Water Flow Adjustment of Pumps in Heating Stations

Diunggah oleh

RazvanJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Water Flow Adjustment of Pumps in Heating Stations

Diunggah oleh

RazvanHak Cipta:

Format Tersedia

Revista Romn de Inginerie Civil, Volumul 4 (2013), Numrul 1 Matrix Rom

Water flow adjustment of pumps in heating stations

Lecturer dr.eng. Emilian tefan Valea

1

, Prof.dr.eng. Ioan Srbu

1

,

Eng. Tamara Pampu

2

1

Politehnica University of Timioara

Piaa Victoriei 1-2, Timioara

E-mail: emilian.valea@ct.upt.ro; ioan.sarbu@ct.upt.ro

2

Technical

College Ferdinand 1

st

Timioara

24A Renaerii str., Timioara

E-mail: tamarapampu@yahoo.com

Abstract. In urban heating stations the heat agent circulation between the energy source

and consumers is assured by pumps, which take part to the energy consumption of the

system in the operation period. The number, the position, and the technical

characteristics of these pumps are established according to the chosen type of the heating

system, the thermal power and the operating regime. Using variable rotation speed

pumps it is possible to have a continuous control over the water pressure according to

the thermal load at a certain moment. In this paper are presented and analyzed some

optimization solutions of pumps operation in urban heating stations from energy point of

view.

Key words: heating stations, energy saving, variable speed centrifugal pump, variable

frequency drives

1. Introducere

Heating stations are dimensioned to provide the consumers energy need in the

coldest period of the year. However, most of the energy need is much lower than the

designed value of the heating station thermal load. Consequently the primary agent

flow must be reduced most of the time from heating season. This flow variation can be

carryed out for constant speed of centrifugal pup using following methods: by-passing

a part of the water discharge (the pump operates at the same operation point and the

absorbed power remains constant); by introducing a supplementary pressure loss (H),

using a regulating valve (the operation point is heading towards left in H-Q diagram)

[1-6]. Another method is to operate with variable rotation speed pumps. [4-8]

2. Thermal load of the heating stations

In Figure 1, the yearly distribution of the daily average outdoor temperature is

presented. The diagram points out the fact that, in the year, the lowest temperatures

Emilian Stefan Valea, Ioan Sarbu, Tamara Pampu

42

represent about 5 %. Thus, if the heating station is dimensioned to cover the maximal

energy need, then 95 % on the year the station is over dimensioned. At the same time,

it can easily be seen that approximately 40 % of the year the average temperature is

higher than +15

o

C. Thus, 40 % of the year the thermal energy provided by heating

station is used only to prepare the domestic hot water, which needs only a small part of

the installed capacity of the heating station.

Fig.1 Average external air temperature in time

At constant difference between the forward and return temperatures of the

warm water, the delivered energy do not varies proportionally with the discharge.

Generally, at constant forward temperature the return temperature is lower when the

required heat decreases.

In Figure 2 is presented the relative produced heat quantity depending on the

relative discharge at constant forward temperature of the warm water. When the water

discharge is reduced, for example at 60 % of the initial value, the produced heat

quantity decreases only at 85 % of the initial value, because the water-cooling is

increased.

Fig. 2 Relative amount of heat delivered in time

for constant forward temperature

The main goal in operating a heating system is to assure the consumers with the

required heat flow according to outdoor climatic parameters. Thus, the heating system

is provided with a regulation system, which can be qualitative, quantitative or mixed.

The quantitative adjustment requires a variation of the flow during the

operation, the warm water parameters being constant. It can be done by:

pumps with different technical characteristics (flow, pumping head);

variable rotating speed pumps.

Water flow adjustment of pumps in heating stations

43

The assurance of the required heat flow, demand an adjustment in the

distribution system between the heat source and consumers. Depending on the applied

methods, important variations of the energy consumption are obtained. In Figure 3 the

energy consumption curves for different adjustment methods are presented.

Fig.3 Energy consumption for variable flow

The variation of energy consumption depends on the global efficiency of the

heating system, the configuration of the distribution system, the operation point and

the type of the adjustment equipments.

Analyzing the presented curves one can observe that the energy consumption in

the case of regulating valves is higher than the energy consumption in the case of

variable rotation speed pumps.

The throttling valve control method of reducing water flow is presented in

Figure 4.

