Pheonwj X DSH 0001 0

Diunggah oleh

Iksan Adityo MulyoJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Pheonwj X DSH 0001 0

Diunggah oleh

Iksan Adityo MulyoHak Cipta:

Format Tersedia

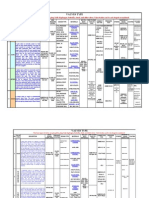

|DOCUMENTUM|2/21/2011|Paper Copies are Uncontrolled|

PT. PHE ONWJ

Piping Data Sheet

Revision Log Register

Document No.

Document Title

Revision

Page

: PHEONWJ-X-DSH-0001

: Piping Data Sheet

: 0

Date

Revision

PHE ONWJ

Reviewer

PHEONWJ-X-DSH-0001 Rev. 0

|DOCUMENTUM|2/21/2011|Paper Copies are Uncontrolled|

Page 2 of 5

PT. PHE ONWJ

Piping Data Sheet

Table of Content

Revision Log Register.......................................................................................................................2

Table of Content ...............................................................................................................................3

1.

Scope .....................................................................................................................................4

2.

Guide Line ..............................................................................................................................4

3.

Data Sheet Attachment..........................................................................................................4

3.1

Valve Data Sheet .........................................................................................................4

3.2

Piping Specialty Item Data Sheet ................................................................................4

3.3

Fire Fighting Data Sheet ..............................................................................................5

PHEONWJ-X-DSH-0001 Rev. 0

|DOCUMENTUM|2/21/2011|Paper Copies are Uncontrolled|

Page 3 of 5

PT. PHE ONWJ

Piping Data Sheet

1.

Scope

This document describes the data sheets format and the minimum requirements for the Manual

Valves, Piping Specialty Items & Fire Fighting Equipments to be installed at offshore and onshore

facilities of PT. Pertamina Hulu Energi Offshore North West Java (PHEONWJ).

2.

Guide Line

The group of Data Sheets in this document is PHEONWJ Standard Data Sheet format, which will

be used in each Project. The following guide line should be taken, to utilize the Standard Data

Sheet

a. The number of document shall follow Project Document Numbering System

b. As required by Project, new items may be added as necessary on the Data Sheet format.

c. Project shall review and revise if necessary, the notes / remarks at below of Data Sheet,

to accommodate Project requirement.

d. Project shall give the feed back to function engineering in case any finding or

improvement of the Data Sheet format

3.

Data Sheet Attachment

3.1

3.2

Valve Data Sheet

3.1.1

Data Sheet Ball Valve Soft Seated

3.1.2

Data Sheet Ball Valve Metal Seated

3.1.3

Data Sheet Gate Valve

3.1.4

Data Sheet Globe Valve

3.1.5

Data Sheet Check Valve

3.1.6

Data Sheet Double Isolation & Bleed Valve (Ball Valve Soft Seated

DIB Valve)

3.1.7

Data Sheet Double Isolation & Bleed Valve (Ball Valve Metal Seated

DIB Valve)

3.1.8

Data Sheet Butterfly Valve

3.1.9

Data Sheet Needle Valve

3.1.10 Data Sheet Plug Valve

Piping Specialty Item Data Sheet

3.2.1

Data Sheet Bleed Ring

3.2.2

Data Sheet Cone Strainer

3.2.3

Data Sheet Y Type Strainer

3.2.4

Data Sheet Basket Type Strainer

3.2.5

Data Sheet T Type Strainer

3.2.6

Data Sheet Spectacle Blind

3.2.7

Data Sheet Auto Drain Trap

3.2.8

Data Sheet Fluidic Vent Tip

3.2.9

Data Sheet Quick Coupling

3.2.10 Data Sheet Quick Opening Closure

PHEONWJ-X-DSH-0001 Rev. 0

|DOCUMENTUM|2/21/2011|Paper Copies are Uncontrolled|

Page 4 of 5

PT. PHE ONWJ

Piping Data Sheet

3.3

3.2.11 Data Sheet Chemical Hose

3.2.12 Data Sheet Sample Bomb

3.2.13 Data Sheet Unloading Hose

3.2.14 Data Sheet Flame Arrestor

3.2.15 Data Sheet Pipe Repair Clamp

Fire Fighting Data Sheet

3.3.1

Data Sheet Fire Hydrant

3.3.2

Data Sheet Fire Monitor

3.3.3

Data Sheet Fire Extinguisher

3.3.4

Data Sheet Hose Reel

3.3.5

Data Sheet Fire Hose Box

3.3.6

Data Sheet Spray Nozzle

PHEONWJ-X-DSH-0001 Rev. 0

|DOCUMENTUM|2/21/2011|Paper Copies are Uncontrolled|

Page 5 of 5

VALVE DATA SHEET

|DOCUMENTUM|2/21/2011|Paper Copies are Uncontrolled|

Project Title:

Document Number

STC - 0488

(PT.Tripatra Engineering)

PHEONWJ-X-DSH-XXXX

Authors Org.

Engineering Group

Validation:

Expired Date:

DATASHEET

BALL VALVE

SOFT SEAT

Approval Sheet

Title

Name

Rev.

Issue Date

06-Sep-10

Revision Status

PT.Tripatra Engineering

Appd.

Pred.

Chkd.

ELS

HWB

EH

Date

Signature

Issue Purpose

Owner

Signature

Issued for Approval

IMS

|DOCUMENTUM|2/21/2011|Paper Copies are Uncontrolled|

PIPING DATA SHEET

BALL VALVE SOFT SEAT

DOC. NO. :

PHEONWJ-X-DSH-XXXX

SHEET

2 OF

27

ENGINEERING GROUP

PROJECT :

DESCRIPTION

REV.

DATE

BY

TABULATION OF REVISION PAGES

SHEET

A

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

REVISION

D E F

SHEET

A

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

|DOCUMENTUM|2/21/2011|Paper Copies are Uncontrolled|

CHECKD

APPVD

PIPING DATA SHEET

BALL VALVE SOFT SEAT

DOC. NO. :

PHEONWJ-X-DSH-XXXX

SHEET

: 3 OF 27

ENGINEERING GROUP

PROJECT :

DESCRIPTION

REV. DATE

BY

CHECKD

APPVD

GENERAL INFORMATION

2 Service :

Process Hydrocarbon, pressure drain, fire water, utility & salt water,

Unit Tag No : D2Z

3

open drain, closed drain, wellhead process hydrocarbon, pressure drain

No Required :

4

Serial No :

5 Brand :

OMB, Balon, Mc. Canna, Oliver Valve, Starline S.p.A, Velan, PBV, Orsenigo,

PO No :

Bonney Forge, Sri, Anderson Greenwood, Argus, Flow Control Oil&Gas Inc,

Hoke, Jamesburry, Keystone, Parker, Star-Line, Whitey. (O.E.M. Only)

TECHNICAL DATA

10 Valve Type :

Ball Valve

11 Valve Size & Rating:

1/2" to 1-1/2" - 800#

Socket Weld x Socket Weld

(Note ii)

12 End Connection :

13

14 Design :

API 608

15

ASME 16.34 Pressure & Temperature Rating

16

Floating Ball, Replaceable Ball & Seat, Full Bore, Fire safe as per BS 10497

17

End to End dimension as per Manufacturer Standard

18

19

20

21

22

23 Operator :

Lever

24

25

MATERIAL CONSTRUCTION

26 Body and Bonnet:

ASTM A105

27 Ball:

ASTM A 182 F316 SS

28 Seat Retainer:

N/A

29 Resilient Seat:

Thermoplastic, Carbon filled PTFE (Reinforced PTFE)

30 Stem:

ASTM A 182 F316 SS

31 Bolt & Nuts:

ASTM A 193 Gr.B7 Studs, Fluorocarbon Coated

32

ASTM A 194 Gr.2H Nuts, Fluorocarbon Coated

33 Body Seal:

Elastomer, Viton, PTFE

34 Body Gasket:

Graphite, Flexible

35 Test and Inspection :

API 598

36

37 Fire Test :

API 607 or BS EN ISO 10497

38

39 Operating Paramaters :

40 Max Diff. Pressure :

Max. Rating Pressure (when not speficied by Purchaser)

o

F

50

-250

41 Temp. Range :

42 Painting :

As Per PHEONWJ-F-PRC-0007 Site Technical Practices (STP) for Painting on Metal Surfaces

43

44 Applicable Standard :

API 608 - latest edition

45

Company Spec : - PHEONWJ-F-PRC-0007 Site Technical Practices (STP) for Painting on Metal Surfaces

46

- PHEONWJ-X-SPE-0003 Valve Specification

47 Remarks :

48 (i) Minimum Seat rating shall be 1500# CWP

49 (ii) Nipple 100mm length plain end, ASTM A106 Gr.B SMLS Sch.80 shall be welded on both side or forged integral nipples to ASTM A105

50 (iii) All valve shall have valid license of quality certificates. Manufacturing shall be done in origin country.

