Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part19

Diunggah oleh

linghuchong0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

24 tayangan4 halamanJudul Asli

Proposed Design Procedures for Shear and Torsion in Reinforced and Prestressed Concrete Ramirez_part19

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

24 tayangan4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part19

Diunggah oleh

linghuchongHak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 4

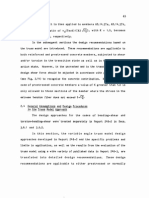

Tests re20rted bl

Krefeld and Thurston

Un

on reinforced concrete T-beams.

(1) (2) (3) (4) (5) (6) (7) (8) (9) (10)

Vc VTEST-Vc

H

TEST

Pvfy

Level of

Hember V

l10 Huo

tan !l I K

Kactual

prestress

1D (kips) (psi)

26-1 12.5 0.44 0.91 79 0.27 1.09 1.0 1.0

0.0

29a-1 16.9 0.31 0.71 53 0.23 0.82

29b-1 16.4 0.32 0.71 53 0.23 0.83

213.5-1 18.4 0.29 0.65 35 0.17 0.76

29a-2 9.6 0.58 0.97 62 0.20 1.24

213.5a-2 16.0 0.36 0.71 42 0.18 0.86

318-1 10.7 0.48 0.99 93 0.29 1.18

321-1 16.4 0.27 0.73 79 0.33 0.82

313.5-2 8.8 0.56 1.04 65 0.25 1.37

318-2 14.9 0.37 0.79 64 0.25 0.93

321-2 15.5 0.36 0.75 55 0.22 0.89

218-2 15.8 0.44 0.73 31 0.13 0.94

39-3 9.6 0.53 1.06 55 0.28 1.28

313.5-2 12.6 0.52 0.95 65 0.21 1.17

318-3 17.8 0.36 0.77 48 0.19 0.91

321-3 21.2 0.19 0.63 42 0.20 0.69

x = 0.99 N 16

s = 0.21

Tests re20rted by Palaskas. 't,tioabe Darwin

!321

on reinforced concrete T-beams.

(1) (2) (3) (4) (5) (6) (7) (8) (9) (10)

Vc VTEST-V

c

H

TEST

PVfy

Level of

Hember

Vuo Muo

tan 0- I K

Kactual

prestress

1D (kips) (psi) (a/f

A25 11.4 0.22 0.46 32 0.17 0.58 1.0 1.0 0.0

A25a 10.6 0.29 0.50 32 0.15 0.67

A50 6.0 0.39 0.62 74 0.29 0.84

A50a 7.3 0.33 0.58 75 0.31 0.77

A75 5.2 0.45 0.75 97 0.31 1.00

825 11.9 0.20 0.55 32 0.19 0.65

650 8.3 0.35 0.76 76 0.32 0.94

C25 10.2 0.21 0.31 32 0.18 0.43

C50 5.1 0.40 0.50 76 0.26 0.75

x = 0.74 N=9

s = 0.18

Overall for Tabh 2:q x = 0.90 N=25

s = 0.23

Table 2.4 Evaluation of reinforced concrete members with light

amounts of web reinforcement under bending and shear

failing in the transition state

57

58

However, on close examination of these specimens, it was found that poor

detailing of the reinforcement was the cause for these premature

failures.

In the case of the specimens from Ref. 31 all but 26-1 had

stirrup spacings in the longitudinal direction in excess of d/2 and in

some instances larger than d. As previously explained in Sec. 2.4.2 of

Report 248-3, large stirrup spacings do not allow the formation of a

uniform diagonal compression field. Instead, those large spacings cause

the excessive concentration of diagonal compression forces in the joints

of the truss formed by the longitudinal and transverse reinforcement

which then produced premature failures by pushing out of the

longitudinal corner bars. Furthermore, when the stirrup spacing is even

larger than d, the first diagonal crack which opens at 45 degrees in

reinforced concrete members will run untouched by a single stirrup

producing a sudden failure of the member.

