iros02-Multi Fingered Exoskeleton Haptic DeviceDokumen6 halamanKoyama Iros02-Multi Fingered Exoskeleton Haptic DeviceRaj HakaniBelum ada peringkat

- Havells Water Heater Review: Looks beautiful, Heats up instantlyDokumen26 halamanHavells Water Heater Review: Looks beautiful, Heats up instantlyRaj HakaniBelum ada peringkat

- Print NET 2014Dokumen88 halamanPrint NET 2014Raj HakaniBelum ada peringkat

- IJSRDV2I11275Dokumen2 halamanIJSRDV2I11275Raj HakaniBelum ada peringkat

- Faq1 - Abu Robocon 2016 - 26 Oct 15Dokumen15 halamanFaq1 - Abu Robocon 2016 - 26 Oct 15Raj HakaniBelum ada peringkat

- GTU Workshop Intro Open Source Boards Arduino Raspberry PiDokumen3 halamanGTU Workshop Intro Open Source Boards Arduino Raspberry PiRaj HakaniBelum ada peringkat

- Presentation 6Dokumen44 halamanPresentation 6SeverusManiBelum ada peringkat

- World Book Day - ActivityDokumen2 halamanWorld Book Day - ActivityRaj HakaniBelum ada peringkat

- News Paper Cutting 17.10.2015Dokumen14 halamanNews Paper Cutting 17.10.2015Raj HakaniBelum ada peringkat

- 4a4 1285Dokumen5 halaman4a4 1285Meenakshi DhasmanaBelum ada peringkat

- MATLAB: An Introduction: Adapted From An Introductory Manual by John Buck, MIT 27 May 1989Dokumen15 halamanMATLAB: An Introduction: Adapted From An Introductory Manual by John Buck, MIT 27 May 1989dineshkagBelum ada peringkat

- Index: Remaining Student Have To Present and Do Their Design Eng WorkDokumen1 halamanIndex: Remaining Student Have To Present and Do Their Design Eng WorkRaj HakaniBelum ada peringkat

- Design & Simulation of Low Loss Circular Corrugated Waveguide For 42 GHZ, 200Kw GyrotronDokumen5 halamanDesign & Simulation of Low Loss Circular Corrugated Waveguide For 42 GHZ, 200Kw Gyrotronbaban1_jpgBelum ada peringkat

- MOSFET Structure and Operation Explained in 40 CharactersDokumen12 halamanMOSFET Structure and Operation Explained in 40 CharactersRaj HakaniBelum ada peringkat

- Yeni-2 Power Electronic ExperimentsDokumen7 halamanYeni-2 Power Electronic ExperimentsRaj HakaniBelum ada peringkat

- GK 7Dokumen13 halamanGK 7Raj HakaniBelum ada peringkat

- NSIT FormDokumen4 halamanNSIT FormRaj HakaniBelum ada peringkat

- 633937171401169110Dokumen16 halaman633937171401169110Raj HakaniBelum ada peringkat

- Assembler, Linker and LoaderDokumen6 halamanAssembler, Linker and LoaderSyed Shiyaz MirzaBelum ada peringkat

- Tracking PositionDokumen16 halamanTracking PositionRaj HakaniBelum ada peringkat

- 8086 Microprocessor Architecture and RegistersDokumen89 halaman8086 Microprocessor Architecture and RegistersRaj HakaniBelum ada peringkat

- Topic: Choppers: Class: 5 Sem. (EE)Dokumen89 halamanTopic: Choppers: Class: 5 Sem. (EE)ankit407Belum ada peringkat

- MOSFET Structure and Operation Explained in 40 CharactersDokumen12 halamanMOSFET Structure and Operation Explained in 40 CharactersRaj HakaniBelum ada peringkat

- CH 11Dokumen34 halamanCH 11Raj Hakani100% (1)

- 8086 ArchitectureDokumen36 halaman8086 ArchitectureVaibhav GodboleBelum ada peringkat

- Explore the 8086/8088 MicroprocessorsDokumen25 halamanExplore the 8086/8088 MicroprocessorsPrashant AngirasBelum ada peringkat

- Tracking PositionDokumen16 halamanTracking PositionRaj HakaniBelum ada peringkat

- High-Side and Low-Side SwitchesDokumen3 halamanHigh-Side and Low-Side SwitcheskheralahBelum ada peringkat

