Indianrailwaysmechanicalvocationaltrainingreport2 Haxxo24ii 130730074651 Phpapp0211

Diunggah oleh

Ashish Rawat0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

90 tayangan71 halamanrailway

Hak Cipta

© © All Rights Reserved

Format Tersedia

DOCX, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen Inirailway

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOCX, PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

90 tayangan71 halamanIndianrailwaysmechanicalvocationaltrainingreport2 Haxxo24ii 130730074651 Phpapp0211

Diunggah oleh

Ashish Rawatrailway

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOCX, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 71

2014

INDUSTRIAL TRAINING REPORT

ACKNOWLEDGEMENT

We take this opportunity to express our sincere gratitude to the peoples who have

been helpful in the successful completion of our industrial training and this project.

We would like to show our greatest appreciation to the highly esteemed and devoted

technical staff, supervisors of the Diesel Loco Shed, Tughlakabad. We are highly

indebted to them for their tremendous support and help during the completion of our

training and project.

We are grateful to Mr. OMM KANT SHARMA, SSE/TRG, Diesel Training

Centre of Diesel Loco Shed Tughlakabad, who granted us the permission of

industrial training in the shed. We would like to thanks to all those peoples who

directly or indirectly helped and guided us to complete our training and project in the

shed, including the following instructors and technical officers of Diesel Training

Centre and various sections.

Date:-12/07/10

CONTENTS

History

Introduction of Diesel Shed TKD

Fuel section

Control room

C.T.A cell

Turbo Supercharger

Expressor/Compressor

Cylinder Head

Bogie

Fuel Injection Pump (FIP)

CTA Cell

Fuel Section

Control Room

Metallurgical Lab.

Yearly (Mech.)

Pit Wheel Lathe

Running /Mech. /Goods

Running /Mech./Mail

Air Brake

Speedometer

Project stud

To study about Project Study

INDIAN RAILWAY HISTORY

INTRODUCTION

Indian Railways is the state-owned railway company of India. It comes under the

Ministry of Railways. Indian Railways has one of the largest and busiest rail networks

in the world, transporting over 18 million passengers and more than 2 million tonnes

of freight daily. Its revenue is Rs.107.66 billion. It is the world's largest commercial

employer, with more than 1.4 million employees. It operates rail transport on 6,909

stations over a total route length of more than 63,327 kilometers(39,350 miles).The

fleet of Indian railway includes over 200,000 (freight) wagons, 50,000 coaches and

8,000 locomotives. It also owns locomotive and coach production facilities. It was

founded in 1853 under the East India Company.

Indian Railways is administered by the Railway Board. Indian Railways is divided

into 16 zones. Each zone railway is made up of a certain number of divisions. There

are a total of sixty-seven divisions. It also operates the Kolkata metro. There are six

manufacturing plants of the Indian Railways. The total length of track used by Indian

Railways is about 108,805 km (67,608 mi) while the total route length of the network

is 63,465 km (39,435 mi). About 40% of the total track kilometer is electrified &

almost all electrified sections use 25,000 V AC. Indian railways uses four rail track

gauges|~|

1. The broad gauge (1670 mm)

2. The meter gauge (1000 mm)

3. Narrow gauge (762 mm)

4. Narrow gauge (610 mm).

Indian Railways operates about 9,000 passenger trains and transports 18 million

passengers daily .Indian Railways makes 70% of its revenues and most of its profits

from the freight sector, and uses these profits to cross-subsidies the loss-making

passenger sector. The Rajdhani Express and Shatabdi Express are the fastest trains of

India

CLASSIFI CATI ON

1. Standard Gauge designations and dimensions:-

W = Broad gauge (1.67 m)

Y = Medium gauge ( 1 m)

Z = Narrow gauge ( 0.762 m)

N = Narrow gauge ( 0.610 m)

2. Type of Traction designations:-

D = Diesel-electric traction

C = DC traction

A = AC traction

CA=Dual power AC/DC traction

3. The type of load or Service designations:-

M= Mixed service

P = Passenger

G= Goods

S = Shunting

4. Horse power designations from June 2002 (except WDP-1 & WDM-2

LOCOS)

3 For 3000 horsepower

4 For 4000 horsepower

5 For 5000 horsepower

A For extra 100 horsepower

B For extra 200 horsepower and so on.

Hence WDM-3A indicates a broad gauge loco with diesel-electric traction. It is for

mixed services and has 3100 horsepower.|~|

DIESEL SHED TUGHLAKABAD

INTRODUCTION

Diesel locomotive shed is an industrial-technical setup, where repair and maintenance

works of diesel locomotives is carried out, so as to keep the loco working properly. It

contributes to increase the operational life of diesel locomotives and tries to minimize

the line failures. The technical manpower of a shed also increases the efficiency of the

loco and remedies the failures of loco.

The shed consists of the infrastructure to berth, dismantle, repair and test the loco and

subsystems. The shed working is heavily based on the manual methods of doing the

maintenance job and very less automation processes are used in sheds, especially in

India.

The diesel shed usually has:-

Berths and platforms for loco maintenance.

Pits for under frame maintenance

Heavy lift cranes and lifting jacks

Fuel storage and lube oil storage, water treatment plant and testing labs

etc.

Sub-assembly overhauling and repairing sections

Machine shop and welding facilities.

ABOUT DIESEL SHED TKD

Diesel Shed, Tughlakabad of Northern Railway is located in NEW DELHI. The shed

was established on 22

nd

April 1970. It was initially planned to home 75 locomotives.

The shed cater the needs of Northern railway. This shed mainly provides locomotive

to run the mail, goods and passenger services. No doubt the reliability, safety through

preventive and predictive maintenance is high priority of the shed. To meet out the

quality standard shed has taken various steps and obtaining of the ISO-9001-200O&

ISO 14001 OHSAS CERTIFICATION is among of them. The Diesel Shed is

equipped with modern machines and plant required for Maintenance of Diesel

Locomotives and has an attached store depot. To provide pollution free atmosphere,

Diesel Shed has constructed Effluent Treatment Plant. The morale of supervisors and

staff of the shed is very high and whole shed works like a well-knit team.

AT A GLANCE

Inception 22

nd

April1970

Present Holding 147 Locomotives

19 WDM2

37 WDM3A

08 WDM3D

11 WDG3A

46 WDP1

26 WDP3A

Accreditation ISO-9001-2000 & ISO

14001

Covered area of shed 10858 SQ. MTR

Total Area of shed 1, 10,000 SQ. MTR

Staff strength sanction 1357

On roll - 1201

Berthing capacity 17 locomotives

SPECI AL MACHI NES & PLANT

Pit wheel lathe machine

This machine is suitable for turn & re-profiles the wheels of locomotives.

Effluent Treatment Plant:-

In order to provide pollution free environment, an ETP PLANT is installed. Various

effluents emitted from diesel shed are passed through the Plant. The water thus

collected is pollution free and is used for non drinking purposes such as gardening and

washing of the locomotives.

TECHNI CAL I NNOVATI ONS

Based on day-to-day maintenance problems a large number of

innovations/modifications have been conceived and implemented in Diesel Shed,

TKD during 2003-2004 which have improved the reliability and downtime of

locomotives.Some of them are under.

Expressor performance test notch wise

Simulation of test stand facility on the loco itself with the help of only

two small fixtures.

Testing the performance of expressor in diesel locomotive engines.

Cylinder head Stud Removal/ Tightening Arrangement

A simple device has been developed to help reduce the time and effort

taken in removal/tightening of cylinder head studs.

Diesel Training Centre-DTC

It was setup in the TKD shed premises in 1975 by the Northern Railway with

view to train diesel loco pilots. It also trains the Diesel Maintenance staff to improve

the availability of qualified manpower and improve the efficiency of and quality of

the technicians. It has five classrooms, a hall ,a Model room(with sectional models of

TSC, expressor, cylinder head LOP, governor etc.). A well qualified team of

instructors from the electrical and mechanical fields provides a quality training to the

p=loco pilots and other trainees.