The characteristic curve of the system H

r1

=f(Q) establishes the nominal pump

operation point in F, according to H

F

pressure head, Q

F

water discharge and the

specific pumping energy w

pF

[5].

Shutting partially the pumps outlet the systems characteristic curve becomes

H

r2

=f(Q) and, according to new operation point the water discharge will decrease to

Q

o

, the pumping head will increase to H

o

, the specific pumping energy will decrease to

w

po

=w

pmin

and the efficiency of the pumps will increase from

F

to

o

.

The higher pumping head will lead to a lower hydraulic efficiency of the

system and finally to a lower global efficiency. From this reason the water discharge

regulation with regulating valves is avoided in practice [3], [7]. However, examining

the specific pumping energy curves w

p

, one can be observe that the global efficiency

of the system increases even when the hydraulically efficiency is decreasing. This is

possible when the regulation is done under the point O that corresponds to the minimal

specific pumping energy, on the characteristic curve of the pump. If the regulation is

made above the point O by increasing the pumping head, then the specific pumping

energy increases, leading thus to an increase of the energy consumption.

Emilian Stefan Valea, Ioan Sarbu, Tamara Pampu

44

Fig.4 Flow variation by throttling valve

Thus, the operation diagram of a centrifugal pump can be separated in two areas

divided by the operation point corresponding to the minimal pumping energy. The

regulation is to be avoided when the pumping head is higher and the regulation is

recommended when the pumping head is lower than the pressure corresponding to

point O.

Although the regulation of water discharge using regulating valves can lead to

higher energy efficiency of the heating system when the nominal pumping head is

lower than the optimal value, this procedure have the followed disadvantages:

an increased wear of regulating valves shutting elements;

noise, vibration and hydraulic impacts with negative effects in the system;

low operation reliability of the pumps.

The best procedure to obtain variable heat flow is the use of variable rotation

speed pumps. The flow regulation (Fig. 5) is done due to the changing of the pump

characteristic curve H (at different rotation speed n

1

and n

2

) on the fixed characteristic

curve of the system H

r

. The operation point F

2

corresponds to the reduced pumping

head H

F2

.

Fig. 5 Variable speed centrifugal pump operation

Water flow adjustment of pumps in heating stations

45

The characteristics of the pumps variable rotation speed could be expressed

with the followed similitude relations:

Q

Q

n

n

1

2

1

2

= (1)

H

H

n

n

1

2

1

2

2

=

(2)

P

P

n

n

1

2

1

2

3

=

(3)

The power demand P, in kW, at certain rotation speed is given by:

P

QH

w Q = =

p

p

1000

3600 (4)

where: is the specific weight of the water, in N/m

3

; Q the pumping discharge, in

m

3

/s; H

p

the pumping head corresponding to the operation point, in m; the global

efficiency of the pumping plant; w

p

the specific pumping energy, in kWh/m

3

.

The efficiency dependence of the rotation speed is given by the relation (5),

thus, one can determine the efficiency

2

in operation point F

2

according to the

rotation speed n

2

in function of

1

and n

1

.

2 1

0,1

1 (1 ) =

n

n

1

2

(5)

In fact, at the majority of the pumps and especially at the big ones, the

efficiency variation can be neglected for a variation of rotational speed of 1/3 from the

nominal value.

In Figure 6 are presented the variation curves of H, Q, P and for centrifugal

pumps depending on rotational speed n. It can be observed that a reduction with 20 %

of the rotational speed will lead to the reduction of power demand with 50 %, at

constant pump efficiency. Thus, results the possibility to reduce the pumping energy

consumption by using variable rotational speed pumps. One of possible ways to

achieve is variable frequency drives (VFDs).

Fig. 6 Variation of centrifugal pump parameters with load

Emilian Stefan Valea, Ioan Sarbu, Tamara Pampu

46

In certain countries, the use of the electronically driving methods of electrical

engines the variation of rotation speed was extended up to industrial scale [1]. The

variation of rotational speed of the electric driven pumps can be carried out with:

frequency converters or variable frequency drives (VFDs), continuous current engines,

voltage control and mechanical drives.

3. Throttling control valve versus variable speed drive for flow control

3.1 Comparative energy analysis of the adjustment process

The energy efficiency of the above presented regulation methods are analyzed

based on the operation regime of a pump for different values of the rotation speed (Fig. 7).

