Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part22

Diunggah oleh

linghuchong0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

15 tayangan4 halamanDimensioning of the Transverse Reinforcement based entirely on the equilibrium conditions in the truss model may unduly penalize members subjected to low levels of shear stress. For members in the uncracked or transition state, components of the shear failure mechanism such as aggregate interlock, and the concrete tensile strength become important. The design shear stress should be adjusted in accordance with the proposed values shown in Fig. 2.14a for reinforced concrete and 2.14b for prestressed concrete

Deskripsi Asli:

Judul Asli

Proposed Design Procedures for Shear and Torsion in Reinforced and Prestressed Concrete Ramirez_part22

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniDimensioning of the Transverse Reinforcement based entirely on the equilibrium conditions in the truss model may unduly penalize members subjected to low levels of shear stress. For members in the uncracked or transition state, components of the shear failure mechanism such as aggregate interlock, and the concrete tensile strength become important. The design shear stress should be adjusted in accordance with the proposed values shown in Fig. 2.14a for reinforced concrete and 2.14b for prestressed concrete

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

15 tayangan4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part22

Diunggah oleh

linghuchongDimensioning of the Transverse Reinforcement based entirely on the equilibrium conditions in the truss model may unduly penalize members subjected to low levels of shear stress. For members in the uncracked or transition state, components of the shear failure mechanism such as aggregate interlock, and the concrete tensile strength become important. The design shear stress should be adjusted in accordance with the proposed values shown in Fig. 2.14a for reinforced concrete and 2.14b for prestressed concrete

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 4

69

reinforcement which yields first in addition to large crack

openings.

2.4.3 Dimensioning of the Transverse Reinforcement. In

Secs. 3.6.1 and 3.6.2 of Report 248-2, the dimensioning of the

transverse reinforcement for the cases of bend ing-shear and combined

torsion-bending-shear was illustrated using the equilibrium conditions

in the truss model (LF

v

= 0).

However, dimensioning of the transverse reinforcement based

entirely on the equilibrium conditions of the truss model may unduly

penalize members subjected to low levels of shear stress.

As explained in Sec. 2.3, many times because of the design

process followed, load ing cond itions, clear span length or even

architectural constraints, flexure will control the design of a given

member. In such case the shear stress on the cross section, defined as

Vu = Vu/bwz for shear, and Vu = Tu/2Aobe for torsion, might be of such

low magnitude that as far as shear stresses are concerned the member at

failure would be in an uncracked state or in a transition state between

its uncracked condition and the behavioral state where the truss action

would provide the entire resistance of the member. Moreover, sometimes

the lower limit of 25 degrees on the inclination of the diagonal strut,

which is established to prevent extensive web cracking under service

load conditions, might force a member into this transition state.

For members in the uncracked and transition states, components

of the shear failure mechanism such as aggregate interlock, and the

concrete tensile strength become of importance. The contribution of

these mechanisms to the ultimate strength of the member is reflected by

70

recognition of an additional concrete contribution to the shear and/or

torsional capacity of the member. For economy, such additional

contribution by the concrete should be considered in the design process.

For members in the uncracked or transition state the design

shear stress should be adjusted in accordance with the proposed values

shown in Fig. 2.14a for reinforced concrete and 2.14b for prestressed

concrete. There is an additional limitation that K can only be taken

larger than 1.0 in those regions of the prestressed member where the

stress in the extreme tension fiber due to the calculated ultimate load

and applied prestressing does not exceed 6 Jif.. Thus, the design shear

stress used to compute the required amount of web reinforcement vTR

shall be taken as [v

u

/- v(], where is a capacity reduction factor,

equal to 0.85, similar to the one required in the current ACI and AASHTO

Specifications (2,1).

In the case of combined shear and torsion the computed concrete

contribution must be distributed part to shear and part to torsion as a

function of the relative s h ~ r and torsion acting on the member. This

procedure is similar to the one suggested in the Swiss Recommendations

(10).