For those members from Ref. 32 the cause of failure was the

inadequate detailing of the longitudinal reinforcement. The

longitudinal reinforcement consisted of ASTM A416 Grade 270 seven-wire

stress-reI ieved strand. The yield strength of this type of strand is

usually defined as the value of stress corresponding to a strain of 0.01

and is usually about 240-250 ksi. The transverse reinforcement used in

these specimens was made out of low carbon, smooth wires. These wires

were annealed and the yield stress obtained was between 60 and 70 ksi.

The long i tud inal rein forcement was left unstressed, thus creating an

enormous difference between the yield strengths of both reinforcements

59

which then led to an excessive redistribution of forces causing very

large strains in transverse reinforcement and in the diagonal

compression strut leading to a premature failure.

This problem does not exist in prestressed concrete members

because the initial tensioning of the strand eliminates the difference

between the strain required to produce yield in the transverse

reinforcement which is usually made out of deformed reinforcing bars

(40-60 ksi) and that required to yield the longitudinal prestressed

reinforcement (Grades 250-270).

The excessive redistribution of forces required in these members

from Ref. 32 is illustrated by the very low values of the angle of

inclination of the diagonal strut required at failure in those members.

The values of tana for each member are shown in column (6) of Table

2.4. As can be seen they differ considerably from the tam= 1.0

equivalent to the 45 degree angle corresponding to initial diagonal

cracking of the concrete member. Of even more importance they fall well

below the lower limit of tana) 0.5 introduced into the design

provisions. These specimens violate that limit severely.

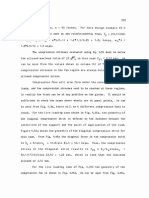

Finally, it must be noted that for the case of prestressed

concrete members subjected to bending and shear, the current AASHTO/ACI

Specifications (1,2) require that the concrete contribution shall be

given by the smaller of the two values vcw and vci where vcw represents

the shear required to produce first inclined cracking in the web of the

member, and vci is the shear stress required to produce first flexure

60

cracking and then cause this flexural crack to become inclined. These

two shear mechanisms have been previously explained in Report 248-2.

The web shear cracking mechanism, v

cw

' is the shear stress in a

nonflexurally cracked member at the time that diagonal cracking occurs

in the web. The design for web shear cracking in prestressed concrete

members is based on the computation of the principal diagonal tension

stress in the web and the limitation of that stress to a certain

specified value. The ACI/AASHTO Specifications indicate that a value

3.5.fii should be used as the limit value of this principal diagonal

tension stress. As seen in Fig. 2.11 from a Mohr's circle it can be

shown that the value of the shear stress at the centroid of the web of a

prestressed concrete beam prior to cracking, vcr' is given by

(2.49)

where f

t

is the principal diagonal tension stress and fps is the

compressive stress due to prestress. In the current AASHTO/ACI

recommendation, f

t

is substituted by the limiting value 3.5.ffJ. and for

simplification the expression is reduced to the generally equivalent

(see Fig. 2.10 of Report 248-2) straight line function

vcw = vcr = 3.5.fFc + 0.3 fps

(2.50)

In the derivation of the proposed concrete contribution for

prestressed concrete members the same approach was followed (see Fig.

2.11) to obtain the value of the shear stress required to produce

initial diagonal cracking in the web of a member uncracked in flexure

Anda mungkin juga menyukai

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (120)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- SSPC Pa 2Dokumen16 halamanSSPC Pa 2Rony Ruiz100% (5)

- Drilling Fluids, Drill String, CirculatingDokumen10 halamanDrilling Fluids, Drill String, CirculatingBianca Quiroga AndiaBelum ada peringkat

- Dry Room in Battery PlantDokumen36 halamanDry Room in Battery Plantcostas matsangosBelum ada peringkat

- Experiment No - 1 Flow Through A Sluice GateDokumen11 halamanExperiment No - 1 Flow Through A Sluice Gatesalman40% (5)

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part12Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part12linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part22Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part22linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part23Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part23linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part21Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part21linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part20Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part20linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part17Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part17linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part10Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part10linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part15Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part15linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part16Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part16linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part13Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part13linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part14Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part14linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part1Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part1linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part18Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part18linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part7Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part7linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part67Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part67linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part4Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part4linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part8Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part8linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part5Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part5linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part2Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part2linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part9Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part9linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part66Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part66linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part3Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part3linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part6Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part6linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part11Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part11linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part68Dokumen2 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part68linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part61Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part61linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part65Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part65linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part60Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part60linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part59Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part59linghuchongBelum ada peringkat

