Tin Can & Offset Printing

Diunggah oleh

Gayashan KulathungaHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Tin Can & Offset Printing

Diunggah oleh

Gayashan KulathungaHak Cipta:

Format Tersedia

MACHINERY REQUIREMENT PLAN FOR TIN CANS &

OFFSET PRINTIG

TUFFLINELTD

October 6, 2011

KULATHUNGA H.G.G.

CONTENT

1.0 INTRODUCTION 01

2.0 TYPES OF CANS AND THEIR USES 02

3.0 TIN CAN MANUFACTURING PROCESSES 03

4.0 THREE PIECE TIN CAN MANUFACTURING PROCESS 04-05

4.1 MACHINERY REQUIREMENT 06

4.2 THREE PIECE CAN MAKING PRODUCTION LINE 01 06

4.2.1 QUOTATIONS 07-08

4.2.2 MACHINE INSTALATION PLAN FOR CAN BODY 09

4.2.3 MACHINE INSTALATION PLAN FOR CAN END 10

4.3 THREE PIECE CAN MAKING PRODUCTION LINE 02 11-12

4.3.1 QUOTATIONS 13

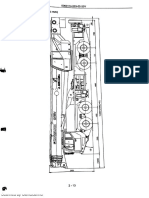

4.3.2 MACHINE INSTALATION LAY OUT 14

5.0 DRAW AND IRON CAN MANUFACTURING PROCESS 15

5.1 MACHINERY REQUIREMENT 15-16

6.0 OFFSET PRINTING 17

6.1 APPLICATIONS 17

6.2 ADVANTAGES 17

6.3 OFFSET PRINTING PROCESS 17

6.4 MACHINERY REQUIREMENT FOR CARTON PRINTING 18

6.5 TECHNICAL PARAMETERS OF SELECTED MACHINE 18

6.6 QUOTATIONS 19

6.7 MACHINE INSTALATION LAYOUT 20

1.0 INTRODUCTION

TIN CANS

A tin can, tin, steel can, or a can, is a sealed container for the distribution or storage of goods,

composed of thin metal. Many cans require opening by cutting the "end" open; others have

removable covers. Cans hold diverse contents: foods, beverages, oil, chemicals, etc.

Tin can industry is a vast industry; there are several types of cans and can making processes. In this

project mainly focused on to prepare a machinery requirement plan for tin cans for food and

beverage industries.

OFFSET PRINTING

Offset printing is a commonly used printing technique in which the inked image is transferred (or

"offset") from a plate to a rubber blanket, then to the printing surface. When used in combination

with the lithographic process, which is based on the repulsion of oil and water, the offset technique

employs a flat (planographic) image carrier on which the image to be printed obtains ink from ink

rollers, while the non-printing area attracts a water-based film (called "fountain solution"), keeping

the non-printing areas ink-free. Also offset printing is used in lot of applications such as newspapers,

magazines, brochures, stationery, books and etc. But this project is focused on to find out the

machinery requirement for carton printing.

2.0 TYPES OF CANS AND THEIR USES

TABLE NO 01 TYPE OF CANS AND THEIR USES

PROCESS

MATERIAL USED

PRODUCTS CONTAINED

Three piece

Steel

Food, juices, spices, aspirin,

& other non-food items such

as paints and glues (includes

decorative tins); includes

aerosols

Draw & iron

Aluminum (1- and 2-piece)

2-piece: primarily beer,

carbonated beverages, juices

1-piece: aerosol & pump

products (perfume, air

freshener, saline solution);

fuel additives

Steel (2-piece only)

Food, other non-food items

2-piece draw/redraw

Steel, aluminum

Food, shoe polish, car wax,

other non-food items

Ends

Steel, aluminum

All (except 1-piece draw &

iron)

