Process Flow Control Plan Worksheet

Diunggah oleh

Puneet SharmaDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Process Flow Control Plan Worksheet

Diunggah oleh

Puneet SharmaHak Cipta:

Format Tersedia

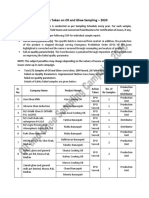

Supplier

Name:

FAT/FAI

Competition Date: Contact:

Supplier

Number:

Flow Chart

Revision Date: Contact Phone:

Location: Prepared By: Contact E-mail:

1 2 3 4 5 6 7 8 9 10 11

Insp Freq/Size or

Store Move Inspect Process

Certification

Review

Type of

Inspection # Out Sourced - Who

L-3 Communications Combat Propulsion Systems Supply Chain Management

Supplier Quality Assurance

QY-2 or QY-10 Flow Chart/Control Plan (FC/CP) Work Sheet

Refer To The Purchase Order

For Correct Quality Clauses

If your Purchase Order has a QY-2 or QY - 10 Clause, this form is to be completed per directions on the Process Flow/Control Plan Work Sheet.

(Check "Yes" on the Inspection Request Form in the "Our PO Has a QY-2 or QY-10 Clause" section)

Process Flow/Control Plan Worksheet

Step # Description of Process Step Work/Inspect Instructions Characteristic Inspected

Part Number:

Part Name:

P.O. Number:

Instructions on Following Page

1 2 3 4 5 6 7 8 9 10 11

Insp Freq/Size or

Store Move Inspect Process

Certification

Review

1

2

3,4,5,6

7

8

9

10

11

12

Process Flow/Control Plan Worksheet Instructions

Enter your specific inspection or work instruction numbers in this column.

Step # Description of Process Step Work/Inspect Instructions Characteristic Inspected

Type of

Inspection # Out Sourced - Who

Describe the actions or steps established in the event nonconformances are detected.

Enter the specific specification you are inspecting/measuring in this column if that applies. For receiving where you may be inspecting several characteristics, you can reference your receiving

inspection document and or the blue print as a link to that information.

Enter the gauge, tester, certification name/number ect. used to measure the specific characteristics listed in column 8. Also enter any specific inspection process techniques.

Enter inspection frequency (how often each shift for example) and sample size as it applies.

Enter the name of the company that does a specific operation if the process is outsourced (i.e. machining, plating, heat treat, ect.).

FILL IN THE APPROPRIATE INFORMATION IN THE HEADING SECTION OF THE DOCUMENT.

Enter the operation step process/number in this column. The flow should start with receiving inspection and end at the packing process for shipment to the customer.

Describe the process step in column 2. This should include any manufacturing, inspection, testing, etc. done on the product during processing.

These columns have symbols representing the process action store, move, inspect, process. Store used if you have a batching process where product is stored/held for future processing on a

different line or operation. Move would be used if transferring product from one station/line/building ect. to another is a significant step in your process (one where product handling ect. might

be important or have effect on the product for example). Inspect this represents any step in your process where raw materials, in process-sub assemblies, or finished goods are checked, tested,

audited, etc. and usually means some specification or critical to quality characteristic is being measured and data is being collected for evaluation. Process is any step that includes machining,

assembly, heat treat, stamping, molding, welding, - essentially any action done on the part to meet customer specifications. NOTE: CLICK UNDER THE APPROPRIATE SYMBOL AND PLACE AN X

IN THE CELL THAT BEST REPRESENTS THE ACTION (STORE, MOVE, INSPECT, PROCESS)

12

Reaction

Plan

L-3 Communications Combat Propulsion Systems Supply Chain Management

Supplier Quality Assurance

QY-2 or QY-10 Flow Chart/Control Plan (FC/CP) Work Sheet

Refer To The Purchase Order

For Correct Quality Clauses

If your Purchase Order has a QY-2 or QY - 10 Clause, this form is to be completed per directions on the Process Flow/Control Plan Work Sheet.

(Check "Yes" on the Inspection Request Form in the "Our PO Has a QY-2 or QY-10 Clause" section)

Process Flow/Control Plan Worksheet

Instructions on Following Page

12

Reaction

Plan

Process Flow/Control Plan Worksheet Instructions

Enter your specific inspection or work instruction numbers in this column.

