Control of Biofouling

Diunggah oleh

Joseph NemeshHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Control of Biofouling

Diunggah oleh

Joseph NemeshHak Cipta:

Format Tersedia

REMEDIATION Winter 2013

Control of Biofouling: Lessons Learned

From a Decade of Carbon Injection

System Operation and Maintenance

Shawn Burnell

Jon Spitzinger

Peng Jin

Jay Erickson

Erin Hauber

Denice Nelson

Over the past decade, we have learned a number of critical lessons surrounding carbon substrate

handling while operating and maintaining hundreds of enhanced in situ biological remedies. The

same qualities that make these substrates effective can also cause biofouling of the mixing system,

piping infrastructure, and remediation wells. Managing biofouling is a key piece of a successful

remedy and requires a unique set of design principles. Small decreases in injection rates can have

considerable impacts to life-cycle costs and performance caused by decreased substrate distribu-

tion and longer injection time frames, resulting in the need for system cleaning, well rehabilitation,

and even well replacement. Biofouling can impair performance in any size system, but effects are

often magnied by large injection volumes and extended time frames. Design should be consid-

ered in all stages of the anaerobic enhanced in situ bioremediation life cycle, particularly related to

reagent mixing, storage, and residence time within the system. By understanding the fundamental

mechanisms of biofouling, practitioners can make operational adjustments to enhance remedy

performance by considering potential biofouling controls in the design; balancing site-specic

strategy and diagnostics; and proactively adjusting and ne tuning control/prevention technology

and methodology.

Ultimately, a combination of chemical and physical methods may be required to operate a

carbon handling system over the long term; however, the operational costs can be greatly reduced

and delivery efciency increased if these methods are understood during the design phase. O

c 2013

Wiley Periodicals, Inc.

INTRODUCTION

Enhanced in situ bioremediation (EISB) involves promoting growth of native microbial

communities that are capable of degrading target contaminants in impacted groundwater

aquifers by introducing organic substrates to create conditions favoring microbial

metabolism. Most groundwater environments contain an active and diverse microbial

population, but growth is limited in the absence of high concentrations of nutrients (Fry,

Selker, & Gorelick, 1997). By introducing organic carbon substrates into contaminated

groundwater, in situ anaerobic bioremediation may be enhanced as metabolic activities

and growth of the native microbial community are accelerated (Cullimore, 1999;

Environmental Security Technology Certication Program [ESTCP], 2005). The same

c 2013 Wiley Periodicals, Inc.

Published online in Wiley Online Library (wileyonlinelibrary.com). DOI: 10.1002/rem.21340 85

Control of Biofouling: Lessons Learned From a Decade of Carbon Injection System Operation and Maintenance

conditions that favor successful remediation, however, stimulate microbial growth and gas

generation within the injection wells and remediation system infrastructure. This can also

result in reduced delivery efciency through injection system fouling and decreases in

hydraulic conductivity and formation porosity. While the potential for biofouling within

these types of systems is generally acknowledged, it is often underestimated at the initial

planning stage of a bioremediation project. Excluding biofouling during the initial design

and planning phase of the project can result in a high risk of operational issues that are

magnied as the size of the mixing and distribution system increases.

Mechanisms of Biofouling

There are several different mechanisms in which biofouling can impact system

performance including:

r

Biolm growth, expansion, and destruction/detachment from surfaces can perma-

nently reduce effective pipe size, formation hydraulic conductivity, permeability of

the porous media, and also clog system equipment.

r

Bacteria attach, grow, and block the well screen, lter pack, and mechanical compo-

nents of the delivery system, thereby limiting or preventing the proper function of

the well and critical system controls.

r

Fermentative gases, which are generated directly fromanaerobic microbial metabolic

activities or shifting of carbonate to carbonic acid and carbon dioxide in groundwater;

these gases occupy pore space and further reduce formation hydraulic conductivity

and permeability of the porous media for an extended period of time before dissipating

in the aquifer (Ye, Sleep, & Chien, 2009).

As shown in Exhibit 1, available carbon substrates and/or electron donors span from

gases, such as pure hydrogen, to solids, such as chitin or bark mulch. The typical organic

substrates used in EISB are aqueous/water-soluble electron donors, such as lactate,

molasses, whey, or diluted slurry of emulsied electron donors, such as emulsied

vegetable oil. These liquid reagents can be delivered through injection wells, which

provide the exibility of altering the dosing concentration, volume, and injection

frequency.

Historically, discussions around the subject of biofouling have focused on the fouling

occurring in wells and aquifers (Cullimore, 1999; ESTCP, 2005). While these are both

important aspects of biofouling associated with EISB systems, biological activity can start

much earlier in the handling process. Microbial activity will begin when the following

conditions exist:

r

the presence of nutrients (organic carbon substrates and minerals);

r

favorable pH and temperature; and

r

no physical and chemical destruction stresses.

