A Full-Scale Wind Tunnel Test

Diunggah oleh

anmol62370 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

102 tayangan7 halamantest of car with wind tunnel

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen Initest of car with wind tunnel

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

102 tayangan7 halamanA Full-Scale Wind Tunnel Test

Diunggah oleh

anmol6237test of car with wind tunnel

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 7

400 Commonwealth Drive, Warrendale, PA 15096-0001 U.S.A.

Tel: (724) 776-4841 Fax: (724) 776-5760

SAE TECHNICAL

PAPER SERIES

2000-01-3548

A Full-Scale Wind Tunnel Test of a

Short Track Race Car

Drew Landman and Eric Koster

Langley Full Scale Tunnel

Reprinted From: Proceedings of the 2000 SAE Motorsports

Engineering Conference & Exposition

(P-361)

Motorsports Engineering Conference & Exposition

Dearborn, Michigan

November 13-16, 2000

Downloaded from SAE International by Vellore Inst of Technology, Wednesday, June 25, 2014

The appearance of this ISSN code at the bottom of this page indicates SAEs consent that copies of the

paper may be made for personal or internal use of specific clients. This consent is given on the condition,

however, that the copier pay a $7.00 per article copy fee through the Copyright Clearance Center, Inc.

Operations Center, 222 Rosewood Drive, Danvers, MA 01923 for copying beyond that permitted by Sec-

tions 107 or 108 of the U.S. Copyright Law. This consent does not extend to other kinds of copying such as

copying for general distribution, for advertising or promotional purposes, for creating new collective works,

or for resale.

SAE routinely stocks printed papers for a period of three years following date of publication. Direct your

orders to SAE Customer Sales and Satisfaction Department.

Quantity reprint rates can be obtained from the Customer Sales and Satisfaction Department.

To request permission to reprint a technical paper or permission to use copyrighted SAE publications in

other works, contact the SAE Publications Group.

No part of this publication may be reproduced in any form, in an electronic retrieval system or otherwise, without the prior written

permission of the publisher.

ISSN 0148-7191

Copyright 2000 Society of Automotive Engineers, Inc.

Positions and opinions advanced in this paper are those of the author(s) and not necessarily those of SAE. The author is solely

responsible for the content of the paper. A process is available by which discussions will be printed with the paper if it is published in

SAE Transactions. For permission to publish this paper in full or in part, contact the SAE Publications Group.

Persons wishing to submit papers to be considered for presentation or publication through SAE should send the manuscript or a 300

word abstract of a proposed manuscript to: Secretary, Engineering Meetings Board, SAE.

Printed in USA

All SAE papers, standards, and selected

books are abstracted and indexed in the

Global Mobility Database

Downloaded from SAE International by Vellore Inst of Technology, Wednesday, June 25, 2014

2000-01-3548

A Full-Scale Wind Tunnel Test of a Short Track Race Car

Drew Landman and Eric Koster

Langley Full Scale Tunnel

Copyright 2000 Society of Automotive Engineers, Inc.

ABSTRACT

A full-scale investigative wind tunnel test was performed

on a dirt track race car in the Langley Full Scale Tunnel

(LFST). Lift and drag forces were measured and flow

visualization studies performed for the purpose of

quantifying the aerodynamic characteristics in order to

assist designers and drivers of this class of vehicle.

Results from the downforce measurements showed a rear

axle biased aerodynamic balance. Flow visualization

studies revealed large areas of separated flow on the

forward portion of the side pods as well as over a large

portion of the rear deck and spoiler behind the driver.

INTRODUCTION

Indigenous to the Northeastern United States, dirt-

modifieds have traditionally exhibited cantankerous

handling qualities, generally attributable to the

combination of high center of gravity, in excess of 60%

rear weight bias and primitive beam-axle suspensions.

These mandated parameters coupled with the

characteristically low traction of slick clay tracks make

maintaining balanced suspension settings a challenge.

Rear axle shaft torque in excess of 2500 ft-lbs.

exacerbates the problem.

Historically, the primary focus for aerodynamic

improvement of these cars has centered on the creation of

increased downforce in order to alleviate corner exit

power-induced wheelspin. Current rules prohibit the use of

inverted wings however, airdams, deflectors and spoilers

have been implemented and generally accepted as being

successful in abating wheelspin. Designers believe that

the large rear downforces generated are balanced by

various configurations of front airdams and deflectors.

Because no experimental force data has been available in

the past, the growing problem of corner entry understeer

has been countered through the evolutionary

implementation of increased rear brake bias along with an

increased differential in left to right rear tire circumference

(known as stagger).