Courses offered :- (regular)

Diesel Assistant to Diesel Loco Driver promotion course

Diesel Assistant Refresher coarse

Diesel Driver refresher course

Other courses:-

Up gradation course of Diesel technicians

Electric traction to diesel traction conversion course

Course for Drivers, Shunters and Asstt. Drivers

3 years Apprentice technician(Diesel mechanical and electrical)

6 months Apprentice Technician(Diesel mechanical and electrical)

Vocational industrial training for B.Tech and Diploma student

1.CONTROL ROOM

It controls and regulates the complete movement, schedules, duty of each loco of

the shed. Division level communications and contacts with each loco on the line are

also handled by the control room. Full record of loco fleet, failures, duty, overdue and

availability of locos are kept by the control room. It applies the outage target of loco

for the shed, as decided by the HQ. It decides the locomotives mail and goods link

that which loco will be deployed on which train. It operates 116 Mail and 11Goods

link from the shed locos. For 0-0 outage total 127 loco should be on line.

The schedule of duty, trains and link is decided by the control room according to the

type of trains. If the loco does not return on scheduled time in the shed then the loco is

termed as over due and control room can use the loco of another shed if that is

available.

The lube oil consumption is also calculated by the control room for each loco:-

Lube Oil Consumption (LOC) = Lube oil consumed in liters/ total kms

travelled 100

New and better operational loco have less LOC.

2.CTA (Chief Technical Assistance) CELL

This cell performs the following functions:-

Failure analysis of diesel locos

Finding the causes of sub system failures and material failures

Formation of inquiry panels of Mechanical and Electrical engineers

and to help the special inquiry teams

Material failures complains, warnings and replacement of stock

communications with the component manufacturers

Issues the preventive instructions to the technical workers and

engineers

Preparation of full detailed failure reports of each loco and sub

systems, components after detailed analysis. The reports are then sent

to the Divisional HQ.

Correspondence with the headquarters is also done by the CTA Cell.

The failures analyzed are:-

Category 1 failures:- If the VIP trains loco fails or the train is delayed by the failure

of another trains loco failure. Failure of the single loco may delay a no of trains.

Non- reported failures:- the failure or delay of the local passenger trains for 2-3 hours

is taken in this category. They are not reported to the higher levels and can be

adjusted in the section operations.

Foreign Railway-FR failures:- If the loco of one division fails in the other division

and affects the traffic seriously in that division. The correspondence in this case is

done by the cell.

2. TURBO SUPERCHARGER

I NTRODUCTI ON

The diesel engine produces mechanical energy by converting heat energy

derived from burning of fuel inside the cylinder. For efficient burning of fuel,

availability of sufficient air in proper ratio is a prerequisite.

In a naturally aspirated engine, during the suction stroke, air is being sucked into the

cylinder from the atmosphere. The volume of air thus drawn into the cylinder through

restricted inlet valve passage, within a limited time would also be limited and at a

pressure slightly less than the atmosphere. The availability of less quantity of air of

low density inside the cylinder would limit the scope of burning of fuel. Hence

mechanical power produced in the cylinder is also limited.

An improvement in the naturally aspirated engines is the super-charged or pressure

charged engines. During the suction stroke, pressurised stroke of high density is being

charged into the cylinder through the open suction valve. Air of higher density

containing more oxygen will make it possible to inject more fuel into the same size of

cylinders and produce more power, by effectively burning it.

A turbocharger, or turbo, is a gas compresser used for forced-induction of an

internal combustion engine. Like a supercharger, the purpose of a turbocharger is to

increase the density of air entering the engine to create more power. However, a

turbocharger differs in that the compressor is powered by a turbine driven by the

engine's own exhaust gases.

TURBO SUPERCHARGER AND ITS WORKING PRINCIPLE

The exhaust gas discharge from all the cylinders accumulate in the common

exhaust manifold at the end of which, turbo- supercharger is fitted. The gas under

pressure there after enters the turbo- supercharger through the torpedo shaped bell

mouth connector and then passes through the fixed nozzle ring. Then it is directed on

the turbine blades at increased pressure and at the most suitable angle to achieve

rotary motion of the turbine at maximum efficiency. After rotating the turbine, the

exhaust gas goes out to the atmosphere through the exhaust chimney. The turbine has

a centrifugal blower mounted at the other end of the same shaft and the rotation of the

turbine drives the blower at the same speed. The blower connected to the atmosphere

through a set of oil bath filters, sucks air from atmosphere, and delivers at higher

velocity. The air then passes through the diffuser inside the turbo- supercharger,

where the velocity is diffused to increase the pressure of air before it is delivered from

the turbo- supercharger.

The engine initially starts as naturally aspirated engine. With the increased quantity of

fuel injection increases the exhaust gas pressure on the turbine.

MAIN COMPONENTS OF TURBO-SUPERCHARGER

Turbo- supercharger consists of following main components.

Gas inlet casing.

Turbine casing.

Intermediate casing

Blower casing with diffuser

Rotor assembly with turbine and rotor on the same shaft.

ROTOR ASSEMBLY

The rotor assembly consists of rotor shaft, rotor blades, thrust collar, impeller,

inducer, centre studs, nosepiece, locknut etc. assembled together. The rotor blades are

fitted into fir tree slots, and locked by tab lock washers. This is a dynamically

balanced component, as this has a very high rotational speed.

LUBRICATING, COOLING AND AIR CUSHIONING

LUBRICATING SYSTEM

One branch line from the lubricating system of the engine is connected to the

turbo- supercharger. Oil from the lube oils system circulated through the turbo-

supercharger for lubrication of its bearings. After the lubrication is over, the oil

returns back to the lube oil system through a return pipe. Oil seals are provided on

both the turbine and blower ends of the bearings to prevent oil leakage to the blower

or the turbine housing.

COOLI NG SYSTEM

The cooling system is integral to the water cooling system of the engine.

Circulation of water takes place through the intermediate casing and the turbine

casing, which are in contact with hot exhaust gases. The cooling water after being

circulated through the turbo- supercharger returns back again to the cooling system of

the locomotive.

AIR CUSHIONING

There is an arrangement for air cushioning between the rotor disc and the

intermediate casing face to reduce thrust load on the thrust face of the bearing which

also solve the following purposes.

It prevents hot gases from coming in contact with the lube oil.

It prevents leakage of lube oil through oil seals.

It cools the hot turbine disc.

Pressurised air from the blower casing is taken through a pipe inserted in the turbo-

supercharger to the space between the rotor disc and the intermediate casing. It serves

the purpose as described above.

AFTER COOLER

It is a simple radiator, which cools the air to increase its density. Scales formation on

the tubes, both internally and externally, or choking of the tubes can reduce heat

transfer capacity. This can also reduce the flow of air through it. This reduces the

efficiency of the diesel engine. This is evident from black exhaust smoke emissions

and a fall in booster pressure.

Fitments of higher capacity Turbo Supercharger- following new generation Turbo

Superchargers have been identified by diesel shed TKD for 2600/3100HP diesel

engine and tabulated in table 1.

TABLE 1

TYPE POWER COOLING

1.ALCO 2600HP Water cooled

2.ABB TPL61 3100HP Air cooled

3.HISPANO SUIZA HS 5800 NG 3100HP Air cooled

4. GE 7S1716 3100HP Water cooled

5. NAPIER NA-295 2300,2600&3100HP Water cooled

6. ABB VTC 304 2300,2600&3100HP Water cooled

TURBO RUN DOWN TEST

Turbo run-down test is a very common type of test done to check the free

running time of turbo rotor. It indicates whether there is any abnormal sound in the

turbo, seizer/ partial seizer of bearing, physical damages to the turbine, or any other

abnormality inside it. The engine is started and warmed up to normal working

conditions and running at fourth notch speed. Engine is then shut down through the

over speed trip mechanism. When the rotation of the crank shaft stops, the free

running time of the turbine is watched through the chimney and recorded by a stop

watch. The time limit for free running is 90 to 180 seconds. Low or high turbo run

down time are both considered to be harmful for the engine.

