Welding Checklist

Diunggah oleh

safety86Deskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Welding Checklist

Diunggah oleh

safety86Hak Cipta:

Format Tersedia

!

!

!

I

D

.

N

O

.

8

1

1

0

5

3

1

0

.

0

9

3

k

C

o

u

n

t

r

y

o

f

o

r

ig

in

:

N

o

r

w

a

y

Safety Checklist

Do not operate equipment for welding or related thermal processes unless you are thoroughly familiar with the

process, the equipment, rules and regulations related to the process and equipment; including proper use of

accessories, e.g. fire extinguishers. Preparation for hot-work onboard should include, without being limited to,

the points below to ensure safe operation.

!

Ensure that all relevant check lists, certificates

and permits for hot work have been issued.

If work is being done outside the ships

workshop, an assistant, protected like the welder

(see under Operator/assistant protection),

should accompany him.

If work has to be done inside a con fined space

the assistant should be located outside, within

view of the welder and with the possi bility to

rapidly cut off gas and power supply.

Tidy up the work place and remove any

flammable materials, liquids and gases from

workplace and adjacent spaces, including

spaces above/below decks, behind bulkheads

and inside pipes or containers which are to be

worked on.

Cover any openings through which sparks may

be led to other areas onboard which have not

been prepared for hot work.

If necessary, shield the workplace to protect

others from sparks and radiation from the arc.

Post a warning sign that welding is in progress.

Ensure that sufficient and correct fire fighting

equipment is available at the workplace, and that

someone familiar with its use is present.

Ensure that the workplace is prop erly ventilated,

if necessary with special fume extraction equip-

ment and fresh air supply. This is especially

important when working on galvanized or other

coated surfaces which may produce harmful

fumes when heated.

Store gas cylinders in suitable storage rooms

above deck. Avoid excessive temperatures. The

use of gas distribution systems is recommended

to increase safety and reduce the need for

transport of cylinders around the ship.

Gas cylinders shall always be fitted with valve

caps before transport, and appropriate cylinder

trollies shall always be used for transport.

Secure the cylinders properly in upright position.

Acetylene and oxygen regulators shall be fitted

with flashback arrestors. Protect cylinders

against heat and mechanical damage. The valve

opening of the acetylene cylinder shall point

away from other compressed gas cylinders, and

a heat resistant mitten shall be available.

Check that the power source functions correctly

according to relevant regulations, is correctly

connected to mains with correct voltage and

frequency, and that you are familiar with the

operator instructions for the power source.

Hoses shall be in good condition, without leaks

or damage, and with correct colour coding for

the gas. (Red for acetylene, blue for oxygen,

black for shielding gases and filtered air). Use

correct hose connectors and hose clamps.

Check all gas connections for leaks, including

torch valves. Replace defective gaskets with

original gaskets only. Never use oil or grease in

connection with welding gases and never use

alloys containing more than 65%copper or 45%

silver in connection with acetylene.

Cables shall be of oil resistant type with

undamaged insulation and properly mounted

cable connectors. Use safety cable connectors

where both halves have recessed current

carrying parts to protect from accidental contact.

Check that torches and electrode holders

are in good working order, including check of

blowpipes, nozzles, tungsten electrodes and

insulation. Electrode holders should be fully

insulated.

Keep hoses and cables clear of passage ways

and protected from sparks, hot metal and

mechanical damage in doorways, hatches, etc.

Both welding and ground clamp cables should

be streched to the work place, and the ground

clamp should be fastened with good electrical

contact directly on the work piece.

When working, wear safety shoes and proper

boiler suit with long sleeves. Do not wear clothes

of highly combustible materials or clothes that

are wet, and do not carry combustible material,

e.g. matches, lighters, oily rags.

Never touch electrically live parts, e.g. the

welding electrode, without being properly

insulated. Dry welding gloves should always be

used, and when necessary also use additional

dry leather clothing for protection against sparks,

heat and electric shock.