This paper provides results from experimental

aerodynamic force testing as well as flow visualization

techniques that should aid designers of dirt-modified style

racecars. It is anticipated that the data will be used to

design safer and more aerodynamically efficient vehicles.

FACILITY DESCRIPTION

Old Dominion University (ODU), working under a

Memorandum of Agreement with NASA Langley Research

Center, operates the Langley Full-Scale Tunnel.

1,2

This

facility is the second largest in the United States in terms

of test section size and is the largest university-operated

wind tunnel in the world.

The building which comprises the LFST measures 132 m

long by 70 m wide by 30 m high. The open jet test

section is semi-elliptical in cross section with a width of

18.29 m (60 ft) and a height of 9.14 m (30 ft). The ground

board is 13 m (42.5 ft) wide by 16 m (52.3 ft) long and

features a turntable with a diameter of 8.7 m (28.5 ft). The

overall aerodynamic layout of the facility, showing the

double return design, is given in references 1 and 2.

Power is supplied by two 3 MW (4000 HP) electric motors

driving two 11 m (36 ft) diameter four-bladed fans. The

current maximum speed is limited by a fan speed of 210

RPM which is about 130 kph (~80 mph) in the test

section. Vehicle drag and individual wheel downforce are

measured using the current automobile balance which

became fully operational in January of 1998.

3

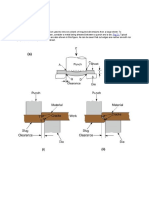

DESCRIPTION OF THE VEHICLE

The "dirt modified" race car that was tested is

representative of the class and is shown in figures 1-3.

Wheelbase and track measure 2.72 m (107 in) and 1.47

m (58 in). The entire chassis is constructed of tubular

steel with body panels fabricated from aluminum sheet.

The rear spoiler is translucent plastic, located between

the side body panels, and extends across the full width of

the car. The drivers compartment is located between two

side pods which are also bounded by the exterior side

body panels. This creates a duct-like passage on either

side of the driver which air flows through. At the front end

Downloaded from SAE International by Vellore Inst of Technology, Wednesday, June 25, 2014

of the car a 0.89 m (35 in) by 0.46 m (18 in) tall wide

sloping concave flow deflector known commonly as a

"snow plow" is bounded by short end plates. Tubular steel

bumpers protrude through the snow plow and also through

the side and rear body panels. The engine is contained

within a rectangular body which tapers to a small cross

section just aft of the snowplow. This compartment and a

raised wedge shaped airbox just forward of the driver are

fed air through three "NACA ducts" visible in figure 2. The

roof and roof pillars are sheet metal fabrication whereas

the driver is protected by a tubular steel cage which is

exposed to the air stream. A small windshield shields the

driver from flying debris. All four tires are exposed with

the rear tires protruding slightly under the sides. The front

suspension shock absorber and springs, located between

the front wheel and snow plow are exposed to the

freestream flow. The central underbody is a sheeted

smooth surface approximately 5 inches above the ground

at race ride heights.

Average speeds for this vehicle vary between 36 m/s (80

mph) in the corners to 67 m/s (150 mph) on the straight

portions of speedways. Since the driver slides the car

through the turns, a yaw angle results that is larger than

that typically found on hard surface track race cars.

EXPERIMENTAL DETAILS

The Langley Full-Scale Tunnel automotive force balance

was used to measure the vehicle downforce resolved at

the front and rear axles, as well as the vehicle drag. The

design and operation of the balance is described in

reference 3. The data presented was taken at a nominal

test section velocity of 60 mph. This speed was chosen

due to the drag force overload limits of the automobile

balance. The uncertainty in the force measurements was

not rigorously evaluated for this preliminary investigative

test but for comparison purposes the 95% (2) uncertainty

level for typical stock car racecars in lift and drag is no

worse than 0.0015 in drag coefficient and .0025 in lift

coefficient. The car was tested for two configurations.

The first was representative of the normal ride heights

used during racing and the second representative of a

lowered ride height (2 inches lower). The floor boundary

layer control suction slot was not used for these initial

tests.

4,5

A tire boundary layer trip was used to simulate

the correct separation point for a rotating wheel when

evaluating the nearby downstream flow field. This device

forces transition at the point of mounting rather than the

natural point (for a non- rotating cylinder) located

approximately 90 degrees clockwise, on the leeward side

of the tire.

