GA Maintavi

Diunggah oleh

773389brDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

GA Maintavi

Diunggah oleh

773389brHak Cipta:

Format Tersedia

TECHNICAL HANDLING MANUAL

CHAPTER IV

MAINTENANCE REPORT &

RECORD

IV MAINT. REPORT & RECORD

TECHNICAL HANDLING MANUAL

Date : Dec. 21, 2011 THM : IV

Issue : 1 Rev : 7 Page : 1 of 16

1. GENERAL

Maintenance record means to entry all technical aspect of work performed on aircraft during

maintenance and issuing maintenance release on assigned form to the type of aircraft

inspection and retains those record in accordance with procedure described in the CASR

121.380 & 121.703. and chapter I I I , VII I this manual.

Maintenance report means to give information of all technical aspect to the concerned unit in

order to have the follow up action of problem during maintenance process.

The following is mandatory report have to be issued by all Line Maintenance Station Engineer:

a. Technical Trouble & Delay Report. f. Inventory Report.

b. MAINTAVI Message. g. Component/ Part Use Report.

c. Accident/ Incident Preliminary Report. h. Third Party Work Report (if any).

d. AOG Report. i. Service Difficulty Report.

e. Personnel Injury Report.

2. TECHNI CAL TROUBLE AND DELAY REPORT

The purpose of the Technical Trouble Delay Report (TTDR) is to give factually irregularities

information to the Cengkareng base Maintenance Control Center (CGKMOGA, CGKMLGA) and

enroute station in order the necessary action to prevent reoccurrence of the delay.

The Technical Trouble Delay Report shall be submitted whenever a technical irregularity

involves either a departure delay exceeding 5 minutes or cancellation of a flight, TTDFR Form

MZ-2-11 shall be used to report that delay. See para 12 TTDR form sample.

a. Definition.

1) Delay Flight.

The condition of aircraft dispatched more than 5 minutes from the assigned

scheduled.

2) Rescheduled Flight.

Assigned flight scheduled has been revised for certain time (more than 12 hours ) at

least 24 hours prior to its original departure time.

3) Cancelled Flight.

When the aircraft can not be dispatch under any circumstance from the assigned

scheduled time.

b. Responsibility.

It is the responsibility of the ground engineer to report any technical trouble delay

occurrence during his duties.

3. MAINTAVI MESSAGE

The MAINTAVI Message (Maintenance Advisement) is an maintenance information consist of

technical irregularity reported by flight crew or ground engineer, servicing and delays during

maintenance in flight line.

This report shall be sent to the Enroute Station and Cengkareng Base (Maintenance Control

Center) CGKMOGA and CGKMLGA immediately to acknowledge the Cengkareng base and

enroute station take the necessary action. MAINTAVi telex formats :

- Address,.

IV MAINT. REPORT & RECORD

TECHNICAL HANDLING MANUAL

Date : Dec. 21, 2011 THM : IV

Issue : 1 Rev : 7 Page : 2 of 16

XXXXXGA (Enroute Sta), CPYXXXX, (Home Base) CGKMLGA, CGKMTGA, and CGKMOGA.

- Sender.

- Telex no.

If there any irregularities or delay flight the telex copy shall be added to CGKMQGA, JKTOMGA,

CGKMOGA and XXXKKGA (local/ departure GA Station manager) .

For requesting material, component the copy telex shall be added to CGKMMGA, CGKMDGA,

CGKBTGA.

Telex address

CGKMOGA - Home base Maintenance Control Center.

CGKMTGA - Cengkareng GMF Line Maintenance.

CGKMLGA - Garuda Indonesia Line Maintenance.

CGKMMGA - Home base parts/ material shipping unit.

CGKMKGA - Home base Cabin Maintenance.

CGKMQGA - GA Airworthiness Management Department.

JKTOMGA - Home base Aircraft Movement Control.

XXXKKGA - Departed Aircraft, (XXX Sta) Local Station Manager.

JKTOFGA - Flight Operation Department.

JKTBTGA - Material AOG Desk.

CGKMDGA - Home Base Material Department.

MAI NTAVI -MESSAGE

PREFIX ADDRESS ENROUTE STATION

ORIGINATOR DATE/TIME (IN UTC)

NUMBER OF MAINTAVI/ FINAL Flt. No/Date

PK-.. ....../..........

KEEP TEXT SHORT AND CLEAR

A. 1. AML/CML Seq no, PILOT / FLIGHT CREW REPORT IN THE AML or CML

2. AML/CML Seq no, PILOT / FLIGHT CREW REPORT IN THE AML or CML

B. 1. XXXXX RECTIFICATION/ ACTION TAKEN TO THE A/C TROUBLE.

2. XXXXX Next RECTIFICATION/ ACTION TAKEN TO THE A/C TROUBLE

C. 1. AML/CML Seq no, FIC ,DEFECT FINDING/ CMC/PFR FOR A-330/ B747-400/

2. AML/CML, Next Finding

D. 1. XXXXX RECTIFICATION OF THE FINDING TROUBLE

2. XXXXX

E. XX/XX/XXXX SERVICING (ENGINE OIL, HYDRAULIC FLUID, ETC)

XX/XX/XX/XX

F. ETA/ATA ETD/ATD THE ESTIMATE/ACTUAL TIME OF ARRIVAL/ DEPARTURE IN UTC

G. TOTAL DELAY AND DELAY CODE (IATA/GA-PIP DELAY CODE)

H. AIRCRAFT RELEASED IN HIL STATUS

SI. SPECIAL INFORMATION FOR ETOPS FOR A330 AND AUTOLAND STATUS / APU STATUS

BRGDS NAME OF RELEASE HOLDER/ AUTH THE NAME OF ORIGINATOR/ SENDER

Form MZ-2-15

a. Normal Condition.

When the aircraft departure on time the MAINTAVI should be made after the aircraft

airborne with text in the item G No Technical Delay .

Example: Route AKL to DPS

QD DPSMMGA CPYXXXX CGKMOGA CGKMLGA

IV MAINT. REPORT & RECORD

TECHNICAL HANDLING MANUAL

Date : Dec. 21, 2011 THM : IV

Issue : 1 Rev : 7 Page : 3 of 16

.IZNMZKE 121145

MM/TX/34/JAN/05

MAINTAVI ONE N FINAL GA-713 PK-GGP/ DTE

A. AML SEQ 37, AUTOLAND (LAND2) WAS SATISFACTORY C/O

B. REF MSG 22405 RESET MM-C GRD TEST RESULT PASSED

C. NIL

D. NIL

E. ENGINE OIL 00/ 01 HYD : 02/ 03

F. ETA/ ATA 2300/ 2250 ETD/ ATD 0100/ 0100

G. NO TECH DEL

H. NIL

BRGDS SURYO /22200

b. Technical Delay Condition.