Finally, recognizing the sudden nature of shear failure, it is

suggested that a minimum amount of transverse reinforcement be provided

for ductility whenever the value of the applied shearing stress exceeds

1/2 of the cracking shearing stress of the concrete section. This is in

order to avoid sudden type failures, since in an unreinforced web the

sudden formation of inclined cracking might lead directly to failure

71

without warning. The minimum amount of web reinforcement then serves as

a back up to the concrete contribution. Since the minimum amount is

required as soon as the value of the shearing stress exceeds 1/2 of the

cracking shearing stress (1.0 ~ , then it is reasonable to suggest

that an amount equal 1.0 .Jf[, which would allow the member to at least

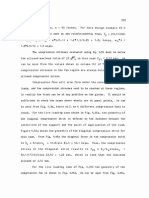

reach its cracking shear stress (2 ./fi), should be provided. In Fig.

2.15 the proposed value for the minimum amount 1.0 ~ is compared with

the ACI Code and AASHTO Speci fications (2,1) recommended minimum of 50 psi.

100

50

Available strength

(psi)

3000

20 psi

5000

Proposed (./it)

50psi

(ACI )AASHTO)

fc (psi)

10000

Fig. 2.15 Minimum amounts of web reinforcement

72

As can be seen from Fig. 2.15 both amounts are approximately the

same plus or minus 20 psi in the 3000 to 5000 psi concrete compressive

strength range. Ho'wever, the suggested value of 1.0.ffJ. reflects an

increase of about 25 to 50 psi for the upper range of concrete

compressive strength greater than 5000 psi). This seems highly

desirable to reflect the intent of the requirement for minimum web

reinforcement. Although in high strength concretes the shear stress

required to produce diagonal cracking increases, the mechanisms of

aggregate interlock diminish. The crack surfaces become smoother, thus

reducing the aggregate interlock which counts heavily on bearing between

the jagged surfaces of the crack in order to transmit shear stresses

between those cracks. Consequently, the concrete contribution does not

increase directly with compressive strength. Since more shear is

allowed to be carried by the concrete contribution in high strength

concrete members, more minimum reinforcement should be provided.

2.4.4 Di mensioning of the Longitudinal Reinforcement. Due to

the presence of an inclined compression field formed by the diagonal

compression struts of the truss model, an area of longitudinal steel in

addition to that required for flexure is necessary to resist the

horizontal component of the diagonal compression struts.

The additional area of longitudinal reinforcement can be

determined from the equilibrium conditions of the truss model (LF

H

= 0).

If a uniform compression field is assumed and the stirrup spacing is

constant wi thin the design zone equal to the hori zontal proj ection of

the inclined crack then the total horizontal component of the

Anda mungkin juga menyukai

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part12Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part12linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part19Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part19linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part21Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part21linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part17Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part17linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part23Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part23linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part15Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part15linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part18Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part18linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part20Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part20linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part16Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part16linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part11Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part11linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part14Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part14linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part13Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part13linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part7Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part7linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part10Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part10linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part4Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part4linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part8Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part8linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part9Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part9linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part68Dokumen2 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part68linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part2Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part2linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part67Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part67linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part6Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part6linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part5Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part5linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part1Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part1linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part66Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part66linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part61Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part61linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part3Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part3linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part65Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part65linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part59Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part59linghuchongBelum ada peringkat

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part60Dokumen4 halamanProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part60linghuchongBelum ada peringkat

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Conveyor Chain GuideDokumen59 halamanConveyor Chain GuideajaykrishnaaBelum ada peringkat

- Week 2 PlanDokumen3 halamanWeek 2 Planapi-427127204Belum ada peringkat

- Oracle Baseline Security ChecklistDokumen15 halamanOracle Baseline Security ChecklistChidi OkerekeBelum ada peringkat

- 6303A HP Flare Drain DrumDokumen16 halaman6303A HP Flare Drain DrumMohammad MohseniBelum ada peringkat

- Basicline BL 21t9stDokumen28 halamanBasicline BL 21t9stgabriel6276Belum ada peringkat

