GE Frame 7EA Loss of Trip Oil Pressure

Diunggah oleh

nabil1608740 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

121 tayangan6 halamanA gas turbine was experiencing intermittent loss of flame trips during startup due to dropping high pressure trip oil pressure. The trip oil pressure would drop slowly over 10-15 seconds from 1300 PSI to 400 PSI, triggering safety valves to close and causing a trip. Troubleshooting efforts so far have ruled out issues with valves and solenoids, and found the low lube oil pressure alarm was likely unrelated. Next steps are to verify calibration of pressure switches and determine the trip point of the valve actuated by lube oil pressure.

Deskripsi Asli:

Judul Asli

GE Frame 7EA Loss of Flame

Hak Cipta

© © All Rights Reserved

Format Tersedia

DOCX, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniA gas turbine was experiencing intermittent loss of flame trips during startup due to dropping high pressure trip oil pressure. The trip oil pressure would drop slowly over 10-15 seconds from 1300 PSI to 400 PSI, triggering safety valves to close and causing a trip. Troubleshooting efforts so far have ruled out issues with valves and solenoids, and found the low lube oil pressure alarm was likely unrelated. Next steps are to verify calibration of pressure switches and determine the trip point of the valve actuated by lube oil pressure.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOCX, PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

121 tayangan6 halamanGE Frame 7EA Loss of Trip Oil Pressure

Diunggah oleh

nabil160874A gas turbine was experiencing intermittent loss of flame trips during startup due to dropping high pressure trip oil pressure. The trip oil pressure would drop slowly over 10-15 seconds from 1300 PSI to 400 PSI, triggering safety valves to close and causing a trip. Troubleshooting efforts so far have ruled out issues with valves and solenoids, and found the low lube oil pressure alarm was likely unrelated. Next steps are to verify calibration of pressure switches and determine the trip point of the valve actuated by lube oil pressure.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOCX, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 6

GE Frame 7EA Loss of Flame/TripOil

Posted by smd123 on 7 May, 2013 - 12:01 pm

Hi,

Background:

We have two GE Frame 7B turbine (converted to EA when we purchased them) running on natural gas. We

run in peaking mode, so winter runs are typically minimal. We did emissions tuning in spring of 2012 on

both units and ran heavily in summer of 2012 with no issues. This problem started occurring around April

2013 on only one of the units.

Problem Description:

After light off (900rpm), the unit will spool up to just below 1000RPM when the high pres. trip oil pressure

starts dropping (as seen on the gauges at the gas control house and on the turbine accessory compartment).

It goes from about 1300PSI down to 400PSI. The hydraulic oil pressure gauge in the sump indicates that it

remains at 1500PSI throughout the startup and trip.

Approximately 15 seconds after the pressure starts dropping, the SRV valve closes. 4 seconds later, the

GCV closes and we get a loss of flame trip at the same time. No other trips or alarms are present. We have

RPM, SRV position, GCV position, and trip timestamps from probably 12+ different occurrences of this

trip and they are all basically the same.

The trip oil pressure does NOT drop instantly. It takes about 10-15 seconds to reach 400PSI, which is

approximately when the SRV closes. We don't have a trip oil pressure transmitter, so this is approximate.

Finally, this problem does not occur consistently. Sometimes the unit starts right away, sometimes it starts

after one trip, and sometimes it takes multiple starts.

Other Info:

SRV and GVC calibrations both check out OK. We have stroked both valves

We have an L63QA (Lube Oil Pressure Low) alarm come in approximately 2 minutes before the loss of

flame alarm. From our drawings, it appears to be unrelated.

We have confirmed that our dump and trip solenoids are not causing this issue.

What would cause this type of pressure loss, and what can we do to trace it down?

Thanks,

Stephen

Reply to this post...

Posted by smd123 on 7 May, 2013 - 1:01 pm

More info - here is a link to a video of the pressure dropping.

http://www.youtube.com/watch?v=KjlolhfOKcg&feature=youtu.be

Reply to this post...