51 Company reserves right to investigate and visit factory

52 (iv) Max Allowable size for all elastomeric seal (incl. O-Ring) shall be six (6) mm

53 (v) Valve marking in accordance with MSS SP-25

54 (vi) Valve shall be new. Valve from stock will be considered in case date of manufactured not longer than two (2) years

55

|DOCUMENTUM|2/21/2011|Paper Copies are Uncontrolled|

PIPING DATA SHEET

BALL VALVE SOFT SEAT

DOC. NO. :

PHEONWJ-X-DSH-XXXX

SHEET

: 4 OF 27

ENGINEERING GROUP

PROJECT :

DESCRIPTION

REV. DATE

BY

CHECKD

APPVD

GENERAL INFORMATION

2 Service :

Process Hydrocarbon, pressure drain, fire water, utility & salt water,

Unit Tag No : D2ZOS

3

open drain, closed drain, wellhead process hydrocarbon, pressure drain

No Required :

4

Serial No :

5 Brand :

OMB, Balon, Mc. Canna, Oliver Valve, Starline S.p.A, Velan, PBV, Orsenigo,

PO No :

Bonney Forge, Sri, Anderson Greenwood, Argus, Flow Control Oil&Gas Inc,

Hoke, Jamesburry, Keystone, Parker, Star-Line, Whitey. (O.E.M. Only)

TECHNICAL DATA

10 Valve Type :

Ball Valve

11 Valve Size & Rating:

1/2" to 1-1/2" - 800#

Socket Weld x Screwed End

(Note ii)

12 End Connection :

13

14 Design :

API 608

15

ASME 16.34 Pressure & Temperature Rating

16

Floating Ball, Replaceable Ball & Seat, Full Bore, Fire safe as per BS 10497

17

End to End dimension as per Manufacturer Standard

18

19 Operator :

Lever

20

21

MATERIAL CONSTRUCTION

22 Body and Bonnet:

ASTM A105

23 Ball:

ASTM A 182 F316 SS

24 Seat Retainer:

N/A

25 Resilient Seat:

Thermoplastic, Carbon filled PTFE (Reinforced PTFE)

26 Stem:

ASTM A 182 F316 SS

27 Bolt & Nuts:

ASTM A 193 Gr.B7 Studs, Fluorocarbon Coated

28

ASTM A 194 Gr.2H Nuts, Fluorocarbon Coated

29 Body Seal:

Elastomer, Viton, PTFE

30 Body Gasket:

Graphite, Flexible

31

32 Test and Inspection :

API 598

33

34 Fire Test :

API 607 or BS EN ISO 10497

35

36 Operating Paramaters :

37 Max Diff. Pressure :

Max. Rating Pressure (when not speficied by Purchaser)

o

F

50

-250

38 Temp. Range :

39 Painting :

As Per PHEONWJ-F-PRC-0007 Site Technical Practices (STP) for Painting on Metal Surfaces

40

41 Applicable Standard :

API 608 - latest edition

42

Company Spec : - PHEONWJ-F-PRC-0007 Site Technical Practices (STP) for Painting on Metal Surfaces

43

- PHEONWJ-X-SPE-0003 Valve Specification

44 Remarks :

45 (i) Minimum Seat rating shall be 1500# CWP

46 (ii) Nipple 100mm length plain end, ASTM A106 Gr.B SMLS Sch.80 shall be welded on both side or forged integral nipples to ASTM A105

47 (iii) All valve shall have valid license of quality certificates. Manufacturing shall be done in origin country.

48 Company reserves right to investigate and visit factory

49 (iv) Max Allowable size for all elastomeric seal (incl. O-Ring) shall be six (6) mm

50 (v) Valve marking in accordance with MSS SP-25

51 (vi) Valve shall be new. Valve from stock will be considered in case date of manufactured not longer than two (2) years

52

53

54

55

|DOCUMENTUM|2/21/2011|Paper Copies are Uncontrolled|

PIPING DATA SHEET

BALL VALVE SOFT SEAT

DOC. NO. :

PHEONWJ-X-DSH-XXXX

SHEET

: 5 OF 27

ENGINEERING GROUP

PROJECT :

DESCRIPTION

REV. DATE

BY

CHECKD

APPVD

GENERAL INFORMATION

2 Service :

Process Hydrocarbon

Unit Tag No : F2Z

3

No Required :

4 Brand :

OMB, Balon, Mc. Canna, Oliver Valve, Starline S.p.A, Velan, PBV, Orsenigo,

Serial No :

Bonney Forge, Sri, Anderson Greenwood, Argus, Flow Control Oil&Gas Inc,

PO No :

Hoke, Jamesburry, Keystone, Parker, Star-Line, Whitey. (O.E.M. Only)

TECHNICAL DATA

10 Valve Type :

Ball Valve

11 Valve Size & Rating:

1/2" to 1-1/2" - 1500#

Socket Weld x Socket Weld

(Note ii)

12 End Connection :

13

14 Design :

API 608

15

ASME 16.34 Pressure & Temperature Rating

16

Bolted Bonnet, Non Lubricated, Floating Ball, Replaceable Ball & Seat, Full Bore,

17

Fire safe as per BS 10498

18

End to End dimension as per Manufacturer Standard

19 Operator :

Lever

20

21

MATERIAL CONSTRUCTION

22 Body and Bonnet:

ASTM A105

23 Ball:

ASTM A 182 F316 SS

24 Seat Retainer:

N/A

25 Resilient Seat:

Thermoplastic, Carbon filled PTFE (Reinforced PTFE)

26 Stem:

ASTM A 182 F316 SS

27 Bolt & Nuts:

ASTM A 193 Gr.B7 Studs, Fluorocarbon Coated

28

ASTM A 194 Gr.2H Nuts, Fluorocarbon Coated

29 Body Seal:

Elastomer, Viton, PTFE

30 Body Gasket:

Graphite, Flexible

31

32 Test and Inspection :

API 598

33

34 Fire Test :

API 607 or BS EN ISO 10497

35

36 Operating Paramaters :

37 Max Diff. Pressure :

Max. Rating Pressure (when not speficied by Purchaser)

o

F

50

-250

38 Temp. Range :

39 Painting :

As Per PHEONWJ-F-PRC-0007 Site Technical Practices (STP) for Painting on Metal Surfaces

40

41 Applicable Standard :

API 608 - latest edition

42

Company Spec : - PHEONWJ-F-PRC-0007 Site Technical Practices (STP) for Painting on Metal Surfaces

43

- PHEONWJ-X-SPE-0003 Valve Specification

44 Remarks :

45 (i) Minimum Seat rating shall be 3705# CWP

46 (ii) Nipple 100mm length plain end, ASTM A106 Gr.B SMLS Sch.160 shall be both on SW side or forged integral nipples to ASTM A105

47 (iii) All valve shall have valid license of quality certificates. Manufacturing shall be done in origin country.

48 Company reserves right to investigate and visit factory

49 (iv) Max. allowable size for all elastomeric seal (incl. O-Ring) shall be six (6) mm. Material of elastomer shall be explosive decompression

50 resistant grade (AED)

51 (v) Valve marking in accordance with MSS SP-25

52 (vi) Valve shall be new. Valve from stock will be considered in case date of manufactured not longer than two (2) years

53

54

55

|DOCUMENTUM|2/21/2011|Paper Copies are Uncontrolled|

PIPING DATA SHEET

BALL VALVE SOFT SEAT

DOC. NO. :

PHEONWJ-X-DSH-XXXX

SHEET

6 OF 27

ENGINEERING GROUP

PROJECT :

DESCRIPTION

REV. DATE

BY

CHECKD

APPVD

GENERAL INFORMATION

2 Service :

Process Hydrocarbon

Unit Tag No : F2ZOS

3

No Required :

4 Brand :

OMB, Balon, Mc. Canna, Oliver Valve, Starline S.p.A, Velan, PBV, Orsenigo,

Serial No :

Bonney Forge, Sri, Anderson Greenwood, Argus, Flow Control Oil&Gas Inc,

PO No :

Hoke, Jamesburry, Keystone, Parker, Star-Line, Whitey. (O.E.M. Only)

TECHNICAL DATA

10 Valve Type :

Ball Valve

11 Valve Size & Rating:

1/2" to 1-1/2" - 1500#

Socket Weld x Screwed End

(Note ii)

12 End Connection :

13

14 Design :

API 608

15

ASME 16.34 Pressure & Temperature Rating

16

Bolted Bonnet, Non Lubricated, Floating Ball, Replaceable Ball & Seat, Full Bore,

17

Fire safe as per BS 10498

18

End to End dimension as per Manufacturer Standard

19 Operator :

Lever

20

21

MATERIAL CONSTRUCTION

22 Body and Bonnet:

ASTM A105

23 Ball:

ASTM A 182 F316 SS

24 Seat Retainer:

N/A

25 Resilient Seat:

Thermoplastic, Carbon filled PTFE (Reinforced PTFE)

26 Stem:

ASTM A 182 F316 SS

27 Bolt & Nuts:

ASTM A 193 Gr.B7 Studs, Fluorocarbon Coated

28

ASTM A 194 Gr.2H Nuts, Fluorocarbon Coated

29 Body Seal:

Elastomer, Viton, PTFE

30 Body Gasket:

Graphite, Flexible

31

32 Test and Inspection :

API 598

33

34 Fire Test :

API 607 or BS EN ISO 10497

35

36 Operating Paramaters :

37 Max Diff. Pressure :

Max. Rating Pressure (when not speficied by Purchaser)

o

F

50

-250

38 Temp. Range :

39 Painting :

As Per PHEONWJ-F-PRC-0007 Site Technical Practices (STP) for Painting on Metal Surfaces

40

41 Applicable Standard :

API 608 - latest edition

42

Company Spec : - PHEONWJ-F-PRC-0007 Site Technical Practices (STP) for Painting on Metal Surfaces

43

- PHEONWJ-X-SPE-0003 Valve Specification

44 Remarks :

45 (i) Minimum Seat rating shall be 3705# CWP

46 (ii) Nipple 100mm length plain end, ASTM A106 Gr.B SMLS Sch.80 shall be welded on SW side or forged integral nipples to ASTM A105

47 (iii) All valve shall have valid license of quality certificates. Manufacturing shall be done in origin country.