Crowns and closures

Steel

Food & non-food items

3.0 TIN CAN MANUFACTURING PROCESSES

TIN CAN

MANUFACTURING

PROCESSES

3-PIECE CAN BODY

MAKING PROCESS

2-PIECE CAN BODY

MAKING PROCESS

DRAW AND IRON

PROCESS

DRAW REDRAW

PROCESS

CAN LID MAKING

PROCESS

CROWNS AND

CLOSURES

MAKING PROCESS

4.0 THREE PIECE TIN CAN MANUFACTURING PROCESS

3 Piece can making process can be categorized into to two groups,

1. Can body manufacturing process

2. Can end manufacturing process

CAN BODY MANUFACTURING PROCESS

STEEL

COILS OR

PLATES

SLITTING

BODY

SHAPE

FORMING

SEAM

WELDING

OR

CEMENTIN

G

COATINGS

& DRYING

FLANGING

SEALING

CAN END MANUFACTURING PROCESS

TIN COILS

OR PLATES

SLITTING

PUNCH

FORMING

EDGE

CURLING

LINING

DRYING

4.1 MACHINERY REQUIREMENT

1. FOR CAN BODY MANUFACTURING

1) Slitter machine

2) Body forming machine

3) Seam welding or cementing machine

4) Coating and drying machine

5) Flanging machine

6) Sealing machine

2. FOR CAN END MANUFACTURING

1) Slitter machine

2) Punch machine

3) Curling machine

4) Ling coating machine

5) Drying machine

The above mentioned machineries require for a three piece tin can making line.

4.2 THREE PIECE TIN CAN MAKING PRODUCTION LINE 01

This is an automated production line for three piece tin cans.

MACHINERIES FOR CAN BODDY MACHINERIES FOR CAN END

Auto Duplex Slitting Machine

Powder spray coating machine

Auto welding machine

External Coating & Conveying

Machine

Induction drying machine

Conveying machine

Flanging\beading\seaming\Necking 3-

station combo machine.

Conveying machine

Auto sheet feeder machine

CNC feeding system

Auto scrap collection machine

Pressing machine 45T

Conveying Machine

Curling Machine

Conveying Machine

Lining & Drying Machine

Maximum production capacity of the production line = 150 cans/min

Total cost of the machines for can body making = $ 387,400

Total cost of the machines for can end making = $ 145,000

Therefore total cost for machines = $ 532,400

4.2.2 MACHINE INSTALATION PLAN FOR CAN BODY

4.2.3 MACHINE INSTALATION PLAN FOR CAN END

4.3 THREE PIECE TIN CAN MAKING PRODUTION LINE 02

This is a semi automatic production line for three piece tin cans.

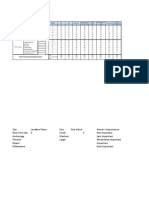

1.0 SEMI AUTOMATIC PRODUCTION LINE FOR CAN BODY

EQUIPMENT NAME

QUANTITY

Slitter(GT1B5) 2

Roll forming machine(GT3A3) 1

Seam welding machine(FN2000-B) 1

Coating & drying machine(GT200U) 1

Flanging machine(GT3TB20)

(for 8500 ml)

1

Flanging machine(QYA180F)

(for 400 ml)

1

Sealing machine(GT4A16B) 2

2.0 SEMI-AUTOMATIC PRODUCTION LINE FOR CAN LID

EQUIPMENT NAME

QUANTITY

40T Punch machine 1

25T punch machine 1

Curling machine (GT2B3) 1

Ling compound machine (GT2C3) 1

Drying machine (GT2D5) 1

Dies for 8500 ml 1(2pieces)

Dies for 400 ml

1(2pieces)

PRODUCTION CAPACITY & OTHER DETAILS OF MACHINES

EQUIPMENT CAPACITY POWER

(kW)

DIMENSIONS

(L*W*H)

Slitter(GT1B5) 1.1 1500*1600*1105

Roll forming machine(GT3A3) 80cans/min 0.25 700*400*840

Seam welding machine(FN2000-B) 25-

50cans/min

15kVA 1350*1300*1700

Coating & drying machine(GT200U) 6-30m/min 10 9600*680*1460

Flanging machine(GT3TB20) 15cans/min 4 1300*700*1750

Flanging machine(QYA180F) 15cans/min 400*500*1380

Sealing machine(GT4A16B 15-

30cans/min

1.5 750*530*1980

40T Punch machine 2.2

25T punch machine 4

Curling machine (GT2B3) 0.37

Ling compound machine (GT2C3) 50-

160cans/min

990*700*1500

Drying machine (GT2D5) 1500-3000

pcs/hour

28.3 6440*1000*1800

Total cost for machines = $ 106900

Maximum production capacity of this line = 15cans/min

5 DRAW AND IRON CAN MAKING MANUFACTURING PROCESS

5.1 MACHINERY REQUIREMENT

Cupper machine

Wall ironer machine

Trimmer machine

Washer machine

Printing machine

Necker and flanger machine

This process is a huge expensive process and also all 2-piece can making machines are manufactured by

USA, British and Germany. Also most of these machines are purchased from America at 30,000,000USD

a line. Therefore the following process can be used for manufacturing beverage cans.