6

FORCE MEASUREMENTS

Drag and individual wheel downforce data were obtained at

two yaw angles:

1) with the car oriented parallel to the flow

direction (yaw=0)

2) with the nose of the car rotated eight degrees

to the left (yaw=-8).

The -8 yaw angle was chosen to represent a typical

sliding turn to the left. Representative force data in

Figure 1 Dirt-Modified Race Car in Test Section

Figure 2 Dirt-Modified Race Car , Front View

Figure 3 Dirt-Modified Race Car , Rear View

Downloaded from SAE International by Vellore Inst of Technology, Wednesday, June 25, 2014

coefficient form for the two configurations is given in table

1. The data in tables 2-5 summarize the expected loads

at each axle for a range of typical operating speeds based

on the assumption that the coefficients are invariant.

Downforce is presented in pounds and drag is reported as

the equivalent horsepower required at the given speed to

overcome the force of aerodynamic drag. This convention

was chosen based on preferences expressed by race

team customers of the LFST. The most interesting aspect

revealed by the force test may be the imbalance between

the front and rear downforce. Unlike previous suppositions

that blamed brake and suspension set-up, poor downforce

distribution appears to be the chief reason for understeer.

FLOW VISUALIZATION

Flow visualization techniques were used to help identify

problem areas. Tufts were placed over much of the body

to map the surface streamlines and show separated

regions. Colored oil was applied to body panels to identify

regions of relatively low shear stress, useful when

evaluating interference relationships, and identifying

regions of recirculation and stagnation. Finally, a smoke

wand helped visualize off body streamlines, stagnation

points and underbody pressure trends.

7,8,9

TUFTS

Tufts were applied over the entire body of the car and

viewed using video and still cameras located in the test

section. The overall flow pattern at zero yaw can be seen

in figure 1 which shows the dirt car in the test section with

the flow on. The external flow over the roof and side

panels is nearly completely attached. The flow over the

wedge shaped hood scoop is more problematic with

separation evident in the fluttering tufts on the side.

Perhaps the most interesting discovery was the separated

region on the top surface of the inner body panels (side

pods) thought to be due to the upstream interference of

the front suspension components (spring towers). A

recirculation region was indicated behind the drivers

compartment as expected. The trailing edge of the airdam

Table 1 Aerodynamic Force Coefficients

Ride height yaw

Clf Clr Cd

race 0 0.111 -0.647 0.694

race -8 0.094 -0.608 0.681

low 0 0.142 -0.65 0.657

low -8 0.113 -0.641 0.65

Table 2 Calculated Forces, Yaw=0, Race Height

Vehicle

Velocity

(mph)

Front

Downforce

(lbs)

Rear

Downforce

(lbs)

Drag (hp)

60 -36 209 36

80 -64 372 85

100 -100 581 166

120 -144 836 287

140 -196 1138 455

150 -225 1306 560

Table 3 Calculated Forces, Yaw=-8, Race Height

Vehicle

Velocity

(mph)

Front

Downforce

(lbs)

Rear

Downforce

(lbs)

Drag (hp)

60 -30 196 35

80 -53 348 83

100 -83 544 162

120 -120 784 280

140 -163 1067 445

150 -188 1225 548

Table 5 Calculated Forces, Yaw=-8, Low Height

Vehicle

Velocity

(mph)

Front

Downforce

(lbs)

Rear

Downforce

(lbs)

Drag (hp)

60 -36 207 33

80 -53 368 79

100 -83 575 155

120 -120 828 268

140 -163 1127 425

150 -188 1294 523

Table 4 Calculated Forces, Yaw=0, Low Height

Vehicle

Velocity

(mph)

Front

Downforce

(lbs)

Rear

Downforce

(lbs)

Drag (hp)

60 -36 207 33

80 -53 368 79

100 -83 575 155

120 -120 828 268

140 -163 1127 425

150 -188 1294 523

Downloaded from SAE International by Vellore Inst of Technology, Wednesday, June 25, 2014

was also found to have a region of separation. Long tufts

were attached to the aft corners of the body at the spoiler

and roof. All of these tufts were seen to spin indicating

trailing vortices in these areas. The tire trip of figure 4 was

used to evaluate the sensitivity of the downstream flow

field to changes in the front tire aft separation point.

While the separation point was seen to change on the tire

as predicted, the overall effect on forces was negligible.

OIL FLOW

Oil flow studies were conducted in regions that were

thought to contain flow separation following the tuft study.