Posted by be_anon on 7 May, 2013 - 1:25 pm

Are you sure the low lube oil pressure is unrelated ? The Model B's I remember have a Low Bearing

Pressure Trip Valve which creates trip oil (OHT) from the hydraulic supply (OH). If lube oil header

pressure goes low (as suggested by the 63QA alarms), this trip valve trips OHT. The trip valve is shown on

the Control Oil schematic.

Reply to this post...

Posted by smd123 on 8 May, 2013 - 2:42 pm

Thanks for the reply!

Regarding the lube oil - I do see where the OH is turned into OHT before going to the overspeed bolt, SRV,

GCV, etc. This is a hydraulically operated valve (VHII-1 ??hard to read), which is operated by lube oil

pressure (25PSI on the drawing) coming through an electrically operated dump valve (20HD-1).

From day 1, this unit has had issues with lube oil pressure due to an unusually sized bearing (apparently

from the B to EA conversion). To "compensate", GE lowered the 63QT setpoint to 6.5PSI during

commissioning and installed a larger impeller on the lube oil pump.

The 63QA alarm has been coming in for the last couple years and we have never had a problem like this

before. Our normal operating pressure (as read on the lube oil gauge on the turbine accessory compartment)

is normally around 15 to 20 PSI.

During the last startup we did, the lube oil pressure fluctuated between 17 and 19 PSI. There was no

correlation to the loss of trip oil pressure.

Do these readings sound reasonable, or should we continue to look at the lube system? What pressure

would you expect the hydraulically operated valve VHII-1 to dump the OHT at?

Thanks,

Stephen

Reply to this post...

Posted by be_anon on 8 May, 2013 - 7:15 pm

In the one very old Model B instruction book I have, the control oil schematic doesn't even show any

device "name". (If yours has a device name, perhaps you can find it listed in the device summary ?)

Otherwise, unless someone on this forum knows the answer, a last resort might be to dig out a part number

and have GE look at the drawing (they have most very old drawings available on-line.) Maybe those GE

Controls Connect people that speak up from time to time on this forum can do it. (Would be an interesting

test to see how useful they are.)

Reply to this post...

Posted by be_anon on 9 May, 2013 - 9:43 am

It does seems odd how slow OHT drops in your video. I looked at some ancient transient data I have from a

test with pressure transducers on an similar vintage unit. When 20HD is de-energized, OHT drops to zero

within 1 second. Unless your OHT pressure gauge has a snubber valve that is slowing it down, it seems like

something else is going on.

Can you relate to anything else that's happening just below 1000 rpm when this occurs ? When it was

modified to a 7EA, were there any mods to the trip oil system (replacing Limitorque IGV actuator with

hydraulics, for example) ? You say you did emissions tuning, so if the unit is now DLN1, was the speed

ratio valve replaced with a low pressure trip oil version modified somehow to work with your high pressure

trip system ? It's simple to say, but hard to troubleshoot: could be trash floating around in the OHT supply

orifice, or perhaps a leak in the OHT system that is somehow intermittent.

Reply to this post...

Posted by smd123 on 9 May, 2013 - 12:21 pm

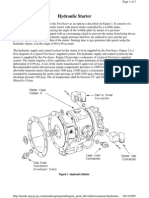

Here's an overview of our high pressure hydraulic system (as shown on prints):

1. Aux Hydraulic Supply Pump and Main Hydraulic Supply Pump each feed into check valves. We have a

pressure gauge after the check valves. This gauge remains at 1500PSI before, during, and after the trip.

2. After check valves, oil is fed into the filter. After the filter, this is the OH header and feeds three other

systems. We have a low pressure alarm 63HQ supposed to be set for 1350PSI. We are going to verify

calibration of this switch later today and that it brings an alarm in. This will confirm whether the problem is

with OH or not. From there, the oil feeds A) starting clutch B) IGV servo C) "Control Oil".