In many systems, these conditions will exist within the storage vessel for the carbon

reagent, throughout the mixing system, and in associated conveyance piping. Biolms will

form on surfaces and consist of microbial cells, extracellular polymeric substances (EPS),

86 Remediation DOI: 10.1002/rem c 2013 Wiley Periodicals, Inc.

REMEDIATION Winter 2013

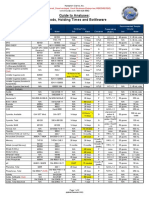

Exhibit 1. Various electron donors/carbon substrates used for EISB remedies; relative longevity

of the substrates increases to the right

Exhibit 2. Biolm, including EPS, microbial cells, and water removed from an

ethanol distribution system

and water (Spath, Flemming, & Wuertz, 1998; Wuertz et al., 2001), as shown in Exhibit

2. While well materials and soil particles are ideal growth media for these sessile microbes,

mixing infrastructure, tanks, pipes, valves, and lters are all susceptible to biofouling.

Microorganisms will adhere to solid surfaces through electrostatic interactions,

hydration forces, and hydrophobic and steric interactions (Elimelech, Gregory, Jia, &

c 2013 Wiley Periodicals, Inc. Remediation DOI: 10.1002/rem 87

Control of Biofouling: Lessons Learned From a Decade of Carbon Injection System Operation and Maintenance

Exhibit 3. Agglomeration of sessile microbial cells

Williams, 1995). When the biolm matures (agglomeration), microbial cells slough off

and are transported downstream to the next surface and the agglomeration process begins

again (Cullimore, 1999). Exhibit 3 shows a conceptual schematic of attachment and

agglomeration of transported cells. The earlier in the handling process that agglomeration

begins, the more problems with biofouling there will be throughout the system

infrastructure and into the subsurface.

Microbial metabolic activity, growth, maturation, and stabilization of biolms are

dynamic biological processes that are both dependent on and signicantly impact

environmental conditions. Ideally, in the EISB process, carbon substrates are introduced

at a concentration that optimizes the biodegradation of contaminants while also

minimizing excessive microbial growth. In reality, however, organic carbon substrates are

often overdosed to compensate for distribution challenges associated with uncertainties in

aquifer biogeochemistry and hydraulics. As a result, excessive microbial growth and

biolm expansion can occur that reduces the pore spaces between soil particles, decreases

the aquifer hydraulic conductivity, reduces injection rates, and decreases overall mixing

and distribution system performance. Biolm expansion may also cause decreased stability

of the agglomerated cells, resulting in either partial or complete detachment of the

biolms. The detached biolms may block the well screen or the connection channels

between pore spaces, which may further reduce the permeability of subsurface formation

(Ghannoum & OToole, 2004; Smith, 1995).

With the maturation of the biolm and extension of anaerobic growth, gases are

generated as by-products and/or end products of anaerobic degradation of organic carbon

substrates. Above saturation levels, gases such as carbon dioxide, methane, and hydrogen

may cause biolm expansion and gas accumulation in system piping and pore spaces,

which can also increase aquifer injection resistance and reduce hydraulic conductivity and

permeability of the subsurface formation (Ye et al., 2009; Zhang & Gillham, 2005). Most

soluble carbon substrates are readily metabolized, and gas generation can occur in real

time during an injection event once the microbial ecology is established within the system

infrastructure or around the injection points (Suthersan, Horst, Nelson, & Potter, 2010).

This is more prevalent during large-volume, long-duration injections.

The relationship between porosity decreases and the resulting change in hydraulic

conductivity is dened by the Kozeny-Carmen equation, which is shown graphically in

Exhibit 4 (Li, Benson, & Lawson, 2005). While this is an empirical formula that generally

oversimplies actual aquifer conditions, it demonstrates that on average slight decreases in

88 Remediation DOI: 10.1002/rem c 2013 Wiley Periodicals, Inc.

REMEDIATION Winter 2013

0%

10%

20%

30%

40%

50%

60%

70%

80%

90%

100%

0% 10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

P

e

r

m

e

a

b

i

l

i

t

y

R

e

d

u

c

t

i

o

n

Porosity Reduction

2

3

1

1

+

=

o

o

o

o

o

n

n n

n

n n

K K

Exhibit 4. The relationship between porosity reduction and hydraulic conductivity

aquifer porosity can have a drastic effect on hydraulic conductivity as demonstrated by

Exhibit 4. As an example, the Kozeny-Carmen equation estimates that a 10 percent

reduction in aquifer porosity reduces the hydraulic conductivity on an aquifer by 33

percent.

DESIGN CONSIDERATIONS

As discussed earlier, biofouling within the storage, mixing, and distribution infrastructure

of carbon substrate injection systems can inhibit delivery and distribution of reagents to

the subsurface, ultimately decreasing the effectiveness of the remedy and increasing the

overall life-cycle cost. Sound design, strategic operation, and proactive maintenance of

injection infrastructure are critical to successful and cost-effective remediation. The

primary considerations when designing an EISB remedy to limit the effects of

biofouling are:

r

system design: in some cases can prevent biofouling, and supports ease of maintenance;

r

injection program formulation: dosing strategies that limit nutrient residence time, use

of bases or other chemicals to inhibit microbial growth, and the like; and

r

system maintenance: physical and chemical rehabilitation.

If the engineering and formulation are not enough to limit biofouling, physical and

chemical cleaning should be used as a nal solution. An effective maintenance strategy

c 2013 Wiley Periodicals, Inc. Remediation DOI: 10.1002/rem 89

Control of Biofouling: Lessons Learned From a Decade of Carbon Injection System Operation and Maintenance

should be proactive and address fouling before large cleaning efforts are required, which

can cause system downtime and increase operational costs. The operation and

maintenance (O&M) cost per gallon is a simple metric that can be used to track how

successful the design, operation, and maintenance of the system is with respect to

sustaining optimal system performance. Tracking cost per gallon over time can paint a

quantitative picture of what is working at a specic site and what is not.