48 Company reserves right to investigate and visit factory

49 (iv) Max. allowable size for all elastomeric seal (incl. O-Ring) shall be six (6) mm. Material of elastomer shall be explosive decompression

50 resistant grade (AED)

51 (v) Valve marking in accordance with MSS SP-25

52 (vi) Valve shall be new. Valve from stock will be considered in case date of manufactured not longer than two (2) years

53

54

55

|DOCUMENTUM|2/21/2011|Paper Copies are Uncontrolled|

PIPING DATA SHEET

BALL VALVE SOFT SEAT

DOC. NO. :

PHEONWJ-X-DSH-XXXX

SHEET

: 7 OF 27

ENGINEERING GROUP

PROJECT :

DESCRIPTION

REV. DATE

BY

CHECKD

APPVD

GENERAL INFORMATION

2 Service :

Process Hydrocarbon, pressure drain, fire water, utility & salt water,

Unit Tag No : A2R

3

open drain, closed drain, wellhead process hydrocarbon, pressure drain

No Required :

4

Serial No :

5 Brand :

O.E.M only; Balon, Ring-O, Grove, OMS Salery, Perar, Petrovalves,

PO No :

6

Pibiviesse, FCT, Tormene, Weir, MSA, Velan, PBV, Orsenigo, Sri, Argus,

7

WKM, KVC, Flow Control Oil&Gas Inc., KTM, KVC, Neles Jamesburry,

8

Orbit, OIC, TK, Stream Flo/Master Flo, KF(USA)

TECHNICAL DATA

10

11 Valve Type :

Ball Valve

12 Valve Size & Rating:

2" and Larger - ANSI 150#

13 End Connection :

RF Flange ASME B 16.5, ASME B16.47 Series A (for size 26")

14

Flange Face Finish 120 to 140 RMS

15 Design :

API 6D (ISO 14313)

16

ASME 16.34 Pressure & Temperature Rating

17

Bolted Bonnet, Replaceable Ball & Seat, Full Bore, Floating Ball up to 4", Trunnion Mounted Ball for 6"

18

and Larger, Side Entry

19

Fire safe as per API 6FA or API 607/BS EN ISO 10497

20

Blow out Proof, Anti Static

Face to face dimension as per ASME B16.10

(Note vi)

21

22 Operator :

Lever Operated : 2" - 4"

23

Gear Operated : 6" and Larger

24

MATERIAL CONSTRUCTION

25 Body and Bonnet:

ASTM A216-WCB

26 Ball:

ASTM A 105 + 3 mills ENP

27 Seat Retainer:

ASTM A 105 + 3 mills ENP

28 Resilent Seat:

Thermoplastic, Reinforced Viton, RPTFE

29 Stem:

Hot rolled Steel AISI 4140

30 Bolt & Nuts:

ASTM A 193 Gr.B7 Studs, Fluorocarbon Coated

31

ASTM A 194 Gr.2H Nuts, Fluorocarbon Coated

32 Body Seal

Elastomer, Viton, PTFE

33 Body Gasket:

Graphite

34 Test and Inspection :

API 6D (ISO 14313) and its modifications in Company Specifications. Acceptable leak rate as per

35

ISO 5208 Rate A

36 Fire Test :

API 607 (BS EN ISO 10497) or API 6FA

37 Operating Paramaters :

38 Max Diff. Pressure :

Max. Rating Pressure (when not speficied by Purchaser)

o

o

50

-250

F

39 Temp. Range :

40 Painting :

As Per PHEONWJ-F-PRC-0007 Site Technical Practices (STP) for Painting on Metal Surfaces

41 Applicable Standard :

API 6D (ISO 14313) - Latest Edition

42

Company Spec : - PHEONWJ-F-PRC-0007 Site Technical Practices (STP) for Painting on Metal Surfaces

43

- PHEONWJ-X-SPE-0003 Valve Specification

44 Remarks :

45 (i) All valve shall have valid license of API 6D monogram and other quality certificates. Manufacturing shall be done in origin country.

46

Company reserves right to investigate and visit factory

47 (ii) Any seal component (esp. O-Ring) in dynamic application must prevent seal extrusion, galvanic corrosion & sticking that could prevent

48

its efficiency after a long stand period.

49 (iii) Max Allowable size for all elastomeric seal (incl. O-Ring) shall be six (6) mm

50 (iv) Seat pocket, seal housing and contact surfaces shall be overlaid by alloy 625 or SS 309

51 (v) For size 10" and larger shall be provided with vent and drain valve on the valve body.

52 (vi) The standard dimension is Long Pattern. For Short Pattern, shall be clearly noted.

53 (vii) Valve marking in accordance with MSS SP-25

54 (viii) Valve shall be new. Valve from stock will be considered in case date of manufactured not longer than two (2) years

55

|DOCUMENTUM|2/21/2011|Paper Copies are Uncontrolled|

PIPING DATA SHEET

BALL VALVE SOFT SEAT

DOC. NO. :

PHEONWJ-X-DSH-XXXX

SHEET

: 8 OF 27

ENGINEERING GROUP

PROJECT :

DESCRIPTION

REV. DATE

BY

CHECKD

APPVD

GENERAL INFORMATION

2 Service :

Process hydrocarbon, fire water, utility & salt water

Unit Tag No : B2R

3

No Required :

4 Brand :

O.E.M only; Balon, Ring-O, Grove, OMS Salery, Perar, Petrovalves,

Serial No :

5

Pibiviesse, FCT, Tormene, Weir, MSA, Velan, PBV, Orsenigo, Sri, Argus,

PO No :

6

WKM, KVC, Flow Control Oil&Gas Inc., KTM, KVC, Neles Jamesburry,

7

Orbit, OIC, TK, Stream Flo/Master Flo, KF(USA)

TECHNICAL DATA

10

11 Valve Type :

Ball Valve

12 Valve Size & Rating:

2" and Larger - ANSI 300#

13 End Connection :

RF Flange ASME B 16.5, ASME B16.47 Series A (for size 26")

14

Flange Face Finish 120 to 140 RMS

15 Design :

API 6D (ISO 14313)

16

ASME 16.34 Pressure & Temperature Rating

17

Bolted Bonnet, Replaceable Ball & Seat, Full Bore, Floating Ball up to 4", Trunnion Mounted Ball for 6"

18

and Larger, Side Entry

19

Fire safe as per API 6FA or API 607/BS EN ISO 10497

20

Blow out Proof, Anti Static

Face to face dimension as per ASME B16.10

(Note vi)

21

22 Operator :

Lever Operated : 2" - 4"

23

Gear Operated : 6" and Larger

24

MATERIAL CONSTRUCTION

25 Body and Bonnet:

ASTM A216-WCB

26 Ball:

ASTM A 105 + 3 mills ENP

27 Seat Retainer:

ASTM A 105 + 3 mills ENP

28 Resilent Seat:

Thermoplastic, Carbon Filled PTFE (Reinforced PTFE), Reinforced Viton

29 Stem:

Hot rolled Steel AISI 4140

30 Bolt & Nuts:

ASTM A 193 Gr.B7 Studs, Fluorocarbon Coated

31

ASTM A 194 Gr.2H Nuts, Fluorocarbon Coated

32 Body Seal

Elastomer, Viton, PTFE

33 Body Gasket:

Graphite

34 Test and Inspection :

API 6D (ISO 14313) and its modifications in Company Specifications. Acceptable leak rate as per

35

ISO 5208 Rate A

36 Fire Test :

API 607 (BS EN ISO 10497) or API 6FA

37 Operating Paramaters :

38 Max Diff. Pressure :

Max. Rating Pressure (when not speficied by Purchaser)

o

o

50

-250

F

39 Temp. Range :

40 Painting :

As Per PHEONWJ-F-PRC-0007 Site Technical Practices (STP) for Painting on Metal Surfaces

41 Applicable Standard :

API 6D (ISO 14313) - Latest Edition

42

Company Spec : - PHEONWJ-F-PRC-0007 Site Technical Practices (STP) for Painting on Metal Surfaces

43

- PHEONWJ-X-SPE-0003 Valve Specification

44 Remarks :

45 (i) All valve shall have valid license of API 6D monogram and other quality certificates. Manufacturing shall be done in origin country.

46

Company reserves right to investigate and visit factory

47 (ii) Any seal component (esp. O-Ring) in dynamic application must prevent seal extrusion, galvanic corrosion & sticking that could prevent

48

its efficiency after a long stand period.

49 (iii) Max Allowable size for all elastomeric seal (incl. O-Ring) shall be six (6) mm

50 (iv) Seat pocket, seal housing and contact surfaces shall be overlaid by alloy 625 or SS 309

51 (v) For size 10" and larger shall be provided with vent and drain valve on the valve body.

52 (vi) The standard dimension is Long Pattern. For Short Pattern, shall be clearly noted.

53 (vii) Valve marking in accordance with MSS SP-25

54 (viii) Valve shall be new. Valve from stock will be considered in case date of manufactured not longer than two (2) years

55

|DOCUMENTUM|2/21/2011|Paper Copies are Uncontrolled|

PIPING DATA SHEET

BALL VALVE SOFT SEAT

DOC. NO. :

PHEONWJ-X-DSH-XXXX

SHEET

: 9 OF 27

ENGINEERING GROUP

PROJECT :

DESCRIPTION

REV. DATE

BY

CHECKD

APPVD

GENERAL INFORMATION

2 Service :

Process Hydrocarbon, pressure drain, fire water, utility & salt water,

Unit Tag No : D2R

3

open drain, closed drain, wellhead process hydrocarbon, pressure drain

No Required :

4

Serial No :

5 Brand :

O.E.M only; Balon, Ring-O, Grove, OMS Salery, Perar, Petrovalves,

PO No :

6

Pibiviesse, FCT, Tormene, Weir, MSA, Velan, PBV, Orsenigo, Sri, Argus,

7

WKM, KVC, Flow Control Oil&Gas Inc., KTM, KVC, Neles Jamesburry,

8

Orbit, OIC, TK, Stream Flo/Master Flo, KF(USA)

TECHNICAL DATA

10

11 Valve Type :

Ball Valve

12 Valve Size & Rating:

2" and Larger - ANSI 600#

13 End Connection :

RF Flange ASME B 16.5, ASME B16.47 Series A (for size 26")

14

Flange Face Finish 120 to 140 RMS

15 Design :

API 6D (ISO 14313)

16

ASME 16.34 Pressure & Temperature Rating

17

Bolted Bonnet, Replaceable Ball & Seat, Full Bore, Floating Ball up to 3", Trunnion Mounted Ball for 4"

18

and Larger, Side Entry

19

Fire safe as per API 6FA or API 607/BS EN ISO 10497

20

Blow out Proof, Anti Static

Face to face dimension as per ASME B16.10

(Note vi)

21

22 Operator :

Lever Operated : 2" - 4"

23

Gear Operated : 6" and Larger

24

MATERIAL CONSTRUCTION

25 Body and Bonnet:

ASTM A216-WCB

26 Ball:

ASTM A 105 + 3 mills ENP

27 Seat Retainer:

ASTM A 105 + 3 mills ENP

28 Resilent Seat:

Thermoplastic, Carbon Filled PTFE (Reinforced PTFE), Reinforced Viton

29 Stem:

Hot rolled Steel AISI 4140

30 Bolt & Nuts:

ASTM A 193 Gr.B7 Studs, Fluorocarbon Coated

31

ASTM A 194 Gr.2H Nuts, Fluorocarbon Coated

32 Body Seal

Elastomer, Viton, PTFE

33 Body Gasket:

Graphite

34 Test and Inspection :

API 6D (ISO 14313) and its modifications in Company Specifications. Acceptable leak rate as per

35

ISO 5208 Rate A

36 Fire Test :

API 607 (BS EN ISO 10497) or API 6FA

37 Operating Paramaters :

38 Max Diff. Pressure :

Max. Rating Pressure (when not speficied by Purchaser)

o

o

50

-250

F

39 Temp. Range :

40 Painting :

As Per PHEONWJ-F-PRC-0007 Site Technical Practices (STP) for Painting on Metal Surfaces

41 Applicable Standard :

API 6D (ISO 14313) - Latest Edition

42

Company Spec : - PHEONWJ-F-PRC-0007 Site Technical Practices (STP) for Painting on Metal Surfaces

43

- PHEONWJ-X-SPE-0003 Valve Specification

44 Remarks :

45 (i) All valve shall have valid license of API 6D monogram and other quality certificates. Manufacturing shall be done in origin country.