A mixture of motor oil (SAE 30) and titanium dioxide was

painted in a stripe over the rear deck just behind the

driver. In areas where the airflow near the deck surface

reached the spoiler, the oil stripe spread and can be seen

in figures 5 and 6 as streaks moving toward the spoiler.

Regions where the airflow is recirculatory or stagnant

caused the oil to remain largely unchanged as can be

seen in the area immediately behind the drivers seat.

Application of a film of oil over the snow plow showed the

wake of the bumper support struts propagating onto the

top surface as shown in figure 7.

SMOKE

A smoke wand was first used to examine the overall flow

field in the region surrounding the snow plow. Flow was

seen to separate at the trailing edge of the snow plow

perhaps aided by the interference from the bumper

supports. Disturbed flow over the side pods indicated by

the tuft study was proven to be caused by the upstream

location of the spring towers. Similarly, the vortices found

with the long tufts were confirmed using smoke. Flow

under the car was seen to remain relatively smooth and

may represent an area that can be exploited for creation

of more downforce. As expected, the flow over and

around the drivers compartment dirtied the spoiler and

Figure 4 Front Tire Trip

Figure 5 Colored Oil Flow Over Rear Deck, Rear View

Figure 6 Colored Oil Flow on Rear Deck, Top View

Figure 7 Oil Flow on Snow Plow

Downloaded from SAE International by Vellore Inst of Technology, Wednesday, June 25, 2014

rear deck where a suspected area of recirculation was

confirmed.

DISCUSSION OF RESULTS

This simple test which involved approximately six hours of

wind tunnel occupancy revealed several significant results

which may help break the experience-based design

evolution common to this class of vehicle.

The origin of understeer is now clearly understood; this

car creates lift at the front axle and substantial rear axle

downforce. The downforce imbalance is due in part to the

spoiler and leverage created by the forward position of the

rear axle. In addition, the snow plow appears to be

relatively ineffective at creating downforce whereas the

front suspension components cause significant

interference on the side pod areas, degrading downforce

production.

As regards drag, there are many areas for improvement

including streamlining exposed tubing, reducing frontal

areas of the passenger compartment and cleaning up the

engine air intakes. Again, minimizing interferences will

yield gains in drag as well as downforce.

CONCLUSIONS

Results from a wind tunnel study on a dirt-modified short

track race car conducted at the Langley Full Scale Tunnel

are felt to help designers understand the complex flow

field around the vehicle. Unexpected levels of front lift

point to a need for a new design with a more evenly

distributed balance. Interior flow through the car over the

side pods was shown to be adversely affected by the

disturbed flow downstream of the front suspension

components.

REFERENCES

1. Britcher, C. P. and Landman, D., "From the 30 by 60

to the Langley Full-Scale Tunnel," presented at the

36

th

AIAA Aerospace Sciences Meeting and Exhibit,

January 1998

2. Britcher, C. P. and Landman, D., "Jurassic Tunnel:

The Life, Death, and Resurrection of the Langley Full-

Scale Tunnel," presented at the European Forum on

Wind Tunnels and Wind Tunnel Test Techniques,

April 1997

3. Landman, D. and Britcher, C. P., "Development of

Race Car Testing at the Langley Full-Scale Tunnel,"

SAE 98MSV-21, 1998

4. Landman, D., Road Simulation for NASCAR Vehicles

at the Langley Full-Scale Tunnel," SAE 00MSV-31,

November 2000

5. Landman, D., Britcher C.P., Martin, P., "A Study of

Ground Simulation for Wind Tunnel Testing of Full-

Scale NASCAR's," AIAA 2000-0153, January 2000

6. Katz, J., "New Directions in Race Car Aerodynamics,

Designing for Speed," Robert Bentley Publishers,

1995

7. Hucho, W. H., "Aerodynamics of Road Vehicles,"

SAE, 1998

8. Barlow, J. B., Rae, W. H. and Pope, A., "Low Speed

Wind Tunnel Testing," 3

rd

Ed., John Wiley and Sons,

1999

9. Barnard, R. H., "Road Vehicle Aerodynamic Design",

Addison Wesley Longman Limited, 1996

Downloaded from SAE International by Vellore Inst of Technology, Wednesday, June 25, 2014

Anda mungkin juga menyukai

- Aerodynamic Design For FSAE CarDokumen4 halamanAerodynamic Design For FSAE CarMohamed NaderBelum ada peringkat

- Aerodynamic Optimization of The Opel Calibra ITC Racing Car Using Experiments and Computational Fluid DynamicsDokumen12 halamanAerodynamic Optimization of The Opel Calibra ITC Racing Car Using Experiments and Computational Fluid DynamicsVyssionBelum ada peringkat