Describe the actions or steps established in the event nonconformances are detected.

Enter the specific specification you are inspecting/measuring in this column if that applies. For receiving where you may be inspecting several characteristics, you can reference your receiving

inspection document and or the blue print as a link to that information.

Enter the gauge, tester, certification name/number ect. used to measure the specific characteristics listed in column 8. Also enter any specific inspection process techniques.

Enter inspection frequency (how often each shift for example) and sample size as it applies.

Enter the name of the company that does a specific operation if the process is outsourced (i.e. machining, plating, heat treat, ect.).

FILL IN THE APPROPRIATE INFORMATION IN THE HEADING SECTION OF THE DOCUMENT.

Enter the operation step process/number in this column. The flow should start with receiving inspection and end at the packing process for shipment to the customer.

Describe the process step in column 2. This should include any manufacturing, inspection, testing, etc. done on the product during processing.

These columns have symbols representing the process action store, move, inspect, process. Store used if you have a batching process where product is stored/held for future processing on a

different line or operation. Move would be used if transferring product from one station/line/building ect. to another is a significant step in your process (one where product handling ect. might

be important or have effect on the product for example). Inspect this represents any step in your process where raw materials, in process-sub assemblies, or finished goods are checked, tested,

audited, etc. and usually means some specification or critical to quality characteristic is being measured and data is being collected for evaluation. Process is any step that includes machining,

assembly, heat treat, stamping, molding, welding, - essentially any action done on the part to meet customer specifications. NOTE: CLICK UNDER THE APPROPRIATE SYMBOL AND PLACE AN X

IN THE CELL THAT BEST REPRESENTS THE ACTION (STORE, MOVE, INSPECT, PROCESS)

Anda mungkin juga menyukai

- Process Flow Control Plan WorksheetDokumen4 halamanProcess Flow Control Plan WorksheetMajdi JerbiBelum ada peringkat

- Process Flow/Control Plan WorksheetDokumen4 halamanProcess Flow/Control Plan WorksheetVu NguyenBelum ada peringkat

- Sudhan Ppap (Sem)Dokumen15 halamanSudhan Ppap (Sem)sudhans029Belum ada peringkat

- Introduction To Control PlansDokumen6 halamanIntroduction To Control Plansamarchavan894Belum ada peringkat

- PAPP Checklists and FormsDokumen27 halamanPAPP Checklists and FormsFazal AhmedBelum ada peringkat

- Anexo 06 - PA - Process Audit v1.1Dokumen19 halamanAnexo 06 - PA - Process Audit v1.1BalajiBelum ada peringkat

- Process AuditDokumen15 halamanProcess Auditdesurkarb100% (2)

- Understanding Control PlansDokumen5 halamanUnderstanding Control PlansVasant bhoknalBelum ada peringkat

- PAPP Checklists and FormsDokumen4 halamanPAPP Checklists and FormsA M100% (1)

- Essential Requirements of PPAPDokumen4 halamanEssential Requirements of PPAPeditor_ijtelBelum ada peringkat

- Purpose:: Customer's Finished Goods Demand ProcessDokumen13 halamanPurpose:: Customer's Finished Goods Demand ProcessLiew Chee KiongBelum ada peringkat

- Ppap, R&R, MsaDokumen8 halamanPpap, R&R, MsaArun SaigalBelum ada peringkat

- System Audit RequirementDokumen37 halamanSystem Audit Requirementavinashbatra171% (7)

- Cqi 9Dokumen55 halamanCqi 9Balram Ji0% (1)

- Production Part Approval Process (PPAP)Dokumen3 halamanProduction Part Approval Process (PPAP)psathishthevanBelum ada peringkat

- Quality ControlDokumen6 halamanQuality ControlEileen WongBelum ada peringkat

- Document and Change ControlDokumen12 halamanDocument and Change Controltrungthanhnguyen_83Belum ada peringkat

- CQI-9v3Forms and Process TablesBDokumen48 halamanCQI-9v3Forms and Process TablesBjkguru75Belum ada peringkat