3. "Control Oil" then feeds into VHII-1 and VHII-2 which are hydraulically operated from 20HD-1 and

20HD-2 dump valves, respectively. VHII-1 and 2 both have orifices.

3A. VHII-2 feeds "OHT-2" to the trip valve for the IGV after going through an orificed check valve. Our

IGV drawing (which is several years older than the rest of our control oil drawings) calls the trip oil "OLT"

instead of "OHT", so it must have been retrofitted for a high pressure system.

3B. VHII-1 feeds the overspeed bolt, the GCV, and an orificed check valve that feeds SRV. The pressure

gauge after VHII-1 is in the video.

4. As mentioned, VHII-1 is actuated from 20HD-1 with Lube Oil pressure. After we check 63HQ's

calibration, we are going to try to slowly bleed the pressure down on the lube system (unit off, of course) to

see if we are near the tripping point of VHII-1.

5. From the check valve to the SRV, there is another gauge, L20FG trip solenoid, and three 63HG OHT

low switches. The gauge at this point exhibits the same behavior as the one in the video.

Other info:

-The 63HG switches are set low enough that we trip on flameout before we trip on loss of OHT. The

flameout trip is what causes the gauge to drop from 400PSI to 0PSI right away in the video.

-When we run the hydraulic system and force L20FG or L20HD off, we get instantaneous drops in

pressure, similar to what you describe. Our overspeed bolt trip lever and manual trip do the same. So, no

snubbers on the gauges.

-We thought maybe the SRV or GFV had some kind of leak. So we stroked each valve very slowly through

their positions during startup but it had no effect on OHT-1 pressure.

I guess the next step is to confirm that 63HQ is functioning correctly, and to see how our actual lube

pressure is to VHII-1's trip point. If both of those prove negative, we will know the leak is in OHT-1, but

not sure what to do from there.

Thanks again,

Stephen

Reply to this post...

Posted by MIKEVI on 9 May, 2013 - 7:13 pm

Stephen,

I am still trying to get my head around your trip oil system, I wish I had a oil schematic, I am more familiar

with the low pressure systems. I am going to look at some of the drawings I have to try and better

understand your system.

The two things that come to mind for me are these:

1) Since this system is flow limited from the orifices, could you have a leak in a fitting that is intermittent?

2) Is it possible that the overspeed bolt mechanism is leaking by sometimes causing a loss of pressure that

is not always there?

As said I am going to look at drawings I have and see if I can come up with any better ideas. Please keep us

informed!

Reply to this post...

Posted by smd123 on 10 May, 2013 - 3:50 pm

It is a bit difficult without seeing the prints. Unfortunately, all our drawings have proprietary stamps on

them...

More info...

1. We were looking at the wrong gauge for lube oil header pressure. The gauge we were looking at was the

emergency (electric) lube oil pump. We took a video of the entire gauge panel during the trip this morning.

On our second start, the unit came up to speed successfully. We tried two more times in the afternoon, both

were successful. We can post videos of the entire gauge panel for trip & successful start if that would be

useful.

2. The actual lube oil header pressure fluctuates around 10 PSI. We haven't been able to find our VHII-1

valve yet. Since we can't drain the lube oil header pressure, we are going to try to attach a pressure pump to

see where it starts to drop out at.

3. We have an inspection plate next to our overspeed bolt. We were able to reach in and push the

mechanism that the shaft rides on. It resulted in an instant drop of OHT. Therefore, we are quite certain the

bolt is not the problem.

4. We looked at our historical data. Around when our problem began, we had 6 consecutive failed starts.

After that, we had 4 successful runs. That was followed by 7 more failed starts, and then the three

successful startups today.

5. Since SRV, L20FG are downstream of an orifice, we are certain these are not related.

6. We have an inspection window in the dump area of the SRV and GCV. Both valves appear to drop a lot

of oil in midposition. We assume this is normal (?).

So, we're down to lube oil, VHII-1, or GCV.

Reply to this post...