46

Company reserves right to investigate and visit factory

47 (ii) Any seal component (esp. O-Ring) in dynamic application must prevent seal extrusion, galvanic corrosion & sticking that could prevent

48

its efficiency after a long stand period.

49 (iii) Max. allowable size for all elastomeric seal (incl. O-Ring) shall be six (6) mm. Material of elastomer shall be explosive decompression

50

resistant grade (AED)

51 (iv) Seat pocket, seal housing and contact surfaces shall be overlaid by alloy 625 or SS 309

52 (v) For size 8" and larger shall be provided with vent and drain valve on the valve body.

53 (vi) The standard dimension is Long Pattern. For Short Pattern, shall be clearly noted.

54 (vii) Valve marking in accordance with MSS SP-25

55 (viii) Valve shall be new. Valve from stock will be considered in case date of manufactured not longer than two (2) years

|DOCUMENTUM|2/21/2011|Paper Copies are Uncontrolled|

PIPING DATA SHEET

BALL VALVE SOFT SEAT

DOC. NO. :

PHEONWJ-X-DSH-XXXX

SHEET

: 10 OF 27

ENGINEERING GROUP

PROJECT :

DESCRIPTION

REV. DATE

BY

CHECKD

APPVD

GENERAL INFORMATION

2 Service :

Process Hydrocarbon

Unit Tag No : E2R

3

No Required :

4 Brand :

O.E.M only; Balon, Ring-O, Grove, OMS Salery, Perar, Petrovalves,

Serial No :

5

Pibiviesse, FCT, Tormene, Weir, MSA, Velan, PBV, Orsenigo, Sri, Argus,

PO No :

6

WKM, KVC, Flow Control Oil&Gas Inc., KTM, KVC, Neles Jamesburry,

7

Orbit, OIC, TK, Stream Flo/Master Flo, KF(USA)

TECHNICAL DATA

10

11 Valve Type :

Ball Valve

12 Valve Size & Rating:

2" and Larger - ANSI 900#

13 End Connection :

RF Flange ASME B 16.5, ASME B16.47 Series A (for size 26")

14

Flange Face Finish 120 to 140 RMS

15 Design :

API 6D (ISO 14313)

16

ASME 16.34 Pressure & Temperature Rating

17

Bolted Bonnet, Replaceable Ball & Seat, Full Bore, Floating Ball up to 3", Trunnion Mounted Ball for 4"

18

and Larger, Side Entry

19

Fire safe as per API 6FA or API 607/BS EN ISO 10497

20

Blow out Proof, Anti Static

Face to face dimension as per ASME B16.10

(Note vi)

21

22 Operator :

Lever Operated : 2" - 3"

23

Gear Operated : 4" and Larger

24

MATERIAL CONSTRUCTION

25 Body and Bonnet:

ASTM A216-WCB

26 Ball:

ASTM A 105 + 3 mills ENP

27 Seat Retainer:

ASTM A 105 + 3 mills ENP

28 Resilent Seat:

Thermoplastic, Carbon Filled PTFE (Reinforced PTFE), Reinforced Viton

29 Stem:

Hot rolled Steel AISI 4140

30 Bolt & Nuts:

ASTM A 193 Gr.B7 Studs, Fluorocarbon Coated

31

ASTM A 194 Gr.2H Nuts, Fluorocarbon Coated

32 Body Seal

Elastomer, Viton, PTFE

33 Body Gasket:

Graphite

34 Test and Inspection :

API 6D (ISO 14313) and its modifications in Company Specifications. Acceptable leak rate as per

35

ISO 5208 Rate A

36 Fire Test :

API 607 (BS EN ISO 10497) or API 6FA

37 Operating Paramaters :

38 Max Diff. Pressure :

Max. Rating Pressure (when not speficied by Purchaser)

o

o

50

-250

F

39 Temp. Range :

40 Painting :

As Per PHEONWJ-F-PRC-0007 Site Technical Practices (STP) for Painting on Metal Surfaces

41 Applicable Standard :

API 6D (ISO 14313) - Latest Edition

42

Company Spec : - PHEONWJ-F-PRC-0007 Site Technical Practices (STP) for Painting on Metal Surfaces

43

- PHEONWJ-X-SPE-0003 Valve Specification

44 Remarks :

45 (i) All valve shall have valid license of API 6D monogram and other quality certificates. Manufacturing shall be done in origin country.

46

Company reserves right to investigate and visit factory

47 (ii) Any seal component (esp. O-Ring) in dynamic application must prevent seal extrusion, galvanic corrosion & sticking that could prevent

48

its efficiency after a long stand period.

49 (iii) Max. allowable size for all elastomeric seal (incl. O-Ring) shall be six (6) mm. Material of elastomer shall be explosive decompression

50

resistant grade (AED)

51 (iv) Seat pocket, seal housing and contact surfaces shall be overlaid by alloy 625 or SS 309

52 (v) For size 8" and larger shall be provided with vent and drain valve on the valve body.

53 (vi) The standard dimension is Long Pattern. For Short Pattern, shall be clearly noted.

54 (vii) Valve marking in accordance with MSS SP-25

55 (viii) Valve shall be new. Valve from stock will be considered in case date of manufactured not longer than two (2) years

|DOCUMENTUM|2/21/2011|Paper Copies are Uncontrolled|

PIPING DATA SHEET

BALL VALVE SOFT SEAT

DOC. NO. :

PHEONWJ-X-DSH-XXXX

SHEET

: 11 OF 27

ENGINEERING GROUP

PROJECT :

DESCRIPTION

REV. DATE

BY

CHECKD

APPVD

GENERAL INFORMATION

2 Service :

Process Hydrocarbon

Unit Tag No : F2J

3

No Required :

4 Brand :

O.E.M only; Balon, Ring-O, Grove, OMS Salery, Perar, Petrovalves,

Serial No :

5

Pibiviesse, FCT, Tormene, Weir, MSA, Velan, PBV, Orsenigo, Sri, Argus,

PO No :

6

WKM, KVC, Flow Control Oil&Gas Inc., KTM, KVC, Neles Jamesburry,

7

Orbit, OIC, TK, Stream Flo/Master Flo, KF(USA)

TECHNICAL DATA

10

11 Valve Type :

Ball Valve

12 Valve Size & Rating:

2" and Larger - ANSI 1500#

13 End Connection :

RTJ Flange ASME B 16.5, ASME B16.47 Series A (for size 26")

14

Flange Face Finish 120 to 140 RMS

15 Design :

API 6D (ISO 14313)

16

ASME 16.34 Pressure & Temperature Rating

17

Bolted Bonnet, Replaceable Ball & Seat, Full Bore, Trunnion Mounted and Larger, Side Entry

18

Fire safe as per API 6FA or API 607/BS EN ISO 10497

19

Blow out Proof, Anti Static

Face to face dimension as per ASME B16.10

(Note vi)

20

21

22 Operator :

Lever Operated : 2" - 3"

23

Gear Operated : 4" and Larger

24

MATERIAL CONSTRUCTION

25 Body and Bonnet:

ASTM A216-WCB

26 Ball:

ASTM A 105 + 3 mills ENP

27 Seat Retainer:

ASTM A 105 + 3 mills ENP

28 Resilent Seat:

Thermoplastic, Carbon Filled PTFE (Reinforced PTFE), Reinforced Viton

29 Stem:

Hot rolled Steel AISI 4140

30 Bolt & Nuts:

ASTM A 193 Gr.B7 Studs, Fluorocarbon Coated

31

ASTM A 194 Gr.2H Nuts, Fluorocarbon Coated

32 Body Seal

Elastomer, Viton, PTFE

33 Body Gasket:

Graphite

34 Test and Inspection :

API 6D (ISO 14313) and its modifications in Company Specifications. Acceptable leak rate as per

35

ISO 5208 Rate A

36 Fire Test :

API 607 (BS EN ISO 10497) or API 6FA

37 Operating Paramaters :

38 Max Diff. Pressure :

Max. Rating Pressure (when not speficied by Purchaser)

o

o

50

-250

F

39 Temp. Range :

40 Painting :

As Per PHEONWJ-F-PRC-0007 Site Technical Practices (STP) for Painting on Metal Surfaces

41 Applicable Standard :

API 6D (ISO 14313) - Latest Edition

42

Company Spec : - PHEONWJ-F-PRC-0007 Site Technical Practices (STP) for Painting on Metal Surfaces

43

- PHEONWJ-X-SPE-0003 Valve Specification

44 Remarks :

45 (i) All valve shall have valid license of API 6D monogram and other quality certificates. Manufacturing shall be done in origin country.

46

Company reserves right to investigate and visit factory

47 (ii) Any seal component (esp. O-Ring) in dynamic application must prevent seal extrusion, galvanic corrosion & sticking that could prevent

48

its efficiency after a long stand period.

49 (iii) Max. allowable size for all elastomeric seal (incl. O-Ring) shall be six (6) mm. Material of elastomer shall be explosive decompression

50

resistant grade (AED)

51 (iv) Seat pocket, seal housing and contact surfaces shall be overlaid by alloy 625 or SS 309

52 (v) For size 6" and larger shall be provided with vent and drain valve on the valve body.

53 (vi) The standard dimension is Long Pattern. For Short Pattern, shall be clearly noted.

