6l Bulletin

Diunggah oleh

FSR1407Deskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

6l Bulletin

Diunggah oleh

FSR1407Hak Cipta:

Format Tersedia

Transmission:

Subject:

Application:

Issue Date:

4L80E

Planetary Damage, Pump Interchange

GM

October, 2013

Technical Bulletin #1117A

4L80E

Planetary Damage, Pump Interchange

An update to the pump cover occurred for 2004-2006 model years on all 4L80E/85E applications. The

pump cover part number was changed to accommodate interim case changes that occurred. The fol-

lowing part numbers for the pump cover based on model year.

1997-2003 24204303

2004-2006 24232405

This is a simple plug kit. Remove cup plug, install the 1 slug. Important: Do not bury the slug all the

way down into the pump. When tapping the slug in, drive it in .355 below the pump surface. Install

the new cup plug. If a kit is not available from your parts supplier you can make your own. The size of

this slug is 1 long and .247 (1 x .247) in diameter, the cup plug is .344.

MB Page 1 of 1 Copyright 2013 ATRA All Rights Reserved

Remove cup plug,

install the 1 slug and

install the new .344

cup plug.

Drive the slug

.355 below the

outer surface.

1997-2003 pumps are

interchangeable if you use

GM Plug Kit #24232339.

Transmission:

Subject:

Application:

Issue Date:

CD4E

Harsh 1-2 Shift or Erratic Shifts

Ford

October, 2013

Technical Bulletin #1561

CD4E

Harsh 1-2 Shift or Erratic Shifts

If you experience a harsh 1-2 shift after rebuild check the assembly of the 2/4 accumulator piston. It is

located in the accumulator section of the valve body. The correct assembly is shown in figure 1.

If by mistake it was assumed that all the accumulators install into the valve body in the same direction,

it may be possible that the 2/4 accumulator piston was misassembled as shown in figure 2.

Special thanks to Ratio Tek for the valve body pictures.

MS Page 1 of 2 Copyright 2013 ATRA All Rights Reserved

Figure 1

MB Page 2 of 2 Copyright 2013 ATRA All Rights Reserved

#1561

CD4E

Harsh 1-2 Shift or Erratic Shifts

Figure 2

Transmission:

Subject:

Application:

Issue Date:

09G

Solenoid ID and Clutch Control Valve

Adjustments, Flare or Bump Shifts

Volkswagen

October, 2013

Technical Bulletin #1562

09G

Solenoid ID and Clutch Control Valve Adjustments

Volkswagen 09G transmission solenoid IDs are listed with the letter N followed by a number in figure

1. The clutch control valve adjusters are K1, K2, B1 and K3.

Clutch

Control

Valve

Adjusters

JW Page 1 of 3 Copyright 2013 ATRA All Rights Reserved

Figure 1

JW Page 2 of 3 Copyright 2013 ATRA All Rights Reserved

#1562

In fgure 2 are the diferent names for the solenoids, Ohms values and functon of the solenoids.

When we have a fare or bump on a shif we are able to make an adjustment to one clutch at a tme.

Before any adjustments are made some things have to be checked frst. Valve body conditon of Sole-

noid Modulaton valves, Lock up Control valves, Pressure Regulator and Secondary Regulator valves

need to be checked for wear. Also the solenoids need to be rebuilt or confrm that the amature in the

solenoid is not stcking when hot (#1 problem).

Make sure all the latest updates to the sofware are installed. The transmission adapts and relearns

procedure needs to be done along with a long test drive. If the relearn is not done properly you will

make more adjustment then necessary.

09G

Solenoid ID & Clutch Control Valve Adjustments

Figure 2

Figure 3

JW Page 3 of 3 Copyright 2013 ATRA All Rights Reserved

#1562

Use the Clutch Apply chart (fgure 3) and Solenoid Firing chart (fgure 4) to learn what clutch needs

adjusted.

One note on the solenoid apply chart remember that when the solenoid is of the clutch is applied.