- Asymptotes Tutorial: Horizontal Vertical Slant and HolesDokumen30 halamanAsymptotes Tutorial: Horizontal Vertical Slant and Holesgregory_k_sherman100% (1)

- TemptDokumen13 halamanTemptJhun Lerry TayanBelum ada peringkat

- Trig Crash CourseDokumen28 halamanTrig Crash CourseHimraj BachooBelum ada peringkat

- (M1 Technical) Cpe0011lDokumen12 halaman(M1 Technical) Cpe0011lJoel CatapangBelum ada peringkat

- History of MaichewDokumen2 halamanHistory of MaichewSehabom Geberhiwot100% (1)

- Gas BookDokumen202 halamanGas Bookomiitg67% (3)

- Fan 7316Dokumen21 halamanFan 7316sontuyet82Belum ada peringkat

- Fludex Md10 1 Flender Standard Couplings en 0909Dokumen51 halamanFludex Md10 1 Flender Standard Couplings en 0909Diego SilvaBelum ada peringkat

- 750 Multilin Feeder Management Relay ManualDokumen446 halaman750 Multilin Feeder Management Relay ManualFerdinandja100% (1)

- CHEM 212 - RecrystallizationDokumen16 halamanCHEM 212 - RecrystallizationkristaBelum ada peringkat

- XI - Science Class Routine 2019: Xi-Isc - I Rm. 234 Xi - Isc-Ii Rm. 334Dokumen2 halamanXI - Science Class Routine 2019: Xi-Isc - I Rm. 234 Xi - Isc-Ii Rm. 334Koushik MajumderBelum ada peringkat

- Manual Umfluxus F808 809v1-2-1enDokumen186 halamanManual Umfluxus F808 809v1-2-1endu lich clipBelum ada peringkat

- Spur Gear DesignDokumen15 halamanSpur Gear DesignMaharaja KanthasamyBelum ada peringkat

- FRAP 30mmDokumen97 halamanFRAP 30mmSkeevekillerBelum ada peringkat

- DatumsDokumen22 halamanDatumsAlberto LobonesBelum ada peringkat

- Banner Details: STABILIZED MUD CONCRETE BLOCK (SMCB) Is Where We Replace CoarseDokumen3 halamanBanner Details: STABILIZED MUD CONCRETE BLOCK (SMCB) Is Where We Replace Coarsemohd sohailBelum ada peringkat

- Spesifikasi Teknis Hyperion X9 PDFDokumen4 halamanSpesifikasi Teknis Hyperion X9 PDFDjuli AgusBelum ada peringkat

- Operating Instructions: Vegapuls 67Dokumen84 halamanOperating Instructions: Vegapuls 67SideparBelum ada peringkat

- 000 ProntoSIL CatalogDokumen12 halaman000 ProntoSIL CatalogAbhijeet SangwanBelum ada peringkat

- Formulas For Physics 1Dokumen7 halamanFormulas For Physics 1thejesterraceBelum ada peringkat

- An Excursion Through Discrete Differential Geometry-Crane-2020Dokumen154 halamanAn Excursion Through Discrete Differential Geometry-Crane-2020Joshua IbrahimBelum ada peringkat

- Niosh Lift Push PullDokumen15 halamanNiosh Lift Push Pullahuan huanBelum ada peringkat

- ch5 PDFDokumen18 halamanch5 PDFspoiled_childBelum ada peringkat

- OptiFDTD Tutorials PDFDokumen36 halamanOptiFDTD Tutorials PDFKhải NguyễnBelum ada peringkat

- R05410403 OpticalcommunicationsDokumen8 halamanR05410403 Opticalcommunications9010469071Belum ada peringkat

- Journal of Natural Gas Science and Engineering 26 (2015) 587-594 PDFDokumen8 halamanJournal of Natural Gas Science and Engineering 26 (2015) 587-594 PDFRafael CeccattoBelum ada peringkat