ALUMINIUM

COIL

CUPPER

WALL

IRONER

TRIMMER

WASHER

DECORATION

NECKER AND

FLANGER

Above shown beverage cans are manufactured by using three piece can manufacture process. This

process is not a big investment at the beginning. Therefore 3 PIECE beverage can is fit for the starting.

But in this process using tin plates, tin plates are little expensive than aluminum. It is a disadvantage of

this process.

For making three piece beverage cans as shown in above can be used the machineries which are

mentioned under the topic THREE PIECE TIN CAN MAKING PRODUCTION LINE 01 by changing

the mold.

6 OFFSET PRINTING

Offset printing is a commonly used printing technique in which the inked image is transferred (or

"offset") from a plate to a rubber blanket, then to the printing surface. When used in combination with the

lithographic process, which is based on the repulsion of oil and water, the offset technique employs a flat

(planographic) image carrier on which the image to be printed obtains ink from ink rollers, while the non-

printing area attracts a water-based film (called "fountain solution"), keeping the non-printing areas ink-

free.

6.1 APPLICATIONS

News papers

Magazines

Brochures

Stationery

Books

6.2 ADVANTAGES

Consistent high image quality.

Quick and easy production of printing plates.

Longer printing plate life than on direct litho presses.

Offset printing is the cheapest method to produce high quality printing in commercial printing

quantities.

6.3 OFFSET PRINTING PROCESS

6.4 MACHINERY REQUIREMENT FOR CARTON PRINTING LINE

Printing machine

Slitter machine

Die cutter machine

Stacker machine

Total cost for the machine = $ 243,300.00

6.5 TECHNICAL PARAMETER OF MACHINE

APSII

Items

AFPS-1600x2800

Max. machine speed of

lead edge feeder (p/min)

180

Recommended speed

(p/min)

120-150

Max. feeding size (mm)

1600x2800

Min. feeding size (mm) 400x650

Skip feeding (mm)

1800x2800

Max. printing area (mm)

1550x2750

Printing precision (mm)

0.5

Printing plate thickness

(mm)

7.2

Min.

slotting

space

Normal knife

(mm)

Reverse knife

(mm)

180x180x180x180

360x80x360x80

Max. slotting depth (mm) 350

Slotting precision (mm)

1

Shanghai Lucky Spring Packing Technology Development Co.,

Ltd.

Add: 728 Room, Kaicheng Building, No.135 Longcao Road, Xuhui,Shanghai, China.

Tel: +86-21-61212752/86- 15900674412 Fax: +86-21-61213230

QUOTATION

AFPS Computerized Flexo Printing Slotting Rotary Die-cutting Machine

Unit priceunitdollar

16002800mm

FOB Shanghai, China

Four colors printer +slitter+ Die cutter

+ stacker

ALL PRICE:

48600+29100x4+34100+33200+11000

=243,300.00 USD

Feeding Unit 48600

Printing Unit (Each Unit) 29100

Slotting Unit 34100

Die Cutting Unit 33200

Stacker 11000

COMMERCIAL CONDITIONS:

Loading port Shanghai

Destination port at buyer's option

offer validity This offer is valid for 1 months

delivery period: Manufacturing period is about 60-90 days upon receipt of prepayment.

Standard payment terms

- 30% pre-payment

- 70% after manufacturing at the factory

Round tickets, board and lodging expenses of specialists shall be covered by the customer.

Also Buyer pays 70 US dollars per day for each expert.

The period of warranty for normal operation of the Equipment is 12 (Twelve) months from the

Date of putting it into operation, which does not include easily wearing parts and human factor.