Fig. 7 Energy consumption for different flow with VFDs

If the maximal load is 350 m

3

/h at the pumping head of 28 m, the absorbed

power is 42,5 kW. If the water discharge is reduced to flow rate of 100m

3

/h using

throttling valve, the pumping head increases up to 50 m and the shaft power will be 23

kW at a constant rotational speed of 1650 rot/min. The operating curves are marked

with A-B on the H-Q and with A-B on the power diagram.

Water flow adjustment of pumps in heating stations

47

The relation with the shaft absorbed power is presented with the dashed curve.

Thus, it is possible to compare the absorbed power, in the case of adjust with valves

and with variable rotational speed pumps. Consequently, if the yearly distribution is

known the energy consumption can be determined.

The numerical results, based on the characteristic curves from Figure 7, are

presented in Table 1.

From the results of the analysis, it can be seen a yearly energy consumption

decrease from 275064 kWh to 124173 kWh, by rotational speed variation. The energy

saving is about 151000 kWh which represents about 55 %.

Table 1

The absorbed power and the energy consumption using

adjusting valves and rotational speed variation

Discharge Distribution Regulating

valves

Variable speed

Q [m

3

/h] % Hours Power

P

[kW]

Energy

W

[kWh]

Power

P [kW]

Energy

W [kWh]

0 1 2 3 4 5 6

350 5 438 42,5 18615 42,5 18614

300 15 1314 38,5 50589 29,0 38106

250 20 1752 35,0 61320 18,5 32412

200 20 1752 31,5 55188 10,0 17520

150 20 1752 28,0 49056 6,5 11388

100 20 1752 23,0 40296 3,5 6132

Total 100 8760

275064

124173

3.2 Prediction of energy savings with variable speed drives in a heating station

The heating stations from Timisoara are being modernized in order to increase

their efficiency and to be less harmful to the environment. Before this modernization

be accomplished, the operation of one pump used in heat supply period was analyzed.

The measured parameters of the pump were: hot water flow rate Q and water

pressure. The measurements were made every hour, during several days in a month

with large variations in flow of hot water, April. Knowing water temperature, for every

hour were calculated the power requirements in two cases: throttle control with a valve

and reducing rotational speed with variable frequency drives.

The characteristics of the pomp are: type: TD 500-400-750; flow rate:

3150m

3

/h; pumping head: 70m. The engine characteristics are: type: MIB-X 710Y;

power: 800 kW; rated current: 94A; Voltage: 6000 V; rotational speed: 995

revolutions per minute-rpm; cos= 0.87; mass: 6000 kg.

Heat flow depends on the temperature of external air and is influenced by the

temperature of the reverse network. The operational water flux of the pump was lower

of course than the nominal one, for which the pump was built. In order to achieve the

desired flow rate, as provided in the chart control it was necessary to act to close the

Emilian Stefan Valea, Ioan Sarbu, Tamara Pampu

48

valve mounted on the pump outlet. Thus reducing the water flow, the head of the

pump becomes higher than that from characteristic curves at the same flow. In Figure

8 are presented characteristic curves for that type of pump: H=f(Q); =f(Q);

P=f(Q).The power absorbed by the electric engine is also lower. For each hour, authors

calculated necessary power P

t

for this case of throttle control of the network, with

relation (4).

Fig. 8 Characteristic curves of the pump

For each day the authors calculated also the daily power used. The pump

necessary power P

2

, when the motor use frequency convertor, is obtained from affinity

laws (1) and (3):

3

1

2

1 2

=

Q

Q

P P (6)

in which: P

1

is the necessary power of fixed speed pump for operating point Q

1

= 3150

m

3

/h and H

1

=70 m.

The relationship between rotation speed of the pump and electric energy

frequency is:

p

n

=

60

where: n is the rotational speed; -energy frequency; p-number of pole pairs of the

engine.

If is necessary to change rotational speed, could be changed number of pole

pairs of the engine or energy frequency. The second case is easily achievable.

In Figure 9 are plotted P

1

, P

t

and P

2

for the whole operating period from April.

The average ratio between P

2

and P

t

is 0.67. This means a reduction of electric energy

applying adjustment method by variable rotational speed using VFDs compared with

throttling valve control of 32.8%, i.e. 2835.2 kWh.