Technical Delay Exceeding 5 Minutes.

If the technical delay is 30 minutes or less (exceeding 5 min), MAINTAVI One and Final

message is only required. Describing the exact reason for the technical delay, including

ETA/ ATA and ETD/ ATD. The message must be sent within 15 minutes after ATD.

Example: Route RUH to CGK.

QD CGKMOGA CGKMTGA CGKMKGA CPYXXXX CGKMQGA JKTOMGA CGKMLGA

.RUHKKGA 181423NOV01

MM/TX/127/ FEB/ 01

MAINTAVI ONE N FINAL GA-975/ PK-GSI/ DTE

A. 1. ENG #1 FUEL FILTER ICING LT REMAIN ILL DURING WHOLE POS GRND N FLT

REMAIN ILL AFTER FUEL HEAT APPLIED

2. RECOMPL NO.4 ADP PRESS LT ILL WITH THE RUN LT ILL X ADP PRESS

FLUCTUATING 2000-2600 PSI

3. LOCK SYS GALLEY 609/659 U/S

4. COFFE MAKER POS 206 U/S

5. READING LT SEAT 25D U/S

B. 1. CHK FOUND FILTER DIFF PRESS SW STUCK CLOSED X DUE TO NIS DISPATCH

PER DDG 01-73 ITEM 4 PAGE-1 N TRF TO HIL

2. FOUND NO.4 ADP TURBINE DRIVE OIL EMPTY X SERVICED OIL ADP TURBINE

DRIVE

X RUN ADP IN AUTO N CONTINOUS POS X ADP OIL LEAK CHECK OK X PRESS

CHK 3000 PSI X PSE REPORT FURTHER

3. RETIGHTENED LOCK POS 609/659 X CHK OK NOW

4. RESET THERMAL SW C/M 206

5. RELAMPED SEAT 25D BUT STILL BAD X SUSPECT DECODER WAS BAD X TRF DUE

TO NIS SPARE P/N 1103070-110

P/N 1103070.

C. NIL

D. NIL

E. ENG OIL 00/02/01/00

F. ETA/ATA 0915/0950 ETD/ATD 1415/ 1440

G. TOTAL DELAY 00.25

H. 1. REF DDG 01-73 FUEL DIFF PRESS SW. STUCK CLOSE HIL CAT C P/N 642067

2. READING LIGHT DECODER P/N 1103070-110 HIL

BRGDS ANGGORO/ 2552

Technical Delay more than 30 Minutes.

If the expected delay more than 30 minutes, the MAINTAVI ONE message should be sent

within 30 minutes after scheduled departure time, not to delay the MAINTAVI TWO

message.

Example:

IV MAINT. REPORT & RECORD

TECHNICAL HANDLING MANUAL

Date : Dec. 21, 2011 THM : IV

Issue : 1 Rev : 7 Page : 4 of 16

QD CGKMOGA CGKMTGA CPYXXXX JKTOMGA CGKMQGA CGKMLGA DPSKKGA

.DPSMMGA 121355/FEB05

MM/TX/187/FEB/05

MAINTAVI ONE GA-443/DTE PK-GGD

LIGHTNING STRIKE DURING APPROACH DPS WITH EXTENDED LANDING GEAR STP.

INSPECTION IAW TO AMM CHAP 5-53-00 IN PROGRESS STP ADVCT 1415 FLSTP

BRGDS MADE/ AUTH. NO.

A MAINTAVI TWO and/ or further MAINTAVI message should be sent if the investigation

has been completed and/ or further information available, describing the finding in detail.

In case of prolong delays, keep home base informed at regular intervals about progress

of work.

Example:

QD CGKMOGA CGKMTGA CPYXXXX JKTOMGA CGKMQGA CGKMLGA DPSKKGA

.DPSMMGA 121447/NOV02

MM/TX/188/NOV/02

MAINTAVI TWO GA-443/DTE PK-GGD

LIGHTING STRIKE INSPECTION PERFORMED WITH FOLLOWING FINDINGS CMA RH STAB

STATIC DISCHARGE COMPLETELY BURN STP PART BEING REPLACED STP ADVCT 1545

FLSTP

BRGDS MADE/ AUTH. NO

As standard time The FINAL MAINTAVI should be sent whenever the repair was

completed. The FINAL MAINTAVI message must contains ETA/ATA and ETD/ATD, TOTAL

TIME DELAY, DELAY CODE (Ref. MAINTAVI...AND FINAL FORM). Use GMT/UTC.

Note: Garuda-Punctuality Improvement Program Delay Code may be used in order to

analysis and decision by management is in precisely manner.

Example:

QD CGKMOGA CGKMTGA CPYXXXX JKTOMGA CGKMQGA CGKMLGA DPSKKGA

.DPSMMGA 121423/FEB02

MM/TX/189/FEB/02

MAINTAVI THREE N FINAL GA-443/ DTE PK-GGD

A. AML SEQ 25 LIGHTING STRIKE DURING APPROACH WITH EXTENDED

LANDING GEAR

B. INSP ACC MAI CHPT 5 PERFORMED

C. FOUND RH STABILIZER DISCHARGER COMPL BURNT

D. REPLACED RH STABILIZER DISCHARGER

E. ADD #3 ENG OIL 2 QTRS

ADD APU OIL 1 QRTS

F. ETA/ ATA 1315/ 1310 ETD/ ATD 1430/ 1550

G. DELAY 1 HR 20 MIN DELAY CODE 43

H. NIL

BRGDS MADE FLSTP / AUTH. NO

Note: After Aircraft departure the Technical Trouble Delay Report shall be made and to

be reported to MCC see par 2.

c. Need for Assistance.

When the assistance (e.g. advise, expert, tools, etc) is needed from home-base/ CGK, the

MAINTAVI shall be composed and send through telex.

Example:

QD CGKMOGA CGKMTGA CPYXXXX CGKMLGA JKTOMGA CGKMQGA BPNKKGA

IV MAINT. REPORT & RECORD

TECHNICAL HANDLING MANUAL

Date : Dec. 21, 2011 THM : IV

Issue : 1 Rev : 7 Page : 5 of 16

.BPNMMGA 261625

MM/TX/022/FEB01

MAINTAVI ONE GA-517/DTE PK-GGR

WITH A/P OFF DURING GEAR EXTENSION A/C BANK 20 DEGREE TO THE RIGHT WITH

UNKNOWN REASON STP NORMAL LANDING PERFORMED STP PSE ADV MAINT AND

PROCEDURE TO FOLLOW FLSTP

BRGDS SUGIATMO/ AUTH. NO

d. Engine Trouble.