- Simulation and Experiments On An Isolated Racecar Wheel Rotating in Ground ContactDokumen15 halamanSimulation and Experiments On An Isolated Racecar Wheel Rotating in Ground ContactVyssionBelum ada peringkat

- Intake Design For Maximum PerformanceDokumen8 halamanIntake Design For Maximum PerformanceCaio Paim100% (2)

- CFD Analysis of Non-Symmetrical Intake Manifold For Formula SAE CarDokumen11 halamanCFD Analysis of Non-Symmetrical Intake Manifold For Formula SAE CarGtatlisBelum ada peringkat

- Air Car: Project ReportDokumen43 halamanAir Car: Project ReportKartik GopalakrishnanBelum ada peringkat

- Porting Relations 2 StrokesDokumen10 halamanPorting Relations 2 Strokespistonbreaker100% (8)

- Numerical Simulation of Drag Reduction in Formula One CarsDokumen5 halamanNumerical Simulation of Drag Reduction in Formula One Carssultanu89Belum ada peringkat

- Design and Analysis of Brake and Gas PedalDokumen5 halamanDesign and Analysis of Brake and Gas PedalIJAERS JOURNAL100% (1)

- Effects of Rear Spoilers On Ground Vehicle Aerodynamic DragDokumen16 halamanEffects of Rear Spoilers On Ground Vehicle Aerodynamic DragVyssionBelum ada peringkat

- Effi Cycle PresentationDokumen13 halamanEffi Cycle Presentationwolfram77web100% (7)

- Simulation Analysis of Flow Field in Engine CompartmentDokumen6 halamanSimulation Analysis of Flow Field in Engine CompartmentarstjunkBelum ada peringkat

- RMD ReportDokumen29 halamanRMD ReportSergio PugazhBelum ada peringkat

- 1 Final Technical Report Mini BajaDokumen14 halaman1 Final Technical Report Mini BajaLucasBelum ada peringkat

- 2000-01-3090 - Design of A Restricted Induction System For A High Speed Four Cylinder EngineDokumen8 halaman2000-01-3090 - Design of A Restricted Induction System For A High Speed Four Cylinder EngineCaio PaimBelum ada peringkat

- Script Bs9 E-Hpvc 22Dokumen6 halamanScript Bs9 E-Hpvc 22VIPIN KUMARBelum ada peringkat

- ROLL CAGE DESIGNDokumen22 halamanROLL CAGE DESIGNRahul ReddyBelum ada peringkat

- Sesb2 ID106Dokumen8 halamanSesb2 ID106kaesarBelum ada peringkat

- Design and Fabrication of Race Spec Go-KartDokumen6 halamanDesign and Fabrication of Race Spec Go-KartAJER JOURNALBelum ada peringkat

- Freightcar PDFDokumen10 halamanFreightcar PDFArasouzaBelum ada peringkat

- Race - Car Front WingsDokumen11 halamanRace - Car Front WingsMarcos Soar100% (1)

- Report MinorPhase 2Dokumen16 halamanReport MinorPhase 2yogesh kumarBelum ada peringkat

- Study of Front-Body of Formula-One Car For Aerodynamics Using CFDDokumen7 halamanStudy of Front-Body of Formula-One Car For Aerodynamics Using CFDInternational Journal of Application or Innovation in Engineering & ManagementBelum ada peringkat

- Topological Optimization of Automobile Rotor Disk Brake: Vipul Matariya, Hiren PatelDokumen5 halamanTopological Optimization of Automobile Rotor Disk Brake: Vipul Matariya, Hiren PatelEmir EsimBelum ada peringkat

- Vehicle Aerodynamics ThesisDokumen6 halamanVehicle Aerodynamics Thesiskimberlythomasarlington100% (2)

- Rally Car Breaking System Progress Report II: SPI: Dr. Wu PW05Dokumen15 halamanRally Car Breaking System Progress Report II: SPI: Dr. Wu PW05Hisham ElkholyBelum ada peringkat

- A CFD Study of Pickup Truck AerodynamicsDokumen9 halamanA CFD Study of Pickup Truck Aerodynamicssh1999Belum ada peringkat

- Indiana UniversityDokumen64 halamanIndiana Universitymdasifkhan2013Belum ada peringkat

- Sae Final Sp01Dokumen112 halamanSae Final Sp01barrtiBelum ada peringkat

- Non-Linear Structural Analysis of An All-Terrain Vehicle Using AnsysDokumen13 halamanNon-Linear Structural Analysis of An All-Terrain Vehicle Using AnsyspramothjBelum ada peringkat