Water flow adjustment of pumps in heating stations

49

Fig. 9 Power consumption for different djustment methods

4. Economical aspects

The practice has shown that the investment cost of the auxiliary equipments for

the maintenance of the safety of the variable rotation speed pumps represents about 10

% of the total exploiting costs. Thus, 90 % represents the energy consumption for the

total exploiting period, which is approximately 1520 years. At the same time, the

obtained energy saving, using variable rotational speed pumps, will lead to a shorter

recovery time of the investment costs.

In a power station operate dozens of pumps which power consumption is about

35% of its domestic consumption. Taking into account that domestic consume of a

power station is about 10,000 kW, energy consumption of pumps 3,500 kW.

Considering energy saved by using variable rotational speed compared with throttle

control of 33%, for yearly operational time during winter 4,000 hours, could be saved

4,480,000 kWh. This could reduce the financial burden with about 500,000 dollars

every year.

5. Conclusions

The water flow adjustment with variable rotation speed pumps is an

advantageous optimization method of water pumping in urban heating stations,

assuring the correlation between the heat demand and water discharge and obtaining,

at the same time, important energy saving which can reach, under certain condition,

even 60 %.

Using the rotation speed variation, the water pressure meet continuously to the

required values, obtaining an important reduction of water losses in the system. At the

same time, the high values of the pressure, which can lead to operation defects of the

system equipments, are avoided.

Emilian Stefan Valea, Ioan Sarbu, Tamara Pampu

50

Using frequency converters, the rotation speed of the power driven pumps can

be increased, obtaining higher values than 50 Hz. Thus, the pumping capacity

increases too. In this cases the lower capacity of a pumping station can increases, using

frequency converters, replacing the engines with other with higher power.

For variation of the rotation speed the frequency converters represents the best

solution, because these should be connected between the engine and the power source

and set for the specific requirements. VFDs offer energy savings and a soft-starting

capability. The voltage fluctuations that can occur in starting up large motors are also

reduced. As reducing water flow by VFDs reduces head, pump and auxiliary wear and

reduced. Motor shaft requirements decreases with cube of pumps rotational speed and

this could life cycle costs of engine-pump assembly.

References

1. K.Bienek, N.Groning, Die regelung die forderleistung von Kreiselpumper nuttels

elektronischercher drehzahlverstellung, Technische Berichte, nr. 6, 1987.

2. R.Cyssau, Manuel de la regulation et de la gestion de lnergie, PYC, Paris, 1991.

3. I. Georgescu Economii de energie prin acionarea cu turaie variabil a pompelor i ventilatoarelor

n automatizarea proceselor tehnologice, Energetica, nr. 3, 1988. pp. 99-109.

4. M. Ilina, S. Burchiu, Pompe cu turaie variabil n instalaiile de nclzire, Rev. Instalatorul, nr. 2,

1996, pp. 5-9.

5. I. Srbu, Optimizarea energetic a sistemelor de distribuie a apei, Ed. Academiei Romne,

Bucureti, 1997.

6. I. Srbu, I. Borza, Energetic optimization of water pumping in distribution systems, Periodica

Polytechnica, Budapest, vol. 42, no. 2, 1998, pp. 141-152.

7. I. Suceveanu, Analiza posibilitilor de reglare a parametrilor tehnologici prin variaia turaiei

agregatelor, Energetica, nr. 4, 1988, pp.156-160.

8. G. McCormick, R.S. Powell, Optimal pump scheduling in water supply systems with maximum

demand charges, Journal of Water Resources Planning and Management, vol. 129, no. 3, 2003,

pp. 372-379.

Anda mungkin juga menyukai

- Lab 5 - Operating Characteristics of A Centrifugal PumpDokumen9 halamanLab 5 - Operating Characteristics of A Centrifugal PumpGianne Nigelle DoriaBelum ada peringkat

- Energy Conservationi N Pumps: M.V.Pande Dy - Director NPTI, NagpurDokumen37 halamanEnergy Conservationi N Pumps: M.V.Pande Dy - Director NPTI, NagpurmvpngpBelum ada peringkat

- 2.4 Performance of A Cooling TowerDokumen2 halaman2.4 Performance of A Cooling TowerSurendra ReddyBelum ada peringkat

- Steam Power PlantDokumen10 halamanSteam Power PlantJoel DaleBelum ada peringkat