Whenever engine trouble occurs which can not be located within a certain time and/ or

engine failure/ damage caused by foreign object, an additional MAINTAVI should be

composed and send through telex.

e. Aircraft On Ground (AOG) and Waiting Spare.

Whenever the aircraft on ground (AOG) at the line station caused by NO GO Item and

should be served from home base, the MAINTAVI should be sent according to procedure

par 3. Following this MAINTAVI the material request telex must be sent soonest to QU

(urgent message).

Example:

QU CGKMMGA CGKMOGA CPYXXXX JKTOMGA CGKMQGA CGKMLGA CGKMDGA CGKBTGA

DPSKKGA

.DPSMMGA 140955

MM/TX/026/JAN01

AOG AOG AOG

PK-GGD AS GA-407/14 AOG DUE TO IAS #1 U/S STP BADLY NEEDED 1EA IAS P/N 2594466-

902 STP PSE SENT ASAP FLSTP

BRGDS WAYAN/ AUTH. NO

Also suggested to contact home base CGKMOGA or phone call 62-021-5502465 or

5506480 or FAX-5502448, before or after sent the telex.

f. Dispatch Authorization.

If Pilot In Command (PIC) agree to dispatch beyond the DDG/ MEL, or if the technical

trouble encountered is of such nature that the safety of the aircraft and its operation is

threatened in anyway. Directly or indirectly (engine shutdown, fire warning, abnormal

landing gear operation or indication, unsatisfactory response or malfunctioning of flight

control, etc) the respective of MAINTAVI message shall be dispatched before departure of

the aircraft. The additional address shall be sent to CGKMLGA (line Maintenance),

CGKMEGA (Engineering Service) and JKTOFGA (Flight Operation).

Example:

(1) Dispatch Authorization telexes will be dispatched using QX priority code. If an

aircraft departs under a Dispatch Authorization, a special telex must be dispatch to

that station and to all en route stations.

(2) The Dispatch Authorization telex will be in addition to any delay or other telexes,

and serves as confirmation that conditions and limitations of issue have been

complied with and as an alert to all en route stations.

(3) Priority telex code QX shall be used to send request Dispatch Authorization

telexes.

Requesting Dispatch Authorization Telex (Sample Format).

QX CGKMOGA CPYXXXX JKTOMGA CGKMQGA JKTOFGA CGKMEGA CGKMLGA

IV MAINT. REPORT & RECORD

TECHNICAL HANDLING MANUAL

Date : Dec. 21, 2011 THM : IV

Issue : 1 Rev : 7 Page : 6 of 16

.NNNMMGA

MMTX/ ZXZ/ DTE

ON ARR FOUND THE AIRCRAFT HAD PROBLEM (SPECIFIED DEFECT/ DAMAGE). TO RECTTIFY THE

PROBLEM SPARE WERE NOT AVAILABLE OR NO FACILITY TO REPAIR, OR LIMITATION IS NOT

COVER ON MEL OR CDL STOP . CHECK & MAKE SURE THAT THE AIRCRAFT CONDITION IS SAFE

FOR FLIGHT STOP AFTER DISCUSED WITH PILOT IN COMMAND N AGREE TO CONTINUED FLIGHT

WITH THIS CONDITION STOP, REQUEST DISPATCH AUTHORIZATION TO DISPATCH THIS

AIRCRAFT TO HOME BASE STOP

BRGDS JOHN/ AUTH. NO

Dispatch Authorization Telex (Sample Format).

QX NNNMGA or CONTRACTOR MAIN CPYXXXX (enroute sta) NNNKKGA CGKMEGA

CGKMQGA CGKMLGA JKTOMGA JKTOFGA

.CGKMOGA

MO/ TX/ ZZZ/ DTE

ATT TO DO

ON BEHALF OF GA AIRWORTHINESS MANAGEMENT ACCORDING TO THE PROBLEM OR DEFECT

OR DAMAGE THE AIRCRAFT IS APPROVED TO DISPATCH WITH DA NO: TO HOME BASE

(ALL OF WORK HASS BEEN DONE REF DA NO:MUST BE RECORDED IN THE AML)

BRGDS CGKMOGA ON DUTY OFFICER NAME/ Auth. No or ID No.

g. Technical Irregularity Status/ Complaint Report in Aircraft Log Book (AML).

To ensure that Cengkareng Base and or the en-route station have the necessary action to

maintain the continuity of operation in airworthy manner, all AML Book items shall include

in the MAINTAVI message especially transfer items.

Example:

QD BTJMMGA CGKMTGA CPYXXXX CGKMOGA JKTOMGA CGKMQGA MESKKGA

.MESMMGA 212015

MM/TX/102/FEB02

MAINTAVI ONE N FINAL GA198/DTE PK-GGR

AML SEQ 36, ENG NO.1 GRND IDLE 5 PERCENT TOO LOW STP IDLE RPM ADJUSTED

ACCORDING MM 71-00-00 PAGE 518 STP PSE OBSERVE AFTER FLT STP NO TECH DELAY STP

BRGDS SETIABUDHI/ AUTH. NO

If no technical delay occur it must be informed into the message with NO TECHNICAL

DELAY.

h. Damage to any Part of the Aircraft by Foreign Object.

Damage to any part of the aircraft by foreign object such as lighting strike, ground

equipment, etc. even immediate repair is not required, the message should be sent to

home base as soon as possible and it must be followed by Damage/Defect Report Form

MZ-2-09. Record this cases on the Aircrat Status Damage Control Sheet MZ-2-07.

Example:

QD CGKMOGA CGKMTGA CPYXXXX CGKMQGA SUBKKGA JKTOMGA CGKMLGA

.SUBMMGA 130945

MM/TX/142/JAN02

MAINTAVI ONE N FINAL GA-411/DTE PK-GWE

A. NIL

B. NIL

C. 1. CML SEQ 23 MAIN WHEEL POS 1 WORN OUT

2. CML SEQ 24 FWD CARGO DOOR SLIGHTLY DAMAGED BY CATERING TRUCK

D. 1. REPLACED MAIN WHEEL POS 1

IV MAINT. REPORT & RECORD

TECHNICAL HANDLING MANUAL

Date : Dec. 21, 2011 THM : IV

Issue : 1 Rev : 7 Page : 7 of 16

2. FWD CARGO DOOR TEMPORARY REPAIR, REF SRM 52-32-01 FIG 101 (SHEET 1).N TRF

TO HIL

E. NIL

F. ETA/ATA 0830/0832 ETD/ATD 0930/0935

G. NO DELAY

BRGDS MUDJIONO/ AUTH NO

i. Technical Delay due to Ground Handling Equipment.

