On-Chip Current Sensing Techniques For

Diunggah oleh

EliasA.TiongkiaoJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

On-Chip Current Sensing Techniques For

Diunggah oleh

EliasA.TiongkiaoHak Cipta:

Format Tersedia

On-chip current sensing techniques for

hysteresis current controlled DCDC

converters

J.-J. Chen, Y.-T. Lin, H.-Y. Lin, J.-H. Su, W.-Y. Chung,

Y.-S. Hwang and C.-L. Tseng

An on-chip current sensing technique for a hysteresis current

controlled step-down DCDC converter is presented. This current

sensing technique has been designed with standard 0.35 mm CMOS

2P4M processes. Experimental results show that the current sensing

circuit measures full-time the inductor current whether the high-side or

low-side switch is turned on.

Introduction: Sensing techniques for the output current are necessary

in both voltage-mode and current-mode switch-mode power conver-

ters (SMPC), because they can detect open-load, short-circuit and

over-current situations for both energy saving and protection

purposes. Especially, for current-mode control schemes, their control-

lers require the sensing of the inductor current throughout the whole

switching period. There are different current sensing techniques,

which have been published or implemented [19]. To sense the

output current of current-mode converters, a sensing resistor is

usually used in series with the inductor or power transistor. The

main concern of this approach is its high power dissipation, as all of

the inductor current or drain current of the power transistor must pass

through the sensing resistor. Another common method is using an

integrator to determine the inductor current. This control scheme is

called sensorless current mode control [1], which would increase the

complexity of designing different kinds of converters as different

topologies have different integrators. In some sensing techniques, the

current transformer is used for sensing the current signal, but this is

not suitable for portable electronic device applications because of the

large transformer size and weight. The sensing technique in [2] uses

the conduction resistance of the power MOSFET instead of the

sensing resistor. The main concern of this sensing scheme is the

value of R

on

required for good control of the converters. One of the

on-chip current-sensing techniques designed with the BiCMOS

process is proposed in [4] and [5], but it cannot sense full-time the

inductor current. Another improved on-chip current sensing scheme is

proposed in [7] and [8], but this scheme can still not measure the

current of the low-side switch.

In current-mode controllers, hysteresis current controlled techniques

can be used to achieve fast transient response [6]. The on-chip current

sensing schemes described above are not suitable for this controller,

because they cannot fully sense the inductor current. In this Letter, an

on-chip current sensing circuit suitable for hysteresis current controlled

DC-DC converters is proposed.

Circuit descriptions: To sense the current of the inductor full-time, a

current sensing circuit is proposed and shown in Fig. 1, which is

process independent and supply voltage independent as compared

with previous work [9]. The number of components shown in Fig. 1 is

less than that proposed in [9]. The output current I

pp

, which ows

through the power transistor MP1, is mirrored to the sense transistor

MS1. The voltage change of node A will mirror a similar change to

node B owing to the virtual short-circuit provided by the operational

amplier. Therefore, the drain-to-source voltage V

DS

of transistors

MP1 and MS1 are almost the same, as well as their current density. If

the aspect ratio of the power switch is larger than that of the sense

transistor, e.g. N:1, the sensing current I

ps

is proportional to the output

current I

pp

and can be described as

I

ps

I

pp

W=L

MS1

W=L

MP1

1

N

1

Conversely, the output current I

np

, which ows through the power

transistor MP2, is mirrored to the sense transistor MS2. The voltage at

node P is virtually grounded owing to the virtual short-circuit provided

by the operational amplier. The drain-to-source voltage V

DS

of

transistors MP2 and MS2 are then almost the same, as well as their

current density. If the aspect ratio of power switch is larger than that of

the sense transistor, e.g. N1:1, the sensing current I

ns

is proportional

to the output current I

np

and can be obtained as

I

ns

I

np

W=L

MS2

W=L

MP2

W=L

MS2

1

N

2

The current I

ind

of the sensing circuit can then be obtained and

described as the summation of sense currents I

ps

and I

ns

. Since the

inductor current I

L

is the summation of power switch currents I

pp

and

I

np

, the output current of sensing circuit I

ind

can be written as:

I

ind

I

L

I

ps

I

ns

I

pp

I

np

1

N

3

Using the current sensing circuit, the step-down hysteresis-controlled

DCDC converter, as shown in Fig. 2a, is designed to work in parallel.