Make adjustments half a turn to one turn at a tme. Turn in the adjuster IN to slow the shif down

(smooth/slow apply rate). Turn the adjuster OUT to speed up the apply rate of the clutch (frmer

shif).

09G

Solenoid ID & Clutch Control Valve Adjustments

Figure 4

Transmission:

Subject:

Application:

Issue Date:

6F35

Leaks Out of the Dipstick

2009 Ford Escape and Mercury Mariner

October, 2013

Technical Bulletin #1563

6F35

Leaks Out of the Dipstick

Some 2009 Escape and Mariner vehicles equipped with 6F35 automatic transmissions and built on or

before 10/29/2008 may exhibit a loss of transmission fluid from the dipstick tube area. This may be

due to transmission being overfilled. A new transmission dipstick and filler tube kit is now available

through Ford with added minimum and maximum fluid level lines to easily determine proper fluid

level and with a revised vent system on the filler tube.

Ford Part #AL8Z-7A020-A for the updated dipstick and tube.

JW Page 1 of 1 Copyright 2013 ATRA All Rights Reserved

Transmission:

Subject:

Application:

Issue Date:

6L80E

Neutrals on Take Off, Checkball Locations

2009 GMC Yukon

October, 2013

Technical Bulletin #1564

6L80E

Check Ball Locations

We have been made aware of a problem with the plastic #1 check ball eroding from .250 to .180 and

getting stuck in the plate. The #1 ball is in play in Drive, from 1st - 6th gears.

#1 Drive 1-6/Drive Braking:

Located in the upper control valve body, this ball shuttle valve style check ball allows drive braking

fluid, in a Drive 1st gear engine braking condition, to enter the 2-6 clutch/1234 clutch feed fluid circuit

to apply the 1-2-3-4 clutch.

#2 Solenoid 1/Reverse:

Located in the upper control valve body, this ball shuttle valve style check ball is seated against the

reverse fluid passage while the transmission is operating in Park, Neutral and Drive 1st (Engine Brak-

ing). With the ball check valve in this position, solenoid 1 fluid enters the CSV2 enable fluid circuit to

apply the clutch select valve 2. When the transmission is operating in Reverse, the ball check valve

seats against the solenoid 1 fluid passage to allow reverse fluid to enter the CSV2 enable fluid circuit

and hold the clutch select valve 2 in the applied position.

#3 Solenoid 2/4-5-6 Clutch:

Located in the upper control valve body, this ball shuttle valve style check ball is seated against the

456 clutch passage while the transmission is operating in Park, Reverse, Neutral, Drive 1st, 2nd and

3rd gear ranges. With the ball check valve in this position, solenoid 2 fluid enters the CSV3 enable fluid

circuit to apply the clutch select valve 3. When the transmission is operating in Drive 4th, 5th or 6th

gear ranges, the ball check valve seats against the solenoid 2 fluid passage to allow 456 clutch fluid to

enter the CSV3 enable fluid circuit and hold the clutch select valve 2 in the applied position.

#4 PS5/4-5-6 Clutch:

Located in the upper control valve body, this ball shuttle valve style check ball is seated against the

456 clutch passage by PS5 fluid while the transmission is operating in Drive 1st, 2nd and 3rd gear rang-

es. With the ball check valve in this position, PS5 fluid enters the SSV2 latch fluid circuit to hold the

clutch select valve 2 in the released position. When the transmission is operating in Drive 4th, 5th or

6th gear ranges, 456 clutch fluid pressure seats the ball check valve against the PS5 fluid passage to al-

low 456 clutch fluid to enter the CSV2 latch fluid circuit to hold the clutch select valve 2 in the released

position.

LW Page 1 of 3 Copyright 2013 ATRA All Rights Reserved

LW Page 2 of 3 Copyright 2013 ATRA All Rights Reserved

#1564

#5 Drive 1-6/3-5 Reverse Supply:

Located in the upper control valve body, this ball shuttle valve style check ball is seated against the

Drive 1-6 fluid passage by 35 reverse feed fluid while the transmission is operating in Reverse. With

the ball check valve in this position, 35 reverse feed fluid enters the 35 reverse supply circuit and is

routed to the #7 ball check valve. When the transmission is operating in Drive 1st, 2nd, 3rd, 4th, 5th or

6th gear ranges, Drive 1-6 clutch fluid pressure seats the ball check valve against the 35 reverse feed

passage to allow Drive 1-6 clutch fluid to enter the 35 reverse supply fluid circuit.

