Torque Values RTJ (B16.5)

Diunggah oleh

RezaSohrabiHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Torque Values RTJ (B16.5)

Diunggah oleh

RezaSohrabiHak Cipta:

Format Tersedia

Flange

NPS

No of

Bolts

Bolt

Size

RBS

(MPa)

=0.09

Copperslip

=0.14

Chesterton

Nickle

=0.225

Unlubricated

Flange

NPS

No of

Bolts

Bolt

Size

RBS

(MPa)

=0.09

Copperslip

=0.14

Chesterton

Nickle

=0.225

Unlubricated

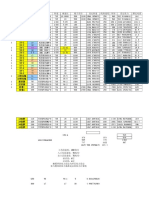

4 276 40 59 90 4 276 40 59 90

4 276 40 59 90 4 276 79 116 178

1 4 276 40 59 90 1 4 276 79 116 178

1 4 276 40 59 90 1 4 276 79 116 178

1 4 276 40 56 90 1 4 276 139 203 313

2 4 276 79 116 178 2 8 276 79 116 178

2 4 276 79 116 178 2 8 276 139 203 313

3 4 276 79 116 178 3 8 276 139 203 313

4 8 276 79 116 178 4 8 276 139 203 313

5 8 276 139 203 313 5 8 276 156 229 352

6 8 276 139 203 313 6 12 276 156 229 352

8 8 276 139 203 313 8 12 276 249 366 565

10 12 276 221 325 502 10 16 1 276 330 485 748

12 12 276 221 325 502 12 16 1 276 479 708 1098

14 12 1 276 330 485 748 14 20 1 276 479 708 1098

16 16 1 276 330 485 748 16 20 1 276 668 992 1543

18 16 1 276 479 708 1098 18 24 1 276 668 992 1543

20 20 1 276 479 708 1098 20 24 1 310 752 1116 1736

24 20 1 276 668 992 1543 24 24 1 310 1329 1988 3108

Please note:

These torque values are only valid for the type of bolting, gasket and lubricant as specified.

These torque values are indicative for general purpose applications. In cases where high temperature conditions, thermal or

pressure cycling, vibration or severe misalignments are present, please contact Klinger Mzansi for advice.

Klinger Mzansi (Pty) Limited

Tel: +27 (0)11 842 8300 | Fax: +27 (0)11 827 9142

Email: sales@klinger.co.za | Website: www.klinger.co.za

CLASS 150

Recommended Minimum Torque Values (Nm)

CLASS 300

Recommended Minimum Torque Values (Nm)

RECOMMENDED BOLT TORQUE REQUIREMENTS

BOLT MATERIALS - ASTM A193 B7, B16 & ASTM A320 L7

Torque Procedure:

1. Ensure that all gasket sealing faces are clean and defect free.

2. Ensure that all friction bearing surfaces are clean and well lubricated.

3. Ensure that the gasket is of the correct material and size.

4. Ensure that initial flange alignment is within 1mm per 200mm diameter.

5. Hand tighten all nuts.

6. Torque nuts following a cross pattern in stages ie 30%, 60% and 100% of final torque value.

7. Do a final check pass in a clocklwise or anticlockwise direction at the final torque value.

8. The final flange alignment must be within 0.5mm.

9. Retorque as required for high temperature or cyclic applications.

For Ring Type Joint Gaskets

ASME B16.5

Flange

NPS

No of

Bolts

Bolt

Size

RBS

(MPa)

=0.09

Copperslip

=0.14

Chesterton

Nickle

=0.225

Unlubricated

Flange

NPS

No of

Bolts

Bolt

Size

RBS

(MPa)