ROTOR BALANCI NG MACHI NE

A balancing machine is a measuring tool used for balancing rotating machine

parts such as rotors of turbo subercharger,electric motors,fans, turbines etc. The

machine usually consists of two rigid pedestals, with suspension and bearings on

top.The unit under test is placed on the bearings and is rotated with a belt. As the part

is rotated, the vibration in the suspension is detected with sensors and that information

is used to determine the amount of unbalance in the part. Along with phase

information, the machine can determine how much and where to add or remove

weights to balance the part.

ADVANTAGES OF SUPER CHARGED ENGI NES

A super charged engine can produce 50 percent or more power than a

naturally aspirated engine. The power to weight ratio in such a case is much

more favorable.

Better scavenging in the cylinders. This ensures carbon free cylinders and

valves, and better health for the engine also.

Better ignition due to higher temperature developed by higher compression

in the cylinder.

It increases breathing capacity of engine

Better fuel efficiency due to complete combustion of fuel .

Defect in Turbochargers

Low Booster Air Pressure (BAP).

Oil throwing from Turbocharger because of seal damage or out of

clearance.

Surging- Back Pressure due to uneven gap in Nozzle Ring or Diffuser

Ring.

Must change components of Turbocharger.

Intermediate casing gasket.

Water outlet pipe flange gasket.

Water inlet pipe flange gasket.

Lube Oil inlet pipe rubber o ring.

Turbine end Bearing.

Blower end Bearing.

Chimney gasket.

Rubber o Ring kit.

Spring Washers.

Lock Washer Rotor Stud.

3.FUEL OIL SYSTEM

I NTRODUCTI ON

All locomotive have individual fuel oil system. The fuel oil system is designed

to introduce fuel oil into the engine cylinders at the correct time, at correct pressure, at

correct quantity and correctly atomised. The system injects into the cylinder correctly

metered amount of fuel in highly atomised form. High pressure of fuel is required to

lift the nozzle valve and for better penetration of fuel into the combustion chamber.

High pressure also helps in proper atomisation so that the small droplets come in

better contact with the compressed air in the combustion chamber, resulting in better

combustion. Metering of fuel quantity is important because the locomotive engine is a

variable speed and variable load engine with variable requirement of fuel. Time of

fuel injection is also important for better combustion.

FUEL OI L SYSTEM

The fuel oil system consists of two integrated systems. These are-

FUEL INJECTION PUMP (F.I.P).

FUEL INJECTION SYSTEM.

FUEL I NJ ECTI ON PUMP

It is a constant stroke plunger type pump with variable quantity of fuel delivery to

suit the demands of the engine. The fuel cam controls the pumping stroke of the

plunger. The length of the stroke of the plunger and the time of the stroke is

dependent on the cam angle and cam profile, and the plunger spring controls the

return stroke of the plunger. The plunger moves inside the barrel, which has very

close tolerances with the plunger. When the plunger reaches to the BDC, spill ports in

the barrel, which are connected to the fuel feed system, open up. Oil then fills up the

empty space inside the barrel. At the correct time in the diesel cycle, the fuel cam

pushes the plunger forward, and the moving plunger covers the spill ports. Thus, the

oil trapped in the barrel is forced out through the delivery valve to be injected into the

combustion chamber

The engine stops because of no fuel injected, and this is known as

NO-FUEL position. When alignment of helix relief with spill port is delayed, it

results in a partly effective stroke and engine runs at low speed and power output is

not the maximum. When the helix is not in alignment with the spill port through out

the stroke, this is known as FULL FUEL POSITION, because the entire stroke is

effective.

FUEL I NJ ECTI ON NOZZLE

The fuel injection nozzle or the fuel injector is fitted in the cylinder head with its

tip projected inside the combustion chamber. It remains connected to the respective

fuel injection pump with a steel tube known as fuel high pressure line. The fuel

injection nozzle is of multi-hole needle valve type operating against spring tension.

The needle valve closes the oil holes by blocking the oil holes due to spring pressure.

Proper angle on the valve and the valve seat, and perfect bearing ensures proper

closing of the valve.

Due to the delivery stroke of the fuel injection pump, pressure of fuel oil in the fuel

duct and the pressure chamber inside the nozzle increases. When the pressure of oil is

higher than the valve spring pressure, valve moves away from its seat, which

uncovers the small holes in the nozzle tip. High-pressure oil is then injected into the

combustion chamber through these holes in a highly atomised form. Due to injection,

hydraulic pressure drops, and the valve returns back to its seat terminating the fuel

injection, termination of fuel injection may also be due to the bypassing of fuel

injection through the helix in the fuel injection pump causing a sudden drop in

pressure.

CALI BRATI ON OF FUEL I NJ ECTI ON PUMPS

Each fuel injection pump is subject to test and calibration after repair or overhaul

to ensure that they deliver the same and stipulated amount of fuel at a particular rack

position. Every pump must deliver regulated and equal quantity of fuel at the same

time so that the engine output is optimum and at the same time running is smooth with

minimum vibration.

The calibration and testing of fuel pumps are done on a specially designed

machine. The machine has a 5 HP reversible motor to drive a cam shaft through V

belt. The blended test oil of recommended viscosity under controlled temperature

is circulated through a pump at a specified pressure for feeding the pump under test.

It is very much necessary to follow the laid down standard procedure of testing to

obtain standard test results. The pump under test is fixed on top of the cam box and its

rack set at a particular position to find out the quantum of fuel delivery at that

position. The machine is then switched on and the cam starts making delivery

strokes. A revolution counter attached to it is set to trip at 500 RPM or 100 RPM as

required. engine.

The calibration value of fuel injection pump as supplied by the makers is tabulated

in table 2 at 300 working strokes, rpm -500, temp.-100 to 120

0

F & pressure 40 PSI:

Table 2.

Dia.of element(mm) Rack(mm) Required volume of fuel(cc)

15 mm 30 mm(full load)

9 mm(Idling)

351 cc +5/-10

34 cc +1/-5

17 mm 28 mm (full load)

9 mm (Idling)

401 cc +4/-11

45 cc +1/-5

.FUEL I NJ ECTI ON NOZZLE TEST

The criteria of a good nozzle are good atomization, correct spray pattern and no

leakage or dribbling. Before a nozzle is put to test the assembly must be rinsed in fuel

oil, nozzle holes cleaned with wire brush and spray holes cleaned with steel wire of

correct thickness.

The fuel injection nozzles are tested on a specially designed test stand, where

the following tests are conducted.

SPRAY PATTERN

Spray of fuel should take place through all the holes uniformly and properly

atomized. While the atomization can be seen through the glass jar, an impression

taken on a sheet of blotting paper at a distance of 1 to 1 1/2 inch also gives a clear

impression of the spray pattern.

SPRAY PRESSURE

The stipulated correct pressure at which the spray should take place 3900-4050 psi

for new and 3700-3800 psi for reconditioned nozzles. If the pressure is down to

3600 psi the nozzle needs replacement. The spray pressure is indicated in the gauge

provided in the test machine. Shims are being used to increase or decrease the tension

of nozzle spring which increases or decreases the spray pressure

DRI BBLI NG

There should be no loose drops of fuel coming out of the nozzle before or after the

injections. In fact the nozzle tip of a good nozzle should always remain dry. The

process of checking dribbling during testing is by having injections manually done

couple of times quickly and checks the nozzle tip whether leaky.

The reasons of nozzle dribbling are (1) Improper pressure setting (2) Dirt stuck up

between the valve and the valve seat (3) Improper contact between the valve and

valve seat (4) Valve sticking inside the valve body.

NOZZLE CHATTER

The chattering sound is a sort of cracking noise created due to free movement of

the nozzle valve inside the valve body. If it is not proper then chances are that the

valve is not moving freely inside the nozzle.

4. EXPRESSOR________________________________________

I NTRODUCTI ON

In Indian Railways, the trains normally work on vacuum brakes and the diesel

locos on air brakes. As such provision has been made on every diesel loco for both

vacuum and compressed air for operation of the system as a combination brake

system for simultaneous application on locomotive and train.