54 (vii) Valve marking in accordance with MSS SP-25

55 (viii) Valve shall be new. Valve from stock will be considered in case date of manufactured not longer than two (2) years

|DOCUMENTUM|2/21/2011|Paper Copies are Uncontrolled|

PIPING DATA SHEET

BALL VALVE SOFT SEAT

DOC. NO. :

PHEONWJ-X-DSH-XXXX

SHEET

: 12 OF 27

ENGINEERING GROUP

PROJECT :

DESCRIPTION

REV. DATE

BY

CHECKD

APPVD

GENERAL INFORMATION

2 Service :

High CO2 Process Hydrocarbons, Amine Regenerator

Unit Tag No : SD2Z

3

No Required :

4 Brand :

OMB, Balon, Mc. Canna, Oliver Valve, Starline S.p.A, Velan, PBV, Orsenigo,

Serial No :

Bonney Forge, Sri, Anderson Greenwood, Argus, Flow Control Oil&Gas Inc,

PO No :

Hoke, Jamesburry, Keystone, Parker, Star-Line, Whitey. (O.E.M. Only)

TECHNICAL DATA

10 Valve Type :

Ball Valve

11 Valve Size & Rating:

1/2" to 1-1/2" - 800#

Socket Weld x Socket Weld

(Note ii)

12 End Connection :

13

14 Design :

API 608

15

ASME 16.34 Pressure & Temperature Rating

16

Floating Ball, Replaceable Ball & Seat, Full Bore, Fire safe as per BS 10497

17

End to End dimension as per Manufacturer Standard

18

19 Operator :

Lever

20

21

MATERIAL CONSTRUCTION

22 Body and Bonnet:

ASTM A182 F51 DSS

23 Ball:

ASTM A182 F316 SS

24 Seat Retainer:

N/A

25 Resilient Seat:

Thermoplastic, Reinforced PTFE

26 Stem:

ASTM A182 F316 SS

27 Bolt & Nuts:

ASTM A 193 Gr B 8M Studs and ASTM A 194 Gr B 8M Nuts, SF Heavy Hex

28 Body Seal:

Elastomer, Viton, PTFE

29 Body Gasket:

Graphite, Flexible

30

31

32 Test and Inspection :

API 598

33

34 Fire Test :

API 607 or BS EN ISO 10497

35

36 Operating Paramaters :

37 Max Diff. Pressure :

Max. Rating Pressure (when not speficied by Purchaser)

o

F

50

-250

38 Temp. Range :

39 Painting :

N/A

40

41 Applicable Standard :

API 608 - latest edition

42

Company Spec : - PHEONWJ-X-SPE-0003 Valve Specification

43

44 Remarks :

45 (i) Minimum Seat rating shall be 1480# CWP

46 (ii) Nipple 100mm length plain end, A 312 Gr. 316L SMLS Sch.80 shall be welded on both sides or forged integral nipples to

47 ASTM A182 F51

48 (iii) All valve shall have valid license of quality certificates. Manufacturing shall be done in origin country.

49 Company reserves right to investigate and visit factory

50 (iv) Max Allowable size for all elastomeric seal (incl. O-Ring) shall be six (6) mm

51 (v) Valve marking in accordance with MSS SP-25

52 (vi) Valve shall be new. Valve from stock will be considered in case date of manufactured not longer than two (2) years

53

54

55

|DOCUMENTUM|2/21/2011|Paper Copies are Uncontrolled|

PIPING DATA SHEET

BALL VALVE SOFT SEAT

DOC. NO. :

PHEONWJ-X-DSH-XXXX

SHEET

: 13 OF 27

ENGINEERING GROUP

PROJECT :

DESCRIPTION

REV. DATE

BY

CHECKD APPVD

GENERAL INFORMATION

2 Service :

Sour Process Hydrocarbons, Amine Regenerator

Unit Tag No : SD2ZOS

3

No Required :

4 Brand :

OMB, Balon, Mc. Canna, Oliver Valve, Starline S.p.A, Velan, PBV,

Serial No :

5 Brand :

OMB, Balon, Mc. Canna, Oliver Valve, Starline S.p.A, Velan, PBV, Orsenigo,

Serial No :

Bonney Forge, Sri, Anderson Greenwood, Argus, Flow Control Oil&Gas Inc,

PO No :

Hoke, Jamesburry, Keystone, Parker, Star-Line, Whitey. (O.E.M. Only)

TECHNICAL DATA

10

11 Valve Type :

Ball Valve

12 Valve Size & Rating:

1/2" to 1-1/2" - 800#

Socket Weld x Screwed End

(Note ii)

13 End Connection :

14

15 Design :

API 608

16

ASME 16.34 Pressure & Temperature Rating

17

Floating Ball, Replaceable Ball & Seat, Full Bore, Fire safe as per BS 10497

18

End to End dimension as per Manufacturer Standard

19

20 Operator :

Lever

21

22

MATERIAL CONSTRUCTION

23 Body and Bonnet:

ASTM A182 F51 DSS

24 Ball:

ASTM A182 F316 SS

25 Seat Retainer:

N/A

26 Resilient Seat:

Thermoplastic, Reinforced PTFE

27 Stem:

ASTM A182 F316 SS

28 Bolt & Nuts:

ASTM A 193 Gr B 8M Studs and ASTM A 194 Gr B 8M Nuts, SF Heavy Hex

29 Body Seal:

Elastomer, Viton, PTFE

30 Body Gasket:

Graphite, Flexible

31

32

33 Test and Inspection :

API 598

34

35 Fire Test :

API 607 or BS EN ISO 10497

36

37 Operating Paramaters :

38 Max Diff. Pressure :

Max. Rating Pressure (when not speficied by Purchaser)

o

o

50

-250

F

39 Temp. Range :

40 Painting :

N/A

41

42 Applicable Standard :

API 608 - latest edition

43

Company Spec : - PHEONWJ-X-SPE-0003 Valve Specification

44

45 Remarks :

46 (i) Minimum Seat rating shall be 1480# CWP

47 (ii) Nipple 100mm length plain end, A 312 Gr. 316L SMLS Sch.80 shall be welded on SW side or forged integral nipples to

48 ASTM A182 F51

49 (iii) All valve shall have valid license of quality certificates. Manufacturing shall be done in origin country.

50 Company reserves right to investigate and visit factory

51 (iv) Max Allowable size for all elastomeric seal (incl. O-Ring) shall be six (6) mm

52 (v) Valve marking in accordance with MSS SP-25

53 (vi) Valve shall be new. Valve from stock will be considered in case date of manufactured not longer than two (2) years

54

55

|DOCUMENTUM|2/21/2011|Paper Copies are Uncontrolled|

PIPING DATA SHEET

BALL VALVE SOFT SEAT

DOC. NO. :

PHEONWJ-X-DSH-XXXX

SHEET

: 14 OF 27

ENGINEERING GROUP

PROJECT :

DESCRIPTION

REV. DATE

BY

CHECKD

APPVD

GENERAL INFORMATION

2 Service :

High CO2 Process Hydrocarbons, Amine Regenerator

Unit Tag No : SF2Z

3

No Required :

4 Brand :

OMB, Balon, Mc. Canna, Oliver Valve, Starline S.p.A, Velan, PBV, Orsenigo,

Serial No :

Bonney Forge, Sri, Anderson Greenwood, Argus, Flow Control Oil&Gas Inc,

PO No :

Hoke, Jamesburry, Keystone, Parker, Star-Line, Whitey. (O.E.M. Only)

TECHNICAL DATA

10 Valve Type :

Ball Valve

11 Valve Size & Rating:

1/2" to 1-1/2" - 1500#

Socket Weld x Socket Weld

(Note ii)

12 End Connection :

13

14 Design :

API 608

15

ASME 16.34 Pressure & Temperature Rating

16

Floating Ball, Replaceable Ball & Seat, Full Bore, Non Lubricated, Fire safe as per BS 10497

17

End to End dimension as per Manufacturer Standard

18

19 Operator :

Lever

20

21

MATERIAL CONSTRUCTION

22 Body and Bonnet:

ASTM A182 F51 DSS

23 Ball:

ASTM A182 F316 SS

24 Seat Retainer:

N/A

25 Resilient Seat:

Thermoplastic, Reinforced PTFE

26 Stem:

ASTM A182 F316 SS

27 Bolt & Nuts:

ASTM A 193 Gr B 8M Studs and ASTM A 194 Gr B 8M Nuts, SF Heavy Hex

28 Body Seal:

Elastomer, Viton, PTFE

29 Body Gasket:

Graphite, Flexible

30

31

32 Test and Inspection :

API 598

33

34 Fire Test :

API 607 or BS EN ISO 10497

35

36 Operating Paramaters :

37 Max Diff. Pressure :

Max. Rating Pressure (when not speficied by Purchaser)

o

F

50

-250

38 Temp. Range :

39 Painting :

N/A

40

41 Applicable Standard :

API 608 - latest edition

42

Company Spec : - PHEONWJ-X-SPE-0003 Valve Specification

43

44 Remarks :

45 (i) Minimum Seat rating shall be 2400# CWP

46 (ii) Nipple 100mm length plain end, A 312 Gr. 316L SMLS Sch.80 shall be welded on both side or forged integral nipples to

47 ASTM A182 F51

48 (iii) All valve shall have valid license of quality certificates. Manufacturing shall be done in origin country.