Injection-Well Design Strategies

As with any remediation well, proper well design will create an optimal connection to the

aquifer, resulting in minimal head loss associated with the well and a reduction in overall

remediation-well life-cycle costs. When considering well fouling, the importance of

properly designed wells is even more critical because well-fouling treatment methods are

dependent on accessing the well screen, lter pack, and nearby aquifer soils.

Well and wellhead completion design should consider the common well-fouling

treatment methods for the following reasons:

r

Access: Most well rehabilitation approaches rely on use of a drill or pump rig. As

such, the well and well vault must be designed to allow placement of the rig over the

well, with adequate room for tooling, and access for a safe working environment for

the cleaning crews. Piping for the well should be designed with adequate unions or

quick connects, and valving to allow efcient and safe removal, and lock out tag out

capability.

r

Diameter: Well casing and screen must be a large enough diameter for use of effective

tooling, including surge blocks, jetting tools, air lifting tooling, pumps, and bailers.

Although some of this tooling is available in 2-inch diameters, it is more common in

4-inch and larger sizes.

r

Material Selection: Casing and screen materials must be compatible with the expected

well-cleaning chemicals, as well as being sturdy enough for the mechanical rehabilita-

tion methods such as surging and jetting. As discussed below, well-cleaning chemicals

can include acids, bases, biocides, and surfactants, all of which could be detrimental

to some well materials. Depending on the chemicals selected for rehabilitation, pH

can range from less than 1 standard unit up to 13 standard units.

Mechanical rehabilitation methods place added stresses on the well casing and screen.

Planning for this within the design will drive the material selection as well. For example,

PVC has many strength issues, which include pressures generated during surging, which

may be above the collapse pressure rating of casing and screens. Additionally, water

jetting pressures can break PVC at pressures above 100 pounds per square inch (psi).

Metal screens can withstand jetting pressures up to 200 psi (Driscoll, 1986).

Mixing and Delivery System Design Strategies

In addition to well-design considerations, there are two key general design principles that

can be used to deter in situ fouling at all sites. First, biomass expansion is most rapid under

aerobic conditions (Cullimore, 1999; Suthersan & Payne, 2005). The proliferation of

90 Remediation DOI: 10.1002/rem c 2013 Wiley Periodicals, Inc.

REMEDIATION Winter 2013

Exhibit 5. Aerobic biomass on injection wellhead tting, the result of entrained air in the injected

reagent

biomass under aerobic conditions has frequently been observed at EISB sites when

oxygenated water is mixed with carbon reagent. The introduction of oxygen into the

carbon solution should be minimized through the use of injection drop tubes, short

residence time of solution ex situ, and elimination of unnecessary turbulence (i.e.,

recirculation of solution to control injection rates). When comparing the higher yield in

energy and carbon dioxide derived from the aerobic respiration of glucose to anaerobic

respiration (fermentation), these observations make sense. The readily available energy

gained from aerobic respiration not only encourages rapid microbial growth and biomass

generation, but also produces carbon dioxide at a faster rate, both of which can quickly

clog injection infrastructure and pore spaces, as demonstrated in Exhibit 5.

Second, designing a system to minimize residence time within the system

infrastructure will minimize the amount of biofouling within the system. Residence time

within the mixing and distribution system is dependent on ow rates and the size of tanks

and pipes. At many sites, a signicant change in the ow rate will be observed as injection

ow rates at individual wells change and the number of injection wells in operation

decreases. Understanding the maximum and minimum ow rates during an event is

required to accurately bracket infrastructure residence times during the design phase.

Therefore, a full-volume injection with a dye tracer for radius of inuence conrmation is

the preferred characterization method, rather than a short-term falling head test or

partial-volume injection test. Even when a full-volume injection test is performed

correctly, the ow-rate data that are collected should not be extrapolated to other areas of

a site without conrming that the subsurface conditions are similar.

c 2013 Wiley Periodicals, Inc. Remediation DOI: 10.1002/rem 91

Control of Biofouling: Lessons Learned From a Decade of Carbon Injection System Operation and Maintenance

After the site hydraulics are thoroughly understood, the infrastructure can be sized to

limit residence time to the extent possible. Design concepts to limit residence times

include in-line substrate dilution as opposed to batch mixing, appropriately sized piping,

and decentralized, node-based mixing and injection to limit pipe lengths. While pipe size

should be optimized to reduce residence time, pipe sizes should not be less than 1-inch

diameter and should include regular clean-outs to facilitate future cleaning.

Decentralized, node-based mixing is a simple approach to decrease the residence time of

mixed reagent in system piping before injection into the subsurface. While large

centralized mixing systems can be enticing for large EISB remedies, the pipe runs to

individual wells can be in excess of 1,000 feet. The result is often prolic biofouling and

operational costs, which far outweigh the original cost-effectiveness of centralized mixing.