In ALCO locos the exhauster and the compressor are combined into one unit and it

is known as EXPRESSOR. It creates 23" of vacuum in the train pipe and 140 PSI air

pressure in the reservoir for operating the brake system and use in the control system

etc.

The expressor is located at the free end of the engine block and driven through the

extension shaft attached to the engine crank shaft. The two are coupled together by

fast coupling (Kopper's coupling). Naturally the expressor crank shaft has eight

speeds like the engine crank shaft. There are two types of expressor are, 6CD,4UC &

6CD,3UC. In 6CD,4UC expressor there are six cylinder and four exhauster whereas

6CD,3UC contain six cylinder and three exhauster.

WORKI NG OF EXHAUSTER

Air from vacuum train pipe is drawn into the exhauster cylinders through the open

inlet valves in the cylinder heads during its suction stroke. Each of the exhauster

cylinders has one or two inlet valves and two discharge valves in the cylinder head. A

study of the inlet and discharge valves as given in a separate diagram would indicate

that individual components like (1) plate valve outer (2) plate valve inner (3) spring

outer (4) spring inner etc. are all interchangeable parts. Only basic difference is that

they are arranged in the reverse manner in the valve assemblies which may also have

different size and shape. The retainer stud in both the assemblies must project upward

to avoid hitting the piston.

The pressure differential between the available pressure in the vacuum train pipe

and inside the exhauster cylinder opens the inlet valve and air is drawn into the

cylinder from train pipe during suction stroke. In the next stroke of the piston the air

is compressed and forced out through the discharge valve while the inlet valve

remains closed. The differential air pressure also automatically open or close the

discharge valves, the same way as the inlet valves operate.

Compressor

The compressor is a two stage compressor with one low pressure cylinder and one

high pressure cylinder. During the first stage of compression it is done in the

low pressure cylinder where suction is through a wire mesh filter. After

compression in the LP cylinder air is delivered into the discharge manifold at a

pressure of 30 / 35 PSI. Workings of the inlet and exhaust valves are similar to that of

exhauster which automatically open or close under differential air pressure A safety

valve known as inter cooler safety valve set at 60 PSI is provided after the inter

cooler as a protection against high pressure developing in the after cooler due to

defect of valves.

After the first stage of compression and after-cooling the air is again compressed in

a cylinder of smaller diameter to increase the pressure to 135-140 PSI in the same

way. This is the second stage of compression in the HP cylinder. Air again needs

cooling before it is finally sent to the air reservoir and this is done while the air passes

through a set of coiled tubes after cooler.

6. AIR BRAKES

I NTRODUCTI ON

An air brake is a conveyance braking system actuated by compressed air.

Modern trains rely upon a fail preventive air brake system that is based upon a design

patented by George Westinghouse on March 5,1872. In the air brake's simplest form,

called the straight air system, compressed air pushes on a piston in a cylinder. The

piston is connected through mechanical linkage to brake shoes that can rub on the

train wheels, using the resulting friction to slow the train.

AI R BRAKE SYSTEM OPERATI ON

The compressor in the locomotive produces the air supplied to the system. It is

stored in the main reservoir. Regulated pressure of 6 kg/cm

2

flows to the feed pipe

through feed valve and 5-kg/cm

2

pressure by drivers brake valve to the brake pipe.

The feed pipe through check valve charges air reservoir via isolating cock and also by

brake pipe through distributor valve. The brake pipe pressure controls the distributor

valves of all the coaches/wagons which in turn control the flow of compressed air

from Air reservoir to break cylinder in application and from brake cylinder to

atmosphere in release.

During application, the driver in the loco lowers the BP pressure. This brake pipe

pressure reduction causes opening of brake cylinder inlet passage and simultaneously

closing of brake cylinder outlet passage of the distributor valve. In this situation,

auxiliary reservoir supplies air to brake cylinder

LAYOUT:-

PEV

AR CR

DV

DC

BC BC

DC

PEASD

PEASD

FP

BP

GEBV

Pressure

gauge

Cut off

angle cock

Passenger alarm

system

Guard

emergency

brake

system

Core

brake

system

The distributor valve connects brake cylinder to atmosphere. The brake cylinder

pressure can be raised or lowered in steps.

There are two case of braking, when only loco move and when entire train move.

Consequently there are two valves in the driver cabin viz SA-9&A-9. Braking

operation of above case is shown in chart below.

VALVES

A-9 Valve

The A-9 Automatic Brake Valve is a compact self lapping, pressure maintaining

Brake Valve which is capable of graduating the application or release of locomotive

and train brakes. A-9 Automatic Brake Valve has five positions: Release, minimum

Reduction, Full Service, Over Reduction and Emergency.

SA-9 Valve

SA-9 Independent Brake Valve is a compact self lapping, pressure maintaining

Brake Valve which is capable of graduating the application or release of Locomotive

Air Brakes independent of Automatic Brake. The SA-9 Independent Brake Valve is

also capable of releasing an automatic brake application on the Locomotive without

affecting the train brake application. The SA-9 Brake Valve has three positions :

quick release, release and application.

D-1 Emergency Brake Valve

The D-1 Emergency Brake Valve is a manually operated device

8. SPEEDOMETER

I NTRODUCTI ON

The electronic speedometer is intended to measure traveling speed and to record

the status of selected locomotive engine parameters every second. It comprises a

central processing unit that performs the basic functions, two monitors that are used

for displaying the measured speed values and entering locomotive drivers

identification data and drive parameters and a speed transducer. The speedometer can

be fitted into any of railway traction vehicles. The monitor is mounted on every

drivers place in a locomotive. It is connected to the CPU by a serial link. Monitor

transmits a driver, locomotive and train identifications data to the CPU and receives

data on travel speed, partial distance traveled, real time and speedometer status from

the CPU A locomotive driver communicates with the speedometer using the monitor:

a keyboard and alphanumeric displays are used for authorization purposes, travel

speed values are monitored on analog and digital displays, whereas alphanumeric

displays, LEDs and a buzzer signal provide information on speedometer and vehicle

status.

WORKI NG MECHANISM

Speedometer is a closed loop system in which opto-electronic pulse generator is

used to convert the speed of locomotive wheel into the corresponding pulses. Pulses

thus generated are then converted into the corresponding steps for stepper motor.

These steps then decide the movement of stepper motor which rotates the pointer up

to the desired position. A feed back potentiometer is also used with pointer that

provides a signal corresponding to actual position of the pointer, which then

compared with the step of stepper motor by measuring and control section. If any

error is observed, it corrected by moving the pointer to corresponding position.

Presently a new version of speed-time-distance recorder cum indicator unit TELPRO

is used in the most of the locomotive. Features and other technical specification of

this speedometer are given below.

Salient features

Light weight and compact in size

Adequate journey data recording capacity

Both analog and digital displays for speed

Both internal and external memories for data storage

Memory freeze facility

Stepless wheel wear compensation

Dual sensor opto electronic pulse generator for speed sensing

Over speed audio visual alarm

7-digit odometer

User friendly Windows-based data extraction and analysis software

Graphical and tabular reports generation for easy analysing of recorded data

Cumulative, Trip-wise, Train-wise, Driver-wise and Date-wise report generation

Master-Slave configuration

Applications

Speed indication for driver.

Administrative control of traction vehicle for traffic scheduling.

Vehicle trend analysis in case of derailment/accident.

Analysis of drivers operational performance to provide training, if required.

Technical Specifications

The system requires a wide operating voltage of 50 V DC to 140 V DC.