=0.09

Copperslip

=0.14

Chesterton

Nickle

=0.225

Unlubricated

4 276 40 59 90 4 276 139 203 313

4 276 79 116 178 4 276 139 203 313

1 4 276 79 116 178 1 4 276 221 325 502

1 4 310 89 130 200 1 4 276 221 325 502

1 4 276 139 203 313 1 4 1 276 330 485 748

2 8 310 89 130 200 2 8 276 221 325 502

2 8 276 139 203 313 2 8 1 276 330 485 748

3 8 310 156 229 352 3 8 310 249 366 565

4 8 310 249 366 565 4 8 1 310 539 797 1235

5 8 1 310 371 545 842 5 8 1 310 752 1116 1736

6 12 1 310 371 545 842 6 12 1 310 539 797 1235

8 12 1 310 539 797 1235 8 12 1 310 1014 1511 2356

10 16 1 310 752 1116 1736 10 16 1 310 1014 1511 2356

12 20 1 310 752 1116 1736 12 20 1 310 1014 1511 2356

14 20 1 310 1014 1511 2356 14 20 1 345 1477 2209 3453

16 20 1 310 1329 1988 3108 16 20 1 345 1893 2839 4447

18 20 1 310 1704 2555 4002 18 20 1 345 2951 4444 6984

20 24 1 310 1704 2555 4002 20 20 2 345 3599 5430 8545

24

24 1 310 2656 4000 6286 24 20 2 310 6410 9728 15369

RECOMMENDED BOLT TORQUE REQUIREMENTS

For Ring Type Joint Gaskets

ASME B16.5

BOLT MATERIALS - ASTM A193 B7, B16 & ASTM A320 L7

CLASS 600

Recommended Minimum Torque Values (Nm)

CLASS 900

Recommended Minimum Torque Values (Nm)

Please note:

These torque values are only valid for the type of bolting, gasket and lubricant as specified.

These torque values are indicative for general purpose applications. In cases where high temperature conditions, thermal or

pressure cycling, vibration or severe misalignments are present, please contact Klinger Mzansi for advice.

Klinger Mzansi (Pty) Limited

Tel: +27 (0)11 842 8300 | Fax: +27 (0)11 827 9142

Email: sales@klinger.co.za | Website: www.klinger.co.za

Torque Procedure:

1. Ensure that all gasket sealing faces are clean and defect free.

2. Ensure that all friction bearing surfaces are clean and well lubricated.

3. Ensure that the gasket is of the correct material and size.

4. Ensure that initial flange alignment is within 1mm per 200mm diameter.

5. Hand tighten all nuts.

6. Torque nuts following a cross pattern in stages ie 30%, 60% and 100% of final torque value.

7. Do a final check pass in a clocklwise or anticlockwise direction at the final torque value.

8. The final flange alignment must be within 0.5mm.

9. Retorque as required for high temperature or cyclic applications.

Flange

NPS

No of

Bolts

Bolt

Size

RBS

(MPa)

=0.09

Copperslip

=0.14

Chesterton

Nickle

=0.225

Unlubricated

Flange

NPS

No of

Bolts

Bolt

Size

RBS

(MPa)

=0.09

Copperslip

=0.14

Chesterton

Nickle

=0.225

Unlubricated

4 276 139 203 313 4 345 173 254 392

4 310 156 209 352 4 345 173 254 392

1 4 310 249 366 565 1 4 379 304 447 691

1 4 310 249 366 565 1 4 1 379 453 666 1029

1 4 1 310 371 545 842 1 4 1 379 659 974 1510

2 8 345 277 407 628 2 8 1 379 453 666 1029

2 8 1 310 371 545 842 2 8 1 379 659 974 1510

3 8 1 345 599 885 1372 3 8 1 345 835 1240 1929

4 8 1 345 835 1240 1929 4 8 1 379 1625 2430 3798

5 8 1 345 1377 2209 3453 5 8 1 379 2618 3935 6174

6 12 1 310 1014 1511 2356 6 8 2 379 3958 5973 9399

8 12 1 345 1893 2839 4447 8 12 2 379 3958 5973 9399

10 12 1 345 2951 4444 6984 10 12 2 345 7122 10809 17077

12 16 2 345 3599 5430 8545 12 12 2 379 10502 15972 25272

14 16 2 345 5161 7813 12321

16 16 2 345 7122 10809 17077

18 16 2 345 9547 14520 22974

20 16 3 345 12431 18940 30005

24 16 3 345 19888 30387 48235

Please note:

These torque values are only valid for the type of bolting, gasket and lubricant as specified.

These torque values are indicative for general purpose applications. In cases where high temperature conditions, thermal or

pressure cycling, vibration or severe misalignments are present, please contact Klinger Mzansi for advice.