- Validation Pharma Industry Pharmaceutics Pharmaceutical Validation PPTDokumen34 halamanValidation Pharma Industry Pharmaceutics Pharmaceutical Validation PPTAmit100% (3)

- Production Part Approval ProcessDokumen3 halamanProduction Part Approval ProcessjitenderbawaliaBelum ada peringkat

- PPAP ElementsDokumen2 halamanPPAP ElementsSenthil Kumar Gunasekaran50% (2)

- Cqi 9Dokumen49 halamanCqi 9Gurvinder SinghBelum ada peringkat

- Production ExecutionDokumen114 halamanProduction ExecutionVijayabhaskar PapanaBelum ada peringkat

- Copia de CQI-23Dokumen79 halamanCopia de CQI-23Ernesto Padilla100% (6)

- Auditando Un Sistema ValidacionDokumen8 halamanAuditando Un Sistema ValidacionIglesias LauraBelum ada peringkat

- PPAP Elements DescriptionDokumen3 halamanPPAP Elements DescriptionagungBelum ada peringkat

- ZEMC-3008 Eng GC2010 OQR0725Dokumen37 halamanZEMC-3008 Eng GC2010 OQR0725Nguyen Duong100% (2)

- Apqp PpapDokumen50 halamanApqp PpapEvandro Ribeiro50% (2)

- Validation in The Oil and Gas IndustryDokumen2 halamanValidation in The Oil and Gas Industryjagop91351Belum ada peringkat

- Sap QMDokumen33 halamanSap QMRohit shahi100% (1)

- Dokumen - Tips - Validation Pharma Industry Pharmaceutics Pharmaceutical ValidationDokumen34 halamanDokumen - Tips - Validation Pharma Industry Pharmaceutics Pharmaceutical ValidationAmjed AL-ShammkhBelum ada peringkat

- Clause Wise Tutorials-7.1.4 Change Control ExplanationDokumen2 halamanClause Wise Tutorials-7.1.4 Change Control ExplanationBharathBelum ada peringkat

- Process Capability and Statistical Process ControlDokumen8 halamanProcess Capability and Statistical Process ControlDeepakh ArunBelum ada peringkat

- SAP Calibiration ProcesDokumen20 halamanSAP Calibiration ProcesTarun ShakyaBelum ada peringkat

- Sabre: Inspection Processes.: ©2008 Rolls-Royce PLCDokumen13 halamanSabre: Inspection Processes.: ©2008 Rolls-Royce PLCisolongBelum ada peringkat

- Ppap-Template 4th EditionDokumen23 halamanPpap-Template 4th EditionAshutosh SinghBelum ada peringkat

- PPAP TemplatesDokumen23 halamanPPAP Templatestejesh77100% (1)

- SAP Revenue Audit Program SampleDokumen5 halamanSAP Revenue Audit Program SampleAshBelum ada peringkat

- Control PlanDokumen6 halamanControl PlanFahmy Khoerul HudaBelum ada peringkat

- Sps0610en Quality WallDokumen21 halamanSps0610en Quality Wallpatima_sv4875100% (1)

- Sap QMDokumen34 halamanSap QMtripathi_erBelum ada peringkat

- List of PPAP DocsDokumen4 halamanList of PPAP DocsSunilBelum ada peringkat

- 8 - Product Audit Checklist ASAP 7 11Dokumen10 halaman8 - Product Audit Checklist ASAP 7 11Sachin KumbharBelum ada peringkat

- Supplier Quality System AssessmentDokumen47 halamanSupplier Quality System Assessmentmehdi810Belum ada peringkat

- Appendix B - 20100903 - 145453Dokumen25 halamanAppendix B - 20100903 - 145453AkoKhalediBelum ada peringkat

- 2 Run at Rate ProcedureDokumen7 halaman2 Run at Rate ProcedureiandriiBelum ada peringkat

- SKF Mexico Jun 03 To 06 - 2013 - Self Audit - CQI-9 - Ed3Dokumen41 halamanSKF Mexico Jun 03 To 06 - 2013 - Self Audit - CQI-9 - Ed3Jorge Díaz BecerrilBelum ada peringkat

- Course Book - NDT Other InspnDokumen48 halamanCourse Book - NDT Other InspnRamya KuturuBelum ada peringkat