Use head and face protection (helmet, shield,

goggles) according to the job. Ensure that filter

glasses are unbroken and have the correct

shade.

Where necessary use a dust filter or breathing

apparatus to avoid inhaling fumes and dust from

the welding process.

Never use acetylene or oxygen to blow away

dust from yourself or the workplace. Always keep

dry and keep the workplace dry, especially when

arc welding.

Always switch off the welding machine and close

off gas supply at the gas outlet station or cylinder

valve, also during short breaks. Always remove

the coated electrode from the electrode holder.

Do not leave the workplace unattended. When

hot work is completed the work place shall be

inspected at regular intervals to ensure that

no risk of fire remains. Only when this has

been assured should fire fighting equipment be

returned to its normal storing place.

1

2

3

4

5

6

7

8

9

16

15

14

13

12

11

18

19

20

21

22

23

17

10

Hot Work Procedure

Work Place

Gas Cylinders

Equipment

When work is interrupted or

completed

Operator / assistant protection

for welding and related thermal processes

Anda mungkin juga menyukai

- John Paul Jackson Prophecies of The FutureDokumen15 halamanJohn Paul Jackson Prophecies of The FutureMeranda Devan100% (9)

- Game Audio - Tales of A Technical Sound Designer Volume 02Dokumen154 halamanGame Audio - Tales of A Technical Sound Designer Volume 02Joshua HuBelum ada peringkat

- Skylift ChecklistDokumen1 halamanSkylift ChecklistSUKHVINDERBelum ada peringkat

- Oxy-Acetylene Inspection Checklist: # Criteria Yes No N/A RemarksDokumen1 halamanOxy-Acetylene Inspection Checklist: # Criteria Yes No N/A RemarksFelcisBelum ada peringkat

- Method Statement Fisher PlugDokumen5 halamanMethod Statement Fisher PlugChezy629Belum ada peringkat

- Hung201 PDFDokumen14 halamanHung201 PDFMua Dong Tuyet RoiBelum ada peringkat

- Safety in Gas Welding & Cutting Process PDFDokumen11 halamanSafety in Gas Welding & Cutting Process PDFviswamanojBelum ada peringkat

- Workplace Vocabulary for Esl Students: With Exercises and TestsDari EverandWorkplace Vocabulary for Esl Students: With Exercises and TestsBelum ada peringkat

- Toolbox Training Session - Harness and LanyardDokumen3 halamanToolbox Training Session - Harness and LanyardSarah AjodhaBelum ada peringkat

- JSA Fiber Tank LiftingDokumen4 halamanJSA Fiber Tank LiftingEngismail KhanBelum ada peringkat

- F-Sp-Hse06-01 Rev 03 Hira NewDokumen14 halamanF-Sp-Hse06-01 Rev 03 Hira Newvishal bailurBelum ada peringkat

- Gas Cutting SafetyDokumen2 halamanGas Cutting SafetyTonmay MajumderBelum ada peringkat

- Cranes and HoistsDokumen3 halamanCranes and HoistsAditya Raj MishraBelum ada peringkat

- Assignment No 1: Submitted By: Jabran ShaukatDokumen3 halamanAssignment No 1: Submitted By: Jabran ShaukatJibran ShaukatBelum ada peringkat

- MME Chemical DistillationDokumen42 halamanMME Chemical DistillationsaketBelum ada peringkat

- Fire Extinguisher Training: Instructor: SGT Michael Chism Bco204 Elm ShopDokumen37 halamanFire Extinguisher Training: Instructor: SGT Michael Chism Bco204 Elm ShopTimmy CheongBelum ada peringkat

- Safety Induction 2019Dokumen10 halamanSafety Induction 2019Muhammad Rizky RamadhanBelum ada peringkat

- Ocp BatchingDokumen1 halamanOcp BatchingAarya Mishra TiwariBelum ada peringkat

- SWP Welder Oxy-Fuel Gas AS563Dokumen2 halamanSWP Welder Oxy-Fuel Gas AS563anon_106345234100% (1)

