RAPID Kasutujuhend ENG

Diunggah oleh

structuralengineersDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

RAPID Kasutujuhend ENG

Diunggah oleh

structuralengineersHak Cipta:

Format Tersedia

RAPID

Aluminium column formwork

Edition 02/2008

Assembly instructions for standard application

Dokument 1 28.04.2005 12:48 Uhr Seite 1

Legend

Important safety Hints Visual Check Site Tips

instructions

Page

Overview 1

Introduction 2

Product features 2

Intended use 2

Safety instructions 3

Standard application

A1 Basic assembly

Cutting-to-size of the formlining 4

Formlining assembly with chamfer strip 4-5

Formlining projection 5

Sharp-edged solution 5

Assembling the formwork halves 6

Crane lifting unit 6

Push-pull props 7

A2 Safety system

Concreting platform 8

Ladder access 9

A3 Shuttering

Positioning the formwork 10

Closing the formwork 11

A4 Application

Striking, moving 12

Oversized cross-sections 13

Height adjustment up to 8.10 m 14

A5 Miscellaneous

Maintenance and Cleaning tips 15

List of materials for the access ladder 16

Components 18-21

Contents

1

4

3

2

1

5

22

23

24 25

27

21

26

11 12 13 14

A1 Overview

RAPID column

1 Column frame

2 Corner profile with column

tie bolt and locking pin

3 Formlining

4 Chamfer strip

5 Crane lifting unit

Access ladder

21 Ladder connector Rapid

22 Access ladder 180/2

23 Ladder 180/6

24 Ladder hook

25 Ladder base

26 Ladder safety cage 75

27 Ladder safety cage 150

Concreting platform (complete)

11 Concreting landing

12 Handrail 134 or 52

13 Crane hook

14 Cam nut DW 15

2

These Assembly Instructions have

been prepared in order to ensure

correct assembly and safe use.

They describe the standard application

of the PERI column formwork, RAPID,

based on H = 3.0 m.

Introduction

The cross-section for square or

rectangular-shaped columns is created

continuously using the wind mill

principle. Column frames are available

in three heights. They can be combined

with each other and height increments

of 30 cm are possible.

The access ladder with ladder safety

cage and concreting platform form the

safety system for the PERI RAPID.

It can be used for closing the column

formwork. Connections for push-pull

props and kicker braces are likewise

available in the system.

Care of the formwork is made simpler

through the attachment of the crane

lifting unit or concreting platform. Large

deposits of concrete are prevented

from forming and any residual concrete

is easily removed due to the powder

coating.

These assembly instructions contain

details regarding the intended use of

the RAPID column formwork from

PERI. Safety instructions and load

specifications must be observed at all

times.

Special permission must be given

by PERI if the formwork is to be used

for applications other than that

which it has been designed for,

together with supplementary

assembly instructions.

Product features

PERI RAPID is the column formwork

for joint-free architectural concrete

Basic assembly takes place with the

column frames in a horizontal position

and without the use of a crane. The

formlining sheets are cut to size and

are clamped from above to the column

framework by means of clamping

profiles. With extended column frames,

the formlining sheet can be fitted over

the element joint itself. Chamfer strips

are simply inserted between sheeting

and clamping profile. Creation of sharp-

edged column cross sections is also

possible.

Two column frames with the integrated

edge connections are connected using

the column tie yoke to form one

formwork half, fitted with appropriate

system parts and then placed into

position.

The intended use is presented in the

basic assembly instructions and the

application of the safety equipment.

In addition, these assembly instructions

are supplemented by information

concerning appropriate maintenance

measures

Dimensions without any unit of

measurement are to be taken as cm.

The programme overview which

follows at the end provides a detailed

look at all system components

complete with dimensions and item

numbers. If you should have any

questions, please contact your local

PERI representative.

Technical data:

Permissible fresh concrete pressure:

120 kN/m

2

Formlining:

21 mm for chamfered columns

30 mm for sharp edged columns

Column frame made of aluminium

Column cross-sections:

square or rectangular-shaped

up to 60 x 60 cm

Sharp-edged columns:

up to 58 x 58 cm

Over-sized cross-sections from

85 x 85 to 130 x 130 cm

Powder-coated column frame:

H = 3.0 m, 2.10 m, 0.60 m

Intended use

Basically, only materials in perfect

condition may be used. Damaged

components must be replaced.

All valid laws and safety regulations

must be observed when using our

products.

This product is intended for commercial

use only.

These assembly instructions as well

as PERI offer and implementation

plans do not replace specific

construction site work and assembly

instructions.

Dokument 1 28.04.2005 12:48 Uhr Seite 1

3

Care instructions for the formlinig

Concrete immersion vibrator with

rubber cap minimizes possible damage

to the formlining.

Spacers for the reinforcement with

large support area minimizes

indentations and markings.

Other regulations

In particular, this currently includes:

Operational Safety Regulations

(BetrSichV)

Technical Regulations for Operational

Safety (TRBS)

Additional

PERI product information

PERI formwork technology design

tables

PERI RAPID brochure

Safety instructions

These assembly instructions are

intended for those persons who work

with PERI RAPID column formwork.

Non-observance of assembly

guidelines and safety instructions can

lead to accidents and damage to

materials.

Responsibilities of the user:

1. The user must ensure that all

required instructions are at the

operators disposal (including the

official assembly instructions).

2. All persons working with the

product must be familiar with the

content of these instructions and

safety information.

3. The user must ensure that all

operators have a full and complete

understanding of these instructions

and safety information.

4. The user must ensure that

assembly, adjusting and

dismantling work carried out, as

well as correct use of the product,

is supervised by trained and

authorised personnel.