49 Company reserves right to investigate and visit factory

50 (iv) Max. allowable size for all elastomeric seal (incl. O-Ring) shall be six (6) mm. Material of elastomer shall be explosive decompression

51 resistant grade (AED)

52 (v) Valve marking in accordance with MSS SP-25

53 (vi) Valve shall be new. Valve from stock will be considered in case date of manufactured not longer than two (2) years

54

55

|DOCUMENTUM|2/21/2011|Paper Copies are Uncontrolled|

PIPING DATA SHEET

BALL VALVE SOFT SEAT

DOC. NO. :

PHEONWJ-X-DSH-XXXX

SHEET

: 15 OF 27

ENGINEERING GROUP

PROJECT :

DESCRIPTION

REV. DATE

BY

CHECKD APPVD

GENERAL INFORMATION

2 Service :

High CO2 Process Hydrocarbons, Amine Regenerator

Unit Tag No : SF2ZOS

3

No Required :

4 Brand :

OMB, Balon, Mc. Canna, Oliver Valve, Starline S.p.A, Velan, PBV, Orsenigo,

Serial No :

Bonney Forge, Sri, Anderson Greenwood, Argus, Flow Control Oil&Gas Inc,

PO No :

Hoke, Jamesburry, Keystone, Parker, Star-Line, Whitey. (O.E.M. Only)

TECHNICAL DATA

10 Valve Type :

Ball Valve

11 Valve Size & Rating:

1/2" to 1-1/2" - 1500#

Socket Weld x Screwed End

(Note ii)

12 End Connection :

13

14 Design :

API/ANSI 608

15

ASME 16.34 Pressure & Temperature Rating

16

Floating Ball, Replaceable Ball & Seat, Full Bore, Non Lubricated, Fire safe as per BS 10497

17

End to End dimension as per Manufacturer Standard

18

19 Operator :

Lever

20

21

MATERIAL CONSTRUCTION

22 Body and Bonnet:

ASTM A182 F51 DSS

23 Ball:

ASTM A182 F316 SS

24 Seat Retainer:

N/A

25 Seat:

Thermoplastic, Reinforced PTFE

26 Stem:

ASTM A182 F316 SS

27 Bolt & Nuts:

ASTM A 193 Gr B 8M Studs and ASTM A 194 Gr B 8M Nuts, SF Heavy Hex

28 Body Seal:

Elastomer, Viton, PTFE

29 Body Gasket:

Graphite, Flexible

30

31

32 Test and Inspection :

API 598

33

34 Fire Test :

API 607 or BS EN ISO 10497

35

36 Operating Paramaters :

37 Max Diff. Pressure :

Max. Rating Pressure (when not speficied by Purchaser)

o

F

50

-250

38 Temp. Range :

39 Painting :

N/A

40

41 Applicable Standard :

API 608 - latest edition

42

Company Spec : - PHEONWJ-X-SPE-0003 Valve Specification

43

44 Remarks :

45 (i) Minimum Seat rating shall be 2400# CWP

46 (ii) Nipple 100mm length plain end, A 312 Gr. 316L SMLS Sch.80 shall be welded on SW side or forged integral nipples to

47

ASTM A182 F51

48 (iii) All valve shall have valid license of quality certificates. Manufacturing shall be done in origin country.

49 Company reserves right to investigate and visit factory

50 (iv) Max. allowable size for all elastomeric seal (incl. O-Ring) shall be six (6) mm. Material of elastomer shall be explosive decompression

51 resistant grade (AED)

52 (v) Valve marking in accordance with MSS SP-25

53 (vi) Valve shall be new. Valve from stock will be considered in case date of manufactured not longer than two (2) years

54

55

|DOCUMENTUM|2/21/2011|Paper Copies are Uncontrolled|

PIPING DATA SHEET

BALL VALVE SOFT SEAT

DOC. NO. :

PHEONWJ-X-DSH-XXXX

SHEET

: 16 OF 27

ENGINEERING GROUP

PROJECT :

DESCRIPTION

REV. DATE

BY

CHECKD APPVD

GENERAL INFORMATION

2 Service :

High CO2 Process Hydrocarbons, Amine Regenerator

Unit Tag No : SA2R

3

No Required :

4 Brand :

O.E.M only; Balon, Ring-O, Grove, OMS Salery, Perar, Petrovalves,

Serial No :

5

Pibiviesse, FCT, Tormene, Weir, MSA, Velan, PBV, Orsenigo, Sri, Argus,

PO No :

6

WKM, KVC, Flow Control Oil&Gas Inc., KTM, KVC, Neles Jamesburry,

7

Orbit, OIC, TK, Stream Flo/Master Flo, KF(USA)

TECHNICAL DATA

10

11 Valve Type :

Ball Valve

12 Valve Size & Rating:

2" and Larger - ANSI 150#

13 End Connection :

RF Flange ASME B 16.5, ASME B16.47 Series A (for size 26")

14

Flange Face Finish 120 to 140 RMS

15 Design :

API 6D (ISO 14313)

16

ASME 16.34 Pressure & Temperature Rating

17

Bolted Bonnet, Replaceable Ball & Seat, Full Bore, Floating Ball up to 4", Trunnion Mounted Ball for 6"

18

and Larger, Side Entry

19

Fire safe as per API 6FA or API 607/BS EN ISO 10497

20

Blow out Proof, Anti Static

Face to face dimension as per ASME B16.10

(Note v)

21

22 Operator :

Lever Operated : 2" - 4"

23

Gear Operated : 6" and Larger

24

MATERIAL CONSTRUCTION

25 Body and Bonnet:

ASTM A182 F51 DSS

26 Ball:

ASTM A182 F316 SS

27 Seat Retainer:

ASTM A182 F316 SS

28 Resilent Seat:

Reinforced PTFE or Reinforced Viton

29 Stem:

ASTM A182 F316 SS

30 Bolt & Nuts:

ASTM A 193 Gr B 8M Studs and ASTM A 194 Gr B 8M Nuts, SF Heavy Hex

31 Body Seal

Elastomer, Viton, PTFE

32 Body Gasket:

Graphite

33

34 Test and Inspection :

API 6D (ISO 14313) and its modifications in Company Specifications. Acceptable leak rate as per

35

ISO 5208 Rate A

36 Fire Test :

API 607 (BS EN ISO 10497) or API 6FA

37 Operating Paramaters :

38 Max Diff. Pressure :

Max. Rating Pressure (when not speficied by Purchaser)

o

o

50

-250

F

39 Temp. Range :

40 Painting :

N/A

41 Applicable Standard :

API 6D (ISO 14313) - Latest Edition

42

Company Spec : - PHEONWJ-X-SPE-0003 Valve Specification

43

44 Remarks :

45 (i) All valve shall have valid license of API 6D monogram and other quality certificates. Manufacturing shall be done in origin country.

46

Company reserves right to investigate and visit factory

47 (ii) Any seal component (esp. O-Ring) in dynamic application must prevent seal extrusion, galvanic corrosion & sticking that could prevent

48

its efficiency after a long stand period.

49 (iii) For size 10" and larger shall be provided with vent and drain valve on the valve body.

50 (iv) Max Allowable size for all elastomeric seal (incl. O-Ring) shall be six (6) mm

51 (v) The standard dimension is Long Pattern. For Short Pattern, shall be clearly noted.

52 (vi) Valve marking in accordance with MSS SP-25

53 (vii) Valve shall be new. Valve from stock will be considered in case date of manufactured not longer than two (2) years

54

55

|DOCUMENTUM|2/21/2011|Paper Copies are Uncontrolled|

PIPING DATA SHEET

BALL VALVE SOFT SEAT

DOC. NO. :

PHEONWJ-X-DSH-XXXX

SHEET

: 17 OF 27

ENGINEERING GROUP

PROJECT :

DESCRIPTION

REV. DATE

BY

CHECKD

APPVD

GENERAL INFORMATION

2 Service :

High CO2 Process Hydrocarbons, Amine Regenerator

Unit Tag No : SB2R

3

No Required :

4 Brand :

O.E.M only; Balon, Ring-O, Grove, OMS Salery, Perar, Petrovalves,

Serial No :

5

Pibiviesse, FCT, Tormene, Weir, MSA, Velan, PBV, Orsenigo, Sri, Argus,

PO No :

6

WKM, KVC, Flow Control Oil&Gas Inc., KTM, KVC, Neles Jamesburry,

7

Orbit, OIC, TK, Stream Flo/Master Flo, KF(USA)

TECHNICAL DATA

10

11 Valve Type :

Ball Valve

12 Valve Size & Rating:

2" and Larger - ANSI 300#

13 End Connection :

RF Flange ASME B 16.5, ASME B16.47 Series A (for size 26")

14

Flange Face Finish 120 to 140 RMS

15 Design :

API 6D (ISO 14313)

16

ASME 16.34 Pressure & Temperature Rating

17

Bolted Bonnet, Replaceable Ball & Seat, Full Bore, Floating Ball up to 4", Trunnion Mounted Ball for 6"

18

and Larger, Side Entry

19

Fire safe as per API 6FA or API 607/BS EN ISO 10497

20

Blow out Proof, Anti Static

Face to face dimension as per ASME B16.10

(Note v)

21

22 Operator :

Lever Operated : 2" - 4"

23

Gear Operated : 6" and Larger

24

MATERIAL CONSTRUCTION

25 Body and Bonnet:

ASTM A182 F51 DSS

26 Ball:

ASTM A182 F316 SS

27 Seat Retainer:

ASTM A182 F316 SS

28 Resilent Seat:

Reinforced PTFE or Reinforced Viton

29 Stem:

ASTM A182 F316 SS

30 Bolt & Nuts:

ASTM A 193 Gr B 8M Studs and ASTM A 194 Gr B 8M Nuts, SF Heavy Hex

31 Body Seal

Elastomer, Viton, PTFE

32 Body Gasket:

Graphite

33

34 Test and Inspection :

API 6D (ISO 14313) and its modifications in Company Specifications. Acceptable leak rate as per

35

ISO 5208 Rate A

36 Fire Test :

API 607 (BS EN ISO 10497) or API 6FA

37 Operating Paramaters :

38 Max Diff. Pressure :

Max. Rating Pressure (when not speficied by Purchaser)

o

o

50

-250

F

39 Temp. Range :

40 Painting :

N/A

41 Applicable Standard :

API 6D (ISO 14313) - Latest Edition

42

Company Spec : - PHEONWJ-X-SPE-0003 Valve Specification

43

44 Remarks :

45 (i) All valve shall have valid license of API 6D monogram and other quality certificates. Manufacturing shall be done in origin country.

46

Company reserves right to investigate and visit factory

47 (ii) Any seal component (esp. O-Ring) in dynamic application must prevent seal extrusion, galvanic corrosion & sticking that could prevent

48

its efficiency after a long stand period.

49 (iii) For size 10" and larger shall be provided with vent and drain valve on the valve body.

50 (iv) Max Allowable size for all elastomeric seal (incl. O-Ring) shall be six (6) mm

51 (v) The standard dimension is Long Pattern. For Short Pattern, shall be clearly noted.