- But I've Always Done It This Way .. ": Do You Really Know What Is The Right WayDokumen43 halamanBut I've Always Done It This Way .. ": Do You Really Know What Is The Right Wayshashiv74Belum ada peringkat

- Cqi 9Dokumen39 halamanCqi 9korray1100% (1)

- Design ProcessDokumen7 halamanDesign Processrobert_kerr_29Belum ada peringkat

- Process Capability: Six Sigma Thinking, #4Dari EverandProcess Capability: Six Sigma Thinking, #4Penilaian: 5 dari 5 bintang5/5 (1)

- Cqi-9 Heat Threatment DetailsDokumen34 halamanCqi-9 Heat Threatment DetailshaydarkasnaklarBelum ada peringkat

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationDari EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationBelum ada peringkat

- Creating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowDari EverandCreating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowPenilaian: 4 dari 5 bintang4/5 (1)

- Practical Guide To Production Planning & Control [Revised Edition]Dari EverandPractical Guide To Production Planning & Control [Revised Edition]Penilaian: 1 dari 5 bintang1/5 (1)

- Pre-Dispatch Inspection ReportDokumen2 halamanPre-Dispatch Inspection ReportPuneet SharmaBelum ada peringkat

- SPC ChartsDokumen4 halamanSPC ChartsPuneet SharmaBelum ada peringkat

- Template FMEA5Dokumen5 halamanTemplate FMEA5Puneet SharmaBelum ada peringkat

- Supplier Template Document For: - Process Flow Diagram, - Pfmea, - Control PlanDokumen6 halamanSupplier Template Document For: - Process Flow Diagram, - Pfmea, - Control PlanPuneet SharmaBelum ada peringkat

- Six Sigma WorksheetsDokumen67 halamanSix Sigma WorksheetsPuneet SharmaBelum ada peringkat

- Part Submission Warrant - PSWDokumen2 halamanPart Submission Warrant - PSWPuneet Sharma100% (1)

- Process Capability Report Form06Dokumen4 halamanProcess Capability Report Form06Puneet SharmaBelum ada peringkat

- Quality Controls: Get Your Instruments Under Control!: Gérald Grégori, PH.DDokumen22 halamanQuality Controls: Get Your Instruments Under Control!: Gérald Grégori, PH.DPuneet SharmaBelum ada peringkat

- ToolingDokumen12 halamanToolingPuneet SharmaBelum ada peringkat

- Control Plan TemplateDokumen3 halamanControl Plan TemplatePuneet SharmaBelum ada peringkat

- PSWDokumen6 halamanPSWPuneet SharmaBelum ada peringkat

- Packing StandardDokumen1 halamanPacking StandardPuneet SharmaBelum ada peringkat

- Drafting FundamentalsDokumen828 halamanDrafting FundamentalsArun KumarBelum ada peringkat

- ARC Machine Tools (P) Ltd. Faridabad: YEAR 2012-2013 Master List of Instruments - Gauges Format NoDokumen1 halamanARC Machine Tools (P) Ltd. Faridabad: YEAR 2012-2013 Master List of Instruments - Gauges Format NoPuneet SharmaBelum ada peringkat

- New PFMEADokumen9 halamanNew PFMEAPuneet SharmaBelum ada peringkat

- Issue of HomosexualityDokumen4 halamanIssue of HomosexualityT-2000Belum ada peringkat

- What Has The Government and The Department of Health Done To Address To The Issues of Reproductive and Sexual Health?Dokumen5 halamanWhat Has The Government and The Department of Health Done To Address To The Issues of Reproductive and Sexual Health?Rica machells DaydaBelum ada peringkat

- KPC Drilling Rig AcceptanceDokumen3 halamanKPC Drilling Rig Acceptanceislam atifBelum ada peringkat

- NTJN, Full Conference Program - FINALDokumen60 halamanNTJN, Full Conference Program - FINALtjprogramsBelum ada peringkat

- Sol. Mock Test CBSE BiologyDokumen3 halamanSol. Mock Test CBSE BiologysbarathiBelum ada peringkat