5. The user is obliged to provide all

requirements to ensure

compliance with all applicable

safety regulations.

Safety information

1. All RAPID components are to be

checked before every use to make

sure they are in perfect working

condition!

Damaged parts are to be

replaced by PERI original

components!

2. All loads arising during the intended

use must not be exceeded!

3. All load effects on the RAPID

formwork must be safely

transferred!

4. Stability must be guaranteed

throughout all building phases!

5. Never remove any safety

equipment!

6. Safe access ways must be

provided for site personnel to reach

all working areas!

7. Working areas must have suitable

safety barriers to prevent site

personnel falling to the ground!

8. All openings must be fitted with

safety barriers!

9. Avoid using in areas of risk during

unfavourable weather conditions!

10. Striking is only to take place when

the concrete is hard enough and

site management has given the

go-ahead!

11. Striking or moving are to be carried

out using suitable tools and

equipment! Do not tear away

formwork elements from the

concrete with the crane!

12. Remove all non-captive

components!

13. Equipment should not be used

in strong winds!

14. Remove lifting accessories from a

lowered formwork component or

unit only when it is in a stable

condition!

4

A1 Basic assembly

Formlining assembly with chamfer

strip

Cutting-to-size of the formlining

Plywood sheet: 21 mm

Horizontal formwork joints must be

arranged on the lateral struts of the

frames.

Width of plywood

Example:

Column width 55 cm 550 mm

- reduction in size 8 mm

Cutting width of formlining 542 mm

Fig.1

Fig. 1

Fig. 2b

1. Place column frames on assembly

trestles. Fig.2a

Column width - 8 mm

SW 30

Fig. 2a

Fig. 2c

3. Mount plywood sheet and insert in the

guide. Fig.2c

2. Bolt column frames together according

to the required length (SW 30). Fig.2b

5

Sharp-edged solution

Max. cross-section dimensions

580 x 580 mm.

For forming without chamfer strips,

a 30 mm thick plywood sheet is

required which has been milled

accordingly. Fig.6

Width of plywood sheet

Example:

Column width 550 mm

+ increase in size 12 mm

Cutting width of formlining 562 mm

It is held in position with the clamping

profile and guide. Fig.6a

Secure plywood sheet against slipping.

A1 Basic assembly

Formlining assembly with chamfer

strip

4. Position chamfer strip next to the

plywood sheet. Fig.3

5. Push clamping profile over chamfer

strip. Fig.3a

6. Tighten by means of G-clamps. Fig.4

7. Clamp in position the plywood sheet

and chamfer strip with clamping profile.

(SW 17 socket wrench)

8. Remove G-clamps.

9. Nail plywood sheet to prevent slipping.

Use drilled holes in the guide. Fig.3a

Install plywood sheets in additional

column frames in the same way.

Fig. 3a

Formlining projection

below approx. 40 mm

above max. 200 mm with crane lifting

unit Fig.5

Fig. 3

Fig. 4

m

a

x

.

4

0

m

a

x

.

2

0

0

Fig. 5

3

0

8 8

8

6

5

Fig. 6a

Fig. 6

Dimensions in mm

Column width + 12 mm

6

A1 Basic assembly

Assembling the formwork halves

1. Place second pre-assembled column

frame on first column frame. Fig.7

2. Insert column tie yokes through the

corner connection.

3. Peg out using the locking pin in the

perforated profile.

4. Tighten with nut. Fig.7a

5. Assemble second formwork half in the

same way.

Fig. 7

Fig. 7a

Crane lifting unit

One crane lifting unit per column frame,

however not with the concreting

platform.

(The crane lifting unit is already attached

here to the concreting platform).

1. Loosen bolt, SW 30, in the column

frame.

2. Position crane lifting unit on the frame

and secure with the bolt, SW 30.

Fig.8 + 8a

Fig. 8

Fig. 8a

SW 30

7

A1 Basic assembly

Push-pull props

Mount 3 push-pull props to ensure

stability!

Mount three brace connectors on one

formwork half. Fig.9

1. Pull out locking pins.

2. Fasten brace connector to perforated

profile.

3. Insert brace connector in the perforated

profile and peg out with locking pins.

Fig.9a

4. Fix push-pull prop and kicker brace

with bolts and cotter pins. Fig.10

Fig. 9

Fig. 9a

Fig. 10

8

a

b

c

SW 30

A2 Safety system

Concreting platform

The concreting platform is assembled

on horizontally-positioned column

halves lying on the ground

1. Remove cam nut of the crane eye.

2. Remove bolt (SW 30) in the column

element.

3. Position platform by hand on its edge

directly against the formwork half.

4. Insert locking pin of the crane eye

through the hole a of the column

element and screw on cam nut.

5. Same procedure using hole b.

6. Align telescopic beam with hole c and

mount third crane eye. Fig.11

7. Install guardrails. Fig.12

Fig. 11

Fig. 12

9

SW 19

SW 19

Ladder access

The access ladder is assembled on

horizontally-positioned column halves

lying on the ground.

1. Place ladder connection on frame and

peg out in the perforated profile with

bolts. Fig.13

2. Pre-assemble ladder:

connect access ladder 180/2 with

ladder 180/6, SW 19. Depending on

the height required, attach additional

ladders 180/6.

mount ladder base and ladder hook on

bottom ladder, SW 19. Fig.14

3. Attach the pre-assembled ladder with

the clamping plates to the ladder

connections, SW 19.

4. Mount ladder safety cage 150 or 75

with clamping plates according to plan.

Clear spacing between the ladder

safety cage elements 30 cm.

Visual check of the clamping plates.