- Duhok Polytechnic University College of Technical Engineering Department of PetrochemicalDokumen17 halamanDuhok Polytechnic University College of Technical Engineering Department of PetrochemicalDll ZarBelum ada peringkat

- OB Afety NalysisDokumen5 halamanOB Afety NalysisNaveed WarraichBelum ada peringkat

- Confined Space - Introduction: Canadian Government Departments Responsible For OH&S Confined Space - ProgramDokumen7 halamanConfined Space - Introduction: Canadian Government Departments Responsible For OH&S Confined Space - ProgramAnge JuanBelum ada peringkat

- ESH Compliance Check List: Noise ControlDokumen1 halamanESH Compliance Check List: Noise ControlRichard BaileyBelum ada peringkat

- Theme Based Safety Discussion (TBT) For Manual Grinding OperationDokumen3 halamanTheme Based Safety Discussion (TBT) For Manual Grinding OperationMr. XBelum ada peringkat

- Guillotine (Metal) PDFDokumen1 halamanGuillotine (Metal) PDFcityofdarwingisBelum ada peringkat

- Confined Spaces CardsDokumen1 halamanConfined Spaces CardsJafar KhanBelum ada peringkat

- Pha ExcavationDokumen13 halamanPha ExcavationirshadBelum ada peringkat

- Generator (Portable) PDFDokumen1 halamanGenerator (Portable) PDFcityofdarwingisBelum ada peringkat

- Kitchen Safety and Sanitation: Think!Dokumen21 halamanKitchen Safety and Sanitation: Think!Tara NahBelum ada peringkat

- December-22 (Week-1)Dokumen11 halamanDecember-22 (Week-1)pabitra pandaBelum ada peringkat

- Job StudyDokumen3 halamanJob StudyVictor PhiriBelum ada peringkat

- The Flow Chart of Waste Tires Recycling Pyrolysis Equipment For 8TDokumen3 halamanThe Flow Chart of Waste Tires Recycling Pyrolysis Equipment For 8Tpyrolysisoil100% (1)

- Index: Cv. Dira Utama SejahteraDokumen12 halamanIndex: Cv. Dira Utama SejahteraFreshop SurabayaBelum ada peringkat

- 1 45Dokumen3 halaman1 45nsadnan0% (1)

- Safety Topic 863 - Working Under Suspended LoadsDokumen2 halamanSafety Topic 863 - Working Under Suspended LoadsAshishBelum ada peringkat

- DCL (Logo) : Hand BookDokumen16 halamanDCL (Logo) : Hand BookJahangir ShaBelum ada peringkat

- 01-Ppe Eng PDFDokumen17 halaman01-Ppe Eng PDFZaki AdamouBelum ada peringkat

- Toolbox Meeting GuideDokumen8 halamanToolbox Meeting Guidebeng acostaBelum ada peringkat

- Job Hazrd AnalysisDokumen2 halamanJob Hazrd AnalysisMelford BernardBelum ada peringkat

- Safety & Health ProgramDokumen2 halamanSafety & Health ProgramD.k. PathakBelum ada peringkat

- Hse Plan 3Dokumen14 halamanHse Plan 3YcRij SeYerBelum ada peringkat

- Working at Heights: Dr.P.MuralidharDokumen48 halamanWorking at Heights: Dr.P.MuralidharRituraj SinghBelum ada peringkat

- JHA 001 Welding OperationsDokumen3 halamanJHA 001 Welding OperationsAhmad alwaelyBelum ada peringkat

- University of Kent General Health & Safety InductionDokumen20 halamanUniversity of Kent General Health & Safety InductionMijanur RahmanBelum ada peringkat

- Summit Lockout TagoutDokumen36 halamanSummit Lockout TagoutMuhammad AdnanBelum ada peringkat

- Daily HSE ReportDokumen5 halamanDaily HSE ReportSayeed MalikBelum ada peringkat