#6 2-6 Clutch/1-2-3-4 Clutch Feed:

Located in the upper control valve body, this one way orifice control style check ball is used to dif-

ferentiate the flow rate of fluid between applying and releasing the 1-2-3-4 clutch. 26 clutch/1234

clutch feed fluid pressure opens the ball check valve while the transmission is operating in Drive 1st

(engine braking), 1st, 2nd, 3rd, 4th, 5th or 6th gear ranges. With the ball check valve in this position,

26 clutch/1234 clutch feed fluid flows freely into the 1234 clutch feed fluid passage. When Park, Re-

verse or Neutral gear is selected after the transmission was operating in Drive, exhausting 1234 clutch

feed fluid seats the ball check valve and fluid is forced through orifice #32. This allows for a controlled

exhaust of 1234 clutch feed fluid.

#7 3-5 Reverse Supply/3-5 Reverse Feed:

Located in the upper control valve body, this one way orifice control style check ball is used to differ-

entiate the flow rate of fluid between applying and releasing the 3-5 reverse clutch. 35 reverse supply

fluid pressure seats the ball check valve against the 35 reverse feed passage while the transmission

is operating in Reverse, Drive 1st, 2nd, 3rd, 4th, 5th or 6 gear ranges. With the ball check valve in this

position, 35 reverse supply fluid is forced through orifice #25 before entering the 35 reverse feed fluid

passage. The orifice helps control the apply rate of the 3-5 clutch when the transmission shifts into

Reverse, 3rd and 5th gears. When Park or Neutral gear is selected after the transmission was operat-

ing in Drive, or Reverse, exhausting 35 reverse feed fluid unseats the ball check valve. This allows for a

faster exhaust of 35 reverse feed fluid and a quick release of the 3-5 reverse clutch.

Special thanks to Kit Lindsay of Lindsay Transmission

6L80E

Neutrals on Take Off, Check Ball Locations

LW Page 3 of 3 Copyright 2013 ATRA All Rights Reserved

#1564

6L80E

Neutrals on Take Off, Check Ball Locations

Transmission:

Subject:

Application:

Issue Date:

6F50N, 6T70/75

Line Pressure Tap Locations and Specs

Ford, GM

October, 2013

Technical Bulletin #1565

6F50N, 6T70/75

Line Pressure Tap Location and Specifications

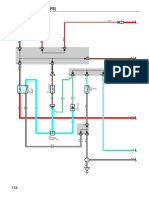

To check line pressure connect a suitable pressure gauge or transducer to the pressure tap indicated in

the illustration below.

BB Page 1 of 1 Copyright 2013 ATRA All Rights Reserved

Line Pressure Tap

Drain Plug

Range Idle WOT

P 5460PSI 5460PSI

R 100105PSI 250300PSI

N 5460PSI 5460PSI

D 8487PSI 240250PSI

L 8487PSI 240250PSI

LinePressureChart

Transmission:

Subject:

Application:

Issue Date:

62TE

Check Ball Locations

Chrysler, Dodge

October, 2013

Technical Bulletin #1566

62TE

Check Ball Locations

There are four checkballs used in the earlier models and three used in later models (2009 & up). There

are nine other checkballs that are used for bore plugs and are not removeable.

BB Page 1 of 2 Copyright 2013 ATRA All Rights Reserved

If there is a hole in the separator plate

at the location indicated, there will be

an underdrive checkball in the pocket.

(Model Dependent)

UD

LR

OD

Rev

BB Page 2 of 2 Copyright 2013 ATRA All Rights Reserved

#1566

62TE

Check Ball Locations

The separator plate without

the hole in the plate can be

used in earlier models and

the checkball can be lef out,

The separator plate with

the hole CANNOT be used in

the later model without the

checkball.