The parallel hysteresis current controlled step-down DCDC converter

shown in Fig. 2b is operated at continuous mode with current sharing

techniques.

V

DH

Ipp

MP1

VA

N:1

V

DD

MS1

Ips

VB

M5 M7

M4

A1

A2

V

p

current sensing circuit

MS2

( 1):1 N-

MP2

V

DL

I

np

C

out

L

out

I

L

V

out

ZL

I

ns

V

DD

M2

M11 M9

- +

I

ind

+ -

Fig. 1 Proposed current sensing circuit

VDD

IAV

CM1

CM2

CM3

VP

VFB

GND

VDD

IAV

CM1

CM2

CM3

VP

VFB

GND

VDD

IAV

CM1

CM2

CM3

VP

VFB

GND

V

DD I

L1 L1

I

L2

L2

I

L3 L3

Rf11

Rf12

C

out1

I

R1

I

R2

C

out2

I

R3

C

out3

ZL

V

out

I

out

b

current

sharing

circuit

frequency

compensated

circuit

hysteresis

current

comparator

current

sensing

circuit

driving

circuit

V

DH

MP1

V

DL

MP2

Rf1

Rf2

VP

L

out

V

DD

power stage

Cp1

Cp2

IAV

CM1

CM2

CM3

hysteresis-current-controlled circuit

VFB

V

ref

C

out ZL

V

out

a

I

ind

Fig. 2 Proposed step-down DCDC converter and parallel DCDC

converter

a Proposed step-down DCDC converter

b Parallel DCDC converter

power

NMOS

driving

circuit

power

PMOS

current

sensing

hysteresis-current-

controlled circuit

bias

circuit

Fig. 3 Photograph of proposed chip, as shown in Fig. 2a

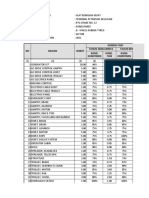

Experimental results: The hysteresis current controlled step-down

DCDC converter using the proposed current sensing circuit has

been implemented with 0.35 mm 2P4M CMOS processes. The

ELECTRONICS LETTERS 20th January 2005 Vol. 41 No. 2

photograph of the proposed converter, as shown in Fig. 2a, is shown

in Fig. 3. The experimental results of this converter are shown in

Figs. 4a and b with 2.5 V supply voltage. As shown in Fig. 4a, from

top to bottom, the waveforms are output voltage V

out

, control voltage

V

DH

and inductor current with 1.5 Voutput voltage, respectively. The

parallel DCDC converter, as shown in Fig. 2a, is also measured. Fig.

4b shows the experimental results of the parallel converter, as shown

in Fig. 2b, with 1.5 V output voltage. From top to bottom, the

waveforms are inductor currents I

L1

and I

L2

, respectively. The induc-

tance of each converter is 59 and 89 mH, respectively. Then the

proposed inductor current sensing circuits work and agree well with

theoretical analysis in the parallel DCDC converter.

4

a

3

T

1

4

b

m1

Fig. 4 Experimental results of proposed converter (from top to bottom,

the waveforms are output voltage V

out

(1 V=div.), control voltage V

DH

(2 V=div.), inductor current (100 mA=div.), respectively); and experimen-

tal results of proposed parallel hysteresis current controlled DCDC

converter (from top to bottom, the waveforms are inductor currents I

L1

and I

L2

(200 mA=div.), respectively)

Inductance of each converter 59 and 89 mH, respectively

a Of proposed converter

b Of proposed parallel hysteresis current controlled DCDC converter

Conclusions: A new on-chip current sensing technique for a hyster-

esis current controlled step-down DCDC converter is presented. The

main advantages of this scheme are threefold: (i) the current sensing

circuit can full-time measure the inductor current through sensing the

current of power switches whether the high-side or low-side switch

is turned on; (ii) the proposed converter can work in parallel hyster-

esis current controlled step-down DCDC converters such that the

load current can be easily managed through control theories; (iii)

the current sensing circuit works well even if the inductors are

mismatched. This current sensing circuit will be useful in portable

parallel DCDC converters, multimedia power supporting and power

electronic and telecommunication applications.