Klinger Mzansi (Pty) Limited

Tel: +27 (0)11 842 8300 | Fax: +27 (0)11 827 9142

Email: sales@klinger.co.za | Website: www.klinger.co.za

Torque Procedure:

1. Ensure that all gasket sealing faces are clean and defect free.

2. Ensure that all friction bearing surfaces are clean and well lubricated.

3. Ensure that the gasket is of the correct material and size.

4. Ensure that initial flange alignment is within 1mm per 200mm diameter.

5. Hand tighten all nuts.

6. Torque nuts following a cross pattern in stages ie 30%, 60% and 100% of final torque value.

7. Do a final check pass in a clocklwise or anticlockwise direction at the final torque value.

8. The final flange alignment must be within 0.5mm.

9. Retorque as required for high temperature or cyclic applications.

RECOMMENDED BOLT TORQUE REQUIREMENTS

For Ring Type Joint Gaskets

ASME B16.5

BOLT MATERIALS - ASTM A193 B7, B16 & ASTM A320 L7

CLASS 1500

Recommended Minimum Torque Values (Nm)

CLASS 2500

Recommended Minimum Torque Values (Nm)

Anda mungkin juga menyukai

- Garlock Metal - Gaskets TorqueDokumen48 halamanGarlock Metal - Gaskets TorqueakenathorBelum ada peringkat

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryDari EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryBelum ada peringkat

- Torque Values RTJ (B16.5)Dokumen3 halamanTorque Values RTJ (B16.5)ariyamanjulaBelum ada peringkat

- Flange Bolt Tightening ProcedureDokumen5 halamanFlange Bolt Tightening ProcedureArya100% (1)

- Dimensions, Sizes and Specification of ANSI ASME B 16.5 FlangesDokumen8 halamanDimensions, Sizes and Specification of ANSI ASME B 16.5 FlangesAndres Nicolas Bouvier100% (1)

- Chemical Resistance GuideDokumen35 halamanChemical Resistance GuideAGPBelum ada peringkat

- Swagelok High Pressure FittingsDokumen8 halamanSwagelok High Pressure FittingsSyahirul AlimBelum ada peringkat

- Torque-Tension Relationship For ASTM A193 B7 Bolts and StudsDokumen1 halamanTorque-Tension Relationship For ASTM A193 B7 Bolts and StudsSiva Krishna ChaudharyBelum ada peringkat

- Lap Joint Flange Vs Slip On FlangeDokumen3 halamanLap Joint Flange Vs Slip On FlangeDarking1390Belum ada peringkat

- Assembly Instructions For Taper JointsDokumen12 halamanAssembly Instructions For Taper JointsmohdBelum ada peringkat

- 3 - Rite Manual de Instalacion y MantenimientoDokumen18 halaman3 - Rite Manual de Instalacion y MantenimientoRoman Arango Herrera0% (1)

- SP-P-001 - Specification For StrainerDokumen30 halamanSP-P-001 - Specification For Strainervishal bhamreBelum ada peringkat

- Vecom - Japanese BlackDokumen2 halamanVecom - Japanese Blackdiaccessltd_17172961Belum ada peringkat

- ASTM F1545 Plastic Lined Pipe 0803 PDFDokumen6 halamanASTM F1545 Plastic Lined Pipe 0803 PDFdavi rodriguesBelum ada peringkat

- Rubber Gasket (Full Face in Flat Face Flanges) Installation & TorqueDokumen4 halamanRubber Gasket (Full Face in Flat Face Flanges) Installation & Torquecavillalobosb8167Belum ada peringkat

- OEUP-InT1000-SOP-OPS-0031 PE Flange Assembly Bolt and Nut TighteningDokumen16 halamanOEUP-InT1000-SOP-OPS-0031 PE Flange Assembly Bolt and Nut TighteningHasan Sevim100% (2)

- 02 Samss 006Dokumen17 halaman02 Samss 006inatt101Belum ada peringkat

- Asme b16.25 Buttwelding EndsDokumen22 halamanAsme b16.25 Buttwelding Endsgst ajahBelum ada peringkat

- Lts Wireloc (Copie Grayloc)Dokumen16 halamanLts Wireloc (Copie Grayloc)toto-gmbhBelum ada peringkat

- IFC Series Y-Strainers: NotesDokumen30 halamanIFC Series Y-Strainers: Notesmarsha.fsdBelum ada peringkat

- Piping Design InfoDokumen273 halamanPiping Design InfoFerry SiswantoBelum ada peringkat