Harsh UD clutch apply could

result.

If there is not a hole in the separator plate at the location indicated, there will not be an underdrive

checkball in the pocket.

(Model Dependent)

Anda mungkin juga menyukai

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideDari EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuidePenilaian: 4.5 dari 5 bintang4.5/5 (8)

- GM 4L80E Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyDari EverandGM 4L80E Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyPenilaian: 5 dari 5 bintang5/5 (1)

- 6L50-6L80-6L90 Updates and Product Issues: Presented By: Steve Garrett ATRA PresenterDokumen42 halaman6L50-6L80-6L90 Updates and Product Issues: Presented By: Steve Garrett ATRA PresenterEsquisof100% (1)

- A Look at The : FeaturesDokumen10 halamanA Look at The : FeaturesDavid Lacunes100% (3)

- Allison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyDari EverandAllison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyPenilaian: 5 dari 5 bintang5/5 (1)

- How to Rebuild & Modify Rochester Quadrajet CarburetorsDari EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsPenilaian: 5 dari 5 bintang5/5 (2)

- 2019 Red ManualDokumen92 halaman2019 Red ManualEd Kruse100% (10)

- Ford AOD Transmissions: Rebuilding and Modifying the AOD, AODE and 4R70WDari EverandFord AOD Transmissions: Rebuilding and Modifying the AOD, AODE and 4R70WPenilaian: 4.5 dari 5 bintang4.5/5 (6)

- 4L30-E 1-2 Band FailureDokumen5 halaman4L30-E 1-2 Band Failurerebuilder67Belum ada peringkat

- 1990 ATRA Seminar Manual ContentsDokumen82 halaman1990 ATRA Seminar Manual Contentsccbulgaria83% (6)

- How to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsDari EverandHow to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsPenilaian: 5 dari 5 bintang5/5 (5)

- THM 200CDokumen80 halamanTHM 200CjuanBelum ada peringkat

- 4 L 80 eDokumen8 halaman4 L 80 eeman123456100% (1)

- 6T70/6T75 Updates and Changes: A Penny Saved Can Cost You BigDokumen76 halaman6T70/6T75 Updates and Changes: A Penny Saved Can Cost You BigRodger Bland100% (3)

- 2007 ATRA Seminar Manual ContentsDokumen272 halaman2007 ATRA Seminar Manual Contentschoco84Belum ada peringkat

- 6l80 IntroductionDokumen28 halaman6l80 IntroductionLojan Coronel José Humberto100% (3)

- ATRA's Powertrain EXPO 2015 GuideDokumen16 halamanATRA's Powertrain EXPO 2015 GuideRodger Bland100% (1)

- 6F35N IntroDokumen47 halaman6F35N Introacmemail583Belum ada peringkat

- 1-2 Shift Neutrals 6L80E Atb1473Dokumen2 halaman1-2 Shift Neutrals 6L80E Atb1473Martin Gardner100% (1)

- ATRA Test Preparation Guide PDFDokumen82 halamanATRA Test Preparation Guide PDFsuattosunBelum ada peringkat

- Chrysler TorqueFlite A-904 and A-727 Transmissions: How to RebuildDari EverandChrysler TorqueFlite A-904 and A-727 Transmissions: How to RebuildPenilaian: 5 dari 5 bintang5/5 (1)

- Ax4n PDFDokumen120 halamanAx4n PDFBeto Veto100% (1)

- GM 6t70 UpdatesDokumen45 halamanGM 6t70 UpdatesThePokeOne100% (9)

- 2014 January/February GEARS Buyers Guide IssueDokumen124 halaman2014 January/February GEARS Buyers Guide IssueRodger Bland100% (1)

- A4ld Update HandbookDokumen110 halamanA4ld Update Handbookvictor agredaBelum ada peringkat

- September 2010Dokumen116 halamanSeptember 2010Rodger Bland100% (1)

- GEARS Buyer's Guide 2015 Issue - January/February 2015Dokumen124 halamanGEARS Buyer's Guide 2015 Issue - January/February 2015Rodger Bland100% (4)