Packing: Stand steel pallet

REF.No. 23092011

TO Mr. Gayashan Kulathunga

Contact person: Cherry

TEL TEL+86-21-61212752 / 86-15900674412

FAX FAX+86-21-61213230

E-mailgkulathunga@gmail.com Date 23/09/2011

Anda mungkin juga menyukai

- Beverage ContainersDokumen14 halamanBeverage Containersadilneu0% (1)

- Containers Printers IntroductionDokumen28 halamanContainers Printers Introductionyhtan09Belum ada peringkat

- How Cans Are MadeDokumen4 halamanHow Cans Are MadeOkeyourying MayourBelum ada peringkat

- Hapa - in House Printing Solutions (Marcel Aeby)Dokumen44 halamanHapa - in House Printing Solutions (Marcel Aeby)Yose RizalBelum ada peringkat

- Printing Inks For Flexible PackagingDokumen11 halamanPrinting Inks For Flexible PackagingSathiya Raj100% (1)

- 2015 BASF Flexible-Packaging-Inks Landscape ELDokumen12 halaman2015 BASF Flexible-Packaging-Inks Landscape ELPongthip PesachpinankulBelum ada peringkat

- Laminating Troubleshooting FinalDokumen25 halamanLaminating Troubleshooting FinalHabteyes AbateBelum ada peringkat

- GravureDokumen17 halamanGravureGopi NathBelum ada peringkat

- Food Cans Manufacturing: Food Packaging FST-4041 BS-final YearDokumen22 halamanFood Cans Manufacturing: Food Packaging FST-4041 BS-final YearSONIA NABIBelum ada peringkat

- Anilox SelectionDokumen2 halamanAnilox SelectionTanneru Hemanth KumarBelum ada peringkat

- Formula For Plastic ProductsDokumen6 halamanFormula For Plastic ProductsRRSBelum ada peringkat

- Project Report On Flexo Printing Manufacturing FacilityDokumen7 halamanProject Report On Flexo Printing Manufacturing FacilityEIRI Board of Consultants and PublishersBelum ada peringkat

- Offset Printing Defects PDFDokumen2 halamanOffset Printing Defects PDFCody0% (2)

- Flexo GravureDokumen34 halamanFlexo Gravurefajar ramadhanBelum ada peringkat

- Car Paint PDFDokumen30 halamanCar Paint PDFMekon-Engineering MkeBelum ada peringkat

- Plastic Design Guide - Part Design, Material Selection, Processing ConditionsDokumen5 halamanPlastic Design Guide - Part Design, Material Selection, Processing ConditionsAdithya SjBelum ada peringkat

- Identifying High-Volume Printing Processes - PDF OTIMA MARIADokumen8 halamanIdentifying High-Volume Printing Processes - PDF OTIMA MARIArafael_faria_4Belum ada peringkat

- CPP (Cast Polypropylene)Dokumen22 halamanCPP (Cast Polypropylene)donisback2010Belum ada peringkat

- CHAPTER 3.0 - GravureDokumen10 halamanCHAPTER 3.0 - GravureGiha Tardan100% (1)

- Indian Printing Industry Profile 2010Dokumen36 halamanIndian Printing Industry Profile 2010Anil YadavBelum ada peringkat

- Gravure PrintingDokumen63 halamanGravure Printingomkar gokhale100% (6)

- Rotogravure Cylinder ProcedureDokumen5 halamanRotogravure Cylinder ProcedureSyed Mujtaba Ali BukhariBelum ada peringkat

- Surface-Coating Industries (2022)Dokumen48 halamanSurface-Coating Industries (2022)sandraBelum ada peringkat

- Flexible Packaging Printing ProcessesDokumen46 halamanFlexible Packaging Printing ProcessesRanga PrasadBelum ada peringkat

- Lamination PresentationDokumen37 halamanLamination PresentationBhupendra Singh100% (15)

- Pu Dispersion Formulation 2Dokumen1 halamanPu Dispersion Formulation 2mrafigBelum ada peringkat

- Lamination Vs CoatingDokumen7 halamanLamination Vs CoatingJscribd100% (1)

- Jindal Poly Films LimitedDokumen13 halamanJindal Poly Films LimitedAhmad ArsalanBelum ada peringkat

- 1 CDI Advance 5080Dokumen2 halaman1 CDI Advance 5080Diana BonanaBelum ada peringkat