A. Operating conditions

Conditions Values

Temperature -5C to +70C

Relative humidity 95% (max)

Accuracy of Master & Slave 1.0% of full scale deflection

B. Analogue indication

Factors Values

Scale spread over 240

Illumination 12 equally spaced LEDs on dial circumference

Brightness control 0-100% in 10 steps

Dial size 120 mm

Dial colour White with black pointer & numerals

Max speed range 0-150, 0-160 & 0-180 Kmph (can be made as per customers

request)

C. Digital indication

Features Values

LCD display 16x2 character alphanumeric LCD with backlit control

Time display HH:MM:SS on 24-hour scale

D. General

Factors Values

Size 145x215x160 mm (typical)

Weight: Master & Slave (approx) 3.5 kg (Master); 3.15 kg (Slave)

Odometer 7 digit with 1km resolution

Input speed sensing 2 inputs for opto-electronic pulse generator 200 or 100 pulses/rev

(configurable)

9. CYLINDER HEAD

I NTRODUCTI ON

The cylinder head is held on to the cylinder liner by seven hold down studs or

bolts provided on the cylinder block. It is subjected to high shock stress and

combustion temperature at the lower face, which forms a part of combustion chamber.

It is a complicated casting where cooling passages are cored for holding water for

cooling the cylinder head. In addition to this provision is made for providing passage

of inlet air and exhaust gas. Further, space has been provided for holding fuel

injection nozzles, valve guides and valve seat inserts also.

Components of cylinder head

In cylinder heads valve seat inserts with lock rings are used as replaceable

wearing part. The inserts are made of stellite or weltite. To provide interference fit,

inserts are frozen in ice and cylinder head is heated to bring about a temperature

differential of 250F and the insert is pushed into recess in cylinder head. The valve

seat inserts are ground to an angle of 44.5 whereas the valve is ground to 45 to

ensure line contact. (In the latest engines the inlet valves are ground at 30 and seats

are ground at 29.5). Each cylinder has 2 exhaust and 2 inlet valves of 2.85" in dia.

The valves have stem of alloy steel and valve head of austenitic stainless steel, butt-

welded together into a composite unit. The valve head material being austenitic steel

has high level of stretch resistance and is capable of hardening above Rockwell- 34 to

resist deformation due to continuous pounding action.

The valve guides are interference fit to the cylinder head with an interference of

0.0008" to 0.0018". After attention to the cylinder heads the same is hydraulically

tested at 70 psi and 190F. The fitment of cylinder heads is done Better heat

dissipation

Maintenance and I nspection

Cleaning: By dipping in a tank containing caustic solution or ORION-355 solution

with water (1:5) supported by air agitation and heating.

Crack I nspection: Check face cracks and inserts cracks by dye penetration test.

Hydraulic Test: Conduct hyd. test (at 70 psi, 200F for 30 min.) for checking water

leakage at nozzle sleeve, ferrule, core plugs and combustion face.

Dimensional check :

Face seat thickness: within 0.005" to 0.020"

Straightness of valve stem: Run out should not exceed 0.0005"

Free & Compressed height (at 118 lbs.) of springs: 3 13/16" & 4 13/16"

Checks during overhauling:

Ground the valve seat insert to 44.5/29.5, maintain run out of insert within 0.002"

with respect to valve guide while grinding.

Grind the valves to 45/30 and ensure continuous hair line contact with valve guide

by checking colour match.

Ensure no crack has developed to inserts after grinding, checked by dye penetration

test.

Make pairing of springs and check proper draw on valve locks and proper condition

of groove and locks while assembling of valves.

Lap the face joint to ensure leak proof joint with liner.

Blow by test:

On bench blow by test is conducted to ensure the sealing effect of cylinder head.

Blow by test is also conducted to check the sealing efficiency of the combustion

chamber on a running engine, as per the following procedure:

Run the engine to attain normal operating temperature (65C)

Stop running after attaining normal operating temperature.

Bring the piston of the corresponding cylinder at TDC in compression stroke.

Fit blow-by gadget (Consists of compressed air line with the provision of a

pressure gauge and stopcock) removing decompression plug.

Charge the combustion chamber with compressed air.

Cut off air supply at 70 psi. Through stop cock and record the time when it comes

down to zero.7 to 10 secs is OK.

10. PIT WHEEL

LATHE

I NTRODUCTI ON

Various type of wear may occur on wheal tread and flange due to wheel skidding and

emergency breaking. Four type of wear may occur as follows:-

Tread wear

Root wear

Skid wear and

Flange wear

For maintaining the required profile pit wheel lathe are used. This lathe is installed in

the pit so that wheel turning is without disassembling the axle and lifting the loco and

hence the name pit wheel lathe

Wheel turning

Wheel turning on this lathe is done by rotating the wheels, both wheels of an axle

are placed on the four rollers, two for each wheel. Rollers rotate the wheel and a fixed

turning tool is used for turning the wheel.

Different gages are used in this section tocheck the tread profile. Name of these

gages are:-

Star gage

Root wear gage

Flange wear gage

J gage

j-gage is used to calculate the app. Dia of wheel.

Dia. Of wheel = 962 +2(j-gage reading) mm

CAUSES OF WHEEL SKI DDI NG-

On excessive brake cylinder pressure (more than 2.5 kg/cm).

Using dynamic braking at higher speeds.

When at the time of application of dynamic braking, the brakes of loco would

have already been applied. (in case of failure of D-1 Pilot valve).

Continue working , when C-3-W Distributor valve P/G handle is in wrong

position.

Due to shunting of coaches with loco without connecting their B.P./vacuum pipe.

Shunting at higher speeds.

Continue working when any of the brake cylinder of loco has gotten jammed.

The time of application/release of brakes of any of the brake cylinder being larger

than the others.

When any of the axle gets locked during on the line.

11. FAILURE ANALYSIS

I NTRODUCTI ON

A part or assembly is said to have failed under one of the three conditions:-

When it becomes completely inoperable-occurs when the component breaks into two

or more pieces.When it is still inoperable but is no longer able to perform its intended

function satisfactorily- due to wearing and minor damages.

When serious deterioration has made it unreliable or unsafe for continuous use, thus

necessitating its complete removal from service for repair or replacement-due to

presence of cracks such as thermal cracks, fatigue crack, hydrogen flaking.

In this section we will study about:-

Metallurgical lab.

Ultrasonic test

Zyglo test and

RDP test.

Metallurgical lab.

Metallurgical lab. concern with the study of material composition and its

properties. Specimens are checked for its desired composition. In this section various

tests are conducted like hardness test, composition test e.g determination of

percentage of carbon, swelling test etc.

Function of some of the metal is tabulated in table below :-

S.No. Compound Function

1. Phosphorous Increase the fluidity property

2. Graphite Increase machinability

3. Cementide Increase hardness

4. Chromium Used for corrosion prevention

5. Nickel Used for heat resistance

6. Nitride rubber Oil resistance in touch of O ring

7. Neoprene Air resistance & oil resistance in fast coupling in

rubber block.

8. Silicon Heat resistance and wear resistance (upto 600 C )

use at top and bottom pore of liner.

Swelling test

Swelling test is performed for rubber in this test percentage increase in weight of the

rubber after immersing in solution is measured and increase in weight should not be

more than 20%. Two type of swelling test viz low swelling and high swelling are

performed in the lab. Three type of oil solution are used for this purpose listed below:-

ASTM 1

ASTM 2

ASTM 3

Procedure

1. Select specimen for swelling test

1. Note the weight of the specimen

2. Put in the vessel containing ASTM 1 or ASTM 3

3. Put the oven at 100 C

4. Put the vessel in the oven for 72 hrs.

5. After 72 hrs. Weigh the specimen.

Rubber

Broadly there are two types of rubber:

1). Natural rubber- this has very limited applications. It is used in windows and has a

life of 1 year.

2). Synthetic rubber- this is further subdivided into five types.

VUNA-N (2 year life)

Polychloroprene or Neoprene (2 year life)

SBR (3 year life)

Betel (3 year life)

Silicone (3 year life).

VUNA-N rubber is used in oily or watery area, neoprene is used in areas surrounded

by oil and air while betel and silicone are used in areas subjected to high temperatures

such as in pistons.

When the fresh supply of rubber comes from the suppliers it is tested to know its

type.The test consists of two solutions, solution 1 and solution 2, which are subjected

to the vapors of the rubber under test and then the color change in solution is used for

determination of the type of rubber. The various color changes are as follows:

Violet- natural rubber

Pink- nit rile

Green-SBR

When no color change is observed the vapours are passed through solution 2. The

colour change in solution 2 is: Pink- neoprene.