Acknowledgments: The authors wish to thank the National Science

Council for project support and the Chip Implementation Center for

chip fabrication. This work was sponsored by NSC-92-2213-E262-012.

# IEE 2005 31 August 2004

Electronics Letters online no: 20056807

doi: 10.1049/el:20056807

J.-J. Chen and Y.-S. Hwang (Department of Electronic Engineering,

National Taipei University of Technology, Taipei 106, Taiwan)

Y.-T. Lin and W.-Y. Chung (Department of Electronic Engineering,

Chung Yuan Christian University, Chung-Li 320, Taiwan)

H.-Y. Lin and J.-H. Su (Department of Electronic Engineering,

Lunghwa University of Science and Technology, Taoyuan 333,

Taiwan)

C.-L. Tseng (Department of Electrical Engineering, National Taipei

University of Technology, Taipei 106, Taiwan)

References

1 Midya, P., et al.: Sensorless current mode controlan observer-based

technique for dcdc converters, IEEE Trans. Power Electron., 2001, 16,

(4), pp. 522526

2 Smith, T.A., et al.: Controlling a dcdc converter by using the power

MOSFET as a voltage controlled resistor, IEEE Trans. Circuits Syst. I,

Fundam. Theory Appl., 2000, 47, (3), pp. 357362

3 Zhou, X., et al.: Improved light-load efciency for synchronous rectier

voltage regulator module, IEEE Trans. Power Electron., 2000, 15, (5),

pp. 826834

4 Ki, W.H.: Current sensing technique using MOS transistors scaling with

matched bipolar current sources, US Patent 5,757,174, 26 May 1998

5 You, F., et al.: An improved tail current source for low voltage

applications, IEEE J. Solid-State Circuits, 1997, 32, (8), pp. 11731180

6 Leung, K.K.S., et al.: Use of state trajectory prediction in hysteresis

control for achieving fast transient response of the buck converter. Proc.

2003 Int. Symp. on Circuits and Systems, May 2003, Vol. 3, pp. III-439

III-442

7 Lee, C.F., and Mok, P.K.T.: On-chip current sensing technique for

CMOS monolithic switch-mode power converter. IEEE ISCAS,

Scottsdale, AZ, USA, May 2002, pp. V265V268

8 Lee, C.F., and Mok, P.K.T.: A monolithic current-mode CMOS dcdc

converter with on-chip current-sensing technique, IEEE J. Solid-State

Circuits, 2004, 39, (1), pp. 314

9 Chen, J.-J., et al.: Integrated current sensing circuits suitable for step-

down DC-DC converters, Electron. Lett., 2004, 40, (3), pp. 200201

ELECTRONICS LETTERS 20th January 2005 Vol. 41 No. 2

Anda mungkin juga menyukai

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (120)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- CAMA HILLROOM Service ManualDokumen355 halamanCAMA HILLROOM Service ManualOrlando Contreras Muñoz100% (1)

- Commissioning and Maintenance MiCOM P125 P126 & P127-P12yEN CMC22Dokumen26 halamanCommissioning and Maintenance MiCOM P125 P126 & P127-P12yEN CMC22dennyyusufBelum ada peringkat

- 2010A IP Answers PDFDokumen1 halaman2010A IP Answers PDFEliasA.TiongkiaoBelum ada peringkat

- Philippines-Marianas Relations in History: Some Notes On Filipino Exiles in GuamDokumen14 halamanPhilippines-Marianas Relations in History: Some Notes On Filipino Exiles in GuamEliasA.Tiongkiao100% (1)

- Read MeyppppppppppppppoooooDokumen2 halamanRead MeyppppppppppppppoooooAnonymous 7dsX2F8nBelum ada peringkat

- Zimmermann2017 PDFDokumen29 halamanZimmermann2017 PDFEliasA.TiongkiaoBelum ada peringkat

- IP Exam Answers - April 2014Dokumen1 halamanIP Exam Answers - April 2014EliasA.TiongkiaoBelum ada peringkat