Departure delay exceeding 5 minutes as a result of maintenance and/ or ground handling

equipment shall be reported to CGKMOGA and JKTOMGA.

Example:

QD CGKMTGA CGKMOGA CPYXXXX CGKMQGA CGKMLGA MESKKGA JKTOMGA

.MESMMGA 150155

MM/TX/276/JAN01

EQPT DEL INFO GA151/15 PK-GWG

DURING ENGINE START FOUND GTC SUDDENTLY AUTO SHUT STP NO REPLACEMENT AVL

STP REPAIR THERMOCOUPLE CABLE BROKEN STP STARTING CONDITION AFTER 55 MINS

REPAIR TIME STP TOTAL DELAY 20 MINS FLSTP

BRGDS SUNARTO/ AUTH. NO

j. Service Difficulty Report (SDR) Telex.

In case of major defect to the aircraft (iaw DGCA Advisory Circular 18-1), the Service

Difficulty Report (SDR) telex must be sent to home base within 24 hours, and one copy to

CGKMQGA Fax No 021-5590472. This event can be the AOG situation.

Example

QU CGKMOGA CGKMTGA CPYXXXX CGKMQGA CGKMEGA CGKMLGA

.SINMMGA 190121

MM/TX/204/FEB2000

SDRSDRSDR-

MAINTAVI TWO GA827/DTE PK-GGN

AFT CRGO DOOR NEAR TO THE MID POST WAS TORN APPROX 8 CM IN HEIGHT N WIDTH FRM

TOP BOTTOM APPROX 2 CM TO 0.5 CM X LWR REAR FUSELAGE SECT 4 NEAR TO APU DOOR

PNL SLIGHTLY SCRATCHES X COTCT SQ FOR TEMPORARY REPAIR STP

BRGDS KADIR / AUTH. NO

k. Spare Part and Material Replacement.

All material used including the loan part were borrowed from other operator and Flight Kit.

Shall be mentioned in the maintavi message in order to enable the home base to initiate

replacement or to entry into the Computerized Data Storage System (SAP). State also if

the material has been ordered from another station.

ROCO (Removal Component) Telex, Example :

QD CGKMMGA CGKMDGA CPYXXXX CGKBTGA CGKMOGA CGKMTGA

.PLMMMGA 201520

MM/TX/051/FEB01

MAINTAVI ONE N FINAL GA108/20 PK-GWP

AML SEQ 15 NO RADAR ANT SWEEP WITH ANT 10 DEGR UP STP REPLACED WX RADAR

ANT STP INSTALLED SPARE FRM CGK STP ATA/ATD 1115/1500 FLSTP

PN 56XXXXX ON 987MMMM OFF 896ZZZZZ

RGDS TOHIR./AUTH. NO

IV MAINT. REPORT & RECORD

TECHNICAL HANDLING MANUAL

Date : Dec. 21, 2011 THM : IV

Issue : 1 Rev : 7 Page : 8 of 16

l. Delivery Time of MAINTAVI.

Always use UTC for estimate time of departure (ETD) and/ or further advice time (ADVCT);

taking into consideration the local facilities, weather conditions, and also such things e.g.

store, workshop, aircraft parking. This time should be fixed, if possible, in coordination

with the Station Manager (KK) and/ or Pilot in Command (PiC).

m. Garuda Long Distance Operation Control Communication.

Aircraft HF Transceiver may be use for long distance communication can be arranged by

using Company Channel Frequency 7646 Khz to Aircraft Movement Control (JKTOMGA),

however direct conversation between Station Engineer and Maintenance Control Center

(Home-base), using telephone calls to MCC by dialing 62-21-5502465 or 62-21-5506480 or

and Facsimile no. 62-21-5502448.

n. Maintavi Addresses.

MAINTAVI messages should be addressed to CGKMOGA, destination STA copy to origin

KKGA, CGKMLGA and to en route station. If there is any delay or suspected delay

concerning to the irregularities or trouble the additional copy of MAINTAVI shall be sent

to JKTOMGA & CGKMQGA. It will be necessary to advise next station(s), if operation is

affected as a consequence of technical trouble e.g. trip fuel, Take Off Gross weight

(TOGW), runway length, flight level, weather condition, etc., in coordination with Station

Manager (KK).

Note: Depending on the importance of the message, it can be given a varying priority

compared to others. There are three remaining queues are the message send

queues:

1) QU - for Urgent Messages.

2) QN - for Normal Messages.

3) QD - for Deferred Messages.

The Deferred Message (with prefix QD) have the lowest priority, and will only be sent

when no Urgent or Normal Message exist in the system.

The line station engineer is responsible to the information contents in the MAINTAVI

message. A message shall be made in English; Indonesian or both (English and

Indonesian) may be use to get more clear interpretation of the message.

4. AI RCRAFT DAMAGE/ DEFECT REPORT

Upon Accident/ Incident occur with damage to the aircraft, equipment or personnel injury a

Line Stations manager should immediately report to home base (CGKMQGA/ CGKMOGA) Fax

No. 62-21-5590472/ 62-21-5502448 by using appropriate form, Form MZ-2-09. Picture or

sketch must be included.

In case of the damage/defect could affect the aircraft airworthiness, report immediately by

phone or by telex to home base before the formal written report is issued. The telex must

contain scope of damage/defect and details of accident/incident.

IV MAINT. REPORT & RECORD

TECHNICAL HANDLING MANUAL

Date : Dec. 21, 2011 THM : IV

Issue : 1 Rev : 7 Page : 9 of 16

DAMAGE REPORT

STATION : B 737-300 DATE : Jan 12, 2010 NO : 01/DR/2010

DAMAGE TO :

A/C Reg PK-GGA A/C Equipment Ground Equipment

Vehicles Building Other

Date of Accident

Place of Accident

Cause of Accident

: Mar 11, 2011

: CGK

: Baggage Tractor hit fwd fuselage Rh side aircraft

Description of accident (Please enclose illustration) :

18.00 A/C on Block On at R 63

19.00 Prior to perform Daily the a/c engineer request electrical ground power

19.30 the ground power arrived towed by baggage tractor.