OPERATIONAL STRATEGIES

While operating dynamic EISB systems, practitioners should continuously analyze and

adjust the operation of a system to meet critical design criteria, most often associated with

parameters such as total organic carbon (TOC) concentrations, aquifer pH, allowable

injection pressure, and target reagent injection volumes. There are a number of

operational adjustments that can be made to prevent biofouling from occurring

throughout this process, as discussed below.

Well Development

Periodic collection and tracking of hydraulic parameters, including wellhead pressures

and/or depth to water within the injection well, static water levels, and injection ow

rate and volume, allow early identication of losses in injection capacity as well as the

relative improvements realized from well maintenance. Additionally, visual inspection of

the well screen throughout the system operation offers insight into the rate and type of

fouling. Deploying a downhole camera (Exhibit 6) can show the relative blockage in the

well screen, color, consistency, and depth of fouling, and prevalence of suspended solids

(sloughing of biomass and mineral precipitates).

In all cases, the design of a treatment regimen must weigh the costs of maintaining

injection capacity against well replacement/abandonment and the impact on remedial

objectives. Cost-effective operation of both small- and large-scale EISB systems depends

on a thorough cost-benet analysis. In the authors experience, the proportion of a wells

life-cycle cost associated with maintenance is often underestimated and can be as much as

50 percent.

Injection-Well Mechanical Rehabilitation

During preliminary design and installation, proper well development is a critical factor in

achieving the necessary communication between the well and the surrounding formation.

As part of the operation of an EISB, mechanical well rehabilitation should be used as a last

resort after all other design and operational strategies have been explored to prevent

fouling. There are three common mechanical methods that are either used alone or in

92 Remediation DOI: 10.1002/rem c 2013 Wiley Periodicals, Inc.

REMEDIATION Winter 2013

Exhibit 6. Injection well biofouling, (a) before rehabilitation and (b) after

rehabilitation

combination for well development. These methods are air lifting, water jetting, and

mechanical surging and are described below.

r

Air lifting can either be performed to pump the well or for surging. In both cases,

compressed air is injected through a line placed into the well to lift water and sediment

from the well. For pumping, air is introduced into the well on a continuous basis.

For surging, air is injected into the well to lift the water to the surface and, when it

reaches the surface, the air supply is shut off, allowing the aerated water column to

fall.

r

Water jetting involves pumping water through a pipe and out a jetting tool at high

velocities with nozzles positioned within the well screen. The high-velocity jets

c 2013 Wiley Periodicals, Inc. Remediation DOI: 10.1002/rem 93

Control of Biofouling: Lessons Learned From a Decade of Carbon Injection System Operation and Maintenance

force the water outward through the well screen openings and agitate the formation

particles surrounding the well screen.

r

Mechanical surging involves inserting a tight tting block of material in the well and

forcing water into and out of the well screen/formation by moving the block upward

and downward inside of the well casing.

A combination of methods will generally be required for effective well development

(both during initial and redevelopment efforts). The well-development process should

begin with brushing followed by airlifting or bailing to dislodge fouling deposits within the

well and to determine that groundwater can ow freely into the well screen.

Water jetting should be added to the airlifting development procedure for wells with

wire-wrapped screens after the initial brushing and pumping activities have been

completed. Jetting can be very effective at breaking up fouling deposits within the screen

and lter pack but is not always effective at moving the dislodged material into the well.

Thereafter, surging using the airlift or surge block method can be phased in to remove the

material and alternated with water jetting and airlifting.

Jetting can be very effec-

tive at breaking up fouling

deposits within the screen

and lter pack but is not

always effective at moving

the dislodged material into

the well.

Injection-Well Chemical Rehabilitation

While mechanical treatments can remove signicant amounts of materials, their

effectiveness is greatly enhanced when used in conjunction with chemicals. If fouling is

severe, a sample of the sludge should be collected to properly characterize the type of

fouling and design an effective treatment regimen. Experience has shown that within the

same site (even nested wells) the fouling signature is often unique, reecting a specic

cocktail of mineral complexes and microbial by-products. For instance, fouling

dominated by mineral complexes may require delivering periodic doses of acids or

caustics to dissolve precipitates, while fouling dominated by biomass and EPS may require

the application of a disinfectant and/or biodispersant to directly degrade and dislodge the

biolm.

The well should be mechanically cleaned (using a stiff brush) to remove as much of

the fouling deposits as possible prior to the addition of well-cleaning chemicals. This is

performed to ensure the applied chemicals are in contact with the targeted lter pack and

near formation material, instead of being utilized by deposits within the casing and screen.

Following brushing, the dislodged material should be removed by bailing, air lifting, or

pumping.

Addition of the chemicals should be conducted slowly, with frequent measurement of

the pH, so that excessive volumes of chemicals are not used. Generally, chemicals require

mixing in the well column, after which most chemicals are allowed to sit in the well

between 12 and 24 hours. The well will be purged until the ambient aquifer pH is

achieved following chemical treatment. Chemical rehabilitating agents that we have found

to be most effective are provided in the sections that follow.

Inorganic Acids

r

Hydrochloric acid (HCl) (muriatic acid)This acid is widely used in well rehabilitation

due to its rapid dissolution of mineral deposits. Health and safety considerations

are required during handling of this acid because of the production of highly toxic

94 Remediation DOI: 10.1002/rem c 2013 Wiley Periodicals, Inc.

REMEDIATION Winter 2013

fumes and its corrosiveness. Some of the problems in the use of hydrochloric acid are

related to this high-corrosion potential against stainless and low-carbon steel screens.