- Chapter 10: Vapor and Combined Power CyclesDokumen8 halamanChapter 10: Vapor and Combined Power CyclesAhmad SairafiBelum ada peringkat

- Efficient Driving at Variable Speeds World Pumps Vol 2013 Issue 4 0Dokumen4 halamanEfficient Driving at Variable Speeds World Pumps Vol 2013 Issue 4 0IzallmachineBelum ada peringkat

- Laboratory ManualDokumen52 halamanLaboratory ManualOsan ThorpeBelum ada peringkat

- Advanced Power Generation Course OutlineDokumen52 halamanAdvanced Power Generation Course Outlineluter alexBelum ada peringkat

- Steam Power Plants EnglishDokumen1 halamanSteam Power Plants EnglishMirza Zubair RazaBelum ada peringkat

- Energy and Cost Savings Through Pumping Stations Rehabilitation. Case Study in BucharestDokumen8 halamanEnergy and Cost Savings Through Pumping Stations Rehabilitation. Case Study in Bucharestrajamannar322Belum ada peringkat

- Application of VFD in Cycling Pumps in Thermal Power PlantDokumen10 halamanApplication of VFD in Cycling Pumps in Thermal Power PlantJose Manuel FreitasBelum ada peringkat

- Evaluating a Simple Steam Power Plant Using P-h DiagramsDokumen8 halamanEvaluating a Simple Steam Power Plant Using P-h DiagramsTHEOPHILUS ATO FLETCHERBelum ada peringkat

- Automatic Water Flow ControlDokumen18 halamanAutomatic Water Flow ControlssgjmlimBelum ada peringkat

- How VFD Speed Affects Centrifugal Pump HydraulicsDokumen6 halamanHow VFD Speed Affects Centrifugal Pump HydraulicsAudrey Patrick KallaBelum ada peringkat

- Optimization of Shell-and-Tube Intercooler in Multistage Compressor SystemDokumen11 halamanOptimization of Shell-and-Tube Intercooler in Multistage Compressor SystemabuahnfBelum ada peringkat

- Write Up For Voc TRGDokumen12 halamanWrite Up For Voc TRGPritish MohanBelum ada peringkat

- Figure 1. Rankine CycleDokumen17 halamanFigure 1. Rankine CycleJikni NobleBelum ada peringkat

- Universal Pump Test R: Analyzing Centrifugal Pump PerformanceDokumen9 halamanUniversal Pump Test R: Analyzing Centrifugal Pump PerformanceOsama RaheelBelum ada peringkat

- Vapour Cycle Thermodynamics TutorialDokumen13 halamanVapour Cycle Thermodynamics TutorialDavid ChikuseBelum ada peringkat

- Energy Efficiency 2Dokumen9 halamanEnergy Efficiency 2Uallace ReisBelum ada peringkat

- Exp # 7,8,9,10 Advanced Fluid Mechanics LabDokumen12 halamanExp # 7,8,9,10 Advanced Fluid Mechanics LabrrBelum ada peringkat

- ME LAB 3 ReportDokumen37 halamanME LAB 3 ReportwijawijaBelum ada peringkat

- 4.2 Water PumpDokumen8 halaman4.2 Water PumpPRATIKBelum ada peringkat

- Centrifugal Pump Performance CharacteristicDokumen7 halamanCentrifugal Pump Performance CharacteristicOrcraBelum ada peringkat

- Dynamic Simulation - Steam SystemDokumen11 halamanDynamic Simulation - Steam SystemDicky Wahyu PerdianBelum ada peringkat

- Performance Analysis of Regenerative Feedwater Heaters in 210Mw Thermal Power PlantDokumen6 halamanPerformance Analysis of Regenerative Feedwater Heaters in 210Mw Thermal Power Plantrsr ecBelum ada peringkat

- Centrifugal Pumps: How They Work and Their Performance CurvesDokumen8 halamanCentrifugal Pumps: How They Work and Their Performance CurvesSaleem Chohan100% (1)

- 1-3 Advanced Steam Power CyclesDokumen14 halaman1-3 Advanced Steam Power CyclesGeethika NayanaprabhaBelum ada peringkat