Posted by smd123 on 10 June, 2013 - 1:50 pm

Just a quick update... we found that our VHII-1 valve (actuated from 25PSI lube oil) is right on the edge. It

appears that our lube oil pressure is marginal and drops slightly during startup, pinching off the supply to

OHT (but not actually dumping the fluid). We are now investigating the lube oil system.

Reply to this post...

Posted by MIKEVI on 11 June, 2013 - 9:04 am

Dear SMD,

thanks for the update to your problem. Please keep up with the information, it is always appreciated by

myself and the rest of the group!!

Reply to this post...

Posted by Dan on 24 December, 2013 - 9:21 pm

Hi,

My Background is:

I work where there are five GE Frame 7EA Gas Turbines with multiple conversions, one to DLN, upgrades

on compressors, combustion components, and also a control system upgrade.

Just a few suggestions:

It sounds to me like you may be getting low pressure on your hydraulic trip system from too low a pressure

on your lube oil bearing system. The lube oil system goes to 20HD-1 which in turn shuttles VH11-1, the

"Low Bearing Pressure Trip valve". This valve may start to drop out giving you the low hydraulic trip

pressure. You should also check the orifices in valve VH11-1. Our units have an orifice of .078' diameter

that feed the hydraulic trip system. also check to make sure the orifices on the liquid fuel system and gas

fuel systems are in place or not too big, which would drag down the hydraulic trip pressure. The orifices on

our fuel oil and gas systems are .020" diameter each.

Hopefully, this may help you in finding the problem.

Dan

Anda mungkin juga menyukai

- List of Illustrations: Lm6000 PD Gek 105061 Ge Industrial Aeroderivative Gas TurbinesDokumen4 halamanList of Illustrations: Lm6000 PD Gek 105061 Ge Industrial Aeroderivative Gas TurbinesJHONNATTAN RODRIGUEZBelum ada peringkat

- 09 IGV SystemDokumen5 halaman09 IGV Systemnabil160874100% (1)

- Pipe Sizing TablesDokumen20 halamanPipe Sizing Tablesangel darioBelum ada peringkat

- NewDokumen46 halamanNewsubhashnadakkalBelum ada peringkat

- Gas Turbines and Turbocompressors For LNG ServiceDokumen35 halamanGas Turbines and Turbocompressors For LNG ServiceRiza Agung NugrahaBelum ada peringkat

- MARKVE Getting A Better Understanding of Gas Turbine Control 1 2 3Dokumen92 halamanMARKVE Getting A Better Understanding of Gas Turbine Control 1 2 3nabil160874100% (1)

- BS Pani Fluid MechDokumen362 halamanBS Pani Fluid MechAnukool VikramBelum ada peringkat

- Basic Hydraulic Symbols and Major ComponentsDokumen31 halamanBasic Hydraulic Symbols and Major Componentsmnowaq100% (1)

- Dynamics Characteristics: Figure 1. LM2500-PE Estimated Load Rejection Transient PerformanceDokumen3 halamanDynamics Characteristics: Figure 1. LM2500-PE Estimated Load Rejection Transient PerformanceDenis JimenezBelum ada peringkat

- Feeder Protection and Control REF620: Application ManualDokumen164 halamanFeeder Protection and Control REF620: Application Manualnabil160874Belum ada peringkat

- GE MS6001B - EmissionDokumen33 halamanGE MS6001B - EmissionMohamad AfifBelum ada peringkat

- Ge Ms5001pDokumen14 halamanGe Ms5001pMohamed Hamed100% (1)

- Protections MarkVDokumen17 halamanProtections MarkVAndri Prodjodiprodjo100% (2)

- MCT Mkvie OmDokumen4 halamanMCT Mkvie Omnabil160874Belum ada peringkat

- MCT Mkvie OmDokumen4 halamanMCT Mkvie Omnabil160874Belum ada peringkat

- GT 9E StartupDokumen41 halamanGT 9E StartupNaveed IrshadBelum ada peringkat

- Igv 7eaDokumen2 halamanIgv 7eaSamir BenabdallahBelum ada peringkat

- Ger 3658d Speedtronic Mark V Gas Turbine Control System PDFDokumen19 halamanGer 3658d Speedtronic Mark V Gas Turbine Control System PDFyos100% (1)