Silicone produces white powder on burning. If there is no result on burning then the

rubber is surely betel.

ULTRASONI C TESTI NG

In ultrasonic testing, very short ultrasonic pulse-waves with center frequencies

ranging from 0.1-15 MHz and occasionally up to 50 MHz are launched into materials

to detect internal flaws or to characterize materials.

Ultrasonic testing is often performed on steel and other metals and alloys, though it

can also be used on concrete, wood and composites, albeit with less resolution. It is a

form of non-destructive testing.

ZYGLO TEST

The zyglo test is a nondestructive testing (NTD) method that helps to locate and

idetify surface defects in order to screen out potential failure-producing defects. It is

quick and accqurate process for locating surface flaws such as shrinkage cracks,

porosity, cold shuts, fatigue cracks, grinding cracks etc. The ZYGLO test works

effectively in a variety of porous and non-porous materials: aluminum, magnesium,

brass, copper, titanium, bronze, stainless steel, sintered carbide, non-magnetic

alloys, ceramics, plastic and glass. Various steps of this test are given below:-

Step 1 pre-clean parts.

Step 2 apply penetrant

Step 3 remove penetrant

Step 4 dry parts

Step 5 apply developer

Step 6 inspection

RED DYE PENETRATI ON TEST (RDP)

Dye penetrant inspection (DPI), also called liquid penetrant inspection (LPI), is a

widely applied and low-cost inspection method used to locate surface-breaking

defects in all non-porous materials (metals, plastics, or ceramics). Penetrant may be

applied to all non-ferrous materials, but for inspection of ferrous components

magnetic particle inspection is preferred for its subsurface detection capability. LPI is

used to detect casting and forging defects, cracks, and leaks in new products, and

fatigue cracks on in-service components.

Principles

DPI is based upon capillary action, where low surface tension fluid penetrates into

clean and dry surface-breaking discontinuities. Penetrant may be applied to the test

component by dipping, spraying, or brushing. After adequate penetration time has

been allowed, the excess penetrant is removed, a developer is applied. The developer

helps to draw penetrant out of the flaw where a visible indication becomes visible to

the inspector.

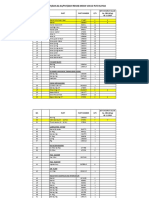

13.YEARLY/MECHANICAL

In this section, major schedules such as M-24, M48 and M-72 are carried out. Here,

complete overhauling of the locomotives is done and all the parts are sent to the

respective section and new parts are installed after which load test is done to check

proper working of the parts. The work done in these sections are as follows:

1). Repeating of all items of trip, quarterly and monthly schedule.

2). Testing of all valves of vacuum/compressed air system. Repair if necessary.

3). Replacement of coalesce element of air dryer.

(4). Reconditioning, calibration and checking of timing of FIP is done. Injector is

overhauled.

(5). Cleaning of Bull gear and overhauling of gear-case is done.

(6). RDP testing of radiator fan, greasing of bearing, checking of shaft and keyway.

Examination of coupling and backlash checking of gear unit is done.

(7). Checking of push rod and rocker arm assembly. Replacement is done if bent or

broken. Checking of clearance of inlet and exhaust valve.

(8). Examination of piston for cracks, renew bearing shell of connecting rod fitment.

Checking of connecting rod elongation.

(9). Checking of crankshaft thrust and deflection. Shims are added if deflection is

more then the tolerance limit.

(10). Main bearing is discarded if it has embedded dust, gives evidence of fatigue

failure or is weared.

(11). Checking of cracks in water header and elbow. Install new gaskets in the air

intake manifold. Overhauling of exhaust manifold is done.

(12). Checking of cracks in crankcase, lube oil header, jumper and tube leakage in

lube oil cooler. Replace or dummy of tubes is done.

(13). Lube oil system- Overhauling of pressure regulating valves, by pass valve, lube

oil filters and strainers is done.

(14). Fuel oil system- Overhauling of pressure regulating valve, pressure relief valve,

primary and secondary filters.

(15). Checking of rack setting, governor to rack linkage, fuel oil high-pressure line is

done.

(16). Cooling water system- draining of the cooling water from system and cleaning

with new water carrying 4 kg tri-phosphate is done. All water system gaskets are

replaced. Water drain cock is sealed. Copper vent pipes are changed and water hoses

are renewed.

(17). Complete overhauling of water pump is done. Checking of impeller shaft for

wear and lubrication of ball bearing. Water and oil seal renewal.

(18). Complete overhauling of expressor/compressor, pistons rings and oil seal

renewed. Expressor orifice test is carried out.

(19). Complete overhauling of Turbo supercharger is done. Dynamic balancing and

Zyglo test of the turbine/impeller is done. Also, hydraulic test of complete Turbo

supercharger is done.

(20). Overhauling of after-cooler is done. Telltale hole is checked for water leak.

(21). Inspection of the crankcase cover gasket and diaphragm is done. It is renewed if

necessary.

(22). Rear T/Motor blower bearing are checked and changed. Greasing of bearing is

done.

(23). Cyclonic filter rubber bellows and rubber hoses are changed. Air intake filter

and vacuum oil bath filter are cleaned and oiled.

(24). Radiators are reconditioned, fins are straightened hydraulic test to detect leakage

and cleaning by approved chemical.

(25). Bogie- Checking of frame links, spring, equalizing beam locating roller pins for

free movement, buffer height, equalizer beam for cracks, rail guard distance is done.

Refilling of center plate and loading pads is done. Journal bearings are reconditioned.

(26). Axle box- cleaning of axle box housing is done.

(27). Wheels- inspection for fracture or flat spot. Wheel are turned and gauged.

(28). Checking of wear on horn cheek liners and T/M snubber wear plates.

(29). Checking of brake parts for wear, lubrication of slack adjusters is done.

Inspection for fatigue, crack and distortion of center buffers couplers, side buffers are

done.

(30). Traction motor suspension bearing- cleaning of wick assembly, checking of

wear in motor nose suspension. Correct fitment of felt wick lubricators is ensured.

Axle boxes are refilled with fresh oil. Testing of all pressure vessels is carried out.

Examination while Engine is running.

(32). Expressor orifice test is performed. Engine over sped trip assembly operation,

LWS operation are checked. Checking of following items is done:

Water and oil leakage at telltale hole of water pump, turbo return pipes for leakage

and crack, air system for leakage, fuel pump and pipes for leakage, exhaust manifold

for leaks, engine lube oil pressure at idle, turbo for smooth run down as engine is

stopped. Difference in vacuum between vacuum reservoir pipe and expressor

crankcase & and pressure difference across lube oil filters at idle and full engine

speed are recorded.

(33). Brakes at all application positions are checked. Checking of fast and flexible

coupling is done and the expressor is properly aligned. Inspection of camshaft.

Lubrication of hand brake lever and chain.

(37). Speedometer- Overhaul, testing of speed recorder and indicator, pulse generator

is done.

(38). Additional items for WDP1:-Overhauling and operation of TBU is done, center

pivot pin is checked, and CPP bush housing liners are checked for wear, inspection of

vibration dampers for oil leakage and their operation. RDP test is done to check for

cracks at critical location in the bogie frame. Checking of coil springs for free height.

(39). Additional items for WDP2 locos:-Checking for cracks bogie frame and

bolster. Checking of hydraulic dampers for oil leakage. Check coil spring for

free height. Zyglo test of guide link bolts is performed. Examination of taper

roller bearing for their condition and clearance is done. Check and change

center pivot liners. Checking of tightness of nuts on brake head pin.

Disassembly, cleaning, greasing, repairing, replacement of brake cylinder

parts is done. Ultrasonic test of axles is performed. Visual Examination of

suspension springs for crack and breakage. Checking of free and working

height of spring. Inspection of bull gear for any visible damage is done and the

teeth profile is checked. Test loco on load box as per RDSO standards.

PROJ ECT STUDY

Project title:- To study about turbo supercharger of locomotive

TURBOSUPERCHARGERS

A turbosupercharger, or turbo, is a gas compressor that is used for forced-induction of

an internal combustion engine. It increases the density of air entering the engine to

create more power.