- Teh 375a PDFDokumen27 halamanTeh 375a PDFomarBelum ada peringkat

- Hybrid Combined Cycle Power Plant: Károly VeszelyDokumen8 halamanHybrid Combined Cycle Power Plant: Károly Veszelyankit407Belum ada peringkat

- Article JEE7-Boiler EfficiencyDokumen6 halamanArticle JEE7-Boiler Efficiencyrashm006ranjanBelum ada peringkat

- 1.0 TITLE Centrifugal PumpDokumen11 halaman1.0 TITLE Centrifugal PumpnorsiahBelum ada peringkat

- Impulse TurbineDokumen15 halamanImpulse TurbineHazwan JamhuriBelum ada peringkat

- Performance PumpDokumen13 halamanPerformance PumpPutera AshrafBelum ada peringkat

- Multistage Centrifugal Pump Test RigDokumen13 halamanMultistage Centrifugal Pump Test Rigأشرف علي100% (1)

- Pump SizingDokumen73 halamanPump SizingIsmael Llamelo PerezBelum ada peringkat

- Energy Conservation in Pumping SystemDokumen33 halamanEnergy Conservation in Pumping SystemFahad KhanBelum ada peringkat

- Assignment in ME 312Dokumen23 halamanAssignment in ME 312jasperBelum ada peringkat

- Vw1004 Control KosoDokumen27 halamanVw1004 Control KosoAnup Mitra100% (1)

- Pumps in Series and ParallelDokumen6 halamanPumps in Series and ParallelSuhadahafiza Shafiee0% (1)

- Irrigation Pump VFD Energy Savings CalculationDokumen15 halamanIrrigation Pump VFD Energy Savings CalculationRavindra Angal0% (1)

- A New Linear Model of Fossil Fired Steam Unit For Power System Dynamic AnalysisDokumen8 halamanA New Linear Model of Fossil Fired Steam Unit For Power System Dynamic AnalysisSara VooDoo HazeBelum ada peringkat

- Ciclo Rankine WilkinsDokumen49 halamanCiclo Rankine WilkinsluisBelum ada peringkat

- Boiler Models For System Dynamic Performance StudiesDokumen9 halamanBoiler Models For System Dynamic Performance StudiesLissete VergaraBelum ada peringkat

- Tear Cooling Tower Energy Operating Cost SoftwareDokumen9 halamanTear Cooling Tower Energy Operating Cost Softwareforevertay2000Belum ada peringkat

- Centrifugal Pump Operation and EfficiencyDokumen9 halamanCentrifugal Pump Operation and Efficiencyasfand12345100% (1)

- Pump Performance - Double PumpsDokumen8 halamanPump Performance - Double PumpsAshBelum ada peringkat

- Air FanDokumen6 halamanAir FanDevi PurnamasariBelum ada peringkat

- Condenser and Cooling Tower Performance PDFDokumen69 halamanCondenser and Cooling Tower Performance PDFsasikumar r100% (1)

- Variable Speed Pumps PipeFLODokumen3 halamanVariable Speed Pumps PipeFLOJavier Alejandro RodriguezBelum ada peringkat

- Vapor Power CyclesDokumen8 halamanVapor Power CyclesGürel ÖzeşmeBelum ada peringkat

- Steam Turbine Versus Pressure Reducing Valve OperationDokumen13 halamanSteam Turbine Versus Pressure Reducing Valve OperationEmerson RwkBelum ada peringkat

- Wilo. Caracteristici TehniceDokumen104 halamanWilo. Caracteristici TehniceIoan Octavian StanciuBelum ada peringkat

- The Influence of Soil Characteristics in Seismic Response of Embedded StructuresDokumen11 halamanThe Influence of Soil Characteristics in Seismic Response of Embedded StructuresRazvanBelum ada peringkat

- Air Vents For The STEEL Pipes - Penstock Calinesti 1Dokumen1 halamanAir Vents For The STEEL Pipes - Penstock Calinesti 1RazvanBelum ada peringkat

- Fig.1 Finite Element Mesh of The Barzur Intake Structure-Foundation-Terrain System Used in ABAQUS CodeDokumen7 halamanFig.1 Finite Element Mesh of The Barzur Intake Structure-Foundation-Terrain System Used in ABAQUS CodeRazvanBelum ada peringkat

- Interacțiunea Seismică Fluid - Structură În Cazul Barajelor ArcuiteDokumen41 halamanInteracțiunea Seismică Fluid - Structură În Cazul Barajelor ArcuiteRazvanBelum ada peringkat