A stepwise dosing with pH measurements should be conducted during application to

avoid very acidic conditions that would generate corrosive waste (pH less than 2).

r

Phosphoric acidPhosphoric acid is a good replacement for hydrochloric acid in well-

cleaning applications. Unlike hydrochloric acid, it has very limited corrosive activity

and is much safer to handle. There are also some metal-chelating effects associated

with phosphoric acid (Schnieders, 2003). One of the disadvantages of using this

acid is the production of phosphate, which could stimulate bacterial growth. Some

commercially available products use phosphoric acid in combination with a polymeric

dispersant that limits phosphate production.

r

Sulfamic acidSulfamic acid is effective at removing carbonate scale deposits but

ineffective at treating iron deposits. Sulfamic acid is available in crystal and/or

powder form, which can be more convenient to ship and handle than liquids.

Phosphoric acid is a good

replacement for hydro-

chloric acid in well-cleaning

applications. Unlike hydro-

chloric acid, it has very lim-

ited corrosive activity and

is much safer to handle.

Organic Acids

r

Hydroxyacetic acidHydroxyacetic acid is also known as glycolic acid and is a liquid

organic acid. It is effective at removing biofouling associated with iron and is relatively

safe to handle (relatively noncorrosive, nonoxidative, and reacts quickly). It also has

some biocidal properties.

r

Citric acidCitric acid is another organic acid that is relatively safe to handle and

known to disrupt the biolm matrix. It is also a carbon substrate, so any residual

citric acid does not have to be removed from the well. However, citric acid is

a metal-chelating agent, so the dosing should be controlled, as it could mobilize

metals.

Antibacterial Agents

r

Hydrogen peroxideHydrogen peroxide is a powerful disinfectant and oxidant. It is

highly reactive, which results in limited migration from point of introduction. One

of the disadvantages in the use of hydrogen peroxide is that it is highly reactive and

that it decomposes to oxygen, so the volume should be limited.

r

ChlorineChlorine is also a powerful disinfectant. If feasible, chlorination should be

applied prior to an acid treatment if large amounts of biolm are present. Shock

chlorination alone may be sufcient for wells with mild biofouling problems.

Biocides

Note that these compounds act primarily by inhibiting bacterial growth but will not break

down and disperse a mature biolm. Therefore, they should be used as a biofouling

control before biofouling has been observed in the well.

r

TolcideTolcide causes damage to the cell membrane of target microorganisms and

it is a potent inhibitor of lactate dehydrogenase, which is a crucial enzyme in the

metabolic pathway for sulfate-reducing bacteria.

c 2013 Wiley Periodicals, Inc. Remediation DOI: 10.1002/rem 95

Control of Biofouling: Lessons Learned From a Decade of Carbon Injection System Operation and Maintenance

Exhibit 7. The hydraulic response to biofouling and rehabilitation

r

EthanolAlthough frequently used as a carbon substrate, ethanol is biocidal at high

concentrations (greater than 50 percent).

The effects of a combination of mechanical and chemical rehabilitation can be

dramatic, as shown by Exhibits 6 and 7. Exhibit 7 also demonstrates the importance of

hydraulic monitoring to determine when well rehabilitation is justied.

Developing an Effective Substrate Dosing Strategy

A soluble carbon substrate delivery system can be ne-tuned by using innovative

approaches to substrate dosing. The operational variables of system operation are dosing

concentrations, timing, and the addition of biocidal amendments. In cases where alcohols,

such as ethanol and methanol, are used as carbon substrates, biocidal doses can be used to

eliminate biofouling rather than merely slowing it down.

Selection of the appropriate organic carbon substrate should include balancing the

aquifer structure, fermentative gas generation rate, utilization kinetics (Exhibit 1),

groundwater velocity, and cost (Suthersan et al., 2010). Solubility of organic carbon

substrates relates to the bioavailability; the utilization kinetics are directly related to the

likelihood of a reagent to biofoul.

To reduce the effective infrastructure residence time, substrates can be pulsed at

concentrations higher than the average target concentration to allow for a subsequent

clean water ush that will slow infrastructure fouling via ushing, and dilute the more

concentrated substrate in the subsurface to achieve the desired concentration. The

performance of each system will vary slightly, and the distribution of substrate in situ can

96 Remediation DOI: 10.1002/rem c 2013 Wiley Periodicals, Inc.

REMEDIATION Winter 2013

Exhibit 8. The effects of pH adjustment on injection ow rates

Ratios of initial injection ow rates and injection ow rates after an extended injection period

improved from less than 0.6 during injections without pH adjustment (rst two events) to above

0.85 when pH adjustment was implemented (last ve events).

be effective by pulsing at higher concentrations. At some sites, careful management of

carbon loading and diligent clean water ushing between injection events has proven

sufcient to control fouling during the treatment time frame. At other sites that require

continuous injections to achieve target treatment time frames, a more aggressive approach

is often needed. This may include periodically dosing the handling system and injection

wells with a chemical, such as an acid, oxidant, or biocide, that suppresses biological

growth.