- Slip AdhesivosDokumen24 halamanSlip AdhesivosMiguelAngelPerezEsparza100% (1)

- Flexo Printing Machinery Catalog English UpdatedDokumen8 halamanFlexo Printing Machinery Catalog English UpdatedOMAR JOSE LEALBelum ada peringkat

- Bobst PDFDokumen52 halamanBobst PDFAbdul BasitBelum ada peringkat

- Blown Film CatalogueDokumen12 halamanBlown Film CatalogueMohammad-reza NabavinezhadBelum ada peringkat

- PKG Materials Standards IIP A A JoshiDokumen45 halamanPKG Materials Standards IIP A A JoshiDeepak VermaBelum ada peringkat

- Basic Laminating Technology 4Dokumen16 halamanBasic Laminating Technology 4Ronaldo latumanuwyBelum ada peringkat

- PET Processing V4 1 PDFDokumen48 halamanPET Processing V4 1 PDFwoongs73100% (1)

- Starch For CorrugatingDokumen20 halamanStarch For Corrugatingsyifa latifa zahidaBelum ada peringkat

- Lombardi Company PresentationDokumen35 halamanLombardi Company PresentationPam Landi0% (1)

- The Seven Laws of Efficient PackagingDokumen12 halamanThe Seven Laws of Efficient Packagingsbaker@cinqpet.co.zaBelum ada peringkat

- 10 Aluminium Foil in Packaging - SBDokumen40 halaman10 Aluminium Foil in Packaging - SBSiddharth Saxena67% (3)

- Materi PrintingDokumen16 halamanMateri PrintingnuryadyBelum ada peringkat

- Laminated Object ManufacturingDokumen6 halamanLaminated Object Manufacturingpapajohn1383Belum ada peringkat

- Flexible PackagingDokumen28 halamanFlexible PackagingWilson1915100% (1)

- Brochure CoatingsDokumen8 halamanBrochure CoatingsĆhãmpäk HãźaríkäBelum ada peringkat

- Testing of Packaging Manual - Keerthana DsecDokumen31 halamanTesting of Packaging Manual - Keerthana DsecAbishek. KBelum ada peringkat

- Niir Handbook On Printing Technology Offset Gravure Flexo Screen 2nd Edition PDFDokumen8 halamanNiir Handbook On Printing Technology Offset Gravure Flexo Screen 2nd Edition PDF107751101137Belum ada peringkat

- Standard Ink Types Report (PDF Copy)Dokumen64 halamanStandard Ink Types Report (PDF Copy)Kevin AnosBelum ada peringkat

- Polyols and Powder Coating ResinsDokumen51 halamanPolyols and Powder Coating Resinskang8886021100% (1)

- 5.1 Alginate Production MethodsDokumen15 halaman5.1 Alginate Production MethodsLana NairfanaBelum ada peringkat

- Rubber, NaturalDokumen24 halamanRubber, NaturalAhmed YounisBelum ada peringkat

- Collapsible Tube For PharmaDokumen8 halamanCollapsible Tube For PharmaAbhishek Singh100% (1)

- TDS PU Sealant Bamco BSSL - Eng - 2014 Rev.03Dokumen4 halamanTDS PU Sealant Bamco BSSL - Eng - 2014 Rev.03JoeBelum ada peringkat

- Parmetol A 26 ZTM P Ic e enDokumen2 halamanParmetol A 26 ZTM P Ic e enalthea badayosBelum ada peringkat

- Flexographic PrintingDokumen56 halamanFlexographic PrintingIvan Božić50% (2)

- Speccoats AntiCorrosiveBrochureDokumen36 halamanSpeccoats AntiCorrosiveBrochurereinpolyBelum ada peringkat

- Rupa FlexiPOLYDokumen1 halamanRupa FlexiPOLYSaravvanan RajendranBelum ada peringkat

- Glossary of Packaging TermsDokumen12 halamanGlossary of Packaging TermsgallesinaBelum ada peringkat

- Company Profile SimpleDokumen7 halamanCompany Profile SimpleAsif MemonBelum ada peringkat

- RatesDokumen1 halamanRatesGayashan KulathungaBelum ada peringkat

- The Design Squad: Project Information Sheet The ClientDokumen2 halamanThe Design Squad: Project Information Sheet The ClientGayashan KulathungaBelum ada peringkat