Ground power operator prepare to start and connect electrical plug to aircraft. while the

tractor disconnected and park in the RH side of the aircraft with engine running.

The baggage tractor move by itself unwatched by the operator than hit the Fwd cargo door

aircraft. This incident cause skin dent length 20cm wide 8cm and deep 6mm

Action Taken :

Replaced Cargo door and damage one sent to work shop for repair

Person and / or Companies involved : GPA Ground equipment provider

Prepared by : Tarman/ 5364XX Sign : Tarman

Checked by : Amir/ 5256YY Sign

: Amir

Approved by : Husain/ 5154 ZX Sign : Husain

Form MZ-2-09

Structure damage should be recorded in the Damage Control Sheet Form MZ-2-07 its available

in the aircraft maintenance log book transparence pocket.

AIRCRAFT STRUCTURAL DAMAGE CONTROL SHEET

A/ C TYPE ______________

A/ C REG ______________

STATUS SEQ

NO

DATE

TYPE OF

DAMAGE

ACTI ON

OPEN CLOSED

REPAIR

INSTRUCTION

STATI ON

NAME

AUTH.NO

Form MZ-2-07

IV MAINT. REPORT & RECORD

TECHNICAL HANDLING MANUAL

Date : Dec. 21, 2011 THM : IV

Issue : 1 Rev : 7 Page : 10 of 16

5. MONTHLY TECHNICAL DELAY REPORT

This report shall be issued every month and send to Cengkareng Base ( CGKMOGA MCC Out

Station Affair) on Saturday afternoon of 4

th

week . Use Form MZ-2-20

LI NE STATI ON MONTHLY TECHNI CAL DELAY REPORT

STATION : SIN NO. REP. :

MM002/02

MONTH / PERIOD : FEB, 02 DATE : MARCH 01, 2002

TOTAL FLIGHT : 400 FLT PREPARED : RAMELAN

TOTAL TECH. DELAY : 1 FLT CHECKED : ALEP

PERCENTAGE OF DELAY : 0,25 % APPROVED : MURAD

NO

DATE FLT NO A/ C

REG

REASON OF DELAY HOURS REMARKS

1.

120202

GA966

PK-GWK AIRCRAFT RTB DUE TO LSA DISAGREE LIGHT

ILLUMINATES FOLLOW BY CONFIG ON NWP

AND OBSERVED LH LSA MOVING WHILE MANU

VER.

LH LSA ACTUATOR REPLACED, AND GROUND

CHECKED NORMAL.

1 HR

Form MZ-2-20

6. AOG REPORT

Any irregularity occurred at the Line Station that already declared as AOG (Aircraft On

Ground), the Line Station Engineer shall report to home base (CGKMOGA) by using the AOG

Form and progress of rectification. Report may be made by telex or facsimile to CGKMOGA/

MCC (fax no. 62-21-5502448 and 5501605).

The AOG detail report shall include the description of AOG trouble/ accident or incident (hard /

crash landing, bird strike, rejected take off, hit by equipment, excessive maneuver, etc),

rectification and action taken, component request, expert/ tools request, the result or progress,

and expecting of aircraft serviceable.

AIRCRAFT ON GROUND REPORT

AI RCRAFT TYPE : A330 DATE : J AN 09, 2007

AI RCRAFT REG. : PK-GPF REF/ NO : SI NMM/ TX/ 147/ 07

STATI ON : SI N TO : CGKMOGA

FROM : SI NMMGA

PREPARED BY : FIRMAN

SUBJ ECT : EGT ENG POS # 2 LOWER

THAN OTHER

APPROVED BY : SUHERMANTO .

DESCRI PTI ON :

GA-992/09 JAN/PK-GPF A.O.G. AT SIN DUE TO EGT ENG POS #2 LOWER THAN THE

OTHER.

REQ SPARE FROM CGK : 1. 1 EA EGT INDICATOR KSSU 742153

2. 4 EA THERMOCOUPLE.

REQ O/B GA-886/09 JAN ATD : 20.00 LT

RECTIFICATI ON :

AFTER CHECKED AT THERMOCOUPLE RACK AND ELECTR. CONNECTOR OF

INDICATOR, CONFIRMED INDICATOR WAS BAD.

EXPERT/ COMPONENT/ SPECIAL TOOL REQUIRED :

AUH STILL WAITING SPARE FROM CGK AS FOLLOWS :

1. 1 EA EGT INDICATOR NNXXX2153 3. 1 EA THERMOCOUPLE P/N 9055M90P02

2. 1 EA THERMOCOUPLE P/N XXNNM14P01 4. 1 EA THERMOCOUPLE P/N 9055M90P01

5. 1 EA THERMOCOUPLE P/N 9055M91P01

RESULT/ PROGRESS : PREPARE SPARE O/B GA-886/DTE

Form MZ-2-19

IV MAINT. REPORT & RECORD

TECHNICAL HANDLING MANUAL

Date : Dec. 21, 2011 THM : IV

Issue : 1 Rev : 7 Page : 11 of 16

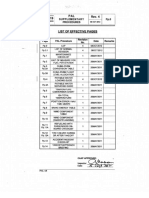

7. I NVENTORY REPORT

This report should be issued to home base every month as a control and for replenishment

allotment purposes (if any). This report including the equipment report and tools report. See

enclosed example.

STATION I NVENTORY REPORT

A /C TYPE : BOEING B737 PARTS / COMPONENTS

STA

CHECKED BY

DATE

APPROVED. BY

:

:

:

:

BKK

JHON

01.03.07

SEAMUS. M

QTY SERIAL NO.

NO. DESCRIPTION

PART

NUMBER

GA CODE

ASS AVL

EXPIRED

REMARK

S

01 FLOW CONT 31040 Z.26.06 2 1 0185 31.12. 01

02 VALVE 898052 - 1 1 U57626 26.04. 02

03 FIREX BOTTLE 3605812 W.49.01 1 1 1P57 12.05.02

8. PART/ COMPONENT USED REPORT

Every components/ parts used for aircraft should be reported to home base (CGKMOGA) in

monthly basis. See enclosed example.