The contact surface must lie against

the ladder profile.

5. For high columns:

Likewise install an access ladder for

closing the formwork in the opposite

formwork half.

A2 Safety system

Fig. 13

Fig. 14

Fig. 15

10

A3 Shuttering

Positioning the formwork

Always erect the formwork half with

the concreting platform first.

Locating boards make it easier to align

the formwork.

Formwork halves with concreting

platform (placing formwork)

1. Attach 3-sling lifting gear to crane eyes,

lift formwork to a vertical position and

transport to place of use.

Fig.16

2. Position formwork halves against

locating boards. Fig.17

3. Fix base plates of push-pull props and

kicker braces to load-bearing

foundations/slab, e.g. with PERI Multi

Monti. Fig.18

4. Check stability and make any

necessary adjustments.

5. Remove crane lifting gear.

The first formwork half is now in

position.

Fig. 16

Fig. 17

Fig. 18

11

A3 Shuttering

Positioning the formwork

6. Attach lifting unit to crane eyes, lift

2nd formwork halve to a vertical

position and transport to place of use.

7. Position this formwork half against

locating boards. Fig.19

Closing the formwork

Use a second access ladder for higher

columns.

When closing the formwork, start at

the bottom and work upwards.

1. Insert column tie yoke through the

corner connection.

2. Peg out in the perforated profile with

locking pins.

3. Tighten with nut. Fig.20

4. Remove crane lifting gear.

The formwork is now in position.

Fig. 19

Fig. 20

12

A4 Application

Striking, moving

Push-pull props, concreting platform

and access ladder remain attached.

Formwork is opened from top to

bottom.

The corner connections remain

attached to the column frames (no

individual components).

Formwork halves without push-pull

props

1. Attach crane lifting gear to the non-

supported formwork half and tension.

2. Separate corner connections between

the formwork halves: pull locking pins

and pull back column tie yokes.

Fig.21

Use second access ladder.

3. Place formwork half on ground for

cleaning.

Formwork halves with push-pull

props

1. Connect lifting gear to crane eyes of

the concreting platform.

2. Remove base plates of push-pull props

and kicker braces from ground.

3. Place formwork half on ground for

cleaning and secure.

Fig.21

Fig. 21

13

A4 Application

Oversized cross-sections

Cross-sections from 85 x 85 cm to

130 x 130 cm

For oversized cross-sections, a

maximum of two column frames

(length and width) are connected with

each other. Connections are carried

out using the TRIO BFD alignment

coupler.

1. For bracing, mount walers to every

perforated profile with column tie yokes

and locking pins.

2. Insert anchor ties in the centre at the

same height as the walers.

Example Fig.22

Fig. 22

No. of pieces for each height

SRZ 120 U100

Height BFD alignment coupler steel waler

Column Frame 300 5 4

Column Frame 210 4 3

Column Frame 60 1 1

14

A4 Application

Height adjustment up to 8.10 m

With three frame heights, height

adjustments are possible in 30 cm

increments.

Combination examples: Fig.21

The column frames are connected

using M20 x 50 bolts (SW 30).

Each RAPID frame is equipped with

these bolts Fig. 2b.

Larger heights are possible.

Height Column Frame

[m] 300 210 60

2.10 - 1 -

2.70 1 1

3.00 1 - -

3.30 - 1 2

3.60 1 - 1

3.90 - 1 3

4.20 - 2 -

4.50 - 1 4

4.80 - 2 1

5.10 1 1 -

5.40 - 2 2

5.70 1 1 1

6.00 2 - -

6.30 1 1 2

6.60 2 - 1

6.90 1 1 3

7.20 2 - 2

7.50 1 1 4

7.80 2 - 3

8.10 2 1 -

15

A5 Miscellaneous

Maintenance tips

What needs to be done?

1. Spray formwork on all sides before first use with

a release agent e.g. PERI BIO Clean.

2. Spray formlining every time after striking with PERI

Bio Clean, then clean.

3. For longer storage periods, e.g. bad weather, store

formwork materials in clean condition and sprayed.

4. Spray (grease if necessary) all moving parts

regularly with a release agent.

5. Transport elements with suitable as well as safe

transportation and lifting gear.

6. Ensure elements and accessories are properly

stored.

7. Do not throw or drop accessories.

8. Never use unnecessary force during assembly

and dismantling.

Cleaning tips

Ensure elements are in a secure position during

cleaning!

Cleaning of elements still attached to the crane

is not allowed!

Remove concrete surplus!

1. Immediately after concreting, spray the rear side

of the formwork with water.

2. After striking has taken place, spray formwork all

over with PERI Bio Clean.

3. Remove nails, battens etc. from the plywood

before any mechanical cleaning.

4. Mechanically clean the elements using suitable

equipment e.g. scraper.

5. Brush clean the elements after mechanical

cleaning. Remove dust and loosened concrete

surplus.

6. After shuttering, element may require spraying

again.

Why?

Provides good protection against sticking and

corrosion before first dirt accumulation.

Helps to remove concrete surplus and makes cleaning

easier. Removing by force or scraping off is not

necessary. Formlining and coating remain intact.

The frame is protected against corrosion and

weathering.

Removes rust, prevents corrosion and keeps parts

in good working order.

Avoids damage through improper transportation.

Prevents damage to the element frame and

accessories. Damage to the formlining through

indentations is avoided.

Maintains the functionality of the parts.

Maintains the functionality of the parts.

Concrete has not yet hardened and can easily be

removed. This reduces the amount of cleaning

required.

Penetrates the concrete surplus, breaks it up and

makes subsequent mechanical cleaning much easier.