As shown in Exhibit 8, another technique used to curb biological activity in injection

infrastructure involves adding a base to the injection solution to increase the pH to a

threshold that suppresses fermentative activity. This delays the rapid breakdown of carbon

and ensuing production of carbon dioxide and methane until the solution mixes with

groundwater. Additionally, at this elevated pH, carbon dioxide is predominantly the

bicarbonate anion (HCO

3

) and, therefore, carbon dioxide off-gasing is limited. Once

sufcient in situ mixing, buffering, and dilution occur, the pH will return to circumneutral

levels conducive to biological activity. While this technique has successfully improved

distribution and limited biomass at some sites, consideration must be given to the

c 2013 Wiley Periodicals, Inc. Remediation DOI: 10.1002/rem 97

Control of Biofouling: Lessons Learned From a Decade of Carbon Injection System Operation and Maintenance

Exhibit 9. An analysis of cost per injected gallon (normalized to the average cost per gallon of

the rst year of operation), before and after proactive maintenance

After a proactive maintenance strategy was implemented, costs per injected gallon decreased

51 percent.

geochemical responses to pH adjustment. For example, increasing the pH of moderately

hard water may cause mineral precipitation and potential scaling.

Developing an Effective O&M Strategy

A well-designed system will only operate successfully if it is maintained properly. In most

cases, soluble carbon substrate delivery systems will require periodic infrastructure

cleaning due to biofouling. The key to cost-effective operation is to monitor

early-indicator parameters, such as friction loss through pipelines, gas buildup, and visual

indicators of fouling before a drop in ow rates due to infrastructure or well fouling is

observed. Proactive monitoring and cleaning can be scheduled based on early-indicator

parameters and is cheaper from a life-cycle perspective than the effort required to recover

a system that has fouled to the point of near failure multiple times throughout a remedy.

Proactive O&M has been proven to reduce costs and increase injection volumes

signicantly over reactive O&M. Exhibit 9 shows how the dollar per gallon of injected

reagent can be controlled by proactive maintenance.

98 Remediation DOI: 10.1002/rem c 2013 Wiley Periodicals, Inc.

REMEDIATION Winter 2013

The design objective of an EISB system is to distribute and maintain TOC above

background levels for a distance that allows the contaminant sufcient residence time for

complete treatment. One technique employed to control biofouling has been to reduce

the rate of carbon loading in the treatment zone. While increasing the in situ

concentration of TOC may lengthen the time between injection events, and therefore

save costs, the potential increase in biological activity may lead to a cascade of adverse

effects, including loss of injection capacity, gas entrapment, and depressed pH. The rate of

carbon loading can be reduced through selection of a lower in situ reagent concentration

and a more complex or slow-release carbon donor.

CONCLUSIONS

Success of an anaerobic EISB remedy relies upon maintaining organic carbon

concentrations in the aquifer above baseline concentrations. Large volumes of dilute

organic carbon reagents must be mixed, handled, and injected into the aquifer in order to

achieve this objective. The potential for biofouling will occur after the conditions in the

mixing and distribution system are amenable to biological growth. Systems can be

designed to both limit biofouling and make it easier to deal with biofouling when it does

occur by understanding the mechanisms of biological proliferation and the measures that

can be taken to control it.

A critical piece of system design includes reagent selection and formulation. The

challenges associated with each type of substrate are often similar; however, there are also

unique benets and challenges associated with each, including biocidal properties, biolm

growth, and fermentative gas generation. Practitioners can minimize operational costs and

drive EISB remedy success by understanding the specic characteristics of the selected

reagent and what proactive maintenance measures can be implemented to limit biological

growth within a particular type of system.

In small systems, one or two of the strategies discussed above may be sufcient.

For larger systems, the design considerations associated with long-term operation are the

most crucial; as these systems tend to handle large volumes of reagents and small

problems can exponentially accelerate to become large operational issues. Remedial

life-cycle costs can be controlled by designing systems that are easy to operate, clean, and

ush to minimize biological growth on system infrastructure surfaces. The design process

and reagent selection can help limit the effects of biofouling, but often an overarching

strategy includes physical and chemical maintenance procedures to negate the effects of

biofouling entirely.

REFERENCES

Cullimore, R. (1999). Microbiology of well biofouling. The sustainable well series. Boca Raton, FL: CRC Press.

Driscoll, F. G. (1986). Groundwater and wells. Amarillo, TX: Johnson Filtration Systems.

Elimelech. M., Gregory, J., Jia, X., & Williams, R. (1995). Particle deposition and aggregation: Measurement,

modeling and simulation. Newton, MA: Butterworth-Heineman.

c 2013 Wiley Periodicals, Inc. Remediation DOI: 10.1002/rem 99

Control of Biofouling: Lessons Learned From a Decade of Carbon Injection System Operation and Maintenance

Environmental Security Technology Certication Program (ESTCP). (2005, October). A review of biofouling

controls for enhanced in situ bioremediation of groundwater. ESTCP Technical Report: White Paper

(ER-0429).

Fry, V. A., Selker, J. S., & Gorelick, S. M. (1997). Experimental investigations for trapping oxygen gas in

saturated porous media for in situ bioremediation. Water Resources Research, 33, 26872696.

Ghannoum, M., & OToole, G. A. (2004). Microbial biolms. Washington, DC: ASM Press.