- Theme Based Safety Discussion - Gas Cylinder Storage & HandlingDokumen2 halamanTheme Based Safety Discussion - Gas Cylinder Storage & HandlingMr. XBelum ada peringkat

- Machine Safety in ConstructionDokumen27 halamanMachine Safety in ConstructionSawyu Nandar100% (1)

- PTW-Hot Work 2-Checklist 35 - Well Entry OperationsDokumen4 halamanPTW-Hot Work 2-Checklist 35 - Well Entry OperationsalizareiforoushBelum ada peringkat

- Standard Operation Procedures (S.O.P) For Milling MachineDokumen1 halamanStandard Operation Procedures (S.O.P) For Milling MachineZulizudinOthmanBelum ada peringkat

- Chemical LabelsDokumen11 halamanChemical LabelsAriel Dela CruzBelum ada peringkat

- Test Method For Earthwork Compaction Control by Nuclear GaugeDokumen29 halamanTest Method For Earthwork Compaction Control by Nuclear GaugeLennieCartujanoLuceñoBelum ada peringkat

- Generic Mechanical Workshop Risk AssessmentDokumen6 halamanGeneric Mechanical Workshop Risk AssessmentMohammad Abubakar SiddiqBelum ada peringkat

- Fork Lift Daily Check: (Only For FL Operated by Batery)Dokumen1 halamanFork Lift Daily Check: (Only For FL Operated by Batery)Martin CabelloBelum ada peringkat

- Window CleaningDokumen1 halamanWindow CleaningSanthoshKumarBelum ada peringkat

- Hand and Power Tools Safety - MCFM - DraftDokumen22 halamanHand and Power Tools Safety - MCFM - DraftEldhose Varghese100% (1)

- GPCB SOP For De-Contamination FacilityDokumen9 halamanGPCB SOP For De-Contamination FacilityEHS HalolBelum ada peringkat

- ABC's of Fall Protection: Murray State University Susan MillerDokumen24 halamanABC's of Fall Protection: Murray State University Susan MillerSam SalesBelum ada peringkat

- JSEA FOR DISMNTLING OF MACHINES (Central Work Shop)Dokumen16 halamanJSEA FOR DISMNTLING OF MACHINES (Central Work Shop)B&R HSE BALCO SEP SiteBelum ada peringkat

- Hot Work Program PDFDokumen49 halamanHot Work Program PDFAnonymous wtK1AZBiBelum ada peringkat

- Scaffold TowerDokumen20 halamanScaffold TowerAndhika HerdiawanBelum ada peringkat

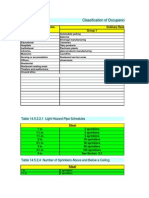

- توابت حسابات الحريق وجداولهاDokumen26 halamanتوابت حسابات الحريق وجداولهاsafety86Belum ada peringkat

- Unsafe Acts Safety TalkDokumen1 halamanUnsafe Acts Safety Talksafety86Belum ada peringkat

- Safety MomentsDokumen1 halamanSafety Momentssafety86100% (1)

- HSE Tool Box TalkDokumen47 halamanHSE Tool Box TalkAbdulKather100% (10)

- 04 Flame TemperatureDokumen38 halaman04 Flame TemperatureGnanasambandan SwaminathanBelum ada peringkat

- Unsafe Acts Safety TalkDokumen1 halamanUnsafe Acts Safety Talksafety86Belum ada peringkat

- Accident Report FormDokumen1 halamanAccident Report Formsafety86Belum ada peringkat

- Fire Fighting: Shabbir ChannaDokumen20 halamanFire Fighting: Shabbir Channasafety86Belum ada peringkat

- Fire Fighting Course - PPSXDokumen58 halamanFire Fighting Course - PPSXsafety86Belum ada peringkat

- 3% Fluoroprotein Foam Concentrate.: PH: 7 0.5 Viscosity at 20 c5: Minimum 7 Cs. Storage Temperature: (-5 To 49) c5Dokumen2 halaman3% Fluoroprotein Foam Concentrate.: PH: 7 0.5 Viscosity at 20 c5: Minimum 7 Cs. Storage Temperature: (-5 To 49) c5safety86Belum ada peringkat