Unnecessary enlargement of nail holes and damage

to the formlining is avoided. No damage to cleaning

equipment.

Formlining surface is clean for the next use.

16

A5 Miscellaneous

List of materials for the access

ladder

For higher columns, mount two

access ladders!

Ladder access A:

with access to the concreting platform

Ladder access B:

without access to the concreting

platform, only for connecting the two

formwork halves

For heights of 7.80 m and more, we

recommend the use of two concreting

platforms

Ladder access B Ladder access A

Item no. Description A* B* A* B* A* B* A* B* A* B* A* B*

037400 Concreting Platform, complete 1 0 1 0 1 0 1 0 1 0 1 0

051410 Ladder 180/6 2 2 2 2 3 3 4 4 5 5 6 6

103724 Access Ladder 180/2 1 0 1 0 1 0 1 0 1 0 1 0

051450 Ladder Safety Cage 150 0 0 1 1 2 2 3 3 4 4 5 5

104132 Ladder Safety Cage 75 1 1 1 0 2 1 2 1 2 1 2 1

051460 Ladder Base 1 1 1 1 1 1 1 1 1 1 1 1

103718 Ladder Hook 2 2 2 2 2 2 2 2 2 2 2 2

103369 Ladder Connector RAPID 2 2 2 2 3 3 4 4 5 5 6 6

2.70 3.90 4.50 6.00 7.80 9.60

3.60 m 4.20 m 5.70 m 7.50 m 9.30 m 10.80 m

A*= ladder access A

B* =ladder access B

Dokument 1 23.11.2006 14:06 Uhr Seite 2

290

2

0

5

1

6

5

2

0

16

20

2

0

35

15

1

5

5

4

794

6

0

0

3

0

0

654

1

2

0

19x30=570 25

60 80

2

3

21

800

2

4

3

500

64

794

2

1

0

0

2

5

0

8

0

0

8

0

0

2

5

0

2

5

0

1

0

0

0

794

3

0

0

0

1

0

0

0

5

0

0

2

5

0

18

Column Frames RAPID, Alu

For column cross section up to 600x600mm.

Complete with:

Clamping Profile, Column Tie Yoke DW15,

Spherical Nut DW15, galv., Locking Pin

20x205, galv., and Hex. Bolt ISO 4017

M20x50-8.8, galv. with Hex. Nut

ISO 7042 M20-8, galv. (2x).

Column Frame 300 59,90 037250

Column Frame 210 42,70 037260

Column Frame 60 14,30 037270

Chamfer Strip RAPID L = 3,00m 0,32 037210

For clamping plywood to the Column

Frames RAPID.

Brace Connector-3 RAPID, galv. 3,05 037190

For fixing Push-Pull Props and

Kicker Braces to the Column Frames RAPID.

Complete with:

Locking Pin 20x205, galv. (1x)

Pin 16x42, (1x), and Cotter Pin 4/1 (2x).

Weight kg Item no.

20x205

FS 4/1

16x42

FS 4/1

DW15

M20x50

106

6

8

125

1

2

0

2

0

5

2

0

2

0

34

290

2

8

21

4

2

250

1

0

0

119

400 118

400 118

500

798

18

22

1

7

8

2

3

0

1

9

5

5

0

2

6

0

661

469

SW 19

19

Crane Lifting Unit-2 RAPID 14,00 037320

4 for a fully assembled column form.

Only 2 needed when a concreting platform

is used.

Load-bearing point

Permissible load: 500kg

Column Tie Yoke DW15 0,60 037150

For tying RAPID Column Frames.

Comes with the RAPID Column Frames.

For Column Frame 300 (4x), 210 (3x), 60 (1x)

Permissible Load to DIN 18216: 90kN

Locking Pin 20x205, galv. 0,74 037160

For tying RAPID Column Frames.

Comes with the RAPID Column Frames.

For Column Frame 300 (4x), 210 (3x), 60 (1x)

Complete with:

Cotter Pin 4/1 (1x)

Spherical Nut DW 15, galv. 0,49 030440

For tying RAPID Column Frames.

Comes with the RAPID Column Frames.

For Column Frame 300 (4x), 210 (3x), 60 (1x)

Permissible Load to DIN 18216: 90kN

Ladder connector RAPID, galv. 6,58 103369

For connecting ladders to RAPID

column frames.

Complete with:

Hex. Bolt ISO 4017 M12x25-8.8, galv. (2x) and

Clamping plate (2x)

Weight kg Item no.

SW 27

DW15

FS 4/1

D

W

1

5

20 405 40

2

0

1

3

0

50

1

3

0

2

0 13

1

8

1

0

2

5

2

2

0

1

5

5

1

9

6

0

5

x

2

9

8

=

1

4

9

0

9

5

400 25

405

2

5

1

0

0

2

1

0

50

5

3

1

3

0

4

0

13

8

0

8

0

50

400

534

1

8

8

5

1

2

0

0

2

2

0

1

6

8

2

9

8

405

120

3

2

0

355

50

5

0

325

294

7

1

0

4

5

0

7

5

0

(

1

5

0

0

)

79

25

20

20

Weight kg Item no.

Ladder 180/6, galv. 13,10 051410

Access Ladder 180/2, galv. 11,10 103724

Complete with:

Hex. Bolts ISO 4017 M12x40-8.8, galv. and

Hex. Nut ISO 7042 M12-8, galv. (4x)

Accessories:

Formwork chain 3kN, 2,5m 1,37 065073

Ladder Hook, galv. 0,68 103718

Only for the lower ladder (2x)

Complete with:

Hex. Bolt ISO 4017 M12x25-8.8, galv. and

Hex. Nut ISO 7042 M12-8, galv. (2x)

Ladder Base 2,36 051460

For preventing the ladders sliding.