A turbosupercharger has the compressor powered by a turbine, driven by the engine's

own exhaust gases. The turbine and compressor are mounted on a shared shaft. The

turbine converts exhaust heat and pressure to rotational force, which is in turn used to

drive the compressor. The compressor draws in ambient air and pumps it in to the

intake manifold at increased pressure, resulting in a greater mass of air entering the

cylinders on each intake stroke.

Turbosupercharging dramatically improves the engine's specific power, power-to-

weight ratio and performance characteristics which are normally poor in non-

turbosupercharged diesel engines.

TURBOS USED IN DIESEL LOCOMOTIVE

In diesel locomotives, different turbos are used for different engines on the basis of

their horsepower and make. Still, their general function remains the same i.e. to

provide compressed air to the engine by employing the energy of exhaust gases. The

exhaust manifold is connected to the inlet of the turbocharger. The exhaust gases enter

the gas inlet casing where they are directed towards the nozzle ring. The function of

the nozzle ring is to guide the exhaust gases and reduce shock on the turbine blades.

The exhaust gases impinge on the turbine blades and cause the turbine to rotate on

\their way out to the atmosphere through the chimney.

The rotating turbine causes the impeller of the compressor to rotate along with it since

they are mounted on the same shaft. The compressor starts sucking air through the air

inlet casing and compresses it due to the centrifugal action of the impeller. After

leaving the impeller, the air gets compressed further in the diffuser vanes. From here

the compressed air is passed into the blower casing, which guides the air to an

aftercooler. The function of the aftercooler is to cool the compressed air and

consequently reduce its specific volume. The pressure of this compressed air is in the

range of 1.2-1.8 kg/cm2, and this is known as BOOSTER AIR PRESSURE (BAP).

This compressed air is then introduced into the air gallery, which is connected to the

intake valves of all the cylinders.

Turbosuperchargers from the following manufacturers are used in diesel locomotives:

ABB

ALCO

NAPI ER

GENERAL ELECTRI C (GE)

HI SPANO SUI ZA

ELGI

COMPARISON OF DIFFERENT TURBO MAKES

The specifications of the turbos used in diesel locomotives are as follows:

1. ALCO-2600

Power Rating: 2600 HP

Cooling System: Water Cooled

Rundown Time: 80-190 seconds

2. ABB-2300

Power Rating: 2300 HP

Cooling System: Water Cooled

Rundown Time: 60-120 seconds

3. ABB-2600

Power Rating: 2600 HP

Cooling System: Water Cooled

Rundown Time: 60-120 seconds

4. ABB-3100

Power Rating: 3100 HP

Cooling System: Water Cooled

Rundown Time: 60-120 seconds

5. ABB-TPR 61

Power Rating: 3300 HP

Cooling System: Air Cooled

Rundown Time: 60-120 seconds

6. NAPI ER-2300

Power Rating: 2300 HP

Cooling System: Water Cooled

Rundown Time: 20-60 seconds

7. NAPI ER-2600

Power Rating: 2600 HP

Cooling System: Water Cooled

Rundown Time: 20-60 seconds

8. NAPI ER-3100

Power Rating: 3100 HP

Cooling System: Water Cooled

Rundown Time: 20-60 seconds

9. GE-3100 SI NGLE DI SCHARGE

Power Rating: 3100 HP

Cooling System: Water Cooled

10. GE-3100 DOUBLE DI SCHARGE

Power Rating: 3100 HP

Cooling System: Water Cooled

*Has two outlets for air in the blower casing and hence uses two aftercoolers.

11. HI SPANO SUI ZA-3100

Power Rating: 3100 HP

Cooling System: Air Cooled

12. ELGI

Power Rating: 4000 HP

ALCO FRONT VIEW

ALCO TOP VIEW

ALCO ASSEMBLY

GE (DOUBLE DISCHARGE) FRONT VIEW

GE (DOUBLE DISCHARGE) TOP VIEW

GE (DOUBLE DISCHARGE) BOTTOM VIEW

GE (DOUBLE DISCHARGE) ASSEMBLY

TURBO OPERATING DIFFICULTIES:

Operating difficulties can be prevented providing the daily turbocharger operating

data is measured and regular maintenance and inspection routines are adhered to.

To assist in identifying causes of performance deterioration, the following table has

been formed:

OPERATI NG

DI FFI CULTI ES

PROBABLE CAUSE REMEDI AL

MEASURES

Engine starts running but

the turbocharger does not.

Foreign matter/debris

caught between the

turbine blade tips and the

shroud ring.

Blade tips rubbing the

shroud ring.

Provide cleaning and

eliminate the cause for the

ingress of the foreign

matter.

Bearing Disorder

Inspect and replace with

new bearing.

Turbocharger experiences

surging during operating.

Fouling of turbine nozzle,

blades.

Engine Cylinder

unbalance.

Note: Rapid Changes of

the engine load,

particularly during shut-

down can cause

turbocharger surging.

Cleaning of the turbine

side of turbocharger as

required.

Refer to Engine Builders

Instruction Manual.

Exhaust gas temperature

higher than normal.

Fouling or damage to

turbine nozzle or turbine

blades.

Lack of air e.g.: dirty air

filter.

Exhaust back pressure too

high.

Charge air cooler dirty,

cooling water temperature

too high.

Cleaning the turbine side

of the turbocharger or

component replacement.

Clean as required.

Investigate cause.

Clean and adjust as

Makers

Instruction Manual.

Engine fault in fuel

injection system.

Charge air (boost)

pressure lower than

normal.

Pressure gauge faulty or

connection to it is leaking.

Gas leakage at engine

exhaust manifold.

Dirty Air filter, causing

pressure drop.

Dirty turbocharger.

Turbine blades or nozzle

ring damage.

Rectify.

See Engine Builders

Instruction Manual.

Clean air as required.

Cleaning of complete

turbocharger required.

Inspect and replace as

necessary.

Charge air pressure

(boost) higher than

normal.

Pressure gauge reading

incorrectly.

Nozzle ring clogged with

carbon deposits.

Engine Overload, engine

output higher than

expected.

Fault in engine fuel

injection system.

Rectify.

Clean as required.

Consult Engine Builders

Instruction Manual.

Consult Engine Builders

Instruction Manual.

TURBO OVERHAULING

The overhauling and servicing of a turbosupercharger is broadly divided into

five parts which are:

Dismantling of the turbo

Cleaning of the turbo

Inspection of different parts

Repair and rotor balancing

Assembly of the turbo

DISMANTLING OF THE TURBO

Turbocharger Vibration Severe unbalance of rotor

due to dirt or damaged

turbine blades.

Bent rotor shaft.

Defective bearings.

Rebalance the rotor

assembly.

Inspect and replace as

necessary.

Inspect and replace as

necessary.

Dismantling of a turbo requires trained personnel and special tools (allen keys,

spanners, suspension yoke, support, etc). It is a complicated process and should be

done very carefully after referring to the manufacturers instruction manual.

CLEANING OF THE TURBO

Cleaning work includes regular visual checks and the cleaning of parts to ensure the

correct functioning of the turbo.

Outline of cleaning work

The following figure explains the various symbols used in the previous figure:

GAS CASING:

Deposits often form on the nozzle ring and the turbine blades. Impaired efficiency and

performance of the engine are the result.

Thick and irregular deposits can also result in an un-permissible unbalance of the

rotor.

Cleaning of the cooling water passage of gas outlet casing:

Commercial HCL of 5% concentration is used for cleaning and defurring. An

inhibitor is added to reduce the corrosion of cast iron.

Neutralisation with 5% NaOH (alkaline) solution follows the acid wash.

Fresh water is used foe flushing/rinsing.

All casing gaskets are replaced.

Gas inlet casing:

Deposits are cleaned with soft wire brush and with either diesel/kerosene + 20%

mineral oil solution (80/20 solution).

BEARI NG CASI NG:

Cleaning of the sealing air ducts:

The carbon deposits are dissolved and cleaning is done with the help of flexible wire

for ensuring free passage.