- Solis 4G Single Phase Inverter: PV Grid Tie Inverter - US VersionDokumen22 halamanSolis 4G Single Phase Inverter: PV Grid Tie Inverter - US VersionJimmy F HernandezBelum ada peringkat

- Using The Vectrex Monitor: Remove Back CoverDokumen4 halamanUsing The Vectrex Monitor: Remove Back CoverEvan HatchBelum ada peringkat

- Eaton RMU RVAC Product Presentation - 06102017Dokumen55 halamanEaton RMU RVAC Product Presentation - 06102017levanphu90-1Belum ada peringkat

- Panel de Alarmas Al8-2 DeifDokumen8 halamanPanel de Alarmas Al8-2 Deifcyrus6_998128100% (1)

- HEAG JN15 Earthing SwitchDokumen2 halamanHEAG JN15 Earthing SwitchAnonymous 2feRXsn30Belum ada peringkat

- SR320Dokumen1 halamanSR32094430s19684Belum ada peringkat

- Monitor Transformer Temperatures with PC-414R IndicatorDokumen4 halamanMonitor Transformer Temperatures with PC-414R IndicatorMKBelum ada peringkat

- Uppen FP Series FP 2400Q Service ManualDokumen47 halamanUppen FP Series FP 2400Q Service ManualemiBelum ada peringkat

- Location HD 325-6Dokumen25 halamanLocation HD 325-6gire_3pich2005Belum ada peringkat

- Form 5 Physics Chapter 4 - Teacher'sDokumen11 halamanForm 5 Physics Chapter 4 - Teacher'sPavithiran75% (4)

- MINIPhase PDFDokumen1 halamanMINIPhase PDFddBelum ada peringkat

- NEC Article 555Dokumen11 halamanNEC Article 555faneveslucas_4723330Belum ada peringkat

- Expt - No.2 (The Direct Current Motor, Part 2)Dokumen6 halamanExpt - No.2 (The Direct Current Motor, Part 2)Danwilliam NabutilBelum ada peringkat

- Sub PDH0054Dokumen9 halamanSub PDH0054Julio Molina MuñozBelum ada peringkat

- Procedure For Making ProjectDokumen24 halamanProcedure For Making ProjectAnkit BishtBelum ada peringkat

- TV & Monitor Power Devices Selection GuideDokumen120 halamanTV & Monitor Power Devices Selection Guidedisuja222Belum ada peringkat

- Instrument Transformers ExplainedDokumen4 halamanInstrument Transformers ExplainedaimizaBelum ada peringkat

- BP5151HCDokumen2 halamanBP5151HCClear PassBelum ada peringkat

- DRS2D Installation Manual (PG12)Dokumen1 halamanDRS2D Installation Manual (PG12)Rob SBelum ada peringkat

- Power Electronics BasicsDokumen7 halamanPower Electronics BasicshasmikaBelum ada peringkat

- Power Contactor 1250 A - HubbellDokumen4 halamanPower Contactor 1250 A - Hubbellmanuel99a2kBelum ada peringkat

- Meiden Singapore Site Investigation ReportDokumen9 halamanMeiden Singapore Site Investigation ReportSurendran RadhakrishnanBelum ada peringkat

- F24 60 en (A4) V1.2Dokumen2 halamanF24 60 en (A4) V1.2dozer_kamilBelum ada peringkat

- Major Faults in An Alternator and Their ProtectionDokumen13 halamanMajor Faults in An Alternator and Their Protectiongreg100% (1)

- Table of Common Electrical Wire Sizes and Amps or Fuse Ratings - ResidentialDokumen1 halamanTable of Common Electrical Wire Sizes and Amps or Fuse Ratings - ResidentialHectorBelum ada peringkat

- S.K. Electricals Provides Electrical Works & MaterialsDokumen1 halamanS.K. Electricals Provides Electrical Works & Materialsproject skelectricalsBelum ada peringkat

- Ned Mohan Power Electronics CH5 SlidesDokumen40 halamanNed Mohan Power Electronics CH5 SlidesTayyab Hussain100% (1)

- Fire Alarm Panel: FeaturesDokumen2 halamanFire Alarm Panel: FeaturesmarvinBelum ada peringkat

- FAN Impeller APW-DB824 - 4825 (Y - 2033632 - 1 - 1) - 1Dokumen8 halamanFAN Impeller APW-DB824 - 4825 (Y - 2033632 - 1 - 1) - 1Yoshi JimenezBelum ada peringkat