- 50-42le AtsgDokumen68 halaman50-42le AtsgcherokewagBelum ada peringkat

- 2006 Seminar Sonnax PDFDokumen18 halaman2006 Seminar Sonnax PDFHumberto LojanBelum ada peringkat

- Atra 12-2009Dokumen19 halamanAtra 12-2009ossoskiBelum ada peringkat

- Atsg 2005 BulletinDokumen46 halamanAtsg 2005 Bulletinlolop434350% (4)

- 2006 174 PDFDokumen14 halaman2006 174 PDFSantiago EscobarBelum ada peringkat

- CLUTCH Clutch System FIAT 500Dokumen28 halamanCLUTCH Clutch System FIAT 500FSR1407100% (3)

- January / February 2013Dokumen124 halamanJanuary / February 2013Rodger Bland100% (3)

- 4T40-E Pontiac Sunfire Elec PDFDokumen128 halaman4T40-E Pontiac Sunfire Elec PDFjosue100% (3)

- Muncie 4-Speed Transmissions: How to Rebuild & ModifyDari EverandMuncie 4-Speed Transmissions: How to Rebuild & ModifyPenilaian: 5 dari 5 bintang5/5 (7)

- Play Ball Transmission TroubleshootingDokumen5 halamanPlay Ball Transmission Troubleshootingcec985458100% (1)

- Seal Aftermarket Products Seal Aftermarket Products: A Fast Fix For The Allison LCT 1000Dokumen68 halamanSeal Aftermarket Products Seal Aftermarket Products: A Fast Fix For The Allison LCT 1000Rodger Bland100% (1)

- Making Good Money: 42/47RE TransmissionsDokumen72 halamanMaking Good Money: 42/47RE TransmissionsRodger Bland100% (1)

- CFT30 IntroDokumen35 halamanCFT30 Intromanos4tech100% (1)

- 2600-O Vss-2600 Valet Plus Operator Manual 09-08-2014Dokumen24 halaman2600-O Vss-2600 Valet Plus Operator Manual 09-08-2014gene smithBelum ada peringkat

- Jan/Feb 2012Dokumen71 halamanJan/Feb 2012Rodger BlandBelum ada peringkat

- TranX 2000 Operator Manual 7-09Dokumen188 halamanTranX 2000 Operator Manual 7-09Robert Holt83% (6)

- 6F35 - 6F55 Installation Guide: Read This Entire Document Before Installing Your TransmissionDokumen8 halaman6F35 - 6F55 Installation Guide: Read This Entire Document Before Installing Your TransmissionPedro Isai Vega100% (2)

- Index: Chrysler 42LE (A606)Dokumen104 halamanIndex: Chrysler 42LE (A606)Javier Ortiz100% (1)

- Five-Speed Automatic Gearbox With Tiptronic (01V)Dokumen6 halamanFive-Speed Automatic Gearbox With Tiptronic (01V)FSR1407Belum ada peringkat

- A246E Automatic Transaxle Specs and Torque SettingsDokumen3 halamanA246E Automatic Transaxle Specs and Torque SettingsFSR14070% (1)

- Express Transmissions: Can't See The Converter For The TreesDokumen68 halamanExpress Transmissions: Can't See The Converter For The TreesRodger BlandBelum ada peringkat

- 2012 10 All OptimizedDokumen89 halaman2012 10 All OptimizedRodger Bland50% (2)

- Trans Digest 12Dokumen68 halamanTrans Digest 12MarcoRimolaGutierrezBelum ada peringkat

- Electrical & Power Control CAN System OverviewDokumen128 halamanElectrical & Power Control CAN System OverviewFSR1407100% (1)

- Torqshift 6Dokumen8 halamanTorqshift 6acmemail583100% (1)

- July 2013Dokumen76 halamanJuly 2013Rodger Bland100% (1)

- 1996-97 Auto Trans ServiceDokumen6 halaman1996-97 Auto Trans ServiceFSR1407Belum ada peringkat

- October/November 2013Dokumen76 halamanOctober/November 2013Rodger Bland100% (2)