Li, L., Benson, C. H., & Lawson, E. M. (2005). Impact of mineral fouling on hydraulic behavior of permeable

reactive barriers. Ground Water, 43, 582596.

Schnieders, J. H. (2003). Chemical cleaning, disinfection and decontamination of water wells. Minnesota, MN:

Johnson Screens.

Smith, S. A. (1995). Monitoring and remediation wells: Problem prevention, maintenance, and rehabilitation.

Boca Raton, FL: CRC Press.

Spath, R., Flemming, H. C., & Wuertz, S. (1998). Sorption properties of biolms. Water Science and

Technology, 37(45), 207210.

Suthersan, S., Horst, J., Nelson, D., & Potter, S. (2010). Aquifer tuning for optimum performance of in situ

remedies. Groundwater Monitoring and Remediation,30(3), 3944.

Suthersan, S., & Payne, F. (2005). In situ remediation engineering. Boca Raton, FL: CRC Press.

Wuertz, S., Spath, R., Hindenberger, A., Griebe, T., Flemming, H. C., & Wilderer, P. A. (2001). A new method

for extraction of extracellular polymeric substances from biolms and activated sludge suitable for direct

quantication of sorbed metals. Water Science and Technology, 43(6), 2531.

Ye, S., Sleep, B. E., & Chien, C. (2009). The impact of methanogenesis on ow and transport in coarse sand.

Journal of Contaminant Hydrology, 103, 4857.

Zhang, Y., & Gillham, R. W. (2005), Effects of gas generation and precipitates on performance of Fe

0

PRBs.

Ground Water, 43(1), 113121.

Shawn Burnell, P.E., is a senior engineer at ARCADIS-US. He is based out of the companys San Francisco,

California, ofce. He received his BA in chemistry from Colby College and his MS in environmental engineering

from Stanford University. He can be reached at shawn.burnell@arcadis-us.com.

Jon Spitzinger, P.E., is a project engineer at ARCADIS-US. He is based out of the companys Highlands Ranch,

Colorado, ofce. He received his BS in civil engineering from Worcester Polytechnic Institute. He can be reached

at jon.spitzinger@arcadis-us.com.

Peng Jin, PhD, P.E., is a staff environmental engineer at ARCADIS-US. He is based out of the companys

Newtown, Pennsylvania, ofce. He received his BE and MS in environmental engineering from Tsinghua Uni-

versity and his PhD in environmental engineering from the University of Cincinnati. He can be reached at

peng.jin@arcadis-us.com.

Jay Erickson, P.G., is a senior hydrogeologist at ARCADIS-US. He is based out of the companys Rapid City,

South Dakota, ofce. He received his BS in earth science from Montana State University. He can be reached at

jay.erickson@arcadis-us.com.

100 Remediation DOI: 10.1002/rem c 2013 Wiley Periodicals, Inc.

REMEDIATION Winter 2013

Erin Hauber is a project engineer at ARCADIS-US. She is based out of the companys Lenexa, Kansas, ofce. She

received her BS in civil engineering from the University of Kansas. She can be reached at erin.hauber@arcadis-

us.com.

Denice Nelson, PhD, P.E., is the in situ remediation practice lead at ARCADIS-US. She is based out of the

companys Minneapolis, Minnesota, ofce. She received her BS, MS, and PhD in environmental engineering from

the University of Minnesota. She can be reached at denice.nelson@arcadis-us.com.

c 2013 Wiley Periodicals, Inc. Remediation DOI: 10.1002/rem 101

Anda mungkin juga menyukai

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5795)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Function Modules Available in MM & EWMDokumen3 halamanFunction Modules Available in MM & EWMgopalaaraoBelum ada peringkat

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Excel FunctionsDokumen13 halamanExcel Functionsfhlim2069Belum ada peringkat

- Project Predictive Modeling PDFDokumen58 halamanProject Predictive Modeling PDFAYUSH AWASTHIBelum ada peringkat

- How To Design 3D Games With Web Technolology - Book 01. Three - Js - HTML5 and WebGL (PDFDrive)Dokumen184 halamanHow To Design 3D Games With Web Technolology - Book 01. Three - Js - HTML5 and WebGL (PDFDrive)van ninhBelum ada peringkat

- AsdDokumen10 halamanAsdsalman khanBelum ada peringkat

- A Detailed Lesson PlanDokumen13 halamanA Detailed Lesson PlanReynaldo Quines Bohol100% (16)

- EE2202 Electromagnetic Theory Lecture NotesDokumen125 halamanEE2202 Electromagnetic Theory Lecture NoteskanjaiBelum ada peringkat

- Spectral FFT Max Ms PDokumen17 halamanSpectral FFT Max Ms Phockey66patBelum ada peringkat

- Certification Authorities Software Team (CAST) Position Paper CAST-30Dokumen12 halamanCertification Authorities Software Team (CAST) Position Paper CAST-30Adeen KhanBelum ada peringkat

- Shunt ResistorDokumen7 halamanShunt ResistorAsghar AliBelum ada peringkat

- Landfill Gas ManagementDokumen20 halamanLandfill Gas ManagementJoseph Nemesh100% (1)

- BioavailabilityDokumen16 halamanBioavailabilityTyshanna JazzyNicole BariaBelum ada peringkat