- API Standards ListDokumen14 halamanAPI Standards ListMirzaBelum ada peringkat

- Agrements TMD Recapitulatif Sept-2014Dokumen30 halamanAgrements TMD Recapitulatif Sept-2014aldo2306Belum ada peringkat

- All-in-One Manual of Industrial Piping Practice and MaintenanceDari EverandAll-in-One Manual of Industrial Piping Practice and MaintenancePenilaian: 5 dari 5 bintang5/5 (1)

- Astm A890 Vs A995Dokumen1 halamanAstm A890 Vs A995ok barveBelum ada peringkat

- API Flange 6A VersionDokumen1 halamanAPI Flange 6A Versiongazwang478Belum ada peringkat

- MS-HKSS-Pigging Testing Drying Rev A - YNB 16''Dokumen64 halamanMS-HKSS-Pigging Testing Drying Rev A - YNB 16''AAISATBelum ada peringkat

- Tablas Weldolets, ThredoletsDokumen44 halamanTablas Weldolets, ThredoletsIng TelloBelum ada peringkat

- Checklist For Above Ground Tanks-QueenslandDokumen2 halamanChecklist For Above Ground Tanks-QueenslandmohanumaBelum ada peringkat

- GTL WPSDokumen6 halamanGTL WPSYoucef ChorfaBelum ada peringkat

- Bolt Torque DeterminationDokumen11 halamanBolt Torque DeterminationRatna Giridhar Kavali100% (1)

- Mercer 9100Dokumen16 halamanMercer 9100dtmgoBelum ada peringkat

- Gasket Installation: DurlonDokumen3 halamanGasket Installation: Durlonlorenzo100% (1)

- Flange Torque RecommendationsDokumen2 halamanFlange Torque RecommendationsTulioLopezJBelum ada peringkat

- MSS-SP-118 (1996)Dokumen25 halamanMSS-SP-118 (1996)mubs997Belum ada peringkat

- Hydrogen Compressor Flange Bolts FailureDokumen8 halamanHydrogen Compressor Flange Bolts FailurePablo ScottBelum ada peringkat

- Bolt Torque ASME B16 5 Flanges Spiral Wound GasketsDokumen29 halamanBolt Torque ASME B16 5 Flanges Spiral Wound Gasketssaiful anwar100% (1)

- Technical Data Chart G16667 (Pressure Rating For ASTM A53-40 ERW Type E)Dokumen2 halamanTechnical Data Chart G16667 (Pressure Rating For ASTM A53-40 ERW Type E)polysourceBelum ada peringkat

- Manual Cartex QN TN DW 00 - enDokumen26 halamanManual Cartex QN TN DW 00 - enRené Mora-CasalBelum ada peringkat

- Liquid SizingDokumen38 halamanLiquid SizingChetan ChuriBelum ada peringkat

- EZR RegulatorDokumen40 halamanEZR RegulatorBranko BabicBelum ada peringkat

- Bolt Pocket ChartDokumen2 halamanBolt Pocket ChartAlex LaraBelum ada peringkat

- Api 661Dokumen6 halamanApi 661margarelliBelum ada peringkat

- LOCK O RING Flanges and PlugsDokumen6 halamanLOCK O RING Flanges and PlugsochableBelum ada peringkat

- Thread o Ring FittingsDokumen4 halamanThread o Ring FittingsLê Đức ThiệnBelum ada peringkat

- Orifice Flange Guide - Daniel FlowDokumen45 halamanOrifice Flange Guide - Daniel FlowSammyBelum ada peringkat

- 01LK0F01Dokumen4 halaman01LK0F01raobabar21Belum ada peringkat

- Api 12FDokumen1 halamanApi 12Fzonova97Belum ada peringkat

- EEMUA Publication 183 - Guide For The Prevention of Tank Bottom Leakage © EemuaDokumen4 halamanEEMUA Publication 183 - Guide For The Prevention of Tank Bottom Leakage © EemuaCRISTIAN SILVIU IANUCBelum ada peringkat

- Torque Values For Insualtion KitDokumen2 halamanTorque Values For Insualtion KitYasser MahmoudBelum ada peringkat

- Torque-Tension Chart For B7Dokumen1 halamanTorque-Tension Chart For B7Ramón C. Silva H.Belum ada peringkat

- Torque Values Graphite Laminate (B16.5)Dokumen2 halamanTorque Values Graphite Laminate (B16.5)Gonçalo Cortez50% (2)