- 272 Concept Class Mansoura University DR Rev 2Dokumen8 halaman272 Concept Class Mansoura University DR Rev 2Gazzara WorldBelum ada peringkat

- Preliminary Design Report for Single-Seat Racing VehicleDokumen8 halamanPreliminary Design Report for Single-Seat Racing VehicleAman MaanBelum ada peringkat

- 2008-Kirk R G-Turbocharger OnEngine Exp Vib TestingDokumen13 halaman2008-Kirk R G-Turbocharger OnEngine Exp Vib TestingAlex CooperBelum ada peringkat

- Design and Development of Hydro-Pneumatic Suspension SystemDokumen11 halamanDesign and Development of Hydro-Pneumatic Suspension SystemzhenyupanBelum ada peringkat

- Aiaa 2010 1021Dokumen22 halamanAiaa 2010 1021brianBelum ada peringkat

- Baja Design Report PDFDokumen9 halamanBaja Design Report PDFZubair HussainBelum ada peringkat

- Baja Design ReportDokumen9 halamanBaja Design ReportRishi KumarBelum ada peringkat

- Baja Sae Design ReportDokumen14 halamanBaja Sae Design Reportlucky_agrawal45Belum ada peringkat

- Albert 2004Dokumen11 halamanAlbert 2004alijannounBelum ada peringkat

- Lit 14 ASEE - 2009-TB3 - 1Dokumen9 halamanLit 14 ASEE - 2009-TB3 - 1kumarpskBelum ada peringkat

- Free Rolling TestDokumen28 halamanFree Rolling TestsiritapeBelum ada peringkat

- 2007-01-3541 Engine-Vehicle Matching For A FSAE Race CarDokumen13 halaman2007-01-3541 Engine-Vehicle Matching For A FSAE Race CarHan TanBelum ada peringkat

- Stress Behaviour Improvement of Automobile Flywheel Under High Centrifugal ForcesDokumen6 halamanStress Behaviour Improvement of Automobile Flywheel Under High Centrifugal ForcesParag NaikBelum ada peringkat

- High Torque Nozzle MK66Dokumen12 halamanHigh Torque Nozzle MK66Sergio SacristanBelum ada peringkat

- Analysis Four Wheel Drive Suspension System by Using FeaDokumen12 halamanAnalysis Four Wheel Drive Suspension System by Using FeaIRJMETS JOURNALBelum ada peringkat

- Vehicle Body Engineering and SafetyDokumen16 halamanVehicle Body Engineering and SafetyMOHAMMED SAQLAINBelum ada peringkat

- Brakes Analysis of BAJA ATVDokumen4 halamanBrakes Analysis of BAJA ATVInfogain publication100% (3)

- Design of Formula SAE Suspension ComponentsDokumen13 halamanDesign of Formula SAE Suspension ComponentsYasser Rohom0% (1)

- Seminar Ski Rad-Tema Formula and AccessoryDokumen6 halamanSeminar Ski Rad-Tema Formula and AccessorymunjamixBelum ada peringkat

- Effect of Turbulence on Savonius Rotor Efficiency in Wind TunnelsDokumen19 halamanEffect of Turbulence on Savonius Rotor Efficiency in Wind TunnelsMilenko ZivancevBelum ada peringkat

- GB Pant Engineering College - BAJA SAE India 2014 - DesignReportDokumen8 halamanGB Pant Engineering College - BAJA SAE India 2014 - DesignReportvardaan510Belum ada peringkat

- 1999-01-1259 Kluger SWRIDokumen8 halaman1999-01-1259 Kluger SWRIManish Kulkarni100% (1)

- Brakes Design ReportDokumen8 halamanBrakes Design ReportSarthhakVashistBelum ada peringkat

- Race Car AerodynamicsDokumen7 halamanRace Car AerodynamicsejjLi100% (1)

- Paper 50001Dokumen9 halamanPaper 50001Mauricio ToroBelum ada peringkat

- Performance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallDari EverandPerformance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallPenilaian: 4 dari 5 bintang4/5 (8)

- How to Rebuild & Modify Rochester Quadrajet CarburetorsDari EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsPenilaian: 5 dari 5 bintang5/5 (2)

- Damping Calculations for Race Vehicle SuspensionDokumen99 halamanDamping Calculations for Race Vehicle SuspensionManu PantBelum ada peringkat