Ladder Safety Cage 75, galv. 15,50 104132

Ladder Safety Cage 150, galv. 25,20 051450

Complete with:

Hex. Bolt ISO 4017 M12x25-8.8, galv. (4x),

Clamping plate (4x)

SW 19

Eyes for security chain

SW 19

840

5

2

0

1340

1

0

0

5

1

0

0

525

7

4

137 60

2

2

5

1

5

0 19

70

1524

1420

1340

525

40

1

5

2

4

500

5

2

5

7

1

0

4

0

20

14

1

3

0

5

38

50

1

1

0

130

21

Concreting Platform, complete 126,00 037400

Used for TRIO, RAPID and QUATTRO columns.

Consisting of:

Concreting Landing (1x)

Handrail 52 galv. (2x)

Handrail 134 galv. (2x)

Crane Hook Concreting Platform (3x)

Concreting Landing, Alu 51,50 037410

Powder-coated

Suitable for any cross section up to a

maximum of 600x600mm. It is mounted

with the Crane Hook Concreting Platform.

Permissible Load: 150kg/m

2

Handrail 52, galv. 10,50 037420

Handrail 134, galv. 18,10 037430

2 of each per concreting platform.

Locks in place automatically.

Crane Hook Concreting Platform 5,70 037440

3 per concreting platform.

Complete with: Captive Fixing Pin

and Cam Nut DW15, galv.

Load-bearing point

Permissible load: 1000kg

Weight kg Item no.

adjustable

620

DW15

Eyes for security chain

22

02

PERI S.A.S.

Zone Industrielle Nord

34-36 rue des Frres Lumire

77109 Meaux Cedex

peri.sas@peri.fr

www.peri.fr

03

PERI AG

Aspstrae 17

8472 Ohringen

info@peri.ch

www.peri.ch

04

PERI S.A. Sociedad

Unipersonal

Ctra. Paracuellos -

Fuente el Saz km. 18,9

Camino de Malatones, km. 0,5

28110 Algete/Madrid

info@peri.es

www.peri.es

05

N.V. PERI S.A.

Industriepark

Nijverheidsstraat 6 PB 54

1840 Londerzeel

info@peri.be

www.peri.be

06

PERI B.V.

v. Leeuwenhoekweg 23

Postbus 304

5480 AH-Schijndel

info@peri.nl

www.peri.nl

07

PERI Formwork Systems, Inc.

7135 Dorsey Run Road

Elkridge, MD 21075

info@peri-usa.com

www.peri-usa.com

08

PT Beton Perkasa Wijaksana

P.O. Box 3737

Jakarta 10210

bpw@betonperkasa.com

www.peri.de

09

PERI S.p.A.

Via G. Pascoli, 4

20060 Basiano (MI)

info@peri.it

www.peri.it

10

PERI Japan K.K.

7F Hakozaki 314 Building,

31-4 Hakozaki-cho,

Nihonbashi Chuo-ku

Tokyo 103-0015

info@perijapan.jp

www.perijapan.jp

11

PERI Ltd.

Market Harborough Road

Clifton upon Dunsmore

Rugby, CV23 0AN

info@peri.ltd.uk

www.peri.ltd.uk

12

PERI Kalp ve skeleleri

San. ve Tic. Ltd. Sti.

akmakl Mahallesi

Akaburgaz Cad.

72. Sokak No: 23

Kra - Bykekmece/

Istanbul 34500

info@peri.com.tr

www.peri.com.tr

13

PERI Kft.

Zdor u. 4.

1181 Budapest

info@peri.hu

www.peri.hu

14

PERI Formwork Malaysia

Sdn. Bhd.

Unit 19-07-4, Level 7

PNB Damansara

19 Lorong Dungun

Damansara Heights

50490 Kuala Lumpur

info@perimalaysia.com

www.perimalaysia.com

15

PERI ASIA Pte. Ltd

Formwork Pte. Ltd.

No. 1 Sims Lane # 06-10

Singapore 387355

pha@periasia.com

www.periasia.com

16

PERI Ges.mbH

Traisenstrae 3

3134 Nudorf ob der Traisen

ofce@peri.at

www.peri.at

17

PERI spol. s r.o.

Prmyslov 392

252 42 Jesenice

info@peri.cz

www.peri.cz

18

PERI Danmark A/S

forskalling og stillads

Greve Main 26

2670 Greve

peri@peri.dk

www.peri.dk

19

PERI Suomi Ltd. Oy

Hakakalliontie 5

05460 Hyvink

info@perisuomi.

www.perisuomi.

20

PERI NORGE AS

Kobbervikdalen 156

3036 Drammen

info@peri.no

www.peri.no

21

PERI Polska Sp. z o.o.

ul. Stoeczna 62

05-860 Pochocin

info@peri.pl.pl

www.peri.pl.pl

22

PERIform SVERIGE AB

Montrgatan 4-6

Box 9073

30013 Halmstad

peri@periform.se

www.periform.se

23

PERI (Korea) Ltd.

8-9th Fl., Yuseong Bldg.

830-67, Yeoksam-dong,

Kangnam-ku,

Seoul 135-080

info@perikorea.com

www.perikorea.com

24

PERIcofragens Lda.

Cofragens e Andaimes

Rua Cesrio Verde,

n 5 - 3 Esq.

Linda-a-Pastora

2790-326 Queijas

info@peri.pt

www.peri.pt

25

PERI S.A.

Ruta Nacional N. 9, km 47,5

(Panamericana Ramal Escobar)

(1625) Escobar/Prov. Bs. As.

info@peri.com.ar

www.peri.com.ar

26

PERI Formas e

Escoramentos Ltda.