- Yellow Electric Pump: Job Card Package Title: HIM - A318/A319/A320/ A321 Tail Number - MSN - FSN ALL ContinousDokumen4 halamanYellow Electric Pump: Job Card Package Title: HIM - A318/A319/A320/ A321 Tail Number - MSN - FSN ALL ContinousSuman BajracharyaBelum ada peringkat

- The hyperwall: A multiple display wall for visualizing high-dimensional dataDokumen4 halamanThe hyperwall: A multiple display wall for visualizing high-dimensional dataMahendra PututBelum ada peringkat

- Rising Stem Ball ValveDokumen6 halamanRising Stem Ball ValveAnupam A. GandhewarBelum ada peringkat

- JupaCreations BWCGDokumen203 halamanJupaCreations BWCGsoudrack0% (1)

- Breaking Water Protection Paradigms: RTM Composite DomesDokumen52 halamanBreaking Water Protection Paradigms: RTM Composite DomesaerostressBelum ada peringkat

- GRC Fiori End User Guide Final - V2Dokumen75 halamanGRC Fiori End User Guide Final - V2Subhash BharmappaBelum ada peringkat

- Schedule of Rates 2011 Rev1Dokumen144 halamanSchedule of Rates 2011 Rev1Screen BiruBelum ada peringkat

- OFFICE 365 PROXY GUIDEDokumen4 halamanOFFICE 365 PROXY GUIDErossloveladyBelum ada peringkat

- Ahmad Humayun SohailDokumen6 halamanAhmad Humayun SohailHumayun SohailBelum ada peringkat

- Stock Register StoreDokumen1.218 halamanStock Register StoreSantanu Kumar SahuBelum ada peringkat

- Grant Park Platform Bedroom Set Furniture RowDokumen1 halamanGrant Park Platform Bedroom Set Furniture Rowjyzjz6sr65Belum ada peringkat

- Saint Louis University Baguio City Principal'S Recommendation FormDokumen1 halamanSaint Louis University Baguio City Principal'S Recommendation FormnidzBelum ada peringkat

- Valve Group-Control - AuxiliaryDokumen3 halamanValve Group-Control - AuxiliarythierrylindoBelum ada peringkat

- Designing The Marketing Channels 13Dokumen13 halamanDesigning The Marketing Channels 13Gajender SinghBelum ada peringkat

- SPP 40 Series Sponsored BE MTech Projects CollegewiseDokumen145 halamanSPP 40 Series Sponsored BE MTech Projects CollegewiseVinay KumarBelum ada peringkat

- Gate Mock Test1Dokumen17 halamanGate Mock Test1Gopinathan SudheerBelum ada peringkat

- Auto Temp II Heat Pump: Programmable Thermostat For Single and Multistage Heat Pump SystemsDokumen22 halamanAuto Temp II Heat Pump: Programmable Thermostat For Single and Multistage Heat Pump Systemswideband76Belum ada peringkat

- Answers About HubSpotDokumen1 halamanAnswers About HubSpotPrasetyaBelum ada peringkat

- F1FR80 Series Quick-Response SprinklersDokumen6 halamanF1FR80 Series Quick-Response SprinklersAtila AmayaBelum ada peringkat

- Reaction PaperDokumen2 halamanReaction PaperRonald CostalesBelum ada peringkat

- 0 EDEM Applications MeDokumen16 halaman0 EDEM Applications MeRuben PurcaBelum ada peringkat

- CCTV Camera Hack With Google Dork ListDokumen3 halamanCCTV Camera Hack With Google Dork ListsarahdianewhalenBelum ada peringkat

- Enclosed Product Catalogue 2012Dokumen24 halamanEnclosed Product Catalogue 2012Jon BerryBelum ada peringkat

- Chap1-Geometrical Optics - ExercisesDokumen3 halamanChap1-Geometrical Optics - ExercisesReema HlohBelum ada peringkat

- Strategic Information Systems Planning: Course OverviewDokumen18 halamanStrategic Information Systems Planning: Course OverviewEmmy W. RosyidiBelum ada peringkat