MONTHLY COMPONENTS USED REPORT

STATION : BKK PERIOD: 01S/D 30 APR 2002 PREPARED BY: JHON

CHECKED BY : SEAMUS MACMAHON

NO COMPONENT PART

NUMBER

S/N IN S/N

OUT

POS A/C REG DATE REMARKS

1

2

3

HEAT -

EXHANGER

EXCITER

GCU

1828203

106310451C

948F4583

73303

46811

NU8004

73311

46802

NIL

102

102

2

PK-GGG

PK-GGG

PK-GGN

030507

060507

010507

AIR LEAK

NO LIGHT

UP

UNABLE

TO FEED

BUS

9. SERVI CE DI FFI CULTY REPORT (SDR)

In case of major defect to the aircraft (DGCA Advisory Circular 43-02), the SDR telex must be

sent to home base CGKMOGA within 24 hours, and one copy to CGKMQGA Fax No 021-

5590472. This event can be the AOG situation.

Service Difficulty Report (SDR) Telex.

QU CGKMOGA CGKMTGA CPYXXXX CGKMQGA SINKKGA

.SINMMGA 190121/DEC07

MM/TX/204/DEC07

SDRSDRSDR-

MAINTAVI TWO GA823/DTE PK-GGW

AFT CARGO DOOR NEAR TO THE MID POST WAS TORN APPROX 8CM IN HEIGHT N WIDTH FRM

TOP BOTTOM APPROX 2CM TO 0.5CM X LWR REAR FUSELAGE SECT BS 827 SLIGHTLY SCRATCHES

X COTCT SQ FOR TEMPORARY REPAIR STP

BRGDS MURAD A / AUTH. NO

The SDR shall be reported to DGCA by using form : 43-01, describing the defect, malfunction or

other service difficulties as explained in AC 43-02 if occur certain malfunction , defect, failure or

occurrence ;

IV MAINT. REPORT & RECORD

TECHNICAL HANDLING MANUAL

Date : Dec. 21, 2011 THM : IV

Issue : 1 Rev : 7 Page : 12 of 16

a. Aircraft Structure

1) Major defect or damage to aircraft structure.

2) Any failure of aircraft primary structure or principal structural element.

3) Cracks, permanent deformation, or corrosion defect or damage of aircraft primary

structure or principal structural element that a repair scheme is not already provided

in the manufacturers repair manual, or that occur after repair.

4) Serious cracks, permanent deformation, burning or serious corrosion of structure

found during scheduled maintenance of the aircraft or component.

5) Any part of the aircraft that would endanger the aircraft or any person becoming

detached in flight or during operations on the ground.

6) Defects or damage to aircraft structures, if more than allowed tolerances.

b. Powerplant

1) Engine in-flight-shut-down (IFSD) neither intentional shutdown or significant power

loss because of flameout, external damage to the engine or aircraft structure occurs,

foreign object ingestion or icing.

2) Malfunction of any engine control system.

3) Un-commanded loss of thrust/power, shutdown or failure of any engine.

4) Uncontained failure of engine compressor, turbines.

5) An engine exhaust system that causes damage during flight to the engine (including

asymmetrical or un-commanded thrust reversal), adjacent structure, equipment, or

components.

c. Aircraft System or Equipment

1) Fires or explosion during flight neither protected or not protected by related fire

warning system.

2) False fire warning during flight including multiple or serious malfunctioning of

avionics, indicating, warning, radio or navigation system resulting in hazardous flight

information, e.g. excessive errors of instruments.

3) Fire warning, except those immediately confirmed as false

4) Aircraft component that causes smoke, vapor, toxic or noxious fume in the aircraft.

5) Fuel or fuel dumping system that affects fuel flow or causes hazardous leakage

during flight.

6) Fuel system malfunction that has significant effect on fuel supply and/or distribution

7) Fuel leakage that results in substantial loss or is a fire hazard.

8) Significant leakage or flow interruption/exhaustion of fuel, hydraulic fluid, or oil that

has significant effect on supply and/or distribution.

9) Unwanted landing gear extension or retraction, or unwanted opening or closing of

landing gear doors during flight. This condition also including failure of landing gear

to retract or extent, or to support the aircraft.

10) Brake system components (consist of failure of wheels, brakes or tires) that result in

loss of brake actuating force when the aircraft is in motion on the ground.

11) Significant loss of braking action.

12) Aircraft components or systems that result in taking emergency actions during flight

(except action to shutdown an engine).

13) Loss of control of cabin pressure.

14) Failure or malfunction of an electrical, hydraulic, or pneumatic system resulting in

loss of that system to the aircraft.

15) Malfunction of any flight control system.

16) Emergency evacuation systems or components including all exit doors, passenger

emergency evacuation lighting systems, or evacuation equipment that are found

defective, or that fail to perform the intended functions during an actual emergency

or during training, schedule testing, maintenance, demonstrations, or inadvertent

deployments.

IV MAINT. REPORT & RECORD

TECHNICAL HANDLING MANUAL

Date : Dec. 21, 2011 THM : IV

Issue : 1 Rev : 7 Page : 13 of 16

d. Other Defect, faults, malfunctions and other occurrences

1) Servicing with incorrect fluids.

2) Lighting or bird strikes, hard or over-weight landings, turbulence, overspeed flight

conditions, and on-aircraft hazardous material spillage that may affect airworthiness

and require a conditional special inspection.

3) Rejected take offs for either actual or for false warning indications of malfunctioning

systems or components.

4) Return to base for any reason.

In any case, where the filing of a report under the preceding paragraph might prejudice

the aircraft maintenance, it will be referred to the DGCA for a determination as to whether

it must be reported.

If the defect or malfunction could result in an imminent hazard to flight, the Garuda

Indonesia will use the most expeditious method to inform the Indonesian DGCA and Type

certificate holder (if applicable) and OEM (if applicable).

10. EMERGENCY RESPONSE

General.

An aircraft accident would involve major structural damage, a major fire, serious injury to

passenger or crew, or any situation serious enough to warrant evacuation of the aircraft.

This procedures is describes to accommodate emergency action in case of aircraft accident /

incident were reported. The definitions of aircraft accident/ incident are explained in the ICAO

Annex 13.

Emergency Response Plan (ERP) manual contain the policy and procedure to manage and

coordinate an emergency successfully.

The ERP Manual is to be used where Garuda Indonesia flights, regional airlines and code-share

flights are affected.

a. Flight Emergency Categories:

1) A major accident without warning where severe damage has occurred to an aircraft

and severe injury or death to passenger and crew.

2) A potentially serious accident where advance notice has been received (such as a

severe fire aboard an aircraft, wheel ups landing, or structural damage in flight)

3) A moderately serious situation involving such items as landing with an engine

inoperative, hydraulic difficulties, and warning light irregularity

4) Potentially serious accident where general cargo or hazardous materials are identified

as toxic or flammable materials.

b. Ground mishaps involve situations such as:

1) Aircraft equipment ground damages.