52 (vi) Valve marking in accordance with MSS SP-25

53 (vii) Valve shall be new. Valve from stock will be considered in case date of manufactured not longer than two (2) years

54

55

|DOCUMENTUM|2/21/2011|Paper Copies are Uncontrolled|

PIPING DATA SHEET

BALL VALVE SOFT SEAT

DOC. NO. :

PHEONWJ-X-DSH-XXXX

SHEET

: 18 OF 27

ENGINEERING GROUP

PROJECT :

DESCRIPTION

REV. DATE

BY

CHECKD APPVD

GENERAL INFORMATION

2 Service :

High CO2 Process Hydrocarbons, Amine Regenerator

Unit Tag No : SD2R

3

No Required :

4 Brand :

O.E.M only; Balon, Ring-O, Grove, OMS Salery, Perar, Petrovalves,

Serial No :

5

Pibiviesse, FCT, Tormene, Weir, MSA, Velan, PBV, Orsenigo, Sri, Argus,

PO No :

6

WKM, KVC, Flow Control Oil&Gas Inc., KTM, KVC, Neles Jamesburry,

7

Orbit, OIC, TK, Stream Flo/Master Flo, KF(USA)

TECHNICAL DATA

10

11 Valve Type :

Ball Valve

12 Valve Size & Rating:

2" and Larger - ANSI 600#

13 End Connection :

RF Flange ASME B 16.5, ASME B16.47 Series A (for size 26")

14

Flange Face Finish 120 to 140 RMS

15 Design :

API 6D (ISO 14313)

16

ASME 16.34 Pressure & Temperature Rating

17

Bolted Bonnet, Replaceable Ball & Seat, Full Bore, Floating Ball up to 3", Trunnion Mounted Ball for 4"

18

and Larger, Side Entry

19

Fire safe as per API 6FA or API 607/BS EN ISO 10497

20

Blow out Proof, Anti Static

Face to face dimension as per ASME B16.10

(Note v)

21

22 Operator :

Lever Operated : 2" - 4"

23

Gear Operated : 6" and Larger

24

MATERIAL CONSTRUCTION

25 Body and Bonnet:

ASTM A182 F51 DSS

26 Ball:

ASTM A182 F316 SS

27 Seat Retainer:

ASTM A182 F316 SS

28 Resilent Seat:

Reinforced PTFE or Reinforced Viton

29 Stem:

ASTM A182 F316 SS

30 Bolt & Nuts:

ASTM A 193 Gr B 8M Studs and ASTM A 194 Gr B 8M Nuts, SF Heavy Hex

31 Body Seal

Elastomer, Viton, PTFE

32 Body Gasket:

Graphite

33

34 Test and Inspection :

API 6D (ISO 14313) and its modifications in Company Specifications. Acceptable leak rate as per

35

ISO 5208 Rate A

36 Fire Test :

API 607 (BS EN ISO 10497) or API 6FA

37 Operating Paramaters :

38 Max Diff. Pressure :

Max. Rating Pressure (when not speficied by Purchaser)

o

o

50

-250

F

39 Temp. Range :

40 Painting :

N/A

41 Applicable Standard :

API 6D (ISO 14313) - Latest Edition

42

Company Spec : - PHEONWJ-X-SPE-0003 Valve Specification

43

44 Remarks :

45 (i) All valve shall have valid license of API 6D monogram and other quality certificates. Manufacturing shall be done in origin country.

46

Company reserves right to investigate and visit factory

47 (ii) Any seal component (esp. O-Ring) in dynamic application must prevent seal extrusion, galvanic corrosion & sticking that could prevent

48

its efficiency after a long stand period.

49 (iii) Max. allowable size for all elastomeric seal (incl. O-Ring) shall be six (6) mm. Material of elastomer shall be explosive decompression

50

resistant grade (AED)

51 (iv) For size 8" and larger shall be provided with vent and drain valve on the valve body.

52 (v) The standard dimension is Long Pattern. For Short Pattern, shall be clearly noted.

53 (vi) Valve marking in accordance with MSS SP-25

54 (vii) Valve shall be new. Valve from stock will be considered in case date of manufactured not longer than two (2) years

55

|DOCUMENTUM|2/21/2011|Paper Copies are Uncontrolled|

PIPING DATA SHEET

BALL VALVE SOFT SEAT

DOC. NO. :

PHEONWJ-X-DSH-XXXX

SHEET

: 19 OF 27

ENGINEERING GROUP

PROJECT :

DESCRIPTION

REV. DATE

BY

CHECKD

APPVD

GENERAL INFORMATION

2 Service :

High CO2 Process Hydrocarbons, Amine Regenerator

Unit Tag No : SE2R

3

No Required :

4 Brand :

O.E.M only; Balon, Ring-O, Grove, OMS Salery, Perar, Petrovalves,

Serial No :

5

Pibiviesse, FCT, Tormene, Weir, MSA, Velan, PBV, Orsenigo, Sri, Argus,

PO No :

6

WKM, KVC, Flow Control Oil&Gas Inc., KTM, KVC, Neles Jamesburry,

7

Orbit, OIC, TK, Stream Flo/Master Flo, KF(USA)

TECHNICAL DATA

10

11 Valve Type :

Ball Valve

12 Valve Size & Rating:

2" and Larger - ANSI 900#

13 End Connection :

RF Flange ASME B 16.5, ASME B16.47 Series A (for size 26")

14

Flange Face Finish 120 to 140 RMS

15 Design :

API 6D (ISO 14313)

16

ASME 16.34 Pressure & Temperature Rating

17

Bolted Bonnet, Replaceable Ball & Seat, Full Bore, Floating Ball up to 3", Trunnion Mounted Ball for 4"

18

and Larger, Side Entry

19

Fire safe as per API 6FA or API 607/BS EN ISO 10497

20

Blow out Proof, Anti Static

Face to face dimension as per ASME B16.10

(Note v)

21

22 Operator :

Lever Operated : 2" - 3"

23

Gear Operated : 4" and Larger

24

MATERIAL CONSTRUCTION

25 Body and Bonnet:

ASTM A182 F51 DSS

26 Ball:

ASTM A182 F316 SS

27 Seat Retainer:

ASTM A182 F316 SS

28 Resilent Seat:

Reinforced PTFE or Reinforced Viton

29 Stem:

ASTM A182 F316 SS

30 Bolt & Nuts:

ASTM A 193 Gr B 8M Studs and ASTM A 194 Gr B 8M Nuts, SF Heavy Hex

31 Body Seal

Elastomer, Viton, PTFE

32 Body Gasket:

Graphite

33

34 Test and Inspection :

API 6D (ISO 14313) and its modifications in Company Specifications. Acceptable leak rate as per

35

ISO 5208 Rate A

36 Fire Test :

API 607 (BS EN ISO 10497) or API 6FA

37 Operating Paramaters :

38 Max Diff. Pressure :

Max. Rating Pressure (when not speficied by Purchaser)

o

o

50

-250

F

39 Temp. Range :

40 Painting :

N/A

41 Applicable Standard :

API 6D (ISO 14313) - Latest Edition

42

Company Spec : - PHEONWJ-X-SPE-0003 Valve Specification

43

44 Remarks :

45 (i) All valve shall have valid license of API 6D monogram and other quality certificates. Manufacturing shall be done in origin country.

46

Company reserves right to investigate and visit factory

47 (ii) Any seal component (esp. O-Ring) in dynamic application must prevent seal extrusion, galvanic corrosion & sticking that could prevent

48

its efficiency after a long stand period.

49 (iii) Max. allowable size for all elastomeric seal (incl. O-Ring) shall be six (6) mm. Material of elastomer shall be explosive decompression

50

resistant grade (AED)

51 (iv) For size 8" and larger shall be provided with vent and drain valve on the valve body.

52 (v) The standard dimension is Long Pattern. For Short Pattern, shall be clearly noted.

53 (vi) Valve marking in accordance with MSS SP-25

54 (vii) Valve shall be new. Valve from stock will be considered in case date of manufactured not longer than two (2) years

55

|DOCUMENTUM|2/21/2011|Paper Copies are Uncontrolled|

PIPING DATA SHEET

BALL VALVE SOFT SEAT

DOC. NO. :

PHEONWJ-X-DSH-XXXX

SHEET

: 20 OF 27

ENGINEERING GROUP

PROJECT :

DESCRIPTION

REV. DATE

BY

CHECKD APPVD

GENERAL INFORMATION

2 Service :

High CO2 Process Hydrocarbons, Amine Regenerator

Unit Tag No : SF2J

3

No Required :

4 Brand :

O.E.M only; Balon, Ring-O, Grove, OMS Salery, Perar, Petrovalves,

Serial No :

5

Pibiviesse, FCT, Tormene, Weir, MSA, Velan, PBV, Orsenigo, Sri, Argus,

PO No :

6

WKM, KVC, Flow Control Oil&Gas Inc., KTM, KVC, Neles Jamesburry,

7

Orbit, OIC, TK, Stream Flo/Master Flo, KF(USA)

TECHNICAL DATA

10

11 Valve Type :

Ball Valve

12 Valve Size & Rating:

2" and Larger - ANSI 1500#

13 End Connection :

RTJ Flange ASME B 16.5, ASME B16.47 Series A (for size 26")

14

Flange Face Finish 120 to 140 RMS

15 Design :

API 6D (ISO 14313)

16

ASME 16.34 Pressure & Temperature Rating

17

Bolted Bonnet, Replaceable Ball & Seat, Full Bore, Floating Ball up to 3", Trunnion Mounted Ball for 4"

18

and Larger, Side Entry

19

Fire safe as per API 6FA or API 607/BS EN ISO 10497

20

Blow out Proof, Anti Static

Face to face dimension as per ASME B16.10

(Note v)

21

22 Operator :

Lever Operated : 2" - 3"

23

Gear Operated : 4" and Larger

24

MATERIAL CONSTRUCTION

25 Body and Bonnet:

ASTM A182 F51 DSS

26 Ball:

ASTM A182 F316 SS

27 Seat Retainer:

ASTM A182 F316 SS

28 Resilent Seat:

Reinforced PTFE or Reinforced Viton

29 Stem:

ASTM A182 F316 SS

30 Bolt & Nuts:

ASTM A 193 Gr B 8M Studs and ASTM A 194 Gr B 8M Nuts, SF Heavy Hex

31 Body Seal

Elastomer, Viton, PTFE

32 Body Gasket:

Graphite

33

34 Test and Inspection :

API 6D (ISO 14313) and its modifications in Company Specifications. Acceptable leak rate as per

35

ISO 5208 Rate A

36 Fire Test :

API 607 (BS EN ISO 10497) or API 6FA

37 Operating Paramaters :

38 Max Diff. Pressure :

Max. Rating Pressure (when not speficied by Purchaser)

o

o

50

-250

F

39 Temp. Range :

40 Painting :

N/A

41 Applicable Standard :

API 6D (ISO 14313) - Latest Edition

42

Company Spec : - PHEONWJ-X-SPE-0003 Valve Specification

43

44 Remarks :

45 (i) All valve shall have valid license of API 6D monogram and other quality certificates. Manufacturing shall be done in origin country.