- Zimmermann2017 PDFDokumen29 halamanZimmermann2017 PDFEliasA.TiongkiaoBelum ada peringkat

- Readings - 8.2. General Theory - TTE01x Courseware - EdXDokumen3 halamanReadings - 8.2. General Theory - TTE01x Courseware - EdXEliasA.TiongkiaoBelum ada peringkat

- Sensordevices 2017 9 10 20010Dokumen3 halamanSensordevices 2017 9 10 20010EliasA.TiongkiaoBelum ada peringkat

- 2011A IP AnswerDokumen1 halaman2011A IP AnswerEliasA.TiongkiaoBelum ada peringkat

- Sathya 2016Dokumen4 halamanSathya 2016EliasA.TiongkiaoBelum ada peringkat

- Reduction of Data Transmission Time Delay With Object Detection in Underwater Acoustic Sensor NetworkDokumen4 halamanReduction of Data Transmission Time Delay With Object Detection in Underwater Acoustic Sensor NetworkEliasA.TiongkiaoBelum ada peringkat

- 0 5micronDokumen2 halaman0 5micronEliasA.TiongkiaoBelum ada peringkat

- A System-Based View of The Standards and Certification Landscape For Electric VehiclesDokumen12 halamanA System-Based View of The Standards and Certification Landscape For Electric VehiclesEliasA.TiongkiaoBelum ada peringkat

- How Does This Fit in With My Research - Graphical Arguments - ELEN7070x Courseware - EdXDokumen1 halamanHow Does This Fit in With My Research - Graphical Arguments - ELEN7070x Courseware - EdXEliasA.TiongkiaoBelum ada peringkat

- SimDokumen2 halamanSimEliasA.TiongkiaoBelum ada peringkat

- 05395926Dokumen6 halaman05395926EliasA.TiongkiaoBelum ada peringkat

- Introduction - 8.1. Introduction - TTE01x Courseware - EdXDokumen2 halamanIntroduction - 8.1. Introduction - TTE01x Courseware - EdXEliasA.TiongkiaoBelum ada peringkat

- 26th ANTS Call For Papers GuidelinesDokumen1 halaman26th ANTS Call For Papers GuidelinesEliasA.TiongkiaoBelum ada peringkat

- Philippine Development: Foregrounding Ethical and Moral ValuesDokumen1 halamanPhilippine Development: Foregrounding Ethical and Moral ValuesEliasA.TiongkiaoBelum ada peringkat

- Philippine Electronics Code - Volume 1Dokumen28 halamanPhilippine Electronics Code - Volume 1janaisha_bai7170100% (3)

- Advanced Industrial Control Processing: 12 March 2012 Clive (Max) MaxfieldDokumen28 halamanAdvanced Industrial Control Processing: 12 March 2012 Clive (Max) MaxfieldEliasA.TiongkiaoBelum ada peringkat

- Computer FundamentalsDokumen17 halamanComputer Fundamentalsdarmahnoor0% (1)

- Hktelec1t115-V019800 DTHDokumen4 halamanHktelec1t115-V019800 DTHEliasA.TiongkiaoBelum ada peringkat

- 07893620Dokumen4 halaman07893620EliasA.TiongkiaoBelum ada peringkat

- Monique Frize-Ethics, Research Methods and Standards in Biomedical Engineering-Morgan & Claypool (2011)Dokumen83 halamanMonique Frize-Ethics, Research Methods and Standards in Biomedical Engineering-Morgan & Claypool (2011)EliasA.TiongkiaoBelum ada peringkat

- Location of MSC LicenseDokumen1 halamanLocation of MSC LicenseEliasA.TiongkiaoBelum ada peringkat

- ReadmeDokumen1 halamanReadmeAsad IslamBelum ada peringkat

- Ieee Copyright Consent Form 2 PDFDokumen1 halamanIeee Copyright Consent Form 2 PDFEliasA.TiongkiaoBelum ada peringkat

- Lab 1Dokumen18 halamanLab 1EliasA.TiongkiaoBelum ada peringkat

- Ieee Copyright Consent Form 2 PDFDokumen1 halamanIeee Copyright Consent Form 2 PDFEliasA.TiongkiaoBelum ada peringkat