- Taper Lock Bush Dimensions.Dokumen12 halamanTaper Lock Bush Dimensions.stuart396275% (4)

- 231,241,271 SchematicDokumen4 halaman231,241,271 Schematicab5951Belum ada peringkat

- ValvesDokumen10 halamanValvesInigoBelum ada peringkat

- Flange DimensionsDokumen7 halamanFlange DimensionsDave DonohueBelum ada peringkat

- Exhaust Gas Brochure - Issue K PDFDokumen12 halamanExhaust Gas Brochure - Issue K PDFFrancisco Mosquera LopezBelum ada peringkat

- Caterpillar 3208 Diesel Engine SM Manual Copy OneDokumen350 halamanCaterpillar 3208 Diesel Engine SM Manual Copy Oneswoods71588% (25)

- 78981330457854Dokumen35 halaman78981330457854César FernándezBelum ada peringkat

- 越南2#HB线电机数据合算Dokumen6 halaman越南2#HB线电机数据合算Vũ HiệuBelum ada peringkat

- A1018 1220124-1Dokumen9 halamanA1018 1220124-1RezaSohrabiBelum ada peringkat

- 100 Top Sire FEI RankingDokumen2 halaman100 Top Sire FEI RankingRezaSohrabiBelum ada peringkat

- WBFSH / Rolex Sire Ranking 2015 - Jumping: Top 100 Ranked StallionsDokumen1 halamanWBFSH / Rolex Sire Ranking 2015 - Jumping: Top 100 Ranked StallionsRezaSohrabiBelum ada peringkat

- A1018 1220124-1Dokumen9 halamanA1018 1220124-1RezaSohrabiBelum ada peringkat

- Benefits BookletDokumen114 halamanBenefits BookletRezaSohrabiBelum ada peringkat

- WBFSH / Rolex Sire Ranking 2015 - Jumping: Top 100 Ranked StallionsDokumen1 halamanWBFSH / Rolex Sire Ranking 2015 - Jumping: Top 100 Ranked StallionsRezaSohrabiBelum ada peringkat

- A1018 1220124-1Dokumen9 halamanA1018 1220124-1RezaSohrabiBelum ada peringkat

- Lincoln GMAW Welding GuideDokumen96 halamanLincoln GMAW Welding GuideМич БјукенонBelum ada peringkat

- UR W pdf159Dokumen264 halamanUR W pdf159RezaSohrabiBelum ada peringkat

- AWS Vs CSADokumen29 halamanAWS Vs CSAEl Shin100% (2)

- Moment Connections Seismic ApplicationsDokumen46 halamanMoment Connections Seismic Applicationsshak543100% (14)

- Duplex Stainless Steel 3rd EditionDokumen68 halamanDuplex Stainless Steel 3rd EditionPhani Sridhar Ch100% (3)

- Valve MaterialTypeEquivalentDokumen3 halamanValve MaterialTypeEquivalentRezaSohrabiBelum ada peringkat

- Comparing 4043 Vs 5356 Welding WireDokumen1 halamanComparing 4043 Vs 5356 Welding WireRezaSohrabiBelum ada peringkat

- Technical DataDokumen48 halamanTechnical Datashekhar2681Belum ada peringkat

- Sigma PhaseDokumen27 halamanSigma PhaseRezaSohrabiBelum ada peringkat

- ITP LegendDokumen4 halamanITP LegendRezaSohrabiBelum ada peringkat

- Iron ManDokumen1 halamanIron ManRezaSohrabiBelum ada peringkat

- Hoop StressDokumen35 halamanHoop StressRezaSohrabiBelum ada peringkat

- Pressure Seal ValvesDokumen47 halamanPressure Seal ValvesRezaSohrabiBelum ada peringkat

- RT Acceptance CriteriaDokumen1 halamanRT Acceptance CriteriaRezaSohrabiBelum ada peringkat

- 30 #150 DrainDokumen1 halaman30 #150 DrainMohammad Reza SohrabiBelum ada peringkat

- CSharp For Sharp Kids - Part 1 Getting StartedDokumen10 halamanCSharp For Sharp Kids - Part 1 Getting StartedBrothyam Huaman CasafrancaBelum ada peringkat

- LF90LS Operations and Service Manual PDFDokumen154 halamanLF90LS Operations and Service Manual PDFJose Vidal100% (9)