- Ec PDFDokumen1.290 halamanEc PDFMayobanex Moya MartinezBelum ada peringkat

- 6r140w IntroDokumen58 halaman6r140w IntroFrank Araya Diaz100% (1)

- Temsa BusDokumen71 halamanTemsa Busmannguyenbkdn100% (1)

- 125C PDFDokumen96 halaman125C PDFIbrain Moran100% (2)

- GEARS August 2016Dokumen68 halamanGEARS August 2016Rodger Bland100% (3)

- AB60E Transmission OperationDokumen1 halamanAB60E Transmission OperationЙордан ВасилевBelum ada peringkat

- HONDA Fit SpecsDokumen24 halamanHONDA Fit SpecsFSR1407100% (2)

- HONDA Fit SpecsDokumen24 halamanHONDA Fit SpecsFSR1407100% (2)

- P533 12Dokumen925 halamanP533 12BlueSkyMasterBelum ada peringkat

- 320b 330bDokumen20 halaman320b 330bAchariya Parprom67% (3)

- Fuse Relay BoxesDokumen3 halamanFuse Relay BoxesFSR1407100% (1)

- Fuse Relay BoxesDokumen3 halamanFuse Relay BoxesFSR1407100% (1)

- Tata Motors Marketing Strategies Project ReportDokumen52 halamanTata Motors Marketing Strategies Project ReportAryan Jain100% (6)

- TITLE Checking Solenoid Resistance in Dodge, Mitsubishi and Nissan TransmissionsDokumen2 halamanTITLE Checking Solenoid Resistance in Dodge, Mitsubishi and Nissan TransmissionsRefaccim Jimenez100% (1)

- Tesla Motors: A Strategic AnalysisDokumen10 halamanTesla Motors: A Strategic AnalysisRaisulIslamBelum ada peringkat

- Engine ControlDokumen8 halamanEngine ControlFSR140750% (2)

- Identifying and Interchanging Forward Clutch Pistons in TH400 TransmissionsDokumen6 halamanIdentifying and Interchanging Forward Clutch Pistons in TH400 Transmissionskkg4782Belum ada peringkat

- May 2014 GEARSDokumen84 halamanMay 2014 GEARSRodger Bland100% (2)

- 45RFEDokumen2 halaman45RFEherusamx100% (2)

- JK 3.6 VVT LeftDokumen3 halamanJK 3.6 VVT LeftFSR1407Belum ada peringkat

- 3.6 RemovalDokumen6 halaman3.6 RemovalFSR1407Belum ada peringkat

- ENGINE Exhaust System FIAT 500Dokumen23 halamanENGINE Exhaust System FIAT 500FSR1407100% (1)

- ENGINE CONTROL SYSTEM TROUBLESHOOTING GUIDEDokumen486 halamanENGINE CONTROL SYSTEM TROUBLESHOOTING GUIDEkendediBelum ada peringkat

- 2013 NISSAN Sentra PWO PDFDokumen6 halaman2013 NISSAN Sentra PWO PDFFSR1407Belum ada peringkat

- AccDokumen4 halamanAccFSR1407Belum ada peringkat

- Front Axle: SectionDokumen8 halamanFront Axle: SectionFSR1407Belum ada peringkat

- PBDokumen10 halamanPBFSR1407Belum ada peringkat

- STCDokumen31 halamanSTCFSR1407100% (1)

- Accelerator control system removal and installationDokumen4 halamanAccelerator control system removal and installationFSR1407Belum ada peringkat

- Wiring 1Dokumen15 halamanWiring 1FSR1407Belum ada peringkat

- JK 3.6 VVT LeftDokumen3 halamanJK 3.6 VVT LeftFSR1407Belum ada peringkat

- ABSDokumen4 halamanABSFSR1407Belum ada peringkat

- BumpersDokumen11 halamanBumpersFSR1407Belum ada peringkat

- AT Indicator 2RZFEDokumen4 halamanAT Indicator 2RZFEFSR1407Belum ada peringkat

- VTECDokumen17 halamanVTECFSR1407Belum ada peringkat

- EGRDokumen22 halamanEGRFSR1407Belum ada peringkat

- VW-095 Transmission BreakdownDokumen1 halamanVW-095 Transmission BreakdownLeo BurnsBelum ada peringkat