2) Cargo damage.

3) Fire resulting from fuel spills or other causes.

4) Personnel injuries / death.

5) Hijack and bomb threat.

c. Procedures.

Regardless of the type of accident, the first priority is the rescue of all involved, and the

second, the protection of the aircraft, aircraft equipment and building.

IV MAINT. REPORT & RECORD

TECHNICAL HANDLING MANUAL

Date : Dec. 21, 2011 THM : IV

Issue : 1 Rev : 7 Page : 14 of 16

Garuda Indonesia shall have emergency plan, and will be coordinated with airport

authority to make sure that no conflicts exist. Detail procedures are covers in the Aircraft

Crisis Manual and Accident/ Incident Manual.

d. Response to Emergency Phase.

1) Immediate Action.

In the vent of aircraft accident/ incident or disaster.

a) Notify Operations Control Center (JKTOPGA) and Maintenance Control Center

(CGKMOGA), Technical Operation Control (CGKMLGA), Airworthiness

Management (CGKMQGA).

b) Prepare and activate Site Control Center.

c) Activate Local ERP.

d) Notify Local airport Authority when coordination is required..

e) Provide information and expertise to assists the rescue authorities as quickly as

possible.

f) Prepare staff to coordinate at the location of accident.

2) Response.

The person or agency must be prepared to act individually and should maintain

contact with the communication to the MCC/ CGKMOGA, CGKMLGA, CGKMQGA

JKTOPGA.

3) Recovery.

Recovery is complex, time consuming operation. Recovery plan must be developed

based on the requirements/ finding of all response agencies.

11. RECORD RETENTION

Record retention means to maintain record and filed in certain time in accordance with the

requirement of Aviation Authority.

a. Freezing Aircraft Record.

Upon the record have to be used for investigation, the respective record shall be

assembled by contracted maintenance and surrounded to the Garuda Indonesia

Airworthiness Management, who will place in secure area until inspected by DGCA

Inspector.

b. Record Retention.

Record of Before Departure/Transit/ Daily/ Service/ Weekly inspection are classified as

routine technical record including station copy Aircraft Maintenance Log (AML) and Cabin

Maintenance Log (CML) of work shall be kept file for six (6) months.

The contracted technical handling agents are requested to send the routine technical

record including station copy of Aircraft Maintenance Log (AML) and Cabin Maintenance

Log (CML) to Cengkareng (TLP) Maintenance Planning & Control Phone : 5508093, Sita

telex, CGKMOGA.

12. Form TTDR

The technical trouble delay report shall be made in English and the hand written in block/

capital letter may be used. In case of TTDR form were not available, station engineer may

reported the technical delay by using printed out from Personal Computer.

IV MAINT. REPORT & RECORD

TECHNICAL HANDLING MANUAL

Date : Dec. 21, 2011 THM : IV

Issue : 1 Rev : 7 Page : 15 of 16

Technical Trouble Delay Report (TTDR) consists of 4 (four) sheets. Please take the last of

sheet for station copy, and the other copy should be sent to home base (CGKMOGA) as

soon as possible to distribute to other selected address may be send by facsimile address

to CGKMOGA 062 21 5502448.

Sample TTDR Form MZ-2-11

Technical Trouble Delay Report

Station Nr

A/C Type A/C Reg Flight Nr Date Classification

ATA

Pilot in Command / Captain

Prepared Approved

Actual Time of Departure Actual Time of Arrival Type of Maintenance

Scheduled or Revised Time of Departure Check

Total Technical Delay Time A/C Ready for Traffic

Cancellation Aborted T/O Flight Remark Preflight Check Remark

Returned to Ramp Return After T/O Inspection Remark

R

E

F

.

T

E

L

E

X

.

.

PRIMARY CAUSE.

NO GO item

Form MZ-2-11 (12-01)

shall be defined as a technical defect or malfunction that caused

the event.

The applicable Aircraft Maintenance Log remark should be quoted.

The concise description of the troubleshooting performed and the

remedying action taken shall also be given in this space.

IV MAINT. REPORT & RECORD

TECHNICAL HANDLING MANUAL

Date : Dec. 21, 2011 THM : IV

Issue : 1 Rev : 7 Page : 16 of 16

2

nd

page

SECONDARY CAUSE

Reserve A/ C Status

Secondary Cause Evaluation

Lack of Spare Parts

Crew Disposition

Ineffective Rectification

Faulty Replacement Part

Lack of Manpower

Ineffective Inspection

Failure Descript Incomplete

Communication Part

Lack of Tools

Difficult Trouble - Shouting

Faulty Ground Equipment

Needs Further Investigation

PREVENTIVE MEASURES

REMARKS

Form MZ-2-11 (12-01) END IV

Shall be accounted for any secondary or contributory circumstances

which have had influence on the delay besides the actual repair itself,

e.g. time required for obtaining spare, tools, and advise, adverse

working condition necessity to remove the aircraft from the ramp,

etc.

Any measures aimed at preventing recurrences that suggested,

considered or in effect should be here accounted for

Remark , any difficulty which could arise during this situation should

be written on this column, such as panel removal, contact home base

by telephone, etc.

Anda mungkin juga menyukai

- Air Crash Investigations - Cracked Solder Joint - The Crash of Indonesia Air Asia Flight 8501Dari EverandAir Crash Investigations - Cracked Solder Joint - The Crash of Indonesia Air Asia Flight 8501Belum ada peringkat

- A320-Mel-Cdl-Cdd StatusDokumen18 halamanA320-Mel-Cdl-Cdd StatusvproBelum ada peringkat

- 14 31-41 EicasDokumen26 halaman14 31-41 EicasAndres Aldunate QuezadaBelum ada peringkat

- 767-05-20-04 B767 48 HR SERVICE CHECK (ELAPSED TIME) TFL, Iss 07Dokumen3 halaman767-05-20-04 B767 48 HR SERVICE CHECK (ELAPSED TIME) TFL, Iss 07samyghallabBelum ada peringkat

- Ahm 560 A340-300 Dow DoiDokumen10 halamanAhm 560 A340-300 Dow DoiFilip SkultetyBelum ada peringkat

- SBcontent PDFDokumen65 halamanSBcontent PDFThanh Vinh NguyenBelum ada peringkat