- 3% Fluoroprotein Foam Concentrate.: PH: 7 0.5 Viscosity at 20 c5: Minimum 7 Cs. Storage Temperature: (-5 To 49) c5Dokumen2 halaman3% Fluoroprotein Foam Concentrate.: PH: 7 0.5 Viscosity at 20 c5: Minimum 7 Cs. Storage Temperature: (-5 To 49) c5safety86Belum ada peringkat

- Foot ProtectDokumen29 halamanFoot Protectjinyuan74100% (1)

- Fire Crisis - PPSXDokumen17 halamanFire Crisis - PPSXsafety86Belum ada peringkat

- Accident Reporting Procedure 1Dokumen2 halamanAccident Reporting Procedure 1safety86Belum ada peringkat

- IMS PolicyDokumen2 halamanIMS Policysafety86Belum ada peringkat

- 27k Crane Lifting PermitDokumen1 halaman27k Crane Lifting Permitsafety86Belum ada peringkat

- Accident Report FormDokumen1 halamanAccident Report Formsafety86Belum ada peringkat

- Human Factors in Accident Investigation: David BirkbeckDokumen30 halamanHuman Factors in Accident Investigation: David Birkbecksafety86Belum ada peringkat

- Safety at Work AwardsDokumen37 halamanSafety at Work Awardssafety86Belum ada peringkat

- Safety at Work: and Here Are The Winners of The CompetitionDokumen23 halamanSafety at Work: and Here Are The Winners of The Competitionsafety86Belum ada peringkat

- Bauer Hse Policy enDokumen1 halamanBauer Hse Policy ensafety86Belum ada peringkat

- Testing of Lifts: Simple Guidance For Lift Owners (INDG339) )Dokumen2 halamanTesting of Lifts: Simple Guidance For Lift Owners (INDG339) )safety86Belum ada peringkat

- Generic PpeDokumen32 halamanGeneric Ppesafety86Belum ada peringkat

- 3% Fluoroprotein Foam Concentrate.: PH: 7 0.5 Viscosity at 20 c5: Minimum 7 Cs. Storage Temperature: (-5 To 49) c5Dokumen2 halaman3% Fluoroprotein Foam Concentrate.: PH: 7 0.5 Viscosity at 20 c5: Minimum 7 Cs. Storage Temperature: (-5 To 49) c5safety86Belum ada peringkat

- Topic One: An Introduction To Health & Safety in IndustryDokumen19 halamanTopic One: An Introduction To Health & Safety in IndustrysrkamBelum ada peringkat

- Editable Health and Safety FormsDokumen32 halamanEditable Health and Safety FormsFlavia Rodrigo Guedes100% (1)

- 2fse Hierarchy of ControlDokumen17 halaman2fse Hierarchy of ControlredbireBelum ada peringkat

- China Hydrotest FailureDokumen7 halamanChina Hydrotest FailureaatkhoBelum ada peringkat

- Welding, Cutting and Brazing ChecklistDokumen11 halamanWelding, Cutting and Brazing ChecklistokamoBelum ada peringkat

- Sample Written Program For Fall Protection: Provided As A Public Service byDokumen25 halamanSample Written Program For Fall Protection: Provided As A Public Service bysafety86Belum ada peringkat

- BERKLYNInformation SheetDokumen6 halamanBERKLYNInformation SheetvillatoreubenBelum ada peringkat

- Bai Tap Avtc2 PrepositionsDokumen5 halamanBai Tap Avtc2 PrepositionsShy NotBelum ada peringkat

- I. Level of Barriers in ICT Knowledge, Skills, and Competencies No ICT Knowledge, Skills and Competency Barriers SDA DA N A SADokumen2 halamanI. Level of Barriers in ICT Knowledge, Skills, and Competencies No ICT Knowledge, Skills and Competency Barriers SDA DA N A SAMuhamad KhoerulBelum ada peringkat