- Cruise Control System: SectionDokumen5 halamanCruise Control System: SectionFSR1407Belum ada peringkat

- Analtech EngineeringDokumen8 halamanAnaltech Engineeringdemo webBelum ada peringkat

- Golf VI Suppliers PDFDokumen1 halamanGolf VI Suppliers PDFBennyLouPlummerBelum ada peringkat

- Schema Cutie de Viteza AD4Dokumen4 halamanSchema Cutie de Viteza AD4istanmoniBelum ada peringkat

- XD PROT 20180622 1514 Turismos253946 WDC0G4GB4HF220545 PCZ3859PROTINGLESDokumen9 halamanXD PROT 20180622 1514 Turismos253946 WDC0G4GB4HF220545 PCZ3859PROTINGLESfausto_titoBelum ada peringkat

- Spicer Off-Highway, Agriculture Steering Components For All Makes OHST-ALLMKS-01 PDFDokumen106 halamanSpicer Off-Highway, Agriculture Steering Components For All Makes OHST-ALLMKS-01 PDFviemey1952Belum ada peringkat

- Rav Bike U 5Dokumen4 halamanRav Bike U 5МИНИОНBelum ada peringkat

- Correct TIMELINE (In "The Truth" It's A Complete Mess - Maybe Intentionally So Nobody Could See The Lies)Dokumen6 halamanCorrect TIMELINE (In "The Truth" It's A Complete Mess - Maybe Intentionally So Nobody Could See The Lies)Anonymous FWhYThnfjBelum ada peringkat

- Company Analysis - CastrolDokumen12 halamanCompany Analysis - CastrolSamirBelum ada peringkat

- Electronic Components Consulting Services Inc. Reliability Calculations: What, Why, When & How They Benefit DesignDokumen16 halamanElectronic Components Consulting Services Inc. Reliability Calculations: What, Why, When & How They Benefit DesignPatel MswaziBelum ada peringkat

- Flying CarDokumen29 halamanFlying CarKunal Mehra0% (1)

- Rto Process DetailsDokumen3 halamanRto Process DetailsAnil DalalBelum ada peringkat

- Benz PDFDokumen52 halamanBenz PDFNéstor CastilloBelum ada peringkat

- Wanderer - 201301 v8Dokumen19 halamanWanderer - 201301 v8rufusmathewsjrBelum ada peringkat

- Kano Model Used For Automobile ManufacturingDokumen28 halamanKano Model Used For Automobile ManufacturingAbin BabyBelum ada peringkat

- SH 2015 1 ICRA Bearing IndustryDokumen5 halamanSH 2015 1 ICRA Bearing IndustryAshwiniBelum ada peringkat

- MM Case PPT - Group 9 - AutomobileDokumen15 halamanMM Case PPT - Group 9 - AutomobileMadan Gopal YadavBelum ada peringkat

- 5) BL Corrector y Manifiesto de CargaDokumen3 halaman5) BL Corrector y Manifiesto de CargaKevin Yair FerrerBelum ada peringkat

- Bhanu Brose Excursion ReportDokumen6 halamanBhanu Brose Excursion ReportBhanu Pratap SinghBelum ada peringkat

- Design of Transmission Systems examDokumen3 halamanDesign of Transmission Systems examCyril JasonBelum ada peringkat

- MTL Intern ReportDokumen25 halamanMTL Intern ReportnumanBelum ada peringkat

- Morzfeld Engineering Portfolio 2014Dokumen1 halamanMorzfeld Engineering Portfolio 2014John MorzfeldBelum ada peringkat

- Kuldeep Minda Company PresentationDokumen18 halamanKuldeep Minda Company Presentationpoojasamyadav100% (1)

- Connect ImperialDokumen164 halamanConnect ImperialAndresBelum ada peringkat