- Mitutoyo Digimatic IndicatorDokumen12 halamanMitutoyo Digimatic IndicatorxbudzekBelum ada peringkat

- Filtre TV EpcosDokumen13 halamanFiltre TV Epcosparvalhao_Belum ada peringkat

- USAREUR Pam 30-60-1 1975 Identification Guide, Part Three Weapons and Equipment, East European Communist Armies Volume II, Mine Warfare and Demolition EquipmentDokumen286 halamanUSAREUR Pam 30-60-1 1975 Identification Guide, Part Three Weapons and Equipment, East European Communist Armies Volume II, Mine Warfare and Demolition EquipmentBob Andrepont100% (3)

- General Specifications: Daqstation DX1000Dokumen20 halamanGeneral Specifications: Daqstation DX1000Abarajithan RajendranBelum ada peringkat

- Ds Transmitter U952TDokumen2 halamanDs Transmitter U952TZafar YabBelum ada peringkat

- Scheduling AgreementDokumen2 halamanScheduling AgreementWupankBelum ada peringkat

- Daily Report MTU UnitDokumen46 halamanDaily Report MTU UnitBayu SaputraBelum ada peringkat

- ASTM E824 Light Meter CalibrationDokumen6 halamanASTM E824 Light Meter CalibrationreiazhBelum ada peringkat

- 2021 11 17 21 55 17620 0Dokumen149 halaman2021 11 17 21 55 17620 0Maricel VirtudezBelum ada peringkat

- W20PGDokumen147 halamanW20PGAnup MishraBelum ada peringkat

- Roc RDO23 PORVENIR PENDEN RAPIDROPDokumen3 halamanRoc RDO23 PORVENIR PENDEN RAPIDROPJhonatan BlanquicettBelum ada peringkat

- 2250 Transmission ToolsDokumen15 halaman2250 Transmission ToolsRakesh KongalaBelum ada peringkat

- Router Board Performance TestsDokumen2 halamanRouter Board Performance TestsedkaviBelum ada peringkat

- Basic Safety Plan: Aker Powergas PVT LTD Page NoDokumen36 halamanBasic Safety Plan: Aker Powergas PVT LTD Page NoAbid AliBelum ada peringkat

- Onan Service Manual 965-0531BDokumen136 halamanOnan Service Manual 965-0531Broger.bunch2285100% (2)

- Astm F 438-04Dokumen7 halamanAstm F 438-04Jorge ToribioBelum ada peringkat

- HASR09A HASC09A HASR12A HASC12A HASR24A HASC24A HASR30C HASC30C Service ManualDokumen71 halamanHASR09A HASC09A HASR12A HASC12A HASR24A HASC24A HASR30C HASC30C Service ManualUEE100% (1)

- Call Setup FailureDokumen24 halamanCall Setup FailureHien NguyenBelum ada peringkat

- Research Designs & Standards Organization: QM-G-7.1-3 Guidelines For Vendor ApprovalDokumen24 halamanResearch Designs & Standards Organization: QM-G-7.1-3 Guidelines For Vendor Approvalgopal sharma100% (1)

- BS en Iso 4287-98 A1-09Dokumen36 halamanBS en Iso 4287-98 A1-09fernando salvatierra100% (2)

- Cylinder Design Standards WSNZDokumen5 halamanCylinder Design Standards WSNZjamilBelum ada peringkat

- Cartagena ProtocolDokumen16 halamanCartagena ProtocolKS KSBelum ada peringkat

- Usermanual pcs100 pcs500 k8031 Uk PDFDokumen25 halamanUsermanual pcs100 pcs500 k8031 Uk PDFleontindemeterBelum ada peringkat

- Underground Cable InstallationDokumen9 halamanUnderground Cable Installationbhaskar_dandapathak100% (1)

- SIB in LTEDokumen19 halamanSIB in LTEsinafe0% (1)

- Passenger Services Conference Resolutions Manual: Resolution 792Dokumen9 halamanPassenger Services Conference Resolutions Manual: Resolution 792Mike WillysBelum ada peringkat

- FAR 145 Inspection SystemDokumen44 halamanFAR 145 Inspection SystemFauzie Ahmad100% (1)

- GS - EP - PVV - 158 - EN MaterialsDokumen74 halamanGS - EP - PVV - 158 - EN MaterialswilBelum ada peringkat