- World Food Day & Boss'S Day: Good Morning Wayners, Happy WednesdayDokumen1 halamanWorld Food Day & Boss'S Day: Good Morning Wayners, Happy WednesdayGayashan KulathungaBelum ada peringkat

- CircularDokumen6 halamanCircularGayashan KulathungaBelum ada peringkat

- Whole Foods Demonstration KitchenDokumen17 halamanWhole Foods Demonstration KitchenGayashan KulathungaBelum ada peringkat

- 8350 FCM2041-U3 Cerberus PRO Modular Operator InterfaceDokumen4 halaman8350 FCM2041-U3 Cerberus PRO Modular Operator InterfaceGayashan KulathungaBelum ada peringkat

- Burn Stomach Fat Fast by Drinking This Before Going To Bed - Wishma LokayaDokumen2 halamanBurn Stomach Fat Fast by Drinking This Before Going To Bed - Wishma LokayaGayashan KulathungaBelum ada peringkat

- View Factor TablesDokumen2 halamanView Factor TablesGayashan KulathungaBelum ada peringkat

- Study About Energy Saving Control Strategies For Variable Air Volume SystemsDokumen2 halamanStudy About Energy Saving Control Strategies For Variable Air Volume SystemsGayashan KulathungaBelum ada peringkat

- Technical Papers Format - 2017Dokumen3 halamanTechnical Papers Format - 2017Gayashan KulathungaBelum ada peringkat

- Zoomlion QY55V - Overall DimensionDokumen2 halamanZoomlion QY55V - Overall DimensionGayashan KulathungaBelum ada peringkat

- MSD 2016 02SDokumen86 halamanMSD 2016 02SGayashan KulathungaBelum ada peringkat

- Vesak PPT - Implementation Details 7.02.2017Dokumen19 halamanVesak PPT - Implementation Details 7.02.2017Gayashan KulathungaBelum ada peringkat

- MATLABDokumen1 halamanMATLABGayashan KulathungaBelum ada peringkat

- Ezv 440Dokumen2 halamanEzv 440Gayashan KulathungaBelum ada peringkat

- Fan Coil Filters: AdvantagesDokumen1 halamanFan Coil Filters: AdvantagesGayashan KulathungaBelum ada peringkat

- Lighting CalculationsDokumen8 halamanLighting CalculationsGayashan KulathungaBelum ada peringkat

- DS-2B - Rain / Snow Sensor ControllerDokumen2 halamanDS-2B - Rain / Snow Sensor ControllerGayashan KulathungaBelum ada peringkat

- Zoomlion HBT100.18.195RSUDokumen1 halamanZoomlion HBT100.18.195RSUGayashan KulathungaBelum ada peringkat

- Vogele Supper 1800-2Dokumen2 halamanVogele Supper 1800-2Gayashan Kulathunga100% (3)

- Sany HBT80C-1818DIIIDokumen1 halamanSany HBT80C-1818DIIIGayashan KulathungaBelum ada peringkat

- Hamm 3410-Service KitsDokumen2 halamanHamm 3410-Service KitsGayashan KulathungaBelum ada peringkat

- Astm F 104 2002Dokumen12 halamanAstm F 104 2002Jamil SalmanBelum ada peringkat

- Vdocuments - MX - Name As Found in CBR Company Name Name As Found in CBR Company Name NaeemDokumen102 halamanVdocuments - MX - Name As Found in CBR Company Name Name As Found in CBR Company Name NaeemAli SyedBelum ada peringkat

- Sigmacover™ 380: Product Data SheetDokumen5 halamanSigmacover™ 380: Product Data SheetGibbs PerBelum ada peringkat

- Journal of Dental Research: Water Absorption and Water Solubility of Soft Lining Materials For Acrylic DenturesDokumen6 halamanJournal of Dental Research: Water Absorption and Water Solubility of Soft Lining Materials For Acrylic DenturesANJALI TMU StudentBelum ada peringkat

- Bearing Insulation Updates With SKF-1Dokumen3 halamanBearing Insulation Updates With SKF-1Shyam KumarBelum ada peringkat