- Design and Fabrication of Automated Manual Gear Transmission in Motor BikesDokumen57 halamanDesign and Fabrication of Automated Manual Gear Transmission in Motor Bikesanmol6237Belum ada peringkat

- Industrial EnclosuresDokumen56 halamanIndustrial Enclosuresanmol6237Belum ada peringkat

- Nissan Walkin ChennaiDokumen2 halamanNissan Walkin Chennaianmol6237Belum ada peringkat

- Nissan Walkin ChennaiDokumen2 halamanNissan Walkin Chennaianmol6237Belum ada peringkat

- List of over 150 Solidworks clientsDokumen4 halamanList of over 150 Solidworks clientsanmol6237Belum ada peringkat

- HW Starter Manual March HresolutionDokumen23 halamanHW Starter Manual March HresolutionCharan KumarBelum ada peringkat

- Sri Ganapathi Industries Kushaiguda Title: Scale Size DRWG No: Sheet NoDokumen2 halamanSri Ganapathi Industries Kushaiguda Title: Scale Size DRWG No: Sheet Noanmol6237Belum ada peringkat

- ME 443/643: Introduction to HyperMeshDokumen37 halamanME 443/643: Introduction to HyperMeshanmol6237Belum ada peringkat

- RGB Color TableDokumen5 halamanRGB Color Tableanmol6237Belum ada peringkat

- Sri Ganapathi Industries Kushaiguda Title: Scale Size DRWG No: Sheet NoDokumen1 halamanSri Ganapathi Industries Kushaiguda Title: Scale Size DRWG No: Sheet Noanmol6237Belum ada peringkat

- Nissan Walkin Chennai 1Dokumen2 halamanNissan Walkin Chennai 1anmol6237Belum ada peringkat

- GD AdvantagesDokumen1 halamanGD Advantagesanmol6237Belum ada peringkat

- Press Tool Cutting ForceDokumen1 halamanPress Tool Cutting Forceanmol6237Belum ada peringkat

- Nissan Walkin ChennaiDokumen2 halamanNissan Walkin Chennaianmol6237Belum ada peringkat

- E2SEM1MT2TD06102012Dokumen3 halamanE2SEM1MT2TD06102012anmol6237Belum ada peringkat

- Creo2 Adv PrimerDokumen174 halamanCreo2 Adv PrimerAmit JhaBelum ada peringkat

- Tool Design TerminologyDokumen5 halamanTool Design Terminologyanmol6237Belum ada peringkat

- Term - 1 - Class - X Communicative English - 2010Dokumen27 halamanTerm - 1 - Class - X Communicative English - 2010Nitin GargBelum ada peringkat

- Parametric Modeling With Creo ParametricDokumen41 halamanParametric Modeling With Creo Parametricfrancesca050168Belum ada peringkat

- GDDokumen2 halamanGDanmol6237Belum ada peringkat

- M Tech Project List 2015 NewDokumen5 halamanM Tech Project List 2015 Newanmol6237Belum ada peringkat

- Train Schedule: From Bhopal To Indore JN BG (INBD) BPL - INBD PassengerDokumen1 halamanTrain Schedule: From Bhopal To Indore JN BG (INBD) BPL - INBD Passengeranmol6237Belum ada peringkat

- Gate Syllabus For Mech EnggDokumen4 halamanGate Syllabus For Mech Engganmol6237Belum ada peringkat

- SHEARINGDokumen6 halamanSHEARINGanmol6237Belum ada peringkat

- Intro To CFD ProblemDokumen1 halamanIntro To CFD ProblemlinoBelum ada peringkat

- Train Schedule: From Bhopal To Indore JN BG (INBD) BPL - INBD PassengerDokumen1 halamanTrain Schedule: From Bhopal To Indore JN BG (INBD) BPL - INBD Passengeranmol6237Belum ada peringkat

- Ansys Training Book.Dokumen15 halamanAnsys Training Book.Sarath Babu SBelum ada peringkat

- Ceed Model Question PaperDokumen21 halamanCeed Model Question PaperSatvender SinghBelum ada peringkat

- More Than 100 Keyboard Shortcuts Must ReadDokumen3 halamanMore Than 100 Keyboard Shortcuts Must ReadChenna Keshav100% (1)

- 2018 TacomaDokumen10 halaman2018 TacomaVISHNU RAVINDRANATHBelum ada peringkat

- Engine Hydraulic SystemDokumen2 halamanEngine Hydraulic SystemTariq KhamaysaBelum ada peringkat