Rodovia Raposo Tavares,

km 41

Colinas Bandeirante

CEP 06730-000

Vargem Grande Paulista

So Paulo

info@peribrasil.com.br

www.peribrasil.com.br

27

PERI Chile Ltda.

C/Jos de San Martin N 104

Parque Industrial Los

Libertadores

Colina, Santiago de Chile

perich@peri.cl

www.peri.cl

28

PERI Romnia SRL

Calea Bucureti nr. 2B

077015 Baloteti - ILFOV

info@peri.ro

www.peri.ro

29

PERI SLOWENIEN

Goran Opalic

Obrena 137

2000 Maribor

peri.slo@triera.net

www.peri.de

30

PERI spol. s r.o.

amornska 18

903 01 Senec

info@peri.sk

www.peri.sk

31

PERI Australia Pty. Ltd.

116 Glendenning Road

Glendenning NSW 2761

info@periaus.com.au

www.periaus.com.au

32

PERI AS

Valdme 8

Tnassilma Tehnopark

76401 Saku vald

Harjumaa

peri@peri.ee

www.peri.ee

2

1

3

4

5

6

9

11

12

13

16

17

18

19

20

22

21

24

28

29

30

32

33

34

38

41

42

46

48

52

53

01 PERI GmbH

Rudolf-Diesel-Strasse

89264 Weissenhorn

info

@

peri.de

www.peri.de

France

Switzerland

Spain

Belgium/Luxembourg

Netherlands

USA

Indonesia

Italy

Japan

United Kingdom/Ireland

Turkey

Hungary

Malaysia

Singapore

Austria

Czech Republic

Denmark

Finland

Norway

Poland

Sweden

Korea

Portugal

Argentina

Brazil

Chile

Romania

Slovania

Slovakia

Australia

Estonia

PERI International

23

33

PERI Hellas Ltd.

Sokratous Str.

5th kil. Koropi-Varis Ave.

P. O. Box 407

194 00 Koropi

info@perihellas.gr

www.perihellas.gr

34

PERI SIA

Granita 26

1057 Riga

info@peri-latvija.lv

www.peri-latvija.lv

35

PERI (L.L.C.)

Brashy Building,

Ofce No. 212

Shk. Zayed Road

P.O. Box 27933

Dubai

perillc@perime.com

www.perime.com

36

PERI Formwork Systems, Inc.

45 Nixon Road

Bolton, Ontario

L7E 1K1

info@peri.ca

www.peri.ca

37

PERI GmbH

Lebanon Representative

Ofce

AYA Commercial Center,

7th oor,

Dora Highway,

Beirut

P.O. Box 90 416 Jdeidet

lebanon@peri.de

www.peri.de

38

PERI UAB

Titnago st. 19

02300 Vilnius

info@peri.lt

www.peri.lt

39

PERI S.A.

Route de Rabat, km. 5

Piste de Beni Touzine

Tanger

peri25@menara.ma

www.peri.de

40

PERI Formwork

Engineering Ltd

16 Moshe Dayan st.,

P.O. Box 10202

Petach Tikva,

49002 Israel

info@peri.co.il

www.peri.co.il

41

PERI BULGARIA EOOD

Kv. Vragdebna

m. Nova Machala Nr. 46

1839 Soa

peri.bulgaria@peri.bg

www.peri.bg

42

MEST ltd.,

Fornubudum 5

220 Hafnarfjordur

mest@mest.is

www.mest.is

43

TOO PERI Kazakhstan

Rubenstein Street 10

(Corner Dostyk Str. 7)

050010 Almaty

peri@peri.kz

www.peri.kz

44

OOO PERI

8 Etage, OOO PERI Buro

Krasnaya Presnya Str. 24

123022 Moskau

moscow@peri.ru

www.peri.ru

45

PERI Wiehahn (Pty.) Ltd.

P.O. Box 2668

Bellville 7535

ask@wiehahn.co.za

www.periwiehahn.co.za

46

TOW PERI Ukraina

23, M. Raskowa Str., B. 822

02002 Kiew

peri@peri.ua

www.peri.ua

47

PERI GmbH

Egypt Branch Ofce

24 A, Obour Gardens,

4th Floor, apt. # 1

Salah Salem Street

11361 Heliopolis

Cairo

info@peri.com.eg

www.peri.com.eg

48

PERI Oplate d.o.o.

Jurija Gagarina 81

11070 Novi Beograd

ofce@peri.co.yu

www.peri.co.yu

49

PERI Cimbras y Andamios,

S.A. de C.V.

Parque de las Amricas

KM 3.5 de la Carretera

Jorobas - Tula

Huehuetoca

Estado de Mxico,

C.P. 54680

info@peri.com.mx

www.peri.com.mx

50

PERI Kalp ve skeleleri

Baku Branch Ofce

28 May K. Ev 72 Menzil 27

Baku

peribaku@peri.com.tr

www.peri.com.tr

51

PERI Kalp ve skeleleri

Agabat Branch Ofce

Groglu Sokak No. 130, Kat 2

744035 Agabat

periashgabat@peri.com.tr

www.peri.com.tr

52

PERI Belarus

Pr. Nesawisimosti 11

Kopus-2 Zimmer: 526,528

220030 Minsk

peri@mail.belpak.by

www.peri.com.tr

53

PERI oplate i skele d.o.o.