- Plumbing Labour Rates Per Bathroom Rs 7,000 (Basic) To Rs 10,000 (Basic)Dokumen2 halamanPlumbing Labour Rates Per Bathroom Rs 7,000 (Basic) To Rs 10,000 (Basic)Franklun Ngaihte72% (18)

- Polyester Fibers: Fig.1: Production of Polyethylene TerephthalateDokumen12 halamanPolyester Fibers: Fig.1: Production of Polyethylene TerephthalateShailendra Mishra100% (1)

- A Guide To Common Plastics PDFDokumen1 halamanA Guide To Common Plastics PDFmuammal abbasBelum ada peringkat

- A New Standard For Repair and Maintenance of Installed Asbestos-Cement MaterialsDokumen6 halamanA New Standard For Repair and Maintenance of Installed Asbestos-Cement MaterialsGustavoBelum ada peringkat

- Ok - Montecolino Moquetas PDFDokumen5 halamanOk - Montecolino Moquetas PDFJavier Molina DelgadoBelum ada peringkat

- Jurnal Mesin Purifikasi Biogas Adsorben Arang Kulit Buah SiwalanDokumen9 halamanJurnal Mesin Purifikasi Biogas Adsorben Arang Kulit Buah Siwalanadji wicaksonoBelum ada peringkat

- Incinerattion of Waste SlidesDokumen19 halamanIncinerattion of Waste SlidesmanishaBelum ada peringkat

- Aw0028 TDS enDokumen2 halamanAw0028 TDS enSaqib NawazBelum ada peringkat

- Science: Quarter 4 - Module 3: Chemical ReactionDokumen30 halamanScience: Quarter 4 - Module 3: Chemical ReactionYanah NicoleBelum ada peringkat

- The Sustainability of Adobe Construction Past To FutureDokumen10 halamanThe Sustainability of Adobe Construction Past To FutureGuadalupe CuitiñoBelum ada peringkat

- Basic Wilderness Survival (By Jim Buller) - WorksheetsDokumen6 halamanBasic Wilderness Survival (By Jim Buller) - WorksheetsJo OhBelum ada peringkat

- Bellows Systems, Inc.: Company OverviewDokumen4 halamanBellows Systems, Inc.: Company OverviewRafik CherniBelum ada peringkat

- New Superalloys PPT Ssk3 RGDokumen34 halamanNew Superalloys PPT Ssk3 RGPrajwal BalapureBelum ada peringkat

- Testing As Per En-13121Dokumen2 halamanTesting As Per En-13121Sabir Nasim100% (1)

- Preco Concrete Accessories Catalog PDFDokumen36 halamanPreco Concrete Accessories Catalog PDFMarchus FontanillaBelum ada peringkat

- Böhler Folder Strip Cladding EN WEB PDFDokumen0 halamanBöhler Folder Strip Cladding EN WEB PDFCarlos Bermejo AlvarezBelum ada peringkat

- Lehigh CementDokumen7 halamanLehigh CementAhmed ElhosainyBelum ada peringkat

- Shaped Wire Compact Concentric-Lay-Stranded Aluminum Conductors, Coated-Steel Supported (ACSS/TW)Dokumen7 halamanShaped Wire Compact Concentric-Lay-Stranded Aluminum Conductors, Coated-Steel Supported (ACSS/TW)Anonymous uux1ScsBelum ada peringkat

- Chef5jan JunDokumen156 halamanChef5jan JunToxic AuraBelum ada peringkat

- Absorption Materials Used in Muffler-842Dokumen7 halamanAbsorption Materials Used in Muffler-842Kushal DhokareBelum ada peringkat

- U2S3-4 - Environmental Impact of Textile IndustriesDokumen9 halamanU2S3-4 - Environmental Impact of Textile IndustriesHieu100% (7)

- Rene Industries Limited General Test ProcedureDokumen2 halamanRene Industries Limited General Test ProcedureMubarak PatelBelum ada peringkat

- Article FS999 Instructions 8 23 2017Dokumen2 halamanArticle FS999 Instructions 8 23 2017ChomikBelum ada peringkat

- Dura Flow IND Spec SheetDokumen2 halamanDura Flow IND Spec SheetForum PompieriiBelum ada peringkat

- Guida Coprax Eng 2015 LightDokumen82 halamanGuida Coprax Eng 2015 Lightairsys7projec100% (1)