- Telsmith Vibro King ScreensDokumen2 halamanTelsmith Vibro King ScreensJesus Dugarte0% (1)

- Ipc Iv-VDokumen492 halamanIpc Iv-Vizamariaa89Belum ada peringkat

- Reovib Mfs 168: Unique Selling PointDokumen8 halamanReovib Mfs 168: Unique Selling PointMarianNeaguBelum ada peringkat

- Dfs I Fusion v3 I Sep '22Dokumen8 halamanDfs I Fusion v3 I Sep '22Achref MmaBelum ada peringkat

- Terex - Luminarias Repuestos PDFDokumen62 halamanTerex - Luminarias Repuestos PDFIliana Georgina RamirezBelum ada peringkat

- d002 Pd17004 Reve Datasheet NcuDokumen20 halamand002 Pd17004 Reve Datasheet Ncuelson brito juniorBelum ada peringkat

- Amorphous MetalDokumen2 halamanAmorphous MetalRamesh BabuBelum ada peringkat

- Form Survey Kondisi Fisik & Draft Rencana BongkarDokumen25 halamanForm Survey Kondisi Fisik & Draft Rencana BongkarKONSULTAN RELOKASI RTGBelum ada peringkat

- Fuji Rep News No. 07135Dokumen5 halamanFuji Rep News No. 07135IvanRemiBelum ada peringkat

- Edwin Bohr Electronics 2015 Ecatalog1Dokumen67 halamanEdwin Bohr Electronics 2015 Ecatalog1Ba MamadouBelum ada peringkat

- Tristar Modbus Specification Morningstar Corporation V04 6 September 2012Dokumen30 halamanTristar Modbus Specification Morningstar Corporation V04 6 September 2012a.anugrahBelum ada peringkat

- 2gb Nand m29b-1879920Dokumen58 halaman2gb Nand m29b-1879920ManunoghiBelum ada peringkat

- Riveted JointsDokumen7 halamanRiveted Jointsjimmy mlelwaBelum ada peringkat

- SD MaterialsDokumen8 halamanSD MaterialsJp LevisteBelum ada peringkat

- Plug in Time Delay Relays C System PDFDokumen4 halamanPlug in Time Delay Relays C System PDFAndré CrowleyBelum ada peringkat

- Audio, Visual & Navigation System PDFDokumen673 halamanAudio, Visual & Navigation System PDFtima tixoBelum ada peringkat

- NAVISTEM B3000 Control Instruction ManualDokumen116 halamanNAVISTEM B3000 Control Instruction Manualdecaso000Belum ada peringkat

- Unit Test I Illumination 17-18Dokumen8 halamanUnit Test I Illumination 17-18Madhura TuljapurkarBelum ada peringkat

- 5Z27 (Zener)Dokumen4 halaman5Z27 (Zener)el_george0079491Belum ada peringkat

- 2FB4 PCDokumen55 halaman2FB4 PClingeshsaikumar030Belum ada peringkat

- Iks-6700A and Iks-6728A-8Poe Series Quick Installation GuideDokumen11 halamanIks-6700A and Iks-6728A-8Poe Series Quick Installation GuideSVS SVSBelum ada peringkat

- 2009 Audi A3: Quick Reference GuideDokumen16 halaman2009 Audi A3: Quick Reference GuideFotokopirnicaSonyPSBelum ada peringkat

- Flyer RCS 9698G H GatewayDokumen2 halamanFlyer RCS 9698G H GatewayBorisBelum ada peringkat

- 1Dokumen1 halaman1ngokhanhtBelum ada peringkat

- AP9MK3 Rev-H ManualDokumen202 halamanAP9MK3 Rev-H ManualRyan PacamarraBelum ada peringkat

- Receiving and Inspection: Installation, Operation and Maintenance ManualDokumen16 halamanReceiving and Inspection: Installation, Operation and Maintenance ManualIvy LeeBelum ada peringkat

- Fire Hydrant With Recording Sys PDFDokumen2 halamanFire Hydrant With Recording Sys PDFMachineryengBelum ada peringkat

- 78d33 DatasheetDokumen4 halaman78d33 DatasheetJorge AdrianBelum ada peringkat