- Calculating spillway discharge using weir equationDokumen2 halamanCalculating spillway discharge using weir equationRazvanBelum ada peringkat

- Technical Visit - Vajont DamDokumen42 halamanTechnical Visit - Vajont DamRazvanBelum ada peringkat

- Influence of The Dynamic Analysis Methods On The Seismic Response of A Buttress DamDokumen17 halamanInfluence of The Dynamic Analysis Methods On The Seismic Response of A Buttress DamRazvan100% (1)

- DIPRA - Design Decision Model For Corrosion Control of DI Pipelines - 2006Dokumen10 halamanDIPRA - Design Decision Model For Corrosion Control of DI Pipelines - 2006ErwinBelum ada peringkat

- Handout Benchmark V1 ALLDokumen48 halamanHandout Benchmark V1 ALLRazvanBelum ada peringkat

- Technical Visit - MOSE SystemDokumen14 halamanTechnical Visit - MOSE SystemRazvanBelum ada peringkat

- Neural Networks DocumentationDokumen406 halamanNeural Networks DocumentationManh Lam LeBelum ada peringkat

- Daily debit data, levels, volumes, at Isalnita Dam in August 2012Dokumen1 halamanDaily debit data, levels, volumes, at Isalnita Dam in August 2012RazvanBelum ada peringkat

- Archer C5 V1.20 User Guide 1910011055Dokumen147 halamanArcher C5 V1.20 User Guide 1910011055RazvanBelum ada peringkat

- Hydraulics of Rubber Dam Overflow: A Simple Design ApproachDokumen4 halamanHydraulics of Rubber Dam Overflow: A Simple Design ApproachRazvanBelum ada peringkat

- Tehnica Calinesti 2 Septembrie 20131 (ORIGINAL)Dokumen21 halamanTehnica Calinesti 2 Septembrie 20131 (ORIGINAL)RazvanBelum ada peringkat

- Air Vents For The PAFSIN Pipes - Penstock Calinesti 1Dokumen1 halamanAir Vents For The PAFSIN Pipes - Penstock Calinesti 1RazvanBelum ada peringkat

- Calculating spillway discharge using weir equationDokumen2 halamanCalculating spillway discharge using weir equationRazvanBelum ada peringkat

- Mathcad - 4. Calcul - Masiv - Ancoraj - 56 - Deg - PN - 30Dokumen6 halamanMathcad - 4. Calcul - Masiv - Ancoraj - 56 - Deg - PN - 30RazvanBelum ada peringkat

- CaeDokumen1.174 halamanCaedeschideochiiBelum ada peringkat

- Vol 6 4 397 410 AMINFARDokumen14 halamanVol 6 4 397 410 AMINFARRazvanBelum ada peringkat

- ActDokumen242 halamanActRazvanBelum ada peringkat

- Microsoft Visual FoxProDokumen2 halamanMicrosoft Visual FoxProRazvanBelum ada peringkat

- Comments Upon Irreversible Displacements From Bradisor Arch DamDokumen13 halamanComments Upon Irreversible Displacements From Bradisor Arch DamRazvanBelum ada peringkat

- ICOLD BM Workshop Information Theme ADokumen12 halamanICOLD BM Workshop Information Theme ARazvanBelum ada peringkat

- Abaqus Fluid Structure Interaction Graz-AustriaDokumen20 halamanAbaqus Fluid Structure Interaction Graz-AustriaRazvanBelum ada peringkat

- LWR Ex 12 43Dokumen46 halamanLWR Ex 12 43RazvanBelum ada peringkat

- GravityDam1Dokumen16 halamanGravityDam1Razvan100% (1)

- 13 467Dokumen11 halaman13 467RazvanBelum ada peringkat

- Geodetic DeformationDokumen34 halamanGeodetic DeformationSilvia Chiorean100% (1)

- Nhessd 1 2319 2013Dokumen33 halamanNhessd 1 2319 2013RazvanBelum ada peringkat

- Gdot Autoturn User Guide Ds FdsDokumen66 halamanGdot Autoturn User Guide Ds FdsMd Didarul AlamBelum ada peringkat

- What Is Family Life CycleDokumen7 halamanWhat Is Family Life Cycleapi-414688913Belum ada peringkat