Dolenica 20

10 250 Donji Stupnik/

Zagreb

info@peri.com.hr

www.peri.com.hr

54

PERI GmbH

Iran Branch Ofce

Flat 27, Blvd. KAVE,

Building No. 246

P.O. Box 9 3979 3669

Tehran

iran@peri.ir

www.peri.ir

55

PERI (India) Pvt Ltd

717 Palm Springs

Palm Court

Malad Link Road

Malad (West)

Mumbai 400064

info@peri.in

www.peri.in

56

PERI Jordan

Saad 5 Center, 4th Floor

Ofce No. 404

Al Madineh

Al Munawara Street

P.O. Box 367

11947 Amman

jordan@peri.de

www.peri.de

57

PERI Kuwait

Arraya Center, 29th Floor

Al-Shuhada Street, Sharq

P.O. Box 1060 Safat

13011 Kuwait

kuwait@peri.de

www.peri.de

58

PERI Saudi Arabia

33 AL-Batraa Street

AL -Shurbatiy Building

AL - Bughdadiah AL -

Gharbiah Distrect

6th Floor, Flat # 61

P.O. Box 11641

Jeddah

saudi-arabia@peri.de

www.peri.de

59

PERI Qatar LLC

P.O. Box 24133

Doha

qatar@peri.de

www.peri.de

60

Socit PERI S.A.S.

Bureau de liaison dAlger

50 bis, Route de Gu

de Constantine

Hai El Badr (ex Apreval)

Immeuble FADLI

Kouba - Alger

peri.sas@peri.fr

www.peri.fr

7

8

10

14

15

23

25

26

27

31

35

36

37

39

40

43

44

45

47

49

50

51

54

59

55 58

57

60

56

Greece

Latvia

United Arab Emirates

Canada

Libanon

Lithuania

Marocco

Israel

Bulgaria

Iceland

Kazakhstan

Russian Federation

South Africa

Ukraine

Egypt

Serbia

Mexico

Azerbaijan

Turkmenistan

Belorussia

Croatia

Iran

India

Jordan

Kuwait

Saudi Arabia

Qatar

Algeria

D

e

0

2

/

2

0

0

8

3

m

a

A

r

t

.

N

r

.

:

7

9

2

2

1

6

C

o

p

y

r

i

g

h

t

b

y

P

E

R

I

G

m

b

H

Wall Formwork

Panel Formwork

Girder Formwork

Circular Formwork

Facade Formwork

Brace Frame

Column Formwork

Square

Rectangular

Circular

Slab Formwork

Panel Formwork

Beam Grid Formwork

Girder Formwork

Slab Table

Beam Formwork

Shoring Systems

Steel Slab Props

Aluminium Slab Props

Tower Systems

Heavy-Duty Props

Climbing Systems

Climbing Scaffold

Self-Climbing System

Climbing Protection Panel

Platform Systems

Scaffold, Stairways,

Working Platforms

Facade Scaffold

Working Platform

Weather Protection Roof

Stairway Access

Bridge and Tunnel

Formwork

Cantilevered Parapet Carriage

Cantilevered Parapet Platform

Engineers Construction Kit

Services

Formwork Assembly

Cleaning / Repairs

Formwork Planning

Software

Statics

Special Constructions

Additional Systems

Plywood

Formwork Girders

Stopend Systems

Pallets

Transportation Containers

PERI GmbH

Formwork Scaffolding Engineering

P.O. Box 1264

89259 Weissenhorn

Germany

Tel +49 (0)73 09.9 50- 0

Fax +49 (0)73 09.9 51- 0

info@peri.de

www.peri.de

PERI Product Range

Anda mungkin juga menyukai

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- Bs4320 PDFDokumen20 halamanBs4320 PDFstructuralengineers100% (1)

- Bs4190 PDFDokumen43 halamanBs4190 PDFstructuralengineersBelum ada peringkat

- The Essence of Success - Earl NightingaleDokumen2 halamanThe Essence of Success - Earl NightingaleDegrace Ns40% (15)

- Article. 415 - 422Dokumen142 halamanArticle. 415 - 422Anisah AquilaBelum ada peringkat

- Brigde Loading 07-08Dokumen72 halamanBrigde Loading 07-08Em Mar100% (1)

- Hollow Sections Book WardenierDokumen199 halamanHollow Sections Book WardenierANUSSBAUMER100% (3)

- Bs3692 PDFDokumen62 halamanBs3692 PDFstructuralengineers100% (1)

- Nikon D750 Camera InstructionsDokumen9 halamanNikon D750 Camera InstructionsstructuralengineersBelum ada peringkat

- Anchor Design ManualDokumen392 halamanAnchor Design ManualveselinBelum ada peringkat

- BS 5400-4 PDFDokumen65 halamanBS 5400-4 PDFstructuralengineers86% (7)

- Nikon D750 User Manual PDFDokumen537 halamanNikon D750 User Manual PDFEdwin WillemsBelum ada peringkat

- Bs4604 2 PDFDokumen17 halamanBs4604 2 PDFstructuralengineersBelum ada peringkat

- Hindustan Coca ColaDokumen63 halamanHindustan Coca ColaAksMastBelum ada peringkat

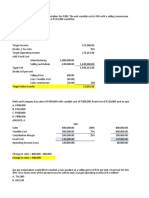

- CVP Solution (Quiz)Dokumen9 halamanCVP Solution (Quiz)Angela Miles DizonBelum ada peringkat

- Bs4570 PDFDokumen34 halamanBs4570 PDFstructuralengineersBelum ada peringkat

- Bs4395 1 PDFDokumen36 halamanBs4395 1 PDFstructuralengineersBelum ada peringkat

- Domestic Water Consumption in ChennaiDokumen18 halamanDomestic Water Consumption in Chennaimaaz0% (1)