Compressed air is used to check that the sealing air ducts in the bearing casing are

unobstructed / unchoked.

Oil Passages:

It is cleaned with 80% kerosene/diesel + 20% mineral oil solution (i.e. 80/20

solution).

AIR OUTLET CASING:

The deposits are cleaned with soft wire brush and 80/20 solution.

ROTOR PARTS:

The turbine blades can be cleaned by glass bead blasting. The seating areas for

compressor wheel set, thrust bearing and floating bushes (Bearing compressor side +

Turbine side) are protected by means of rubber sleeve. The cleaning of the

compressor wheel set is carried out with 80/20 solution and therefore with malmal

(piece of cloth).

Rotating parts are thoroughly cleaned uniformly as uneven residual deposits lead to

unbalance.

BEARING PARTS:

All bearing parts, bearing covers are cleaned in 80/20 solution and with malmal (piece

of cloth). Special care is taken to clean the carbon deposits from the O ring grooves

and the oil supply/oil drain lines.

INSPECTION OF THE TURBO:

After dismantling and cleaning of the turbo, it is inspected for any faults. All the

clearances and blade conditions are checked and a note of all the repair work needed

is made.

REPAIR AND BALANCING OF ROTOR:

Various parts of the turbo are repaired as necessary. The rotor is examined carefully

and any distorted turbine blade is ground with a grinder so that it is smooth again. The

rotor is then checked if it is unbalanced and is balanced on a Rotor Balancing

Machine if needed.

In the course of manufacture, following parts are balanced individually:

Shaft

Sets of compressor wheel

While the engine is running, many reasons may cause unbalance to the rotor:

Mechanical damages on the rotor, i.e. foreign bodies.

Uneven deposits of layer of dirt/carbon.

Abrasion on the compressor or the turbine caused by hard particles in the intake air or

in the exhaust gas.

Balancing must be done when:

Rotating components feature mechanical damages.

After reblading of turbine.

After repairs on the inducer or compressor wheel.

After replacing the inducer or compressor wheel.

Balancing is not required when:

A new bladed shaft is assembled into the turbocharger.

If, due to a change of specification, the set of wheels has to be changed for a new one.

ABRO ROTOR BALNCING MACHINE

GE ROTOR ON BALANCING MACHINE

TURBO RUNDOWN TIME

The Turbo Rundown Time (TRD) of a turbo is the total time taken by the turbo to

come to a standstill, measured from the instant the crankshaft of the engine stops. This

time should be within a certain limit prescribed by the manufacturer. If not so, it

indicates a fault in the turbo. The rundown times of different turbos have been

mentioned earlier.

Turbo Rundown Test (for WDM-2 Loco)

This test is to be conducted if the Booster (Turbocharger in WDM-2 pidgin) is not

developing proper pressure during a run.

1. Secure the loco: Keep the A9 (Train Brake lever) in released condition; keep

the SA9 (Loco brake lever) in an applied condition; switch off the GF

(Generator Field); keep the reverser in neutral condition; and put the ECS

(Engine control switch) in the run mode.

2. Ensure that the water temperature is higher than 49 degrees Celsius.

3. The driver should climb on top of the hood and sight the turbine of the

turbocharger through the chimney.

4. The assistant should raise the engine to 4th notch rpm and allow the engine to

stabilize in speed.

5. The assistant should now shut the engine down by operating the MUSD

(Multiple Unit Shut Down) breaker on the control stand.

6. As the engine begins to stop turning, the assistant must quickly get down and

come to the hood door to the Expressor.

7. He must give a signal to the driver as to the instant the huge engine stops

rotating by looking at the crankshaft of the engine coupled to the expressor.

8. The driver must count the number of seconds the exhaust turbine takes to

come to a stop, from the instant the engine has come to a standstill.

9. If the turbine (which revolves at 18,000 to 19,000 rpm) takes more than 90

seconds then it is a good turbocharger, any reduction in the period of spinning

down is an indication of a faulty turbo.|~|

REFERENCES:

I.R.I.M.E.E, JAMALPUR

R.D.S.O, LUCKNOW

TKD SHED LIBRARY

INTERNET

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Nuradi Maintain A Safe Engineering Watch - pdf-1Dokumen74 halamanNuradi Maintain A Safe Engineering Watch - pdf-1Dimas wangsit indraprasti0% (5)

- ASTM D5185-18-ICP-L-Bpn (29-01-2019)Dokumen9 halamanASTM D5185-18-ICP-L-Bpn (29-01-2019)I Wayan Arief Pradana Putra100% (3)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- CAE Oxford Aviation Academy - 020 Aircraft General Knowledge 3 - Powerplant (ATPL Ground Training Series) - 2014 PDFDokumen460 halamanCAE Oxford Aviation Academy - 020 Aircraft General Knowledge 3 - Powerplant (ATPL Ground Training Series) - 2014 PDFAli93% (15)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Book of The Honda by John Thorpe 1966Dokumen112 halamanThe Book of The Honda by John Thorpe 1966greaternorthroad8820100% (1)

- Alpha Lubricator System Operation (ALCU 2004-04-13) Manual MCDokumen236 halamanAlpha Lubricator System Operation (ALCU 2004-04-13) Manual MCraden_aditiya39Belum ada peringkat

- Thermo Cycles 2Dokumen16 halamanThermo Cycles 2cobalt boronBelum ada peringkat

- Catalog No. EP-30MV-06: Weatherly Index 002 2006Dokumen82 halamanCatalog No. EP-30MV-06: Weatherly Index 002 2006RichardReveloBelum ada peringkat

- Project ReportDokumen25 halamanProject ReportARUN KUMAR78% (9)

- Push - Rod Suspension System Used in F-1Dokumen23 halamanPush - Rod Suspension System Used in F-1Ashish RawatBelum ada peringkat

- Babbitt MetalDokumen23 halamanBabbitt MetalAshish Rawat100% (1)

- Report On Pushrod SuspensionDokumen33 halamanReport On Pushrod SuspensionAshish Rawat100% (4)

- Seminar Report Rohit JainDokumen49 halamanSeminar Report Rohit JainAshish Rawat25% (4)

- Sheet Metal Working PressesDokumen48 halamanSheet Metal Working PressesAshish RawatBelum ada peringkat

- BoilersDokumen47 halamanBoilersAshish RawatBelum ada peringkat

- Sensors 1Dokumen24 halamanSensors 1Ashish RawatBelum ada peringkat

- Aayush Sable Mechanical EngineeringDokumen40 halamanAayush Sable Mechanical EngineeringAshish RawatBelum ada peringkat

- Order On ARR and Tariff Petition of IPGCL For FY 2006-07Dokumen55 halamanOrder On ARR and Tariff Petition of IPGCL For FY 2006-07Aggyapal Singh JimmyBelum ada peringkat

- YingPai BrochureDokumen20 halamanYingPai BrochureM2 XBelum ada peringkat

- Spare Parts Catalogue: 26 kVA - 200 kVA DieselDokumen470 halamanSpare Parts Catalogue: 26 kVA - 200 kVA DieselDmitryBelum ada peringkat

- Emergency Diesel Generator Set Stage-1Dokumen14 halamanEmergency Diesel Generator Set Stage-1raghavendran raghuBelum ada peringkat

- Rehab VOLVO PENTA TAD 1630 GE Kayoa PDFDokumen4 halamanRehab VOLVO PENTA TAD 1630 GE Kayoa PDFsasen setyonoBelum ada peringkat

- WH713 1 WH714 1 WH714H 1 WH716 SN 395F70001-Up PDFDokumen655 halamanWH713 1 WH714 1 WH714H 1 WH716 SN 395F70001-Up PDFdrmasster100% (1)

- Aakash Ic EngineDokumen41 halamanAakash Ic EngineAakash ManavBelum ada peringkat

- Mechatronics 1Dokumen112 halamanMechatronics 1vijayBelum ada peringkat

- 5307 5407.2.IA Operator HandbookDokumen170 halaman5307 5407.2.IA Operator HandbookJames Peng100% (1)