- Dwyer A Young Franklin Actuators Frm6UG09Dokumen22 halamanDwyer A Young Franklin Actuators Frm6UG09JavierBelum ada peringkat

- Gas Turbine Cooling Requirements for Temperature ControlDokumen6 halamanGas Turbine Cooling Requirements for Temperature ControlDenis JimenezBelum ada peringkat

- Frame 9a5 DifinitionDokumen2 halamanFrame 9a5 Difinitionnabil160874Belum ada peringkat

- Watersheds and River Basins ActivityDokumen3 halamanWatersheds and River Basins Activityapi-330049990Belum ada peringkat

- MK IV Temp Control Curve ModificationDokumen6 halamanMK IV Temp Control Curve ModificationCris RonaldBelum ada peringkat

- Spectra RMS Molded Case Circuit Breakers: GEH-702 Users ManualDokumen52 halamanSpectra RMS Molded Case Circuit Breakers: GEH-702 Users Manualnabil160874100% (1)

- Testing Spark Plugs of Mark-V Control SystemDokumen21 halamanTesting Spark Plugs of Mark-V Control SystemMuhammad UsmanBelum ada peringkat

- How Moog servo valves operate and differences between simplex and TMR controllersDokumen5 halamanHow Moog servo valves operate and differences between simplex and TMR controllersMikoto Rifky100% (1)

- Better Understanding of Gas Turbine ControlDokumen117 halamanBetter Understanding of Gas Turbine ControlShahzad James100% (1)

- Calibrate Servo ValvesDokumen2 halamanCalibrate Servo ValvesChidiebere Samuel OkogwuBelum ada peringkat

- Figure 1. Hydraulic StarterDokumen3 halamanFigure 1. Hydraulic StarterDenis JimenezBelum ada peringkat

- Fuel System: PerformanceDokumen3 halamanFuel System: PerformanceDenis JimenezBelum ada peringkat

- Swirl AngleDokumen3 halamanSwirl AngleNIGERE100% (4)

- M&M at DLN1Dokumen8 halamanM&M at DLN1Muralimohan MolabantiBelum ada peringkat

- Servo Valve CalibrationDokumen19 halamanServo Valve Calibrationnabil160874Belum ada peringkat

- lIQUID FUEL SYSTEM PDFDokumen23 halamanlIQUID FUEL SYSTEM PDFJJBelum ada peringkat

- Med Riad: Sponsored by Control Technology Corp. ..Dokumen8 halamanMed Riad: Sponsored by Control Technology Corp. ..nabil160874Belum ada peringkat

- Gas Turbine Performance MonitoringDokumen109 halamanGas Turbine Performance MonitoringSamir Benabdallah100% (1)

- Gas Turbine Control SystemDokumen1 halamanGas Turbine Control SystemSreedev SureshbabuBelum ada peringkat

- 109T7219 - E - Network Topology PDFDokumen12 halaman109T7219 - E - Network Topology PDFnabil160874Belum ada peringkat

- Ge GT Tag NameDokumen6 halamanGe GT Tag NameHBNBILBelum ada peringkat

- Geh 6811 - 2Dokumen30 halamanGeh 6811 - 2nabil160874Belum ada peringkat

- Fundamentals of Speedtronic CopieDokumen21 halamanFundamentals of Speedtronic CopieHassanSaidiBelum ada peringkat

- Customer Course CatalogDokumen102 halamanCustomer Course Catalognabil160874Belum ada peringkat

- SBLM2500 IND 174rev1Dokumen7 halamanSBLM2500 IND 174rev1Daniil SerovBelum ada peringkat

- Gas Turbine ControlDokumen9 halamanGas Turbine ControlHBNBILBelum ada peringkat

- GE Power Systems Gas Turbine Speed Control Constant Settable DroopDokumen9 halamanGE Power Systems Gas Turbine Speed Control Constant Settable DroopZaki nouiBelum ada peringkat

- 109T7219 - E - Network Topology PDFDokumen12 halaman109T7219 - E - Network Topology PDFnabil160874100% (1)

- Design of AbsorberDokumen9 halamanDesign of Absorberhaseeb tahir50% (2)

- Sistema Hco EJC 145 (Colores)Dokumen92 halamanSistema Hco EJC 145 (Colores)JorgeBelum ada peringkat

- Membrane Treatment Processes Offer Versatility and Physical Barrier for Contaminant RemovalDokumen8 halamanMembrane Treatment Processes Offer Versatility and Physical Barrier for Contaminant RemovalbazediBelum ada peringkat

- I Am Wondering If There Is Any Value To Adding Cdms To My GT With Dln. Does Anyone Have These Systems? and If So Which Ones Would You RecommendDokumen11 halamanI Am Wondering If There Is Any Value To Adding Cdms To My GT With Dln. Does Anyone Have These Systems? and If So Which Ones Would You RecommendSahariar Bin ShafiqueBelum ada peringkat

- Null Bias ControlDokumen44 halamanNull Bias ControlAbderrahmane AyounBelum ada peringkat

- NIC 13.20 Rev.01Dokumen15 halamanNIC 13.20 Rev.01Mahmoud Ahmed100% (1)

- Gas Turbine Control ParametersDokumen16 halamanGas Turbine Control Parameterstetsa zangetsuBelum ada peringkat

- Som5462608 Opc ListDokumen82 halamanSom5462608 Opc Listbali abdelazizBelum ada peringkat

- February 2003 Subject: Troubleshooting Hydraulic Ratchet ProblemsDokumen4 halamanFebruary 2003 Subject: Troubleshooting Hydraulic Ratchet ProblemsKarim MuhammedBelum ada peringkat

- IGV, Servos and LVDT - Automation & Control Engineering ForumDokumen1 halamanIGV, Servos and LVDT - Automation & Control Engineering ForumHBNBILBelum ada peringkat

- Vol 01Dokumen153 halamanVol 01chandrasingh4564Belum ada peringkat

- Mnit001 Meter Manual PDFDokumen9 halamanMnit001 Meter Manual PDFSergio Andres Rivera JaramilloBelum ada peringkat

- T48 SpreadDokumen1 halamanT48 SpreadKarim MuhammedBelum ada peringkat

- Fact Sheet: GE Energy EX2100e Excitation Control For Gas Turbine GeneratorsDokumen2 halamanFact Sheet: GE Energy EX2100e Excitation Control For Gas Turbine Generatorsvcharles100% (1)

- 07 Gas Turbine Valves - 0Dokumen14 halaman07 Gas Turbine Valves - 0VILAS VIJAYANBelum ada peringkat

- 104T4691 - A Liquid FuelDokumen3 halaman104T4691 - A Liquid FuelseshatsBelum ada peringkat

- CPD When Operating at Base LoadDokumen1 halamanCPD When Operating at Base Loadvankayalasurya100% (1)

- LM2500 16th Stage Bleed Manifold KitDokumen2 halamanLM2500 16th Stage Bleed Manifold KitDenis JimenezBelum ada peringkat

- GE Air Valve Installation and Maintenance GuideDokumen7 halamanGE Air Valve Installation and Maintenance Guidecachuco1234Belum ada peringkat

- Nic 13.05Dokumen14 halamanNic 13.05BouazzaBelum ada peringkat

- Temperature Control at 19MW On MS5001Dokumen4 halamanTemperature Control at 19MW On MS5001chdi100% (1)

- Null BiasDokumen33 halamanNull BiasGoh Seng TakBelum ada peringkat

- Hydraulic SystmDokumen4 halamanHydraulic SystmArchana Choudhary100% (1)