- Fuel Injection PDFDokumen11 halamanFuel Injection PDFscaniaBelum ada peringkat

- List of Every National School Walkout PDF LinksDokumen373 halamanList of Every National School Walkout PDF LinksStephanie Dube Dwilson100% (1)

- Bye Laws For MirzapurDokumen6 halamanBye Laws For MirzapurUtkarsh SharmaBelum ada peringkat

- 05271/MFP YPR SPL Sleeper Class (SL)Dokumen2 halaman05271/MFP YPR SPL Sleeper Class (SL)Rdx BoeBelum ada peringkat

- BTL - 5000 SWT - Service Manual PDFDokumen158 halamanBTL - 5000 SWT - Service Manual PDFNuno Freitas BastosBelum ada peringkat

- E10.unit 3 - Getting StartedDokumen2 halamanE10.unit 3 - Getting Started27. Nguyễn Phương LinhBelum ada peringkat

- Business Maths Chapter 5Dokumen9 halamanBusiness Maths Chapter 5鄭仲抗Belum ada peringkat

- Anin, Cris Adrian U. Experiment Water Flirtation ELECTIVE 103Dokumen2 halamanAnin, Cris Adrian U. Experiment Water Flirtation ELECTIVE 103Cris Adrian Umadac AninBelum ada peringkat

- Financial/ Accounting Ratios: Sebi Grade A & Rbi Grade BDokumen10 halamanFinancial/ Accounting Ratios: Sebi Grade A & Rbi Grade Bneevedita tiwariBelum ada peringkat

- Dr. Muhammad Mumtaz: Thesis TitleDokumen10 halamanDr. Muhammad Mumtaz: Thesis TitleDr. Muhammad MumtazBelum ada peringkat

- 2062 TSSR Site Sharing - Rev02Dokumen44 halaman2062 TSSR Site Sharing - Rev02Rio DefragBelum ada peringkat

- Role of ACT, S & WHO Guidlines For The Treatment of MalariaDokumen34 halamanRole of ACT, S & WHO Guidlines For The Treatment of MalariasalmanBelum ada peringkat

- Nanomedicine Lecture 2007Dokumen59 halamanNanomedicine Lecture 200778912071Belum ada peringkat

- Kharrat Et Al., 2007 (Energy - Fuels)Dokumen4 halamanKharrat Et Al., 2007 (Energy - Fuels)Leticia SakaiBelum ada peringkat

- Trading Book - AGDokumen7 halamanTrading Book - AGAnilkumarGopinathanNairBelum ada peringkat

- Strategy Guide To Twilight Imperium Third EditionDokumen74 halamanStrategy Guide To Twilight Imperium Third Editioninquartata100% (1)

- Festival Implementation PlanDokumen5 halamanFestival Implementation Planapi-318058589Belum ada peringkat

- Denso - History PDFDokumen5 halamanDenso - History PDFVenkateswaran KrishnamurthyBelum ada peringkat

- Simple Fat Burning Exercises at Home or GymDokumen6 halamanSimple Fat Burning Exercises at Home or GymShirleyBelum ada peringkat

- Annexure I Project Details DateDokumen4 halamanAnnexure I Project Details DateAshish SinghaniaBelum ada peringkat

- Syllabus Math 305Dokumen4 halamanSyllabus Math 305Nataly SusanaBelum ada peringkat

- Module No.3 Prepare Architectual Job Requirements Architectural Working DrawingDokumen23 halamanModule No.3 Prepare Architectual Job Requirements Architectural Working DrawingJay S. On100% (1)

- FWN Magazine 2018 - Leonor VintervollDokumen48 halamanFWN Magazine 2018 - Leonor VintervollFilipina Women's NetworkBelum ada peringkat

- Bylaws of A Texas CorporationDokumen34 halamanBylaws of A Texas CorporationDiego AntoliniBelum ada peringkat