- Perfo 321Dokumen62 halamanPerfo 321Maurizio PezzoniBelum ada peringkat

- 1 Additional Lecture - Direct Maintenance Cost - Art or ScienceDokumen28 halaman1 Additional Lecture - Direct Maintenance Cost - Art or Scienceoliver_porras_3Belum ada peringkat

- klmB1 Mod 11.17Dokumen55 halamanklmB1 Mod 11.17andrinjoBelum ada peringkat

- LIM LimitationsDokumen152 halamanLIM LimitationsQuynh NguyenBelum ada peringkat

- Avionics Systems PDFDokumen647 halamanAvionics Systems PDFAhsan MalikBelum ada peringkat

- Ata 46 FSA Booklet HO B1B2Dokumen64 halamanAta 46 FSA Booklet HO B1B2SATHYARAJ A/L G. PALANIVELU MBS221080Belum ada peringkat

- FD RT 4 - Basic Performance HandbookDokumen51 halamanFD RT 4 - Basic Performance Handbooksidsharma31Belum ada peringkat

- CPCDokumen15 halamanCPCFredoBelum ada peringkat

- A32f Mel Rev27 23apr2013Dokumen1.536 halamanA32f Mel Rev27 23apr2013Marcos FilhoBelum ada peringkat

- FOT-999-0130!16!00 Incorrect Characteristic Speeds Computation Due To Absence of The ZFWCG ValueDokumen3 halamanFOT-999-0130!16!00 Incorrect Characteristic Speeds Computation Due To Absence of The ZFWCG ValueGermanTobonBelum ada peringkat

- Part 0 Feb07Dokumen16 halamanPart 0 Feb07MikeBelum ada peringkat

- Ea 767 31-002 Eicas Upgrade Ops6 PDFDokumen5 halamanEa 767 31-002 Eicas Upgrade Ops6 PDFjuanf490Belum ada peringkat

- 09 36 000080id4945571tp1548Dokumen104 halaman09 36 000080id4945571tp1548blechasapo.cvBelum ada peringkat

- A320-214 - Yom 2014 (Sale)Dokumen6 halamanA320-214 - Yom 2014 (Sale)Francisco SoFuentesBelum ada peringkat

- SVC A330Dokumen9 halamanSVC A330Maria Amparo Corredor TorresBelum ada peringkat

- Ahm VN A687 Iss03rev01 TempDokumen41 halamanAhm VN A687 Iss03rev01 TempHung NguyenBelum ada peringkat

- Ito-Ip Rnav AppDokumen277 halamanIto-Ip Rnav AppaleBelum ada peringkat

- ETOPS Maintenance, Planning and StoresDokumen69 halamanETOPS Maintenance, Planning and StoresEduardo RuizBelum ada peringkat

- RAM 747-200/7Q: Distribution ListDokumen20 halamanRAM 747-200/7Q: Distribution ListStiliyana BakalovaBelum ada peringkat

- Mel Boeing 767 PDFDokumen818 halamanMel Boeing 767 PDFEddy JhetBelum ada peringkat

- Aom MD80 V1Dokumen637 halamanAom MD80 V1david milleBelum ada peringkat

- Summary of Easyjet Manuals: Airbus Edition, Version 2.1.1Dokumen88 halamanSummary of Easyjet Manuals: Airbus Edition, Version 2.1.1Sheng ShiBelum ada peringkat

- NAA OM-A Rev 5Dokumen482 halamanNAA OM-A Rev 5fantabaires86Belum ada peringkat

- HYDRO B737 Equipment-CatalogueDokumen138 halamanHYDRO B737 Equipment-CatalogueSauli Waziri SimkondaBelum ada peringkat

- OM Part D Checklist - Rev2 (A)Dokumen118 halamanOM Part D Checklist - Rev2 (A)Mohamed Iriwa100% (1)

- Foca Gm/Info: Ground Operations Manual (GOM)Dokumen7 halamanFoca Gm/Info: Ground Operations Manual (GOM)Dav DegoevBelum ada peringkat

- ATS TEAM - MOE - Rev 15Dokumen229 halamanATS TEAM - MOE - Rev 15MikeBelum ada peringkat

- @airbus: Issue: Sep 30/85 Rev: Sep 01/10Dokumen332 halaman@airbus: Issue: Sep 30/85 Rev: Sep 01/10Guillermo PatataBelum ada peringkat

- B 737 DraftDokumen98 halamanB 737 DraftAlrino Dwi PrasetyoBelum ada peringkat

- 1 Ata 00Dokumen32 halaman1 Ata 00Andy Pamelita DiegoBelum ada peringkat

- AC - 20-97B - CHG - 1 - Aircraft Tire Maintenance and Operarional PracticesDokumen12 halamanAC - 20-97B - CHG - 1 - Aircraft Tire Maintenance and Operarional PracticesUjang SetiawanBelum ada peringkat

- Boeing 7x7 ETOPS FLIGHT CREW GUIDEDokumen24 halamanBoeing 7x7 ETOPS FLIGHT CREW GUIDEericvolmerBelum ada peringkat

- 23 CommunicationsDokumen322 halaman23 CommunicationsbiratesBelum ada peringkat

- Line Station Manual: QTR TechnicalDokumen269 halamanLine Station Manual: QTR TechnicalSAIF YOUNSIBelum ada peringkat

- 5 Perfo Per Tof Bel NorDokumen23 halaman5 Perfo Per Tof Bel NorLuis HernandezBelum ada peringkat

- FDM Rev 10.1 - ElectronicDokumen460 halamanFDM Rev 10.1 - ElectronicVighnesh VBelum ada peringkat

- 04 - Operations Manual (English Version) - v5r104Dokumen1.442 halaman04 - Operations Manual (English Version) - v5r104Edgardo LozanoBelum ada peringkat

- A320 A320 Sharklets 1/14Dokumen12 halamanA320 A320 Sharklets 1/14Edwar ZulmiBelum ada peringkat

- Service Letter Atr42: TITLE: Time Limits Document - ATR42-200/-300/-320 - MLG and NLG Additional InformationDokumen11 halamanService Letter Atr42: TITLE: Time Limits Document - ATR42-200/-300/-320 - MLG and NLG Additional Informationa_sharafiehBelum ada peringkat

- infoETOPS PDFDokumen4 halamaninfoETOPS PDFhaider551Belum ada peringkat

- Boeing 737: Preflight CheckDokumen4 halamanBoeing 737: Preflight CheckDenysadenisa100% (1)

- D. Amm WZZ Nov 06Dokumen27 halamanD. Amm WZZ Nov 06lucisteauaBelum ