GROWLER-6 WELL REPORT SUMMARIZES KEY FINDINGS

Diunggah oleh

Christabel AnteneroJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

GROWLER-6 WELL REPORT SUMMARIZES KEY FINDINGS

Diunggah oleh

Christabel AnteneroHak Cipta:

Format Tersedia

GROWLER-6 GEOLOGICAL WELL REPORT

GROWLER-6

PRL 15

EROMANGA BASIN

SOUTH AUSTRALIA

GEOLOGICAL WELL REPORT

L.E.L. BURGESS

(Consultant, Westminster Geological Pty Ltd)

April 2012

GROWLER-6 GEOLOGICAL WELL REPORT

CONTENTS PAGE

LOCATION MAP

WELL DATA CARD & SUMMARY

1.0 GENERAL INFORMATION 1

2.0 GEOLOGICAL INFORMATION 2

2.1 Drilling Rationale 2

2.2 Stratigraphic Summary 2

2.3 Seismic Summary 5

2.4 Hydrocarbon Summary 8

3.0 WELL EVALUATION 10

3.1 Wellsite Geology 10

3.2 Mud Logging 10

3.3 Cuttings Sampling 10

3.4 Coring 10

3.5 Sidewall Coring 11

3.6 Drill-Stem Testing 11

3.7 Hydrocarbon and Water Analyses 11

3.8 Wireline Logging 11

3.9 Log Interpretation 12

3.10 Net Pay Summary 12

3.11 Geothermal Gradient 13

4.0 CONCLUSIONS 14

FIGURES

1. Growler Field Seismic Amplitude Map 6

2. Growler Field Seismic Section through wells G3, G4, G5, G6 7

APPENDICES

1. Lithological Descriptions 4. Wireline Log Interpretation

2. Coring 5. Sample Manifest

(i): Core Description Logs

(ii): Table of Core Samples 6. Final Well Location Survey

(iii): Core Analysis Report

7. Location Site Map

3. Wireline Logging Reports

(i) Logging Order Form 8. Initial Completion Data

(ii) Wireline Logging Report

(iii) MFT Pressure Survey Data

ENCLOSURES

A. 1:200 Growler-6 Composite Log

B. 1:200 Growler-6 Mudlog

GROWLER-6 GEOLOGICAL WELL REPORT

LOCATION MAP

GROWLER-6 GEOLOGICAL WELL REPORT

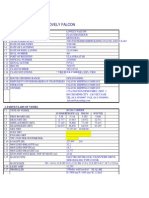

WELL DATA CARD

WELL DATA CARD

WELL: GROWLER-6 WELL TYPE: OIL DEVELOPMENT

BLOCK/LICENCE: PRL 15, South Australia STATUS: COMPLETED BIRKHEAD FM OIL WELL

TYPE TRAP: stratigraphically isolated channel-sandstones. TOTAL DEPTH: 1830.6m Drlr, 1826.7m Lgr

PROPOSED TOTAL DEPTH: 1850m, MDRT.

SEISMIC LOCATION:

Mollichuta 3D Seismic Survey (2008)

SPUDDED: 12:30 hrs, 17/10/2011

TD REACHED: 19:15 hrs, 1/11/2011

RIG RELEASED: 19:00 hrs, 5/11/2011

LONGITUDE: 139 34' 11.49" E

LATITUDE: 27 33' 59.91" S

(GDA 94, GRS80 Ellipsoid)

EASTING: 358817.89m

NORTHING: 6949985.95m

(MGA 94, Zone 54)

RIG: ENSIGN RIG-48

MAX DEVIATION: 2.6 at 1384m

MAX RECORDED TEMPERATURE: 92.4C at 1783.4m

ELEVATIONS (AHD): GROUND: 37.7m RT: 42.2m WELLSITE GEOLOGIST: LES BURGESS

CASING SIZE SHOE DEPTH TYPE

406mm (16") 12.0m, Driller -

244mm (9.625") 664m Driller and Logger 36 LB/FT K55, BTC

178mm (7") 1823.82m Driller 23 LB/FT N80, BTC

AGE FORMATION TOPS

DEPTH,

LOGGER (m)

TRUE

THICKNESS

HIGH (H)

LOW (L)

RT SSTVD* (m) (m)

L. PALEOCENE RECENT SURFICIAL TO EYRE FM 4.5 +37.7 131.5 0.2 H

LATE CRETACEOUS WINTON FORMATION 136.0 -93.8 577.9 38.2 H

EARLY LATE CRETACEOUS MACKUNDA FORMATION 714.0 -671.7 168.5 33.3 H

EARLY CRETACEOUS ALLARU MUDSTONE 882.5 -840.2 176.4 19.8 H

EARLY CRETACEOUS TOOLEBUC FORMATION 1059.0 -1016.6 17.0 13.4 H

EARLY CRETACEOUS WALLUMBILLA FORMATION 1076.0 -1033.6 287.8 14.4 H

EARLY CRETACEOUS CADNA-OWIE FORMATION 1364.0 -1321.4 58.0 4.6 H

EARLY CRETACEOUS MURTA FORMATION 1422.0 -1379.4 43.4 25.4 L

EARLY CRETACEOUS McKINLAY MEMBER 1465.5 -1422.8 4.5 10.8 L

EARLY - LATE CRETACEOUS NAMUR SANDSTONE 1470.0 -1427.3 26.0 5.3 L

LATE JURASSIC WESTBOURNE FORMATION 1496.0 -1453.3 153.9 16.7 H

LATE JURASSIC ADORI SANDSTONE 1650.0 -1607.3 36.9 9.3 L

LATE JURASSIC BIRKHEAD FORMATION (1) 1687.0 -1644.2 96.0 5.2 L

MIDDLE - LATE JURASSIC HUTTON SST (Main Porosity) 1783.0 -1740.2 47.6+ 13.8 H

TD 1830.6 -1787.8 N/A 20.2 H

N/A = NOT APPLICABLE. (1) Primary oil objectives. * Corrected for deviation.

CORING SUMMARY

CORE

NO.

FORMATION INTERVAL RECOVERY REMARKS

1 BIRKHEAD

1734.80-1744.42m, Dlr

1733.30-1742.92m, Lgr

9.62m, 100% TOP RESERVOIR AND SEAL

2 BIRKHEAD

1744.42-1753.90m, Dlr

1742.92-1752.40m, Lgr

9.48m, 100% RESERVOIR (to 1748m)

3 BIRKHEAD

1753.90-1763.60m, Dlr

1752.40-1762.10m, Lgr

9.70m, 100% WEAK FLUORESCENCE SHOWS

GROWLER-6 GEOLOGICAL WELL REPORT

WIRELINE LOGGING SUMMARY

RUN /

TRIP

TYPE OF LOG: FROM

(m)

TO

(m)

REMARKS

Standard resolution data (0.1m) 1690m to casing shoe.

High resolution (0.025m) TD - 1690m

1/1 SUPERCOMBO Max. temp 91C/196F at 1808m after 19.3hrs static mud.

GRGS

1808.8

5 GAMMA RAY TO SURFACE

SPDL

1813.1

664.4 SPONTANEOUS POTENTIAL

NPRL

1815

664.4 NEUTRON POROSITY (LIMESTONE MATRIX)

DEN/HDEN

1821.2

664.4/1690 BULK DENSITY

DCOR

1823.3

664.4 DENSITY CORRECTION FACTOR

CLDC

1828.9

664.4 DENSITY CALIPER

PDPE

1832.5

664.4 PHOTO-ELECTRIC

DT35

1836.5

664.4 SONIC, FIRST ARRIVAL, 36-60" INTERVAL^

MFE

1838.3

664.4 SHALLOW RESISTIVITY

DDLL-DSLL

1843.05

664.4 DEEP AND SHALLOW RESISTIVITY

MRRS

1828.6

664.4 INVADED ZONE RESISTIVITY

MATC

1847.5

664.4 CALIPER

1 / 2 GR-MFT 1791 1729.5

16 FORMATION PRESSURE SURVEYS

Max. temp 92.4C/198F at 1783m after 31hrs static mud.

NET PAY AND PERFORATIONS SUMMARY

LOG INTERPRETATION REMARKS PERFORATIONS

Interval, m

(Logger)

NET PAY

m

Vsh

%

%

SW

%

Birkhead Fm

1735.62-1738.42

2.80 36.7 17.7 70.1

1738.57-1738.62 0.05 44.6 14.0 58.4

1738.9-1739.37 0.48 34.0 19.2 57.0

1739.57-1745.23 5.65 15.4 22.9 36.6

1746.01-1747.78 1.78 29.0 19.0 50.7

TOTAL 10.75 24.2 20.7 47.1*

Not tested in the

open hole

1736.0-1747.5m

4.5", 5 spf, HMX, 39 gm.)

* Porosity weighted

GROWLER-6 GEOLOGICAL WELL REPORT

SUMMARY:

Growler-6 was an oil developm ent well drilled from late Oct ober to early November, 2011 in the Growler Field, PRL 15,

South Australia. The well was located 700m south-southeast of Growler-5 and 1km southeast of Growler-1.

Growler-6 was drilled as the first well in the Growler Field to test interpreted 3D seismic amplitude anomalies used to map

the mid-Birkhead oil reservoir. The well was to test fo r a s outhern ext ension of t he channel sandst one system, t o provide

valuable reservoir core data and to increase oil offtake. W ell spacing design was allowing each Growler well to drain

approximately 80 acres.

Growler-6 spudded on the 17th October 2011 and drilled a 311mm (12.25") hole to 666m. 244 mm (9.625") surface casing

was then run to 664m Driller and Logger. A 216mm (8.5") hole was drilled to 1734.8m, Driller, and three successive 89mm

(3.5") cores were cut into the mid Birkhead reservoir to 1763.6m. The cored section included the basal 2m of the reservoir

cap-rock (shale and siltstone). Following coring, drilling continued to a total depth at 1830.6m Driller, 1826.7m Logger (on-

bottom fill interpreted), terminating 47.6m below the top of the Hutton Sandstone Main Porosity.

During drilling and coring, oil shows were only recorded in the middle Birkhead Formation. Wireline logs were run at total

depth, at high-resolution across the reservoir zone, and at standard resolution to the casing shoe (GR to surface). A formation

pressure survey using the MFT tool was performed. Some reservoir depletion was measured in Growler-6.

The well was cased with 178mm (7") casing to 1823.82m, Driller. Ensign Rig-48 was released on the 5th November 2011

following the drilling operations.

Log interpretation, supported by core analysis, has interpreted 10.75m net oil pay in the Birkhead reservoir.

The Birkhead reservoir was perforated between 1736-1747.5m at 5 shots per foot. During initial production, oil free-flowed

at a rate of 1374 BOPD (barrels oil per day).

Growler-6 was successful in helping to verify the mapping of the Birkhead reservoir by seismic amplitude anomalies and

proved up a southern extension to the reservoir. The well was also a productive oil offtake well for the Growler Field.

L.E.L. BURGESS, MARCH 2012.

1

1.0 GENERAL INFORMATION

Well Name : Growler-6

Well Classification : Oil Development

Operator : Senex Energy Ltd

Participants : Victoria Oil exploration (1977) Pty Ltd 40%

Impress (Cooper Basin) Pty Ltd 25%

Permian Oil Pty Ltd 20%

Springfield Oil & Gas Pty Ltd 15%

Permit (Production Licence) : PRL 15, South Australia

Latitude : 27 33' 59.91" South (GDA 94)

Longitude : 139 41' 11.49" East

Northing : 6949985.95m (MGA 94, Zone 54)

Easting : 358817.89m

Seismic Station : Off seismic line, based on channel interpretation,

Mollichuta 3D Seismic Survey (2008)

Ground / RT Elevations : GL 37.7m AHD / RT 42.2m AHD

Proposed TD : 1850.0m RT, -1808.0m SSTVD (Driller)

Actual TD : 1830.6m RT, -1787.8m SSTVD (Logger)

Primary Objectives : mid Birkhead Formation - oil

Secondary Objectives : None

Status : Completed Oil Well

Drilling Contractor : Ensign International

Rig : Ensign Rig-48

Drilling Supervision : David Hair, Rocco Rossouw (consultants)

Geological Supervision : Les Burgess (Westminster Geological Pty Ltd)

Drilling Fluids : RMN Drilling Fluids

Mud Logging Services : Geoservices Overseas SA

Cementing Services : Halliburton Well Services

Wireline Logging : Weatherford

Core Handling & Analysis Services : Weatherford Laboratories (Australia) Pty Ltd

2

2.0 GEOLOGICAL INFORMATION

2.1 Drilling Rationale:

Growler-6 was an oil development well drilled 700m south south-east of Growler-5 to verify the

southern extension of, and to provide an oil offtake point for the mid Birkhead channel-sand mapped in

the Growler Field, PRL 15, South Australia (see Location Map).

The mapping was based on the 2008 Mollichuta 3D Seismic Survey and a seismic amplitude anomaly

interpreted to represent channel sand development. This geophysical technique was previously

successfully exploited in the nearby Snatcher Field. The middle Birkhead reservoir is interpreted as a

stratigraphically trapped system with no significant structural component.

There were no secondary hydrocarbon objectives for this well.

The well reached a total depth of 1830.6m (Driller), 1826.7m Logger (interpreted on-bottom fill) in the

Hutton Sandstone.

2.2 Stratigraphic Summary:

Growler-6 penetrated a true thickness of 1825.5m of Surficial, Lake Eyre Basin and Eromanga Basin

sediments (Surface to total depth of 1830.6mRT in the upper Hutton Sandstone). The final surveyed

drill-floor height (referred to as RT) was 42.2m above Australian Height Datum (AHD). Ground level

was 37.7m. All depths are Logger's.

The stratigraphic sequence intersected was as prognosed. The depth prognosis was based on average

velocity and formation data from adjacent wells. Of the formations of interest, the Birkhead Formation

was intersected 5.2m low and the Hutton Sandstone (Main Porosity) 13.8m high to prognosis

respectively. (See the stratigraphic table on the Wellcard).

A brief review of the Growler-6 stratigraphic sequence from total depth up to the top of the Cadna-owie

Formation follows. All depths mentioned are Logger's:

Growler-6 reached a total depth of 1830.6m RT, 47.6m below the top of the Hutton Sandstone (Middle

Jurassic). The top of m ain Hutton Sandstone porosity was defined by the appearance of dom inantly

medium to very coarse and occasionally granule si zed quartz grains deposited in generally bed-loaded

braided and meandering river sandstones. Grains th at were angular to rounded and poorly sorted, had

weak to occasional m oderately strong siliceous cem ent, friable to locally m oderately hard aggregates

and showed predominantly good to only minor poor visual porosity.

In places, subordinate intra-channel, over-bank and localised lacustrine siltstones and silty sandstones

occurred in the sequence. The siltstones were predominantly arenaceous and graded into silty sandstone.

Silty sandstones were very fine to fine and had poor porosity.

The bulk of the overlying Birkhead Formation (Middle to Late Jurassic) consisted of interbedded and

intergradational thin to relatively thick blocky to coarsening-upward channel and crevasse-splay

3

sandstones; intergradational silty sandstones and siltstones formed in fluvial flood-plain environments.

Upper Birkhead siltstones were likely formed in lacustrine conditions.

The lower Birkhead comprised some well developed fluvial sandstones with fine to medium and

occasionally coarse grains, had weak to minor strong siliceous or calcareous cement, local kaolinitic

matrix, occasional coal laminae and flakes, local mica and feldspar flakes and good to poor visual

porosity. Intergradational and interbedded silty sandstones were very fine to fine, angular to subrounded,

moderately well sorted, had weak to strong siliceous cement, common carbonaceous laminae and

fragments, silty matrix, lithics, feldspar, trace mica, firm to moderately friable aggregates and were

moderately friable to subfissile in parts with poor visual porosity. Siltstones were pale to medium grey,

argillaceous, occasionally laminated with very fine silty sandstone, had micro and macro mica, feldspar,

trace lithics, common coal specks to laminae grading to carbonaceous siltstone, were shaley in parts,

brittle to moderately friable where arenaceous and subfissile to sub blocky.

The channel sandstones of the mid Birkhead reservoir were dominantly very fine to medium grained,

moderately well-sorted, had weak to moderately strong calcareous and siliceous cement, were clean to

silty with common silt sized quartz matrix, were friable to moderately hard and had good to poor visual

porosity. Cores displayed cross and current bedding features, zones of high energy deposition with large

siltstone breccia from channel bank collapse, rip-up clasts and scoured bases and intervening intervals of

quieter deposition with horizontal, finely laminated bedding.

Above the mid Birkhead reservoir zone, generally finer grained clastics deposited in deeper and 'quieter'

water seem to dominate. Porosity was mainly poor in silty and calcareous sandstones.

The upper Birkhead comprises argillaceous siltstone with intergradational claystone from lacustrine

deposition.

The Birkhead Formation was the primary oil objective for the well. Oil fluorescence shows were

recorded from 1731-1775m. Three successive cores were cut from the base of the overlying siltstone

seal to water saturated sandstones below the reservoir in Growler-6.

Overlying the Birkhead floodplain sequence was the Adori Sandstone (Late Jurassic). This

widespread unit of generally massive, bed-loaded braided river sands typically comprised fine to very

coarse and occasionally pebble sized poorly sorted quartz grains with weak to minor strong siliceous

cement and mainly very good porosity. No oil has been found in the Adori Sandstone.

The Westbourne Formation (Late Jurassic) also comprised well developed, braided-river sands

deposited in relatively high energy environments like the underlying Adori Sandstone but zones within

the Westbourne Formation were also deposited in less energetic meandering to floodplain environments.

These tended to be finer grained and had more matrix. Sandstones were very fine to medium,

moderately well sorted, had weak to moderately strong siliceous cement, local to common silt sized

quartz, argillaceous and occasional kaolinitic matrix, traces of coal, lithics and mica and formed firm to

moderately friable aggregates with fair to good porosity.

Lying between the better developed fluvial channel sandstones were intergradational silty sandstone

units, very fine to fine and occasionally medium and commonly matrix dominated, and arenaceous to

minor argillaceous siltstones formed as overbank, abandoned channel fill and lacustrine deposits.

The relatively thin (26m) Namur Sandstone (Late Jurassic to Early Cretaceous) consisted

predominantly of massive, well-developed sandstones. The major Namur sandstones were clear to

translucent and occasionally white and off-white, had fine to occasionally very coarse grains (and

occasional granule sized grains and pebble fragments in parts) and mainly poorly sorted aggregates. The

4

aggregates were predominantly clean though local silt and kaolinite matrix was present. The siliceous

cement was predominantly weak and inferred and visual porosity was good to excellent.

The base of the Namur Sandstone in this area has been defined as the top of the first moderately well

developed finer grained and generally siltier floodplain deposits lying below the Namur massive

sandstone, i.e, the top of the Westbourne Formation. In reality the Namur Sandstone and Westbourne

Formation could be combined into one formation as elsewhere in the Eromanga Basin where massive

sandstones dominate.

Lying above Namur Sandstone was the McKinlay Member (Early Cretaceous) of the Murta

Formation. This thin (4.5m) floodplain zone lacked major sandstone development.

The McKinlay Member merged up into the lacustrine to deltaic-floodplain deposits of the Murta

Formation (Early Cretaceous). This formation consisted predominantly of thinly interbedded

siltstones, silty sandstones and occasional thin sandstones. The general GR log profile of the sandstones

and their morphology suggests they could have been derived as lacustrine deltaic units. Better quality,

cleaner, sandstones may have been worked by waves to enhance porosity. Localised calcareous cement

may have been deposited by changes in mineral-saturated ground water levels. Cyclical subsidence of

the deltaic system would have flooded the sandstones leading to further siltstone deposition.

The Murta siltstone was typically off white to light and medium grey, occasionally pale to medium

brown-grey, arenaceous grading to silty and kaolinitic sandstone, had micro-feldspar, micro-

carbonaceous and lithic inclusions, was commonly banded with coal, mica flakes and microlithics on

bedding planes and was blocky to firm and occasionally friable. Sandstones were thin and mainly

coarsening and cleaning-upward, were fine to very fine and occasionally medium with traces of coarse

grains in part, and were friable to firm and hard where calcareous. Porosity was generally tight to poor.

Common silty sandstones were pale coloured, very fine to fine to occasionally medium, moderately well

sorted, had weak to strong calcite and siliceous cement, common silt sized quartz, carbonaceous and

argillaceous matrix, were firm to friable and hard poor to occasionally fair porosity.

The Murta Formation conformably merged into the Cadna-owie Formation (Early Cretaceous). This

formation comprised interbedded silty sandstones and siltstone with increasing calcareous sandstones

becoming more common higher up in the formation.

The sandstones were predominantly translucent to pale grey and pale grey-brown becoming off-white

higher in the sequence as kaolinitic matrix increased. Aggregates were very fine to fine, locally medium

in the upper sections, had subangular to subrounded quartz grains, were poorly to well sorted, had weak

to moderately strong calcareous cement, contained common feldspar, micromica and lithic and

occasional minor glauconite accessories. Porosity was occasionally fair but predominantly poor to tight.

Intergradational silty to argillaceous (kaolinitic) sandstones were light to medium grey and off-white,

had very fine to fine quartz grains, well-sorted and weakly cemented (generally calcareous cemented)

aggregates and abundant silt and kaolinitic matrix. Interbedded siltstones were medium to light grey,

predominantly arenaceous grading to silty sandstone, occasionally carbonaceous, and had common

feldspar and lithic inclusions. Cuttings were friable to sub blocky.

On wireline log profiles, the Cadna-owie Formation was seen to progressively 'clean up' through the

sequence from predominantly siltstone and silty sands, at the base, to a sandy uppermost section with

calcareous sandstones towards the top. The environment of deposition for this formation was interpreted

5

to be parallic/lagoonal. As the sea transgressed into the region, the sequence represented the transition

between the underlying terrestrial deposits and overlying shallow marine sediments.

For general stratigraphic information on formations lying above the Cadna-owie Form ation, refer to an

earlier Growler well report.

Detailed lithological descriptions of the sequence from drilled cuttings are contained in Appendix 1.

These descriptions are also presented on the composite log.

2.3 Seismic Summary:

Based on seismic amplitude data from the Mollichuta 3D Seismic Survey, it was interpreted that a gross

mid Birkhead channel sandstone system of between 15-20m thick can be mapped in the Growler and

Snatcher fields area. The channel sandstone had been identified in Growler wells 1,2, 3,4 and 5.

Growler-6 was the first well to test this interpretation in the Growler Field and was to prove up a

southern extension to the reservoir, see Figures 1 and 2.

Formation tops were intersected relatively close to prognosis. The Murta Formation prediction (25.4m

low) was erroneous and should have been around 20m deeper. The Westbourne Formation (16.7m high)

may not be a firm regional pick being based on the first relatively thick sequence of finer grained

clastics lying below the coarse grained Namur Sandstone braided river sediments. Similarly, the top

Hutton Main Porosity was based on the onset of coarse to very coarse-grained sandstone and may vary

locally due to facies variations.

The target Birkhead Formation was intersected 5.2m low to prognosis.

FIGURE 1: GROWLER FIELD SIESMIC AMPLITUDE MAP

FIGURE-2: GROWLER FIELD SEISMIC SECTION

8

2.4 Hydrocarbon Summary:

The primary oil objective for the well was the mid Birkhead Formation channel sandstones productive in

the older five Growler wells.

During drilling, oil shows were recorded in the Birkhead Formation from 1731m (cuttings), lying above

the thin upper seal of the main reservoir section. The first oil show in the reservoir section was at

1736.8m in Core-1.

A summary of the oil fluorescence shows follows.

TABLE 1: SUMMARY OF OIL FLUORESCENCE SHOWS

LOGGER'S DEPTH,

(mMD)

(Driller's depths were

1.5m deeper than

Logger's based on core

vs log GR correlations).

DESCRIPTION

GAS SHOWS, (units)

Peak/Background

Composition

C1:C2:C3:C4:C5

Birkhead Formation

1729.5m

TRACE SHOW

(spot sample): trace pale yellow, even, slow diffuse pale blue

cut, thin pale blue residue film from tight calcareous sandstone.

3/1

27:0:0:25:48

1729.5-1732.5m

FAIR SHOW

40% of sandstone had fluorescence, pale yellow, even, good

blooming pale blue cut, aggregates leached of fluorescence, thin

pale blue film residue in very fine to fine, slightly calcareous

sandstone with fair to poor porosity, no oil odours or oil in mud.

8/3

27:0:0:25:48

CORE-1

1735.3-1737.8m

1737.8-1738.4m

1739.3-1739.4m

1740.4-1740.7m

1742.1-1742.2m

1742.5-1742.6m

GOOD SHOWS

100% to variable, solid to banded and patchy pale yellow, slow

diffuse to instant, occasionally slow to moderately fast

streaming pale blue cut, generally thin to occasionally

moderately thick pale blue film residue, aggregates often

leached of fluorescence. Weaker shows on surface may have

been due to partial flushing by coring. Freshly broken surfaces

and mud log shows did not suggest that a transitional oil-water

zone had been intersected.

1735.3-1736.5m

42/2, 45:0:0:23:32

1736.5-1742.9m,

base of core:

55/2, 14:1:2:31:52.

1730.5-1737.5m

1739.9-1740.4m

1742.5-1742.9m

(base of core)

FAIR SHOWS

Fluorescence: as above. Gas: as above.

CORE-2

1742.9-1744.9m

GOOD SHOW

100% bright pale blue, even, instant diffuse then slow streaming

pale blue cut, aggregates leached of fluorescence, moderately

thick yellow blue ring to film residue from very fine to coarse

sandstone with good porosity strong oil odours.

50, 14:1:2:31:52

1746.0-1746.5m

FAIR TO GOOD

SHOW

100% pale blue, moderately bright, even, very slow streaming

cut, sample leached of fluorescence, thin pale blue film. Core

'weeping' oil from fine to medium sandstone.

60/20, 14:0:2:31:53

1746.9-1747.25m

FAIR TO POOR SHOW

100% dull pale blue, even, instant weak diffuse to very slow

streaming cut, sample leached of fluorescence, thin pale blue

film. Core 'weeping' oil, strong oil odours.

30, 14:1:2:29:54.

9

LOGGER'S DEPTH,

(mMD)

(Driller's depths were

1.5m deeper than

Logger's based on core

vs log GR correlations).

DESCRIPTION

GAS SHOWS, (units)

Peak/Background

Composition

C1:C2:C3:C4:C5

1747.25-1748.95m

FAIR TO POOR SHOW

100% dull pale blue, even, instant weak diffuse to very slow

streaming cut, sample leached of fluorescence, thin pale blue

film, trace oil odours.

40, 14:1:2:29:54

1749.3-1749.5m

FAIR SHOW.

100%, moderately bright pale blue, even, very slow streaming

cut, sample leached of fluorescence, thin pale blue film. Core

'weeping' oil from fine to very fine friable sandstone, strong oil

odours.

35, 14:1:2:29:54.

1749.5-1750.9m

POOR to FAIR SHOW

100%, moderately bright pale blue, even, very slow pale blue

streaming cut, sample leached of fluorescence, thin pale blue

film. Core 'weeping' oil from fine to very fine, hard to

moderately hard sandstone with poor visual porosity, no oil

odours.

30/20, 14:1:2:29:54

1750.9-1751.0m

FAIR SHOW

100%, fluorescence dull to moderately bright yellow, even,

slow streaming to blooming cut, thin pale blue film residue

from very fine to fine sandstone with poor to fair porosity, core

weeping oil, good oil odours.

30/20, 14:1:2:29:54

1752.05-1752.4m

(base of core)

FAIR SHOW

100% as above in moderately hard to hard sandstone with poor

visual porosity, strong oil odours.

20, 14:1:2:29:54

CORE-3

1752.8-1753.1m

FAIR TO POOR SHOW

mild to strong oil odours

1753.35-1753.6m

FAIR SHOW

mild to strong oil odours

1753.9-1754.5m

FAIR TO POOR SHOW

mild to strong oil odours

1755.05-1755.5m

FAIR SHOW

mild oil odours

1755.7-1756.5m

FAIR TO POOR SHOW

weak oil odours

1756.5-1758.5m,

1759.7-1759.8m,

1760.0-1760.2m,

1760.75-1760.85m

POOR SHOWS

weak oil odours

1761.5-1762.1m

POOR SHOW

dull yellow, very weak oil odours

Gas levels were very

low when cutting

Core-3.

The breakdown was

100% C5 (measurable)

with assumed heavier

hydrocarbons beyond

iC5.

Only trace oil films

were seen in 1m mud

samples.

1762.1-1773.5m

FAIR SHOW

50% decreasing to 10% bright yellow, even, slow to streaming

to blooming pale yellow cut , thin film residue from sandstone

with good porosity. No oil in mud.

17 units

30:0:0:7:63

10

Gas Shows:

There were no significant gas shows denoting potential gas-reservoirs in this well. The highest

hydrocarbon gas peaks were from oil fluorescence zones, where the presence of oil in the mud increased

hydrocarbon levels as seen on the table above and composite and mudlogs.

11

3.0 WELL EVALUATION

3.1 Wellsite Geology:

Geological supervision of the drilling, testing and logging phases from surface to total depth was

provided by Les Burgess (Westminster Geological Pty Ltd). The composite log (Enclosure A) was also

constructed by the author.

3.2 Mud Logging:

Mud logging services were provided by Geoservices Overseas SA from surface to TD. Equipment

available included sensors for recording and monitoring depth, total and chromatographic gas,

fluorescence, mud-pit levels, weight on bit (WOB), RPM and torque. Refer to Enclosure B for the 1:200

metric mudlog.

3.3 Cuttings Sampling:

The following cutting samples were taken at the wellsite:

Cuttings, Washed and Dried one set for DMITRE (Department for Manufacturing, Innovation, Trade,

Resources and Energy) and one set for Senex Energy Ltd.

Nominal (dependent on drilling speed) 30m sampling from 11m to 660m, 10 from 660-1370m and 3m

intervals from 1370m to total depth at 1830m , Dr iller. Additional spot sam ples were taken over

hydrocarbon shows. Refer to the sample manifest, Appendix 5.

3.4 Coring:

Three full-hole 102m m (4") diam eter cores were cut in this well for Birkhead reservoir and top seal

evaluation.

TABLE 2: SUMMARY OF FULL-HOLE CORES

CORE

NO.

FORMATION INTERVAL RECOVERY REMARKS

1 BIRKHEAD

1734.80-1744.42m, Dlr

1733.30-1742.92m, Lgr

9.62m, 100% TOP RESERVOIR AND SEAL

2 BIRKHEAD

1744.42-1753.90m, Dlr

1742.92-1752.40m, Lgr

9.48m, 100% RESERVOIR (to 1748m)

3 BIRKHEAD

1753.90-1763.60m, Dlr

1752.40-1762.10m, Lgr

9.70m, 100% WEAK FLUORESCENCE SHOWS

Samples were sealed at the wellsite for W eatherford laboratory analysis. The relationship between

porosity and permeability is practically linear, as expected. Porosity reduction at overburden (pressured)

status is approxim ately 1% less than m easured at am bient, surface conditions. Perm eability was

significantly reduced at overburden conditions.

12

The core has been used to support log interpreted net pay in Growler-6 and to calibrate wireline log

interpretation, such as m atching porosities. Special Core Analysis (SCAL) is program med for the

reservoir core well which may further define net pay.

The core description logs, sample lists and analysis data are also included in Appendix 2.

3.5 Sidewall Coring:

No sidewall cores were obtained in Growler-6.

3.6 Drill-Stem Testing:

No drill-stem tests were run in Growler-6.

3.7 Hydrocarbon and Water Analyses:

There were no formation water or hydrocarbon samples obtained in Growler-6.

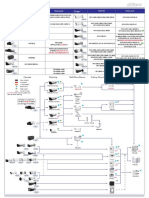

3.8 Wireline Logging:

Weatherford conducted the wireline logging at total depth. Run-1 was the Supercombo suite run

comprising resistivity, gamma-ray, sonic, neutron and density tools. Logs were run in high-resolution

mode from total depth to above the Birkhead Formation and in standard resolution mode to the casing

shoe at 664m. The gamma ray was run through the casing to close to surface.

Run-2 comprised the MFT formation pressure evaluation tool. A total of 16 pressure surveys were

recorded in the Birkhead Formation and upper Hutton Sandstone. Refer to Appendix 3 (iii).

TABLE 2: LOGGING RUN SUMMARY

RUN /

TRIP

TYPE OF LOG: FROM

(m)

TO

(m)

REMARKS

Standard resolution data (0.1m) 1690m to casing

shoe. High resolution (0.025m) TD - 1690m

1/1 SUPERCOMBO Max. temp 91C/196F at 1808m after 19.3hrs static

mud.

GRGS 1808.8 5 GAMMA RAY TO SURFACE

SPDL 1813.1 664.4 SPONTANEOUS POTENTIAL

NPRL 1815 664.4 NEUTRON POROSITY (LIMESTONE MATRIX)

DEN/HDEN 1821.2 664.4/1690 BULK DENSITY

DCOR 1823.3 664.4 DENSITY CORRECTION FACTOR

CLDC 1828.9 664.4 DENSITY CALIPER

PDPE 1832.5 664.4 PHOTO-ELECTRIC

DT35 1836.5 664.4 SONIC, FIRST ARRIVAL, 36-60" INTERVAL^

MFE 1838.3 664.4 SHALLOW RESISTIVITY

DDLL-DSLL 1843.05 664.4 DEEP AND SHALLOW RESISTIVITY

MRRS 1828.6 664.4 INVADED ZONE RESISTIVITY

MATC 1847.5 664.4 CALIPER

1 / 2 GR-MFT 1791 1729.5

16 FORMATION PRESSURE SURVEYS. Max.

temp 92.4C/198F at 1783m after 31hrs static mud.

13

Hole conditions were very good in this well. The well was generally in gauge with minor washouts of up

to 2" at 1560m and 1520m. The hole was washed out through the interval 1490-1380m but was

predominantly in gauge up to the casing shoe at 664m.

The wireline logging order form and report can be seen in Appendix 3.

3.9 Log Interpretation:

This report presents a wireline data evaluation produced by the author of this report. Parameters used in

the interpretation were based on local and regional sources and included core data. The interpretation

was based on both objective and subjective evaluation. Core porosity results closely matched the

calculated log interpretation porosities.

Conventionally for the Growler Field, net pay was only defined where there was oil fluorescence. With

limited water-resistivity values, low water saturation values may indicate potential oil pay in fully water

saturated zones.

The log interpretation report is included in Appendix 4.

3.10 Net Pay Summary:

A total of 10.75m of net oil pay had been interpreted from logs in the mid Birkhead channel sandstone

reservoir. Core analysis results and rock examination tend to support this pay estimate.

This pay is summarised tabulated below:

TABLE 3: SUMMARY OF INTERPRETED OIL PAY

LOG INTERPRETATION RESULTS

Interval, m

(Logger)

NET PAY

m

Vsh

%

%

SW

%

Birkhead Fm

1735.62-1738.42

2.80 36.7 17.7 70.1

1738.57-1738.62 0.05 44.6 14.0 58.4

1738.9-1739.37 0.48 34.0 19.2 57.0

1739.57-1745.23 5.65 15.4 22.9 36.6

1746.01-1747.78 1.78 29.0 19.0 50.7

TOTAL 10.75

Net sand cut-offs were porosity 8% or greater and shale volume 45% or lower. The nominal water

saturation cut-off was 75%.

14

3.11 Geothermal Gradient:

The geothermal gradient for the well has been constr ucted from temperature data obtained from the two

logging runs. The following data were available:

TABLE 4: TEMPERATURE DATA SUMMARY

SOURCE TEMPERATURE

C

DEPTH (Lgr),

m

TIME SINCE

LAST CIRCULATION, HRS

LOG RUN-1, SUPERCOMBO

AT MAXIMUM

TEMPERATURE DEPTH

91 1808 19.3

LOG RUN-2, HIGHEST MFT

RECORDED TEMPERATURE

92.4 1783 31

The extrapolated stabilised formation temperature at total depth was based on temperatures recorded by

the supercombo logs, Run-1, and the maximum MFT pressure survey temperature at 183m, 92.4C.

Generally, a static mud circulation time of 35 hrs is considered long enough for the mud to reach

geologic temperature. For Growler-6 a maximum temperature of 93C (200F) has been used.

After subtracting an assumed, constant surface temperature of 21C, and incorporating the total depth of

1830.6m, the geothermal gradient for the well was extrapolated as 3.93C/100m.

The geothermal gradient plot is presented below:

Geothermal Gradient

0

200

400

600

800

1000

1200

1400

1600

1800

2000

0 20 40 60 80 100 120 140

Extrap. BHT

93 C @ 1830.6m

21 C

Ambient

Surface Temp

GROWLER-6

Geothermal Gradient

= 3.93C / 100m

D

E

P

T

H

,

m

TEMP, DEG C

SENEX ENERGY LTD

GROWLER-6

15

4.0 CONCLUSIONS

Growler-6 was a successful oil developm ent well which supported the geophysical seism ic amplitude

modelling in the area by intersecting a well developed m id Birkhead channel sandstone reservoir

section.

The well also extended the m id Birkhead reservoir limits southwards and provided valuable reservoir

and cap-rock core data. The well will be a good offtake point for oil drainage.

During initial production oil free-flowed from the Birkhead at a rate of 1374 BOPD.

APPENDICES

APPENDIX 1:

(i) LITHOLOGICAL DESCRIPTIONS

1

This appendix summarises lithological data from the Cadna-owie Formation to total depth by facies

intervals as indicated by sample and log data. All depths are Logger's, RT (42.2m). Thicknesses are true

corrected from deviation results.

CADNA-OWIE FORMATION (EARLY CRETACEOUS)

1364.0-1422.0m, TRUE THICKNESS: 58.0m

1364.0-1389.0 DOMINANTLY CALCAREOUS SANDSTONE WITH MINOR SILTY SANDSTONE AND

SILTSTONE__

CALCAREOUS KAOLINITIC SANDSTONE: off-white, very fine to occasionally fine and

medium, well-sorted, subrounded to rounded, weak to moderately strong calcareous cement,

common kaolinitic matrix grading to argillaceous sandstone, minor glauconite, coal, lithics and

mica, firm to moderately friable, poor visual porosity, no fluorescence.

SANDSTONE: mottled off-white/pale green/pale brown/pale brown-grey, very fine to

medium, generally fine, moderately well sorted, rounded to subangular, weak to moderately

strong calcareous and local siliceous cement, local kaolinitic matrix, common feldspar, trace

glauconite, mica and lithics, firm to friable, tight to poor porosity, no fluorescence.

SILTY SANDSTONE: medium brown-grey, predominantly very fine grading to arenaceous

siltstone, well-sorted, subrounded to subangular, slightly calcareous, local feldspar and mica,

trace carbonaceous fragments, firm to moderately hard, poor visual porosity, no fluorescence.

SILTSTONE: medium to dark grey, medium brown-grey, generally laminated with very fine

silty sandstone and sandstone, slightly calcareous, trace coal, local feldspar, firm to soft, sub

blocky to amorphous.

LIMESTONE: trace yellow brown, micritic, blocky, hard.

1389.0-1422.0m PREDOMINANTLY SILTY SANDSTONE WITH INTERGRADATIONAL SANDSTONE

AND SILTSTONE__

SILTY SANDSTONE: medium to pale grey, off-white in parts, fine to mainly very fine

grading to arenaceous siltstone, well-sorted, subrounded to subangular, slightly calcareous,

common kaolinitic matrix, local feldspar and mica, trace carbonaceous fragments, firm to

moderately hard, poor visual porosity, no fluorescence.

SANDSTONE: dark to light grey, very fine to fine, moderately well sorted, angular to

subrounded, weak siliceous and minor calcareous cement, com feldspar, carbonaceous specks,

laminated in parts with silty sandstone and siltstone, firm to moderately friable, poor to fair

visual porosity, no fluorescence.

SILTSTONE: dark grey, arenaceous grading to silty sandstone, weak siliceous cement,

carbonaceous in parts, firm to friable, occasionally sub blocky.

MURTA FORMATION (EARLY CRETACEOUS).

1422.01465.5m TRUE THICKNESS: 43.4m

1422.0-1451.0m SILTSTONE WITH INTERBEDDED SANDSTONE AND TRACE LIMESTONE__

SILTSTONE: medium to light grey, minor medium brownish-grey, generally arenaceous

grading to very fine sandstone, common mica, occasional carbonaceous specks, trace feldspar,

firm to friable, occasional sub blocky.

SANDSTONE: light to medium grey, very fine to occasionally fine, moderately well sorted,

subrounded to subangular, weak siliceous cement, clean to local silt matrix, friable, poor to fair

porosity, no fluorescence.

SANDSTONE: clear to translucent quartz, fine to very coarse, poorly sorted, rounded to

angular (bit fractured), weak siliceous cement, trace kaolinitic matrix, generally clean, good

inferred porosity, no fluorescence.

SILTY SANDSTONE: as above.

2

1451.0-1465.5m SANDSTONE WITH INTERBEDDED SILTSTONE__

SANDSTONE: light grey, very fine to fine, moderately well sorted, angular to subrounded,

weak siliceous and minor calcareous cement, common feldspar, carbonaceous specks,

laminated in parts with silty sandstone and siltstone, firm to moderately friable, poor to fair

visual porosity, no fluorescence.

SILTY SANDSTONE: white/pale grey, very fine to fine to occasionally medium clear to

translucent and minor brown translucent quartz, moderately well sorted, subrounded to sub

angular, weak to moderately strong siliceous cement, common to abundant kaolinitic and silty

matrix, mica, firm to friable, poor to tight visual porosity, no fluorescence.

SILTSTONE: medium to light grey, off-white, argillaceous in parts, generally arenaceous

grading to sandstone, micaceous, common very fine quartz, firm to occasionally moderately

friable, sub blocky in parts.

McKINLAY MEMBER (EARLY CRETACEOUS).

1465.51470.0m TRUE THICKNESS: 4.5m

1465.5-1470.0m THIN COARSENING-UPWARD SANDSTONE WITH INTERBEDDED SILTY

SANDSTONE AND SILTSTONE__

SANDSTONE: clear to translucent quartz, fine to very coarse, poorly sorted, rounded to

angular (bit fractured), weak siliceous cement, trace kaolinitic matrix, generally clean, good

inferred porosity, no fluorescence.

SILTY SANDSTONE: white/pale grey, very fine to fine to occasionally medium clear to

translucent and minor brown translucent quartz, moderately well sorted, subrounded to sub

angular, weak to moderately strong siliceous cement, common to abundant kaolinitic and silty

matrix, mica, firm to friable, poor to tight visual porosity, no fluorescence.

SILTSTONE: medium to light grey, off-white, argillaceous in parts, generally arenaceous

grading to sandstone, micaceous, common very fine quartz, firm to occasionally moderately

friable, sub blocky in parts.

NAMUR SANDSTONE (LATE JURASSIC TO EARLY CRETACEOUS)

1470.0-1496.0m, TRUE THICKNESS: 26.0m

1470.0-1496.0 MASSIVE SANDSTONE: clear to translucent quartz, very fine to coarse and occasionally

granule, very poorly sorted, rounded to angular (bit fractured), disaggregated, clean, very good

inferred porosity, no fluorescence.

WESTBOURNE FORMATION (LATE JURASSIC)

1496.0-1650.0m, TRUE THICKNESS: 153.9m

1496.0-1526m SANDSTONE WITH INTERBEDDED SILTSTONE AND SILTY SANDSTONE__

SANDSTONE: as above with light brown to off white argillaceous matrix in parts.

SILTY SANDSTONE: white/pale grey/pale brown-grey, very fine to fine, occasionally

medium, moderately well sorted, subangular to subrounded, weak to moderately strong

siliceous cement, common kaolinitic matrix, silty in parts, micromica, firm to occasionally

friable, poor to tight visual porosity, no fluorescence.

SILTSTONE: dark grey, argillaceous to arenaceous, common very fine quartz, coal and mica,

friable to firm, sub blocky in parts.

3

1526-1551m INTERBEDDED SILTSTONE, SILTY SANDSTONE AND SANDSTONE__

SILTSTONE: dark grey, argillaceous to arenaceous, common very fine quartz, coal and mica,

friable to firm, sub blocky in parts.

SILTY SANDSTONE: white/pale grey/pale brown-grey, very fine to fine, occasionally

medium, moderately well sorted, subangular to subrounded, weak to moderately strong

siliceous cement, common kaolinitic matrix, silty in parts, micromica, firm to occasionally

friable, poor to tight visual porosity, no fluorescence.

SANDSTONE: clear to translucent quartz, fine to very coarse, poorly sorted, rounded to

angular (bit fractured), weak siliceous cement, trace kaolinitic matrix, generally clean, good

inferred porosity, no fluorescence.

1551-1585m MASSIVE SANDSTONE: clear to translucent and milky white, rare pink, red and yellow

(citrine) quartz, very fine to very coarse and occasionally granule sized, very poorly sorted,

rounded to angular (bit fractured), disaggregated, clean, very good inferred porosity, no

fluorescence.

1585-1599m FINELY INTERBEDDED SANDSTONE, SILTY SANDSTONE AND SILTSTONE__

SANDSTONE: as above predominantly fine to medium, good porosity, no fluorescence.

SILTY SANDSTONE: patchy pale brown/white, very fine to fine and occasionally medium,

moderately well sorted, rounded to subangular, weak siliceous cement, com kaolinitic and clay

matrix, occasional mica flakes, trace coal, friable, poor visual porosity, no fluorescence.

SILTSTONE: medium to light brown-grey, arenaceous grading to silty sandstone, common

micro sand laminae ,trace mica, coal and lithics, firm to friable, trace pyrite, friable to

occasionally sub blocky.

1599-1610m SANDSTONE: clear to translucent quartz, very fine to medium, poorly sorted, rounded to

angular (bit fractured), disaggregated, clean, very good inferred porosity, no fluorescence.

1610-1650m FINELY INTERBEDDED SANDSTONE, SILTY SANDSTONE, SILTSTONE AND

TRACES OF COAL__

SANDSTONE: patchy to laminated pale brown/white, very fine to fine, occasionally medium,

moderately well sorted, angular to subrounded, weak to moderately strong siliceous cement,

local silty matrix, argillaceous in parts, trace coal, mica and lithics, firm to moderately hard,

poor visual porosity, no fluorescence.

SANDSTONE: clear translucent quartz, fine to medium, occasionally coarse, poorly sorted,

rounded to subangular, generally loose, good inferred porosity, no fluorescence.

SILTY SANDSTONE: patchy pale brown/white, very fine to fine and occasionally medium,

moderately well sorted, rounded to subangular, weak siliceous cement, com kaolinitic and clay

matrix, occasional mica flakes, trace coal, friable, poor visual porosity, no fluorescence.

SILTSTONE: medium to light brown-grey, dark grey to black where carbonaceous,

argillaceous and moderately firm to generally arenaceous grading to silty sandstone, common

micro sand laminae and lenses, trace mica, coal and lithics, occasional disseminated and

nodular pyrite, firm to friable, trace pyrite, friable to occasionally sub blocky.

COAL: black, sub vitreous, conchoidal to subconchoidal fracture surfaces, banded in parts,

brittle to firm.

ADORI SANDSTONE (LATE JURASSIC)

1650.0-1687.0m, TRUE THICKNESS: 36.9m

1650-1671m MASSIVE SANDSTONE: clear to minor translucent quartz, rare pink to yellow grains, fine to

very coarse, occasional granules, very poorly sorted rounded to subangular, disaggregated,

good inferred porosity, no fluorescence.

4

1671-1677m SILTSTONE WITH INTERBEDDED SANDSTONE__

SILTSTONE: dark grey, argillaceous, massive to laminated in parts, trace mica, firm, blocky.

SILTSTONE: medium to dark grey, arenaceous, very fine quartz in parts, local sandstone

laminae, argillaceous matrix in parts, firm, sub blocky to blocky.

SILTY SANDSTONE: medium to light grey, fine to very fine, common silt sized quartz

grains, well-sorted, weak to moderately strong siliceous cement, local feldspar, slightly

calcareous, firm to friable, poor visual porosity, no fluorescence.

SANDSTONE: clear to minor translucent quartz, fine to very coarse, poorly sorted rounded to

subangular, disaggregated, good inferred porosity, no fluorescence.

1677-1687m MASSIVE SANDSTONE: clear to minor translucent quartz, fine to very coarse, occasional

granules, very poorly sorted, rounded to subangular, generally disaggregated, good inferred

porosity, no fluorescence.

BIRKHEAD FORMATION (MIDDLE TO LATE JURASSIC)

1687.0-1783.0m, TRUE THICKNESS: 96.0m

1687-1698m PREDOMINANTLY SILTSTONE WITH INTERBEDDED CLAYSTONE, SILTY

SANDSTONE AND SANDSTONE__

SILTSTONE: dark brown-grey, argillaceous to occasionally arenaceous grading to silty

sandstone in parts, common very fine quartz grains, micromica, coal fragments, firm, sub

blocky to blocky, occasionally subfriable.

CLAYSTONE: dark grey, firm, waxy texture, striated conchoidal fracture surfaces, massive,

firm, sub blocky.

SANDSTONE: (10%) patchy white/brown/black/translucent aggregates, fine to very fine,

moderately well sorted, subangular to subrounded, weak siliceous cement, local kaolinitic

matrix, common coal fragments, moderately friable to firm, poor visual porosity, no

fluorescence.

1698-1702.5m SILTSTONE WITH INTERBEDDED SANDSTONE AND TRACE CLAYSTONE__

SILTSTONE: brownish black, argillaceous to arenaceous as above, firm to occasionally

moderately friable where arenaceous, sub blocky to blocky.

SANDSTONE: (10%) clear to translucent quartz, very fine to medium, occasionally coarse,

poorly sorted, subangular to subrounded, weak siliceous cement, local kaolinitic matrix, trace

lithics and coal, friable to occasionally firm, poor to fair visual porosity, no fluorescence.

CLAYSTONE: as above.

1702.5-1710m SANDSTONE WITH MINOR INTERGRADATIONAL SILTY SANDSTONE AND

SILTSTONE__

SANDSTONE: clear to translucent quartz, very fine to medium, occasionally coarse, poorly

sorted, subangular to subrounded, weak siliceous cement, local kaolinitic matrix, trace lithics

and coal, friable to occasionally firm, poor to fair visual porosity, no fluorescence.

SILTY SANDSTONE: dark to medium brown grey, very fine to fine, common silt sized quartz

grains matrix, moderately well sorted, weak to moderately strong siliceous cement, argillaceous

matrix in parts, trace coal, firm to friable, poor porosity, no fluorescence.

5

1710-1725m CALCAREOUS SANDSTONE WITH INTERBEDDED SILTY SANDSTONE AND

SILTSTONE__

CALCAREOUS SANDSTONE: mottled pale brown/white/pale grey/translucent aggregates,

fine to very coarse, poorly sorted, rounded to angular, occasional pitted surfaces, weak to

moderately strong white calcareous cement, silty and argillaceous in parts, local coal

fragments, trace mica, poor visual porosity, fair to poor inferred porosity, firm to hard,

occasionally friable,

SILTY SANDSTONE: pale brown grey, mottled white/pale brown, very fine to fine, common

silt sized quartz matrix, moderately well sorted, weak to moderately strong calcareous cement,

argillaceous matrix in parts, trace coal and mica, firm to friable, poor porosity, no fluorescence.

SILTSTONE: dark to medium grey, predominantly argillaceous, laminated in parts with very

fine silty sandstone, occasionally carbonaceous, firm to brittle, blocky to sub blocky.

1725-1734.8m SANDSTONE WITH MINOR INTERGRADATIONAL SILTY SANDSTONE AND THIN

SILTSTONE__

SANDSTONE: pale brown, white, translucent aggregates, very fine to medium, predominantly

fine, moderately well sorted, angular to subrounded, weak to moderately strong calcareous and

siliceous cement, clean to locally silty, friable to firm and moderately hard, poor to fair

porosity. FLUORESCENCE: maximum 40% of sandstone at 1733-34m.

SILTY SANDSTONE: as above

SILTSTONE: as above

CORE-1 DESCRIPTIONS, 1734.80-1744.42m

1734.8-1736.8 FINELY INTERBEDDED SILTSTONE, CLAYSTONE AND SUBORDINATE SILTY

SANDSTONE__

SILTSTONE: medium to dark grey, argillaceous grading to claystone in parts, occasional very

fine quartz grains, trace mica, blocky to sub blocky, firm to brittle.

CLAYSTONE: light to medium grey, occasional brownish grey, massive, waxy texture in

parts, subconchoidal fracture surfaces, firm, blocky.

SILTY SANDSTONE: pale brown-grey, very fine to silt sized quartz grains, well-sorted, well-

sorted, subangular to subrounded, clay matrix supported to occasional moderately strong

calcareous cement, occasional coal microlaminae and fragments, micaceous in parts, local

feldspar, firm to occasionally friable, occasionally soft, tight to very poor porosity.

1736.8-1741.5m PREDOMINANTLY SANDSTONE WITH OCCASIONAL SILTY SANDSTONE,

CARBONACEOUS SILT AND RARE COAL LAMINAE__

SANDSTONE: typically pale grey aggregates, clear to translucent quartz, very fine to fine with

gradational medium to coarse units (multi stacked, thin fining-upward sequences), moderately

well sorted to poorly sorted, subrounded to subangular and minor angular, common silt sized

quartz in finer grained beds, occasional subhedral recrystallised quartz, weak to locally

moderately strong siliceous cement, rare calcareous cement, generally clean aggregates but

local mica and coal fragments, friable to firm and occasionally hard, good to poor visual and

inferred porosity. CORE FLUORESCENCE: from 1736.8m.

SILTY SANDSTONE: as above with minor coal mica and fragments, poor visual porosity, no

fluorescence.

CARBONACEOUS SILTSTONE: dark grey to black, argillaceous to occasionally arenaceous,

common disseminated coal, occasional vitreous to sub vitreous coal laminae and fragments,

local mica, occasional very fine quartz, firm, blocky to sub blocky, occasionally subfissile

where very carbonaceous.

COAL: black, vitreous to sub vitreous, subconchoidal fracture surfaces, blocky, cleated,

friable.

6

1741.5-1743.7 SANDSTONE WITH INTERBEDDED COALY AND SILTY LAMINAE AND 30-40

DIPPING BEDS__

SANDSTONE: medium to light grey aggregates, translucent to clear quartz, medium to fine,

local very fine and silt sized quartz grains, moderately well sorted, angular to subrounded,

weak to moderately strong siliceous cement, minor kaolinitic matrix, firm to friable, fair visual

porosity. FLUORESCENCE: moderately dull pale yellow, slow diffuse pale blue cut,

aggregates leached of fluorescence. POOR to GOOD SHOW.

CARBONACEOUS SILTSTONE: dark grey/black, arenaceous to argillaceous, common to

abundant vitreous to sub vitreous blocky coal fragments, mica, occasional very fine quartz,

firm, blocky to occasionally subfissile.

1743.7-1744.4

END CORE-1

SANDSTONE: pale yellow brown aggregates (oil stained), translucent to clear quartz, fine to

very fine and occasionally medium, moderately well sorted, angular to subrounded, moderately

strong to strong siliceous cement, occasional subhedral recrystallised quartz, occasional mica,

siltstone laminae in parts, hard to moderately hard, poor visual porosity. FLUORESCENCE:

GOOD SHOW as above with strong oil odours.

CHIP

DESCRIPTIONS

CORE-2 DESCRIPTIONS, 1744.42-1753.90m

1744.95m SANDSTONE WITH MINOR CARBONACEOUS LAMINAE__

SANDSTONE: pale yellow brown aggregates (oil stained), translucent to clear quartz, very

fine to coarse, generally medium to fine, poorly sorted, angular to subrounded, occasional

subhedral recrystallised quartz, weak siliceous cement, generally clean, common silt sized

quartz grains, occasional coal and silt fragments, friable to moderately hard in parts, good to

fair visual porosity. FLUORESCENCE: 100% with strong oil odours. GOOD SHOW.

CARBONACEOUS SILTSTONE: black, dark grey, common to abundant sub vitreous to

vitreous coal, mica, argillaceous matrix in parts, firm to occasionally friable.

1746.7-1747.5 SANDSTONE WITH ABUNDANT VERY FINE DARK BROWN CARBONACEOUS

AND SILT LAMINAE__

1746.7m SANDSTONE: pale grey, off-white, very fine to fine, well-sorted, angular to subrounded,

moderately strong to strong siliceous cement, local kaolinitic and silty matrix, common mica,

coal and dark grey brown silty sandstone laminae, occasional feldspar and lithics, moderately

hard, generally hard, poor to no visual porosity. FLUORESCENCE: 40% with oil odours.

1747.75-1748.6 MASSIVE SANDSTONE

1747.75m SANDSTONE: pale yellow brown aggregates (oil stained), translucent to clear quartz, very

fine to medium, generally fine, poorly sorted, angular to subrounded, occasional subhedral

recrystallised quartz, weak siliceous cement, generally clean, common silt sized quartz grains,

occasional coal and silt fragments, friable to moderately hard in parts, good to fair visual

porosity.

FLUORESCENCE: 100% as above with oil odours.

1748.6-1749.55 SANDSTONE WITH COMMON CARBONACEOUS AND SILT LAMINAE.

1748.5m SANDSTONE: pale grey, off-white, very fine to fine, well-sorted, angular to subrounded,

moderately strong to strong siliceous cement, local kaolinitic and silty matrix, common mica,

coal and dark grey brown silty sandstone laminae, occasional feldspar and lithics, moderately

hard, generally hard, poor to no visual porosity. FLUORESCENCE: 100% dull pale blue

with oil odours. FAIR to POOR SHOW.

7

1749.5m SANDSTONE: pale yellow brown aggregates (oil stained), translucent to clear quartz, very

fine to fine, poorly sorted, angular to subrounded, strong to occasionally weak siliceous

cement, generally clean, common silt sized quartz grains, occasional coal and silt fragments,

hard to moderately hard, poor to tight visual porosity.

FLUORESCENCE: 100% as above with oil odours. POOR to FAIR SHOW.

1749.5-1750.45m SANDSTONE WITH VERY DISTORTED BEDDING (SLUMPS) AND

OCCASIONALLY CARBONACEOUS LAMINAE (no sample)

1750.45-1751m BANDED SANDSTONE WITH WEEPING OIL

1750.85m SANDSTONE: pale yellow brown aggregates (oil stained), translucent to clear quartz, very

fine to fine, poorly sorted, angular to subrounded, moderately weak to strong siliceous cement,

generally clean, common silt sized quartz grains, occasional coal and silt fragments, moderately

friable to hard, good to poor visual porosity. FLUORESCENCE: 100% as above, slow

streaming with oil odours. FAIR SHOW.

1751-1752m THINLY BEDDED CHANNEL AND LAMINATED SANDSTONE AND OCCASIONAL

COARSE SAND WITH RIP-UP CLASTS

1751.55m SANDSTONE: pale yellow brown aggregates (oil stained), translucent to clear quartz, very

fine to fine, poorly sorted, angular to subrounded, moderately weak to strong siliceous cement,

generally clean, common silt sized quartz grains, occasional coal and silt fragments, moderately

friable to hard, good to poor visual porosity. FLUORESCENCE: 100% as above, slow

streaming with oil odours. FAIR SHOW.

1752-1753.6m SANDSTONE WITH COMMON CURRENT BEDDING

1752.25m SANDSTONE: white/translucent aggregates, very fine to fine, well-sorted, angular to

subrounded, strong to moderately strong siliceous cement, local kaolinitic matrix, generally

hard, poor visual porosity. FLUORESCENCE: 100% dull to moderately bright yellow,

slow blooming cut. POOR to FAIR SHOW.

1753.6-1753.9m TOP OF CHANNEL SANDSTONE

1753.65m SANDSTONE: white/translucent aggregates, very fine to fine, well-sorted, angular to

subrounded, strong t moderately strong siliceous cement, local kaolinitic matrix, generally

hard, poor visual porosity. FLUORESCENCE: 100% dull to moderately bright yellow,

slow blooming to streaming cut, sample leached of fluorescence, strong oil odours GOOD

SHOW.

CORE-3 DESCRIPTIONS, 1753.9-1763.6m

1753.9-1755.5 Predominantly horizontally bedded very fine sandstone, silty sandstone, siltstones and thin

carbonaceous/coal beds, thin zones possible bank collapse breccia, minor cross-bedded fine

sand and thin siltstones. Fluorescence was Fair to Poor in the sandstones with strong to

weak odours.

1755.5-1756.2 Abundant breccia sandstone with large (50mm) silt clasts from bank collapses or rip-up

clasts. Poor fluorescence.

1756.2-1761m Predominantly sandstone with structureless to horizontally bedded channel sands, common

rippled cross-bedding, occasional large rip-up siltstone clasts and minor carbonaceous siltstone

and coal laminae. Fluorescence was Fair to Poor to 1758m then Poor to 1761m.

8

1761-1763.6

Base Core-3

Sandstone with common rip-up clasts, larger bank collapse siltstone clasts, occasional current

cross-bedding and thin dark grey siltstone beds. Fluorescence was POOR with weak oil odours.

1763.6-1775m SANDSTONE WITH INTERBEDDED SILTY SANDSTONE AND SILTSTONE__

SANDSTONE: clear/translucent/white aggregates, very fine to very coarse, poorly sorted,

subrounded to subangular, weak siliceous cement, local kaolinitic matrix, occasional

recrystallised subhedral quartz, occasional lithics, trace coal, firm to moderately friable, good

visual and inferred porosity. FLUORESCENCE: 60% decreasing to 10% from 1763.6-

1775m.

SILTY SANDSTONE: light to medium grey, patchy dark to medium grey, very fine to

occasionally fine, well-sorted, angular to subrounded, weak to strong siliceous cement,

common silt sized quartz grains, slightly carbonaceous, argillaceous matrix in parts, occasional

mica, firm to moderately hard, occasionally friable, poor to tight porosity, no fluorescence.

SILTSTONE: pale to medium grey, argillaceous, occasionally laminated with very fine

sandstone, carbonaceous in parts, occasional mica, trace pyrite, firm to moderately hard, sub

blocky.

1775-1783m SILTSTONE WITH INTERGRADATIONAL SILTY SANDSTONE AND SANDSTONE__

SILTSTONE: as above and local CARBONACEOUS SILTSTONE: dark grey to brownish

black, arenaceous to argillaceous, common coal fragments, sub blocky t subfissile in parts.

SILTY SANDSTONE: predominantly pale grey, very fine to occasionally fine, well-sorted,

angular to subrounded, weak to moderately strong siliceous cement, abundant silt sized quartz

grains matrix, coal laminae and fragments in parts, mica, firm to moderately friable, poor

porosity, no fluorescence.

SANDSTONE: as above maximum 30%. No fluorescence.

HUTTON SANDSTONE (MIDDLE JURASSIC).

1783.01830.6m, TRUE THICKNESS: 47.6+m

1783-1830.6m SANDSTONE: clear to translucent, occasional patchy pale brown stained quartz, very fine to

coarse and granule sized grains, common frosted surfaces, rounded to angular, very poorly

sorted, minor moderately strong siliceous cement, common silica overgrowths (disaggregated),

clean to minor kaolinitic matrix, fair to good inferred porosity, no fluorescence.

APPENDIX 2:

CORING

CORING SUMMARY

CORE

NO.

FORMATION INTERVAL RECOVERY REMARKS

1 BIRKHEAD

1734.80-1744.42m, Dlr

1733.30-1742.92m, Lgr

9.62m, 100% TOP RESERVOIR AND SEAL

2 BIRKHEAD

1744.42-1753.90m, Dlr

1742.92-1752.40m, Lgr

9.48m, 100% RESERVOIR (to 1748m)

3 BIRKHEAD

1753.90-1763.60m, Dlr

1752.40-1762.10m, Lgr

9.70m, 100% WEAK FLUORESCENCE SHOWS

APPENDIX 2:

CORING

(i) COREDESCRIPTION LOGS

Core depths are Driller's. Logger's depths are 1.5m shallower.

These logs contain low resolution core photographs taken by Challenger Geological Services, Adelaide.

Annotated, good resolution core photographs can be viewed digitally on the accompanying CD-ROM.

APPENDIX 2:

CORING

(ii) TABLE OF CORE SAMPLES

Senex

Growler-6

CORE 1

Top Depth (m) 1734.80

Bottom Depth (m) 1744.42

Total Core (m) 9.62

Core sections Top Depth (m) Bottom Depth (m) Preserved sections Top Depth (m) Bottom Depth (m)

C1 Section 1 1734.80 1735.00 Lab #1 1734.80 1735.00

C1 Section 2 1735.00 1736.00 - - -

C1 Section 3 1736.00 1737.00 Lab #2 1736.78 1737.00

C1 Section 4 1737.00 1738.00 Lab #3 1737.69 1737.90

C1 Section 5 1738.00 1739.00 Lab #4 1738.30 1738.49

C1 Section 6 1739.00 1740.00 Lab #5 1739.15 1739.34

C1 Section 7 1740.00 1741.00 Lab #6 1740.65 1740.81

C1 Section 8 1741.00 1742.00 Lab #7 1741.34 1741.49

C1 Section 9 1742.00 1743.00 Lab #8 1742.41 1742.62

C1 Section 10 1743.00 1744.00 Lab #9 1743.56 1743.64

C1 Section 11 1744.00 1744.42 Lab #10 1744.25 1744.42

Senex

Growler-6

CORE 2

Top Depth (m) 1744.42

Bottom Depth (m) 1753.90

Total Core (m) 9.48

Core sections Top Depth (m) Bottom Depth (m) Preserved sections Top Depth (m) Bottom Depth (m)

C2 Section 1 1744.42 1745.00 Lab #11 1744.86 1744.96

C2 Section 2 1745.00 1746.00 Lab #12 1745.60 1745.71

C2 Section 3 1746.00 1747.00 Lab #13 1746.54 1746.67

C2 Section 4 1747.00 1748.00 Lab #14 1747.71 1747.87

C2 Section 5 1748.00 1749.00 Lab #15 1748.58 1748.69

C2 Section 6 1749.00 1750.00 Lab #16 1749.76 1749.88

C2 Section 7 1750.00 1751.00 Lab #17 1750.72 1750.86

C2 Section 8 1751.00 1752.00 Lab #18 1751.56 1751.75

C2 Section 9 1752.00 1753.00 Lab #19 1752.65 1752.82

C2 Section 10 1753.00 1753.90 Lab #20 1753.50 1753.66

Senex

Growler-6

CORE 3

Top Depth (m) 1753.90

Bottom Depth (m) 1763.60

Total Core (m) 9.70

Core sections Top Depth (m) Bottom Depth (m) Preserved sections Top Depth (m) Bottom Depth (m)

C3 Section 1 1753.90 1755.00 Lab #21 1754.78 1754.93

C3 Section 2 1755.00 1756.00 Lab #22 1755.56 1755.81

C3 Section 3 1756.00 1757.00 Lab #23 1756.74 1756.89

C3 Section 4 1757.00 1758.00 Lab #24 1755.55 1757.69

C3 Section 5 1758.00 1759.00 Lab #25 1758.77 1758.94

C3 Section 6 1759.00 1760.00 Lab #26 1759.36 1759.51

C3 Section 7 1760.00 1761.00 Lab #27 1760.31 1760.47

C3 Section 8 1761.00 1762.00 Lab #28 1761.43 1761.62

C3 Section 9 1762.00 1763.00 Lab #29 1762.28 1762.49

C3 Section 10 1763.00 1763.60 Lab #30 1763.35 1763.51

APPENDIX 2:

CORING

(iii) CORE ANALYSIS DATA

OVERBURDEN CORE ANALYSI S PRELI MI NARY REPORT

Client : Senex Energy Limited Date : 15/02/2012

Well : Growler-6 File : 0530-02

Overburden Pressure: 2525psi

Sample Ambient OB1 Grain Ambient OB1

Number Depth Dir Porosity Porosity Density Permeability Permeability Remarks

(metres) (Percent) (Percent) (g/cm

3

) (mD) (mD)

V1 1735.03 V 0 failed

1 1735.21 H 7.9 2.62 micro frac, lam

2 1735.54 H 7.9 2.62 micro frac, lam

V2 1736.03 V 0 failed

3 1736.46 H 7.4 2.61 micro frac

4 1736.73 H 7.7 2.62 frac

V3 1737.03 V 19.4 18.5 2.67 3.68 2.64 S.P., Irreg

5 1737.08 H 17.0 16.0 2.65 3.55 2.60

6 1737.38 H 16.2 15.4 2.65 3.67 2.99 lam

7 1737.63 H 17.4 16.7 2.65 3.61 2.82

V4 1738.02 V 16.9 15.9 2.66 1.99 1.53

8 1738.21 H 15.8 14.9 2.64 1.19 0.80

9 1738.74 H 13.4 12.6 2.65 2.14 1.76 lam

V5 1739.02 V 18.3 17.5 2.65 2.88 2.01

10 1739.10 H 20.0 19.4 2.65 58.4 37.0 frac

12 1739.88 H 18.3 17.5 2.65 37.5 35.0 lam

13 1740.17 H 20.1 2.65 68.3 lam, frac?

V6 1740.22 V 21.9 21.1 2.65 80.8 72.4

Weatherford Laboratories (Australia)

ABN: 81 008 273 005

Overburden Pressure: 2525psi

Sample Ambient OB1 Grain Ambient OB1

Number Depth Dir Porosity Porosity Density Permeability Permeability Remarks

(metres) (Percent) (Percent) (g/cm

3

) (mD) (mD)

14 1740.48 H 20.6 19.8 2.64 119 106

15 1740.97 H 21.3 20.7 2.64 492 460

V7 1741.02 V 23.8 23.0 2.64 160 140

16 1741.18 H 22.7 22.2 2.65 895 819

17 1741.69 H 24.1 23.3 2.64 570 513

18 1741.97 H 22.3 21.7 2.64 1129 1040

V8 1742.02 V 13.5 12.6 2.65 0.35 0.100

19 1742.20 H 21.3 20.6 2.64 1255 1137

20 1742.68 H 23.3 22.5 2.64 1924 1735

21 1742.91 H 23.4 22.6 2.64 2746 2438

V9 1743.02 V 21.3 20.6 2.64 827 752

22 1743.24 H 22.2 21.5 2.64 2494 2211

23 1743.51 H 21.3 20.6 2.65 146 135

24 1743.77 H 22.0 21.3 2.64 342 327 lam

V10 1744.02 V 11.4 10.7 2.46 0.12 0.018 carb lam

25 1744.13 H 19.3 18.7 2.65 69.2 62.1

26 1744.60 H 23.1 22.5 2.64 2448 2127

27 1744.82 H 23.5 22.8 2.64 2061 1849

28 1745.11 H 22.0 21.3 2.64 754 686

V11 1745.17 V 22.3 21.4 2.64 381 342

29 1745.39 H 19.0 18.3 2.65 58.2 51.4

30 1745.81 H 22.1 21.4 2.65 541 496

V12 1746.03 V 21.0 20.3 2.67 10.2 6.1

31 1746.10 H 21.6 21.0 2.66 111 100.0

Weatherford Laboratories (Australia)

ABN: 81 008 273 005

Overburden Pressure: 2525psi

Sample Ambient OB1 Grain Ambient OB1

Number Depth Dir Porosity Porosity Density Permeability Permeability Remarks

(metres) (Percent) (Percent) (g/cm

3

) (mD) (mD)

32 1746.41 H 13.6 2.60 carb lam, frac

33 1746.78 H 10.6 9.8 2.65 0.13 0.050 lam

V13 1747.03 V 8.9 8.4 2.66 0.006 0.002

34 1747.18 H 10.2 9.3 2.64 0.15 0.033 lam

35 1747.61 H 23.1 22.5 2.64 561 518

36 1747.93 H 21.8 21.2 2.64 128 121

V14 1748.03 V 23.6 22.8 2.64 306 284

37 1748.23 H 23.1 22.5 2.64 611 564

38 1748.52 H 16.2 15.1 2.62 3.28 1.90 carb lam

39 1748.83 H 14.6 13.2 2.57 1.89 0.31 carb lam

V15 1749.03 V 15.2 14.1 2.64 0.18 0.052

40 1749.13 H 15.1 14.2 2.63 1.23 0.50 carb lam

41 1749.43 H 10.0 9.5 2.52 0.23 0.12 carb lam

42 1749.69 H 18.1 2.66 frac, irreg

V16 1750.03 V 11.9 10.8 2.42 0.042 0.007 carb lam

43 1750.12 H 14.6 13.8 2.63 0.25 0.050 carb lam

44 1750.52 H 6.6 6.3 2.69 0.028 0.004 slt

45 1750.93 H 20.2 19.5 2.66 31.8 27.6

V17 1751.03 V 20.3 19.5 2.66 4.32 2.71

46 1751.13 H 19.9 19.2 2.66 26.4 22.8

47 1751.41 H 17.6 16.9 2.65 83.7 74.9 slt intbd

48 1751.90 H 13.4 12.6 2.67 5.4 2.12 slt intbd

V18 1752.03 V 18.3 17.5 2.65 1.18 0.65 lam

49 1752.19 H 8.1 7.8 2.72 0.096 0.004 slt

Weatherford Laboratories (Australia)

ABN: 81 008 273 005

Overburden Pressure: 2525psi

Sample Ambient OB1 Grain Ambient OB1

Number Depth Dir Porosity Porosity Density Permeability Permeability Remarks

(metres) (Percent) (Percent) (g/cm

3

) (mD) (mD)

50 1752.52 H 8.8 8.2 2.63 0.032 0.006

51 1752.91 H 16.5 15.6 2.67 46.7 42.1 dual lith

V19 1753.03 V 8.7 8.0 2.63 0.020 0.004

52 1753.12 H 9.4 8.9 2.67 0.018 0.004

53 1753.41 H 10.6 10.0 2.68 0.043 0.018

54 1753.84 H 18.7 18.0 2.66 18.0 15.1

V20 1754.03 V 17.2 2.38 0.27 S.P, carb lam, failed

55 1754.15 H 11.0 2.57 3.83 carb lam, frac?

56 1754.48 H 16.5 15.7 2.66 3.20 2.31

57 1754.96 H 9.0 2.71 lam, frac

V21 1755.03 V 10.2 9.8 2.74 0.003 0.002 lam, H-frac

58 1755.27 H 8.0 7.7 2.68 0.10 0.005

59 1755.88 H 16.1 15.4 2.67 12.1 10.3

V22 1756.03 V 14.2 13.2 2.69 1.01 0.22 slt intbd, H-frac

60 1756.19 H 12.5 2.71 frac, slt

61 1756.57 H 22.4 21.6 2.65 177 162

62 1756.93 H 21.0 20.3 2.65 68.5 60.2 lam

V23 1757.03 V 20.9 19.8 2.65 60.0 52.2 S.P

63 1757.22 H 19.2 18.3 2.66 27.1 22.9

64 1757.47 H 18.8 17.9 2.65 58.3 46.1

65 1757.94 H 17.2 16.3 2.66 565 503 lam, dual lith, frac?

V24 1758.03 V 19.0 18.2 2.67 1.67 0.79 lam

66 1758.21 H 16.2 15.6 2.67 10.0 8.2 slt intbd

67 1758.49 H 15.6 14.7 2.66 1.88 1.39 lam

Weatherford Laboratories (Australia)

ABN: 81 008 273 005

Overburden Pressure: 2525psi

Sample Ambient OB1 Grain Ambient OB1

Number Depth Dir Porosity Porosity Density Permeability Permeability Remarks

(metres) (Percent) (Percent) (g/cm

3

) (mD) (mD)

68 1759.03 H 16.1 15.1 2.67 8.4 5.7 slt intbd

V25 1759.10 V 14.2 13.2 2.66 1.52 0.036 slt intbd, fracs

69 1759.31 H 20.2 19.5 2.66 138 59.9 slt lam, frac?

70 1759.58 H 18.4 17.7 2.67 37.7 26.5

71 1759.87 H 11.4 10.3 2.68 4.58 0.19 slt intbd, frac?

V26 1760.05 V 4.3 3.7 2.65 0.002 0.001 slt, H-frac

72 1760.26 H 18.5 17.9 2.66 11.9 10.4

73 1760.60 H 21.1 20.3 2.66 107 93.0

74 1760.89 H 19.1 18.3 2.65 22.4 19.7

V27 1761.03 V 8.6 7.1 2.66 0.18 0.007 S.P, slt intbd

75 1761.21 H 11.4 2.67 frac, slt intbd, g.l

76 1761.83 H 9.2 8.5 2.68 2.36 0.046 slt intbd

V28 1762.03 V 11.2 10.1 2.66 0.51 0.028 slt intbd, H-frac

77 1762.14 H 16.3 15.5 2.66 154 138 slt intbd

78 1762.63 H 10.8 9.9 2.67 3.09 0.13 slt intbd, fracs?

79 1762.80 H 10.2 9.4 2.67 2.73 0.052 slt intbd

V29 1763.03 V 11.8 11.0 2.66 1.30 0.094 slt intbd

80 1763.20 H 13.5 12.4 2.66 8.1 5.2 slt intbd

81 1763.55 H 17.8 16.9 2.66 46.5 38.4 slt intbd

11 1793.58 H 19.5 18.9 2.65 50.0 45.8

Weatherford Laboratories (Australia)

ABN: 81 008 273 005

POROSI TY PLOT

Client Senex Energy Limited

Well Growler-6

0

5

10

15

20

25

0 5 10 15 20 25

Ambient Porosity (%)

O

v

e

r

b

u

r

d

e

n

P

o

r

o

s

i

t

y

(

%

)

H-plugs

V-plugs

PERMEABI LI TY PLOT

Client Senex Energy Limited

Well Growler-6

0.001

0.01

0.1

1

10

100

1000

10000

0.001 0.01 0.1 1 10 100 1000 10000

Ambient Permeability (mD)

O

v

e

r

b

u

r

d

e

n

P

e

r

m

e

a

b

i

l

i

t

y

(

m

D

)

H-plugs

V-plugs

POROSI TY vs PERMEABI LI TY PLOT

Client Senex Energy Limited

Well Growler-6

0.001

0.01

0.1

1

10

100

1000

10000

0 5 10 15 20 25

Ambient porosity (%)

A

m

b

i

e

n

t

P

e

r

m

e

a

b

i

l

i

t

y

(

m

D

)

H-plugs

V-plugs

APPENDIX 3:

WIRELINE LOGGING REPORTS

(i) LOGGING ORDER FORM

GROWLER-6 DAILY GEOLOGICAL REPORT

SENEX ENERGY LTD Page 1

GENERAL DATA

COMPANY:

SENEX ENERGY LTD

WELL: GROWLER-6 FIELD: GROWLER FIELD (PRL 15)

RIG: ENSIGN RIG-48 WELL TYPE: OIL DEVELOPMENT

SEISMIC

LOCATION:

Mollichuta 3D Seismic

Survey (2008)

STATE:

BLOCK/PRL:

SOUTH AUSTRALIA

PRL 15

LATITUDE: 27 34' 00" South (GDA 94) LONGITUDE: 139 34' 11.5" E (GDA 94)

EASTING: 358817m East (MGA 94) NORTHING: 6949984m (MGA 94)

ELEVATIONS: GL: 37m (AHD) (preliminary) RT: 42m (AHD, prelim) DF: _________

311 mm (12.25") HOLE: 666m 244 mm (9.625") CASG: 664m WT: 36 ppf

ID: 8.921" (K55)

216m (8.5") HOLE: 1830.6m TD PLANNED

PRODUCTION CASG:

OD: 7"

178mm

WT: 23 ppf

ID: 6.37" (N80)

MUD SYSTEM: KCL/PHPA CIRCULATION STOPPED: 20:00 hrs, 1/11/11

WT:

9.7

VISC: 37 PV/YP: 10/14 pH: 8.5 FLUID

LOSS:

7.8 Cl: 47k

Rm:

Temp C.

0.116

25

Rmf:

Temp: C

0.101

25

Rmc:

Temp: C

0.319

25

KCl: % 2.0 Barite: Trace K+: 10.5

(MUD RESISTIVITY DATA FROM WIRELINE LOGGERS

EXPECTED

BHT:

84 C

(184 F)

GEOLOGIST: LES BURGESS MAXIMUM DEVIATION: 2.6@ 1384m

INFORMATION GIVEN ABOVE IS TO BE USED ON LOG HEADING SHEETS.

HOLE CONDITIONS / MISCELLANEOUS COMMENTS: (TIGHT SPOTS, DEVIATION, COALS ETC).

TIGHT HOLE: none

COALS: NO MAJOR COALS

DRILL STEM TESTS: NONE. CORED INTERVALS: 1734.8-1763.6m

FORMATION TOPS (DRILLER'S DEPTHS):

Cadna-owie Formation 1368, McKinlay Member 1444m, Namur Sst 1462m, Birkhead Fm 1690m, Hutton Sst 1788m

COMMENTS: (TO BE INCLUDED IN REMARKS SECTION ON HEADER SHEET):

PLEASE RECORD DOWNLOG AT OPTIMUM SPEEDS, SUITABLE FOR SPLICING INTO MAIN LOG.

PLEASE RECORD MUD WEIGHT ON LOG HEADER IN g/c3 and PPG.

PLEASE RUN HIGH RESOLUTION MODE (0.025m) FROM TOTAL DEPTH TO 1630m.

GROWLER-6 DAILY GEOLOGICAL REPORT

SENEX ENERGY LTD Page 2

LOGS INTERVAL REMARKS

TRIP /

RUN

STANDARD MODE (0.1m/10cm) TD TO SHOE,

GR TO SURFACE. HIGH RESOLUTION

MODE (0.025m/2.5cm) TD-XXXXm.

1/1 MDL-MMR-GR,

MSS, MPD-MDN

(triple combo)

GR

TOTAL DEPTH TO

SURFACE CASING SHOE

@ 664m

TD TO SURFACE -

DUAL LATEROLOG, MFE, SONIC (FIRST

ARRIVAL), GAMMA RAY (NON-

SPECTRALOG), NEUTRON, DENSITY, PEF,

SPONTANEOUS POTENTIAL

AS SHALLOW AS POSSIBLE.

1/2) MFT-GR TO BE DECIDED IN

TOWN

PRESSURE SURVEYS ONLY

REMARKS: ALL OPERATIONS ARE TO CONFORM TO CURRENT SENEX ENERGY LTD AND

WEATHERFORD OPERATING PROCEDURES. PLEASE RECORD DOWNLOG FROM SHOE.

1. TENSION CURVE - TO BE DISPLAYED ON THE LOG FROM TD TO CASING SHOE.

2. ALL CALIBRATIONS (CASING CHECKS) IN CASING MUST BE PLOTTED VERSUS DEPTH AND

PRESENTED ON LOG TAIL, eg CALIPER AND SONIC (IN UNCEMENTED CASING IF POSSIBLE)

3. SIGNIFICANT ZONES OF SONIC CYCLE SKIPPI NG OR POOR QUALITY DATA TO BE NOTED (AND

POSSIBLY REPEATED) IN REMARKS SECTION.

4. ALL THERMOMETER READINGS W ITH DEPTHS ARE TO BE RECORDED ON LOG HEADER +