- HI 800 251 Supplementary Sheet ELOP II Factory PDFDokumen4 halamanHI 800 251 Supplementary Sheet ELOP II Factory PDFBouazzaBelum ada peringkat

- DLN Controls Code Development 9fa+ EnhancedDokumen28 halamanDLN Controls Code Development 9fa+ Enhancednabil160874Belum ada peringkat

- Gas ValveDokumen9 halamanGas ValveJJBelum ada peringkat

- Exhaust Temp Spreads PDFDokumen2 halamanExhaust Temp Spreads PDFzoveisi100% (1)

- 125 V DC Fault AlarmDokumen7 halaman125 V DC Fault AlarmThetTinAungBelum ada peringkat

- GTST Protection TestDokumen3 halamanGTST Protection TestluriahBelum ada peringkat

- Adjust Axial Bently Nevada ProbesDokumen3 halamanAdjust Axial Bently Nevada Probesmic-grBelum ada peringkat

- Docslide - Us Servo Valve CalibrationDokumen19 halamanDocslide - Us Servo Valve CalibrationnboulegrouneBelum ada peringkat

- Servo Valve CalibrationDokumen19 halamanServo Valve Calibrationmohamed abourayaBelum ada peringkat

- Master the T-CLOCS Pre-Ride Safety Inspection in 15 MinutesDari EverandMaster the T-CLOCS Pre-Ride Safety Inspection in 15 MinutesBelum ada peringkat

- AbreviationDokumen2 halamanAbreviationnabil160874Belum ada peringkat

- Contacts and permissions for a field breaker switchDokumen3 halamanContacts and permissions for a field breaker switchnabil160874Belum ada peringkat

- AbreviationDokumen2 halamanAbreviationnabil160874Belum ada peringkat

- 389b3172ae B PDFDokumen31 halaman389b3172ae B PDFnabil160874Belum ada peringkat

- CS18214 Orbit - Q32019 - R1Dokumen8 halamanCS18214 Orbit - Q32019 - R1nabil160874Belum ada peringkat

- GE Frame 9E Gas TurbinesDokumen8 halamanGE Frame 9E Gas TurbinesbananosnetBelum ada peringkat

- I To Hmi Upgrades Product Overview EnglishDokumen2 halamanI To Hmi Upgrades Product Overview Englishnabil160874Belum ada peringkat

- ABB Protection CurvesDokumen60 halamanABB Protection Curvesnabil160874Belum ada peringkat

- 635345136746345000Dokumen28 halaman635345136746345000nabil160874Belum ada peringkat

- 7fatripoildualfuel 140301161154 Phpapp01Dokumen28 halaman7fatripoildualfuel 140301161154 Phpapp01Jeya PrakashBelum ada peringkat

- Voltage Protection and Control REU615: Standard ConfigurationsDokumen4 halamanVoltage Protection and Control REU615: Standard Configurationsnabil160874Belum ada peringkat

- Abb Ref615-2Dokumen186 halamanAbb Ref615-2frajaprBelum ada peringkat

- Classeur 1Dokumen345 halamanClasseur 1nabil160874Belum ada peringkat

- REF620 Product Guide 1MAC506635-PG Rev BDokumen64 halamanREF620 Product Guide 1MAC506635-PG Rev Bnabil160874Belum ada peringkat

- Newtb 141Dokumen7 halamanNewtb 141proxywarBelum ada peringkat

- Exhaust Temperature Spread 2Dokumen5 halamanExhaust Temperature Spread 2nabil160874Belum ada peringkat

- EM5367Dokumen17 halamanEM5367nabil160874Belum ada peringkat

- Example Diagnostic Report - UsDokumen72 halamanExample Diagnostic Report - UsQuick sickBelum ada peringkat