- A Study On Customer Perception On The Maruti Suzuki Services and Products at BangaloreDokumen12 halamanA Study On Customer Perception On The Maruti Suzuki Services and Products at BangaloreVedashree TnBelum ada peringkat

- ST 330-75-1975 Chevrolet Light Truck Service Overhaul SupplementDokumen324 halamanST 330-75-1975 Chevrolet Light Truck Service Overhaul Supplementpancho100% (1)

- History of Royal EnfieldDokumen2 halamanHistory of Royal EnfieldAbhimanyu Rajendran100% (1)

- Stok KosongDokumen4 halamanStok KosongSitisrikasihBelum ada peringkat

- DSI M11 V.2010 2013.3 ADDDCoDokumen7 halamanDSI M11 V.2010 2013.3 ADDDCoAlex Maceira Graterol100% (3)

- Service Manual Bajaj Caliber 115 PDFDokumen4 halamanService Manual Bajaj Caliber 115 PDFchinnathambijBelum ada peringkat

- 01-69 Central Locking System OBD PDFDokumen55 halaman01-69 Central Locking System OBD PDFRaheel FaroukBelum ada peringkat

- Tata Nano Supply Chain ImportanceDokumen25 halamanTata Nano Supply Chain ImportanceSathisha He H EBelum ada peringkat

- Zbook - Eaa8959c B9e9 40bb A30a f856d4 - 4d77c6Dokumen20 halamanZbook - Eaa8959c B9e9 40bb A30a f856d4 - 4d77c6gaelBelum ada peringkat

- Marine-Transmission DMT170HL BrochureDokumen2 halamanMarine-Transmission DMT170HL BrochureChocolateBelum ada peringkat

- Frame and Battery Box AssemblyDokumen68 halamanFrame and Battery Box AssemblyFabio MacielBelum ada peringkat

- Compactor With Vibration and OscillationDokumen2 halamanCompactor With Vibration and OscillationCopemaq CopemaqBelum ada peringkat

- Touring Bus HDDokumen2 halamanTouring Bus HDnew launchBelum ada peringkat

- Ci Ing03 S3 2016 ViDokumen20 halamanCi Ing03 S3 2016 ViAntonio TichyBelum ada peringkat

- Control de Precios e Inventario La Universal125, C.A.Dokumen457 halamanControl de Precios e Inventario La Universal125, C.A.Gregory MorenoBelum ada peringkat

- Vehicle Body Repair Dimensions and TolerancesDokumen6 halamanVehicle Body Repair Dimensions and TolerancesS SBelum ada peringkat

- NAVISTAR International LT - Series - SleeperSheet - S13 - R8Dokumen2 halamanNAVISTAR International LT - Series - SleeperSheet - S13 - R8lushnuBelum ada peringkat

- Cat 16HDokumen3 halamanCat 16Hirfan_prastyaBelum ada peringkat

- 2022 Corolla CrossDokumen8 halaman2022 Corolla CrossHikaruBelum ada peringkat

- ABRITES Commander For VAG ManualDokumen161 halamanABRITES Commander For VAG ManualpadrandyBelum ada peringkat

- Mack MP7 Engine: More Power To Your TruckDokumen3 halamanMack MP7 Engine: More Power To Your Truckluis eduardoBelum ada peringkat

- Group 2 Specifications: 1. General LocationsDokumen8 halamanGroup 2 Specifications: 1. General LocationsAndré TarginoBelum ada peringkat

- 986 Group 2 Fuel-ExhaustDokumen96 halaman986 Group 2 Fuel-ExhaustPeter BourneBelum ada peringkat

- Toyota Car RecallDokumen2 halamanToyota Car RecallSubha RudraBelum ada peringkat

- Triumph Modern Classics 2009 EnlgishDokumen69 halamanTriumph Modern Classics 2009 Enlgishneusun001Belum ada peringkat

- Comparison and Contrast Essay 3 Final DraftDokumen4 halamanComparison and Contrast Essay 3 Final Draftapi-259376307Belum ada peringkat

- Product Recommendation Toyota (EU) Yaris XP10 Yaris 1.3 16V VVT-i (2003-2005)Dokumen3 halamanProduct Recommendation Toyota (EU) Yaris XP10 Yaris 1.3 16V VVT-i (2003-2005)marranBelum ada peringkat

- R1.4 2.5 D435 TG 04 2021 EMEA Rev00 EN v1 PDFDokumen16 halamanR1.4 2.5 D435 TG 04 2021 EMEA Rev00 EN v1 PDFGilo MonterrubioBelum ada peringkat