- A Comparative GrammarDokumen503 halamanA Comparative GrammarXweuis Hekuos KweBelum ada peringkat

- Kajo 5 PDFDokumen3 halamanKajo 5 PDFJonathan ChauBelum ada peringkat

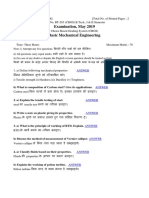

- BT 203 Basic Mechanical Engineering May 2019 PDFDokumen2 halamanBT 203 Basic Mechanical Engineering May 2019 PDFKunta PatleBelum ada peringkat

- ExportDokumen361 halamanExportStefanBelum ada peringkat

- The Sevenfold Seeking and Noesis of The Hebdomian WayDokumen15 halamanThe Sevenfold Seeking and Noesis of The Hebdomian WayDark Japer100% (1)

- Content-Based Image Retrieval System Using SketchesDokumen50 halamanContent-Based Image Retrieval System Using SketchesHoney Merrin SamBelum ada peringkat

- Decision Wise Whitepaper 3 Essential Components of Employee EngagemenDokumen8 halamanDecision Wise Whitepaper 3 Essential Components of Employee EngagemenRatna Srinivas Kosuri100% (1)

- Đề 1Dokumen9 halamanĐề 1trung anBelum ada peringkat

- Real-Time Temperature Tracking Web ServiceDokumen4 halamanReal-Time Temperature Tracking Web ServiceVirna Uli SamosirBelum ada peringkat

- Ifw Process GimDokumen24 halamanIfw Process Gimmyownhminbox485Belum ada peringkat

- ETHOSUXIMIDEDokumen14 halamanETHOSUXIMIDEAfrizal MahadiBelum ada peringkat

- Tool ShopDokumen6 halamanTool ShopJiwithe NidahaseBelum ada peringkat

- READMEDokumen162 halamanREADMEBurtBelum ada peringkat

- Deutsche Bank Human Resources Report 2017Dokumen57 halamanDeutsche Bank Human Resources Report 2017YamBelum ada peringkat

- Dfs Dev Guide Documentum 6 SP 1Dokumen223 halamanDfs Dev Guide Documentum 6 SP 1jazarja100% (7)

- TheImpactofEmployeeEngagementonOrganizationsProductivity PDFDokumen10 halamanTheImpactofEmployeeEngagementonOrganizationsProductivity PDFSapna SharmaBelum ada peringkat

- A2 Unit of WorkDokumen18 halamanA2 Unit of Workapi-486612781Belum ada peringkat

- Identity Collage RubricDokumen1 halamanIdentity Collage Rubricapi-709145254Belum ada peringkat

- BCGDokumen36 halamanBCGdadaisgreat100% (1)

- Cascade Approach of DWT-SVD Digital Image WatermarkingDokumen5 halamanCascade Approach of DWT-SVD Digital Image WatermarkingPrashant SangulagiBelum ada peringkat

- (Collected Works of Northrop Frye) Estate of Northrop Frye, Jan Gorak-Northrop Frye On Modern Culture-University of Toronto Press (2003)Dokumen460 halaman(Collected Works of Northrop Frye) Estate of Northrop Frye, Jan Gorak-Northrop Frye On Modern Culture-University of Toronto Press (2003)Bunătăți Din Argeș100% (4)

- Form 4 Student Subject AllocationDokumen5 halamanForm 4 Student Subject Allocationapi-484150872Belum ada peringkat

- FormworksDokumen94 halamanFormworksLouie Zavalla LeyvaBelum ada peringkat

- 04 Literary Lens in MacbethDokumen3 halaman04 Literary Lens in MacbethNikki MohammadiBelum ada peringkat

- CRC CDokumen13 halamanCRC Cjosei_telspecBelum ada peringkat

- Project Vetting Worksheet-9472538Dokumen4 halamanProject Vetting Worksheet-9472538kovzsanBelum ada peringkat

- SGSITS Prospectus 2013Dokumen113 halamanSGSITS Prospectus 2013Rohit Kumar Anchaliya100% (1)

- FGD on Preparing Learning Materials at Old Cabalan Integrated SchoolDokumen3 halamanFGD on Preparing Learning Materials at Old Cabalan Integrated SchoolRAQUEL TORRESBelum ada peringkat