- CIDECT Design Guide 9Dokumen213 halamanCIDECT Design Guide 9paris06250% (2)

- VSP-12Way - Is Rev.03Dokumen55 halamanVSP-12Way - Is Rev.03Marcelo AlmeidaBelum ada peringkat

- 6066Dokumen19 halaman6066Palani KumarBelum ada peringkat

- 1498 (Classification & Identification of Soil For Generel Engineering Purpose)Dokumen28 halaman1498 (Classification & Identification of Soil For Generel Engineering Purpose)Kumud PriyadarshiBelum ada peringkat

- Bs4604 3 PDFDokumen16 halamanBs4604 3 PDFstructuralengineers100% (1)

- Hot Weather ConcretingDokumen1 halamanHot Weather ConcretingstructuralengineersBelum ada peringkat

- Bs4395 2 PDFDokumen36 halamanBs4395 2 PDFstructuralengineersBelum ada peringkat

- Rat Trap BrickDokumen1 halamanRat Trap BrickstructuralengineersBelum ada peringkat

- 224 2R-92 PDFDokumen12 halaman224 2R-92 PDFfarhadamBelum ada peringkat

- Eurocode Concrete StructuralDokumen26 halamanEurocode Concrete StructuralstructuralengineersBelum ada peringkat

- Bs4395 3 PDFDokumen23 halamanBs4395 3 PDFstructuralengineersBelum ada peringkat

- Bs1449 1 PDFDokumen39 halamanBs1449 1 PDFstructuralengineersBelum ada peringkat

- BS 8110 - 1 PDFDokumen142 halamanBS 8110 - 1 PDFstructuralengineersBelum ada peringkat

- bs3923p1 PDFDokumen94 halamanbs3923p1 PDFstructuralengineersBelum ada peringkat

- Bsen10155 PDFDokumen26 halamanBsen10155 PDFstructuralengineersBelum ada peringkat

- Tall BuildingDokumen289 halamanTall BuildingLuis Mendoza67% (6)

- BS Detailing Manual PDFDokumen120 halamanBS Detailing Manual PDFstructuralengineers100% (5)

- The Rules For Being Amazing PDFDokumen1 halamanThe Rules For Being Amazing PDFAkshay PrasathBelum ada peringkat

- Organization Structure GuideDokumen6 halamanOrganization Structure GuideJobeth BedayoBelum ada peringkat

- Philippines Taxation Scope and ReformsDokumen4 halamanPhilippines Taxation Scope and ReformsAngie Olpos Boreros BaritugoBelum ada peringkat

- ДСТУ EN ISO 2400-2016 - Калибровочный блок V1Dokumen11 halamanДСТУ EN ISO 2400-2016 - Калибровочный блок V1Игорь ВадешкинBelum ada peringkat

- Data SheetDokumen14 halamanData SheetAnonymous R8ZXABkBelum ada peringkat

- ApudDokumen53 halamanApudlatifahBelum ada peringkat

- HSPA+ Compressed ModeDokumen10 halamanHSPA+ Compressed ModeAkhtar KhanBelum ada peringkat

- Warranty Information Emea and CisDokumen84 halamanWarranty Information Emea and CisHenriques BrunoBelum ada peringkat

- Capran+980 CM en PDFDokumen1 halamanCapran+980 CM en PDFtino taufiqul hafizhBelum ada peringkat

- Sampling Fundamentals ModifiedDokumen45 halamanSampling Fundamentals ModifiedArjun KhoslaBelum ada peringkat

- 63db2cf62042802 Budget Eco SurveyDokumen125 halaman63db2cf62042802 Budget Eco SurveyNehaBelum ada peringkat

- Ridge Regression: A Concise GuideDokumen132 halamanRidge Regression: A Concise GuideprinceBelum ada peringkat

- Courier - Capstone WebApp - Round 3 ReportDokumen23 halamanCourier - Capstone WebApp - Round 3 Reportmarmounette26Belum ada peringkat

- JRC Wind Energy Status Report 2016 EditionDokumen62 halamanJRC Wind Energy Status Report 2016 EditionByambaa BattulgaBelum ada peringkat

- Safety of High-Rise BuildingsDokumen14 halamanSafety of High-Rise BuildingsHananeel Sandhi100% (2)

- CaseHistoriesOnTheApplication of Vacuum PreloadingDokumen25 halamanCaseHistoriesOnTheApplication of Vacuum PreloadingvaishnaviBelum ada peringkat

- WPB Pitch DeckDokumen20 halamanWPB Pitch Deckapi-102659575Belum ada peringkat

- Maths Lit 2014 ExamplarDokumen17 halamanMaths Lit 2014 ExamplarAnymore Ndlovu0% (1)

- Request Letter To EDC Used PE PipesDokumen1 halamanRequest Letter To EDC Used PE PipesBLGU Lake DanaoBelum ada peringkat

- AB InBev Code of Business Conduct PDFDokumen10 halamanAB InBev Code of Business Conduct PDFcristian quelmis vilca huarachiBelum ada peringkat

- DOLE AEP Rule 2017Dokumen2 halamanDOLE AEP Rule 2017unhoopterenceBelum ada peringkat

- Final Project Report: Uop, LLCDokumen165 halamanFinal Project Report: Uop, LLCSiddharth KishanBelum ada peringkat

- Lenex 3.0 Technical DocumentationDokumen31 halamanLenex 3.0 Technical DocumentationGalina DBelum ada peringkat

- MTS Material Testing SolutionsDokumen34 halamanMTS Material Testing SolutionskarthegreBelum ada peringkat

- C - Official Coast HandbookDokumen15 halamanC - Official Coast HandbookSofia FreundBelum ada peringkat