- HW1Dokumen1 halamanHW1HaeunMelloKimBelum ada peringkat

- D09222835 PDFDokumen8 halamanD09222835 PDFjade_rpBelum ada peringkat

- Enerpac High Pressure Pumps CatalogDokumen2 halamanEnerpac High Pressure Pumps CatalogTitanplyBelum ada peringkat

- KSB Influence of Pumps On Energy ConsumptionDokumen14 halamanKSB Influence of Pumps On Energy Consumption@sssBelum ada peringkat

- Metrology and Measurement Systems: Index 330930, ISSN 0860-8229 WWW - Metrology.pg - Gda.plDokumen14 halamanMetrology and Measurement Systems: Index 330930, ISSN 0860-8229 WWW - Metrology.pg - Gda.pleduryuBelum ada peringkat

- Calvert (1970)Dokumen5 halamanCalvert (1970)Mateus RochaBelum ada peringkat

- Worksheet - Pressure Losses and Pump Performance WorksheetDokumen10 halamanWorksheet - Pressure Losses and Pump Performance WorksheetUmair AnwarBelum ada peringkat

- VISCOPROPDokumen2 halamanVISCOPROPSamiir ÁlbertoBelum ada peringkat

- Tribology International 41 (2008) 296–306: Aeration effects on the performance of a turbocharger journal bearingDokumen11 halamanTribology International 41 (2008) 296–306: Aeration effects on the performance of a turbocharger journal bearingFrank WhittleBelum ada peringkat

- Introduction to Petroleum SystemsDokumen16 halamanIntroduction to Petroleum SystemsRizki KhikmawatiBelum ada peringkat

- Underbalanced Drilling (UBD) : Lesson 1Dokumen39 halamanUnderbalanced Drilling (UBD) : Lesson 1HunterBelum ada peringkat

- Dokumen - Tips - Screw Compressor Packages Grasso sp2 Operating Manual Documentsgrasso PackageDokumen42 halamanDokumen - Tips - Screw Compressor Packages Grasso sp2 Operating Manual Documentsgrasso PackageaeropheeBelum ada peringkat

- Me303-4 1 1Dokumen2 halamanMe303-4 1 1Tanesh SelvarajuBelum ada peringkat

- Rate of Flow Limiter Pilot Valve: Fuelling ProductsDokumen2 halamanRate of Flow Limiter Pilot Valve: Fuelling Productschristos79ersBelum ada peringkat

- RE 2 - M222CIL MPT PM LSP 3001 - Rev B1 PDFDokumen6 halamanRE 2 - M222CIL MPT PM LSP 3001 - Rev B1 PDFsumit kumarBelum ada peringkat

- Cirro R&O Oils: Key Features: Customer BenefitsDokumen2 halamanCirro R&O Oils: Key Features: Customer BenefitsJuan Carlos FernandezBelum ada peringkat

- Vortex Motion Study Visualizes Forced and Free Flow PatternsDokumen12 halamanVortex Motion Study Visualizes Forced and Free Flow PatternsPrantik SinhaBelum ada peringkat

- Groundwater Eng Geol 07Dokumen58 halamanGroundwater Eng Geol 07Raymart BulagsacBelum ada peringkat

- Discussion Conclusion Report FluidDokumen5 halamanDiscussion Conclusion Report Fluidnurlisa khaleeda100% (2)

- Self-Actuated Flaps For Passive Flow Separation ControlDokumen5 halamanSelf-Actuated Flaps For Passive Flow Separation ControlInternational Journal of Innovative Science and Research TechnologyBelum ada peringkat

- Distillation Columns Containing Structured Packings. A Comprehensive Model For Their Performance. 1. Hydraulic ModelsDokumen11 halamanDistillation Columns Containing Structured Packings. A Comprehensive Model For Their Performance. 1. Hydraulic ModelsJohan Sebastian Moreno LaraBelum ada peringkat

- A Physical Hydraulic Model of Saigon River in Southern VietnamDokumen5 halamanA Physical Hydraulic Model of Saigon River in Southern VietnamDương ÁnhBelum ada peringkat