46

Company reserves right to investigate and visit factory

47 (ii) Any seal component (esp. O-Ring) in dynamic application must prevent seal extrusion, galvanic corrosion & sticking that could prevent

48

its efficiency after a long stand period.

49 (iii) Max. allowable size for all elastomeric seal (incl. O-Ring) shall be six (6) mm. Material of elastomer shall be explosive decompression

50

resistant grade (AED)

51 (iv) For size 6" and larger shall be provided with vent and drain valve on the valve body.

52 (v) The standard dimension is Long Pattern. For Short Pattern, shall be clearly noted.

53 (vi) Valve marking in accordance with MSS SP-25

54 (vii) Valve shall be new. Valve from stock will be considered in case date of manufactured not longer than two (2) years

55

|DOCUMENTUM|2/21/2011|Paper Copies are Uncontrolled|

PIPING DATA SHEET

BALL VALVE SOFT SEAT

DOC. NO. :

PHEONWJ-X-DSH-XXXX

SHEET

: 21 OF 27

ENGINEERING GROUP

PROJECT :

DESCRIPTION

REV. DATE

BY

CHECKD

APPVD

GENERAL INFORMATION

2 Service :

Chlorinated seawater, Potable water

Unit Tag No : H2Z

3

No Required :

4 Brand :

Chemtrol "TU" Series or Equal

Serial No :

5

PO No :

TECHNICAL DATA

10

11 Valve Type :

Ball Valve

12 Valve Size & Rating:

3" and smaller - 150# WOG

Socket End (Solvent Cement Joint)

(Note ii)

13 End Connection :

14

ASTM D 2467 and F 439 for Schedule 80 Pressure Fitting

15 Design :

16

Full port, Floating Ball, Double Union design.

17

Self /Non Lubricating seats

Automatic adjust for seat wear

18

Face to face dimension as per manufacturers standard

19

20

Lever /Handle

21 Operator :

22

23

MATERIAL CONSTRUCTION

24 Body

PVC Type-1 Grade-1 (ASTM D-1784)

25 Ball

PVC Type-1 Grade-1 (ASTM D-1784)

26 Seal Carrier

PVC Type-1 Grade-1 (ASTM D-1784)

27 Resilient Seat

Viton, PTFE

28 Carrier O-Ring

Viton, EPDM

29 Stem :

PVC Type-1 Grade-1 (ASTM D-1784)

30 Lever /Handle

PVC Type-1 Grade-1 (ASTM D-1784)

31 Union Nuts

PVC Type-1 Grade-1 (ASTM D-1784)

32 End Connector

PVC Type-1 Grade-1 (ASTM D-1784)

33 Body Seal

Viton, EPDM

34 Stem Seal

Viton, EPDM

35

36 Test and Inspection :

Certified to ASTM F 1970

37

38 Fire Test :

N/A

39

40 Operating Paramaters :

41 Max Diff. Pressure :

Max. Rating Pressure (when not speficied by Purchaser)

42 Temp. Range :

Ambient to 140 F

43 Painting :

N/A

44

45 Applicable Standard :

ASTM D 2467

46

Company Spec : - PHEONWJ-X-SPE-0003 Valve Specification

47 Remarks :

48 (i) All valve shall be rated for 150 psi non-shock water service at 73 F and have a minimum burst rating of 3.3 times the rated working

49 pressure.

50 (ii) Socket ends to conform to ASTM D2467 & ASTM F439 & suitable for heat fusion welding as per ASTM D 2567 technique 1

51 (iii) All valve shall have valid license of quality certificates. Manufacturing shall be done in origin country.

52

Company reserves right to investigate and visit factory

53 (iv) Valve shall be clearly marked with the Manufacturers trade mark, nominal size, ASTM No., and NSF International certification mark

54

55

|DOCUMENTUM|2/21/2011|Paper Copies are Uncontrolled|

PIPING DATA SHEET

BALL VALVE SOFT SEAT

DOC. NO. :

PHEONWJ-X-DSH-XXXX

SHEET

: 22 OF 27

ENGINEERING GROUP

PROJECT :

DESCRIPTION

REV. DATE

BY

CHECKD APPVD

GENERAL INFORMATION

2 Service :

Potable water (outside living quarter), fire water, utility & salt water,

Unit Tag No : K2S

3

instrument air, utility air

No Required :

4

Serial No :

5 Brand :

OMB, Balon, Mc. Canna, Oliver Valve, Starline S.p.A, Velan, PBV,Orsenigo,

PO No :

Bonney Forge, Sri, Anderson Greenwood, Argus, Flow Control Oil&Gas Inc,

7

Hoke, Jamesburry, Keystone, Parker, Star-Line, Whitey. (O.E.M. Only)

TECHNICAL DATA

10

11 Valve Type :

Ball Valve

12 Valve Size & Rating:

2" and smaller - 250 Lb

13 End Connection :

Screwed Both Ends to ASME B1-20-1

14

MSS-SP 110, API 608

15 Design :

16

Bolted Bonnet, Replaceable Ball & Seat, Full Bore, Floating Ball

17

Non Lubricated Seal

18

Side entry, Blowout proof Stem

End to end dimension as per Manufacturers Standard

19

20

21

Lever /Handle

22 Operator :

23

24

MATERIAL CONSTRUCTION

Cast Bronze ASTM B 584 Alloy C84400

25 Body /Body End and Bonnet

26 Ball

Hard Chrome Plated Forged Brass ASTM B 16 Alloy C36000

27 Seat Retainer

N/A

28 Seat

PTFE or Reinforced PTFE

Bronze ASTM B 371 Alloy C69430

29 Stem

30 Packing

PTFE or Viton

31 Bolt & Nuts

N/A

32 Seal

PTFE

33 Body Seal

PTFE

34 Test and Inspection :

API 598

35

36 Fire Test :

N/A

37

38 Operating Paramaters :

39 Max Diff. Pressure :

Max. Rating Pressure (when not speficied by Purchaser)

40 Temp. Range :

AMB to 200 F

41 Painting :

N/A

42

43 Applicable Standard :

API 608 - latest edition

44

Company Spec : - PHEONWJ-X-SPE-0003 Valve Specification

45 Remarks :

46 (i) All valve shall have valid license of quality certificates. Manufacturing shall be done in origin country.

47

Company reserves right to investigate and visit factory

48 (ii) Any seal component (esp. O-Ring) in dynamic application must prevent seal extrusion, galvanic corrosion & sticking

49

that could prevent its efficiency after a long stand period.

50 (iii) The standard screwed/threaded shall be in accordance with ASME B1.20.1

51 (iv) Valve shall be clearly marked with the Manufacturers trade mark, nominal size, ASTM No. and NSF

52

53

54

55

|DOCUMENTUM|2/21/2011|Paper Copies are Uncontrolled|

PIPING DATA SHEET

BALL VALVE SOFT SEAT

DOC. NO. :

PHEONWJ-X-DSH-XXXX

SHEET

: 23 OF 27

ENGINEERING GROUP

PROJECT :

DESCRIPTION

REV. DATE

BY

CHECKD

APPVD

GENERAL INFORMATION

2 Service :

Chemical Injection, Sample Line

Unit Tag No : S2S

3

No Required :

4 Brand :

O.E.M only; Balon, Ring-O, Grove, OMS Salery, Perar, Petrovalves,

Serial No :

Pibiviesse, FCT, Tormene, Weir, MSA, Velan, PBV, Orsenigo, Sri, Argus,

PO No :

6

WKM, KVC, Flow Control Oil&Gas Inc., KTM, KVC, Neles Jamesburry,

Orbit, OIC, TK, Stream Flo/Master Flo, KF(USA)

TECHNICAL DATA

10

11 Valve Type :

Ball Valve

12 Valve Size & Rating:

3/4" and smaller - 1500#

13 End Connection :

Screwed Both Ends to ASME B1-20-1

14

15 Design :

API 608

16

ASME 16.34 Pressure & Temperature Rating

17

Bolted Bonnet, Replaceable Ball & Seat, Full Bore

18

Fire safe as per BS EN ISO 10497 or API 607

19

Face to face dimension as per Manufacturers Standard

20

21

22

Lever Arm

23 Operator :

24

25

MATERIAL CONSTRUCTION

26 Body and Bonnet:

A 182 F 316 SS

27 Ball:

A 182 F 316 SS

28 Seat Retainer:

N/A

29 Seat:

Thermoplastic, Carbon Filled PTFE (Reinforced PTFE)

30 Stem:

A 182 F 316 SS

31 Bolt & Nuts:

ASTM A 193 Gr.B8M Studs

32

ASTM A 194 Gr.2HM Nuts, SF Heavy Hex.

33 Seal:

Elastomer, Viton

34 Body Gasket:

Graphite, Flexible

35 Test and Inspection :

API 598

36

37 Fire test:

API 607 or BS EN ISO 10497

38

39 Operating Paramaters :

40 Max Diff. Pressure :

Max. Rating Pressure (when not speficied by Purchaser)

41 Temp. Range :

AMB to 200 F

42 Painting :

N/A

43

44 Applicable Standard :

API 608 - latest edition

45

Company Spec : - PHEONWJ-X-SPE-0003 Valve Specification

46 Remarks :

47

(i) Minimum Seat rating shall be 2240 psig at 100

48 (ii) All valve shall have valid license of quality certificates. Manufacturing shall be done in origin country.

49 Company reserves right to investigate and visit factory

50 (iii) Any seal component (esp. O-Ring) in dynamic application must prevent seal extrusion, galvanic corrosion & sticking

51

that could prevent its efficiency after a long stand period.

52 (iv) Valve marking in accordance with MSS SP-25

53 (v) Valve shall be new. Valve from stock will be considered in case date of manufactured not longer than two (2) years

54

55

|DOCUMENTUM|2/21/2011|Paper Copies are Uncontrolled|

PIPING DATA SHEET