- Binocular Vision Development, Depth Perception and DisordersDokumen275 halamanBinocular Vision Development, Depth Perception and DisordersJuliana ToméBelum ada peringkat

- Sample Container, Volumes, Preservatives, and Holding Times: General ChemistryDokumen23 halamanSample Container, Volumes, Preservatives, and Holding Times: General ChemistryJoseph NemeshBelum ada peringkat

- Dillah Kalish Lessons Learned During LF-10-Year StruggleDokumen8 halamanDillah Kalish Lessons Learned During LF-10-Year StruggleJoseph NemeshBelum ada peringkat

- BlanksDokumen2 halamanBlanksJoseph NemeshBelum ada peringkat

- Guide To Analyses: Methods, Holding Times and BottlewareDokumen2 halamanGuide To Analyses: Methods, Holding Times and BottlewareJoseph NemeshBelum ada peringkat

- PerimeterDokumen108 halamanPerimeterJoseph NemeshBelum ada peringkat

- Map 135Dokumen1 halamanMap 135Joseph NemeshBelum ada peringkat

- OIL SHEEN BAOAC PresentationDokumen29 halamanOIL SHEEN BAOAC PresentationJoseph NemeshBelum ada peringkat

- Foam Fact SheetDokumen4 halamanFoam Fact SheetJoseph NemeshBelum ada peringkat

- Magar, 2001Dokumen16 halamanMagar, 2001Joseph NemeshBelum ada peringkat

- Hudson River Case Studies FP5001Dokumen146 halamanHudson River Case Studies FP5001Joseph NemeshBelum ada peringkat

- Item # 4529-010, True Union 2000 Industrial Ball Check ValveDokumen1 halamanItem # 4529-010, True Union 2000 Industrial Ball Check ValveJoseph NemeshBelum ada peringkat

- The Four Rs of Environmental Dredging: Resuspension, Release, Residual, and RiskDokumen63 halamanThe Four Rs of Environmental Dredging: Resuspension, Release, Residual, and RiskJoseph NemeshBelum ada peringkat

- 42in Bagger: Zero-Turn-Radius Riding MowerDokumen20 halaman42in Bagger: Zero-Turn-Radius Riding MowerJoseph NemeshBelum ada peringkat

- Channel Stability RosgenDokumen11 halamanChannel Stability RosgenJoseph NemeshBelum ada peringkat

- QP NTSE Stage 1 2016 17 AndhraPradeshDokumen27 halamanQP NTSE Stage 1 2016 17 AndhraPradeshsudhir_narang_3Belum ada peringkat

- BaseballDokumen37 halamanBaseballBeeWinBelum ada peringkat

- Latex ProjectDokumen3 halamanLatex ProjectPrincess MiroBelum ada peringkat

- Foundations of Nonlinear Algebra (John Perry)Dokumen425 halamanFoundations of Nonlinear Algebra (John Perry)Tao-Wei HuangBelum ada peringkat

- CELLSDokumen21 halamanCELLSPhia LhiceraBelum ada peringkat

- Unit 9: Areas and PerimetersDokumen22 halamanUnit 9: Areas and PerimetersSanchit GargBelum ada peringkat

- Cytomat Software InformationDokumen34 halamanCytomat Software InformationCarlosReisBelum ada peringkat

- Scale Drawing and Scale Models RubricDokumen1 halamanScale Drawing and Scale Models RubricArgoNavisBelum ada peringkat

- Sanitizermachine ZeichenDokumen7 halamanSanitizermachine ZeichenprasannaBelum ada peringkat

- Spicer Info - AXSM-8663 PDFDokumen28 halamanSpicer Info - AXSM-8663 PDFRay Ayala100% (1)

- Pedestrian Volume Studies: A Case Study in The City of GothenburgDokumen80 halamanPedestrian Volume Studies: A Case Study in The City of GothenburgPaula A. FigueroaBelum ada peringkat

- Basic Concepts in Biostatistics 1-1Dokumen36 halamanBasic Concepts in Biostatistics 1-1Teslim RajiBelum ada peringkat

- CADCAM PortfolioDokumen5 halamanCADCAM PortfolioGuhan MBelum ada peringkat

- Design, Development, Fabrication and Testing of Small Vertical Axis Wind TurbinevDokumen4 halamanDesign, Development, Fabrication and Testing of Small Vertical Axis Wind TurbinevEditor IJTSRDBelum ada peringkat

- Radionics PatentsDokumen112 halamanRadionics Patentschad ballBelum ada peringkat

- The Effects of GeoGebra Software On Pre-Service Mathematics Teachers' Attitudes and Views Toward Proof and ProvingDokumen22 halamanThe Effects of GeoGebra Software On Pre-Service Mathematics Teachers' Attitudes and Views Toward Proof and ProvingLidra Ety Syahfitri Harahap lidraety.2022Belum ada peringkat

- 3107 Enthusiast Score Advanced Paper-2 (E+H) JADokumen56 halaman3107 Enthusiast Score Advanced Paper-2 (E+H) JAsonu goyalBelum ada peringkat

- Summative Test Ist (2nd G)Dokumen2 halamanSummative Test Ist (2nd G)Rosell CabalzaBelum ada peringkat