- 220hp Caterpillar 3306 Gardner Denver SSP Screw Compressor DrawingsDokumen34 halaman220hp Caterpillar 3306 Gardner Denver SSP Screw Compressor DrawingsJVMBelum ada peringkat

- Hospital - Data Collection & Literature StudyDokumen42 halamanHospital - Data Collection & Literature StudyNagateja MallelaBelum ada peringkat

- ContinueDokumen2 halamanContinueNeal ReppBelum ada peringkat

- Derivative Investment!Dokumen24 halamanDerivative Investment!Asif Riaz100% (2)

- Manual of GardeningDokumen812 halamanManual of GardeningPrakash PatelBelum ada peringkat

- Iso 9227Dokumen13 halamanIso 9227Raj Kumar100% (6)

- 2-Product Spec PDFDokumen10 halaman2-Product Spec PDFMhooMOoChaappHteenBelum ada peringkat

- Checklist For Surge Arrester Rev00Dokumen3 halamanChecklist For Surge Arrester Rev00Santhosh Kumar VinayagamBelum ada peringkat

- Bitumen BasicsDokumen25 halamanBitumen BasicsMILON KUMAR HOREBelum ada peringkat

- Boeco BM-800 - User ManualDokumen21 halamanBoeco BM-800 - User ManualJuan Carlos CrespoBelum ada peringkat

- Energy Optimization of A Large Central Plant Chilled Water SystemDokumen24 halamanEnergy Optimization of A Large Central Plant Chilled Water Systemmuoi2002Belum ada peringkat

- COT RPMS Rating Sheet For MT I IV For SY 2021 2022 in The Time of COVID 19Dokumen2 halamanCOT RPMS Rating Sheet For MT I IV For SY 2021 2022 in The Time of COVID 19Don Mariano Marcos Elementary SchoolBelum ada peringkat

- Cemco T80Dokumen140 halamanCemco T80Eduardo Ariel Bernal100% (3)

- User Manual: 3603807 CONTACT US - 09501447202,8070690001Dokumen1 halamanUser Manual: 3603807 CONTACT US - 09501447202,8070690001Arokiaraj RajBelum ada peringkat

- Universal ING - LA.Boschi Plants Private LimitedDokumen23 halamanUniversal ING - LA.Boschi Plants Private LimitedAlvaro Mendoza MaytaBelum ada peringkat

- IB Final ShellDokumen25 halamanIB Final ShellsnehakopadeBelum ada peringkat

- Biology 1st Term PaperDokumen2 halamanBiology 1st Term PapershrirahulambadkarBelum ada peringkat

- Chi - Square Test: PG Students: DR Amit Gujarathi DR Naresh GillDokumen32 halamanChi - Square Test: PG Students: DR Amit Gujarathi DR Naresh GillNaresh GillBelum ada peringkat

- Full Test Bank For Health Economics and Policy 7Th Edition Henderson PDF Docx Full Chapter ChapterDokumen34 halamanFull Test Bank For Health Economics and Policy 7Th Edition Henderson PDF Docx Full Chapter Chapterpeeepochaq15d100% (9)

- Jurnal SOL MeningiomaDokumen6 halamanJurnal SOL MeningiomaConnie SianiparBelum ada peringkat

- BHP Billiton Petroleum Contract Letter For ABDUL SATTARDokumen5 halamanBHP Billiton Petroleum Contract Letter For ABDUL SATTARAbdul SattarBelum ada peringkat

- RMP ContractDokumen181 halamanRMP ContractHillary AmistosoBelum ada peringkat

- Adult Module 1 - Five Healthy Habits Handout (English) PDFDokumen2 halamanAdult Module 1 - Five Healthy Habits Handout (English) PDFKennedy FadriquelanBelum ada peringkat

- Missoula County Fairgrounds Phase 2Dokumen10 halamanMissoula County Fairgrounds Phase 2Olivia IversonBelum ada peringkat

- Action Taken On Oil and Ghee Sampling - 2020Dokumen2 halamanAction Taken On Oil and Ghee Sampling - 2020Khalil BhattiBelum ada peringkat

![Practical Guide To Production Planning & Control [Revised Edition]](https://imgv2-2-f.scribdassets.com/img/word_document/235162742/149x198/2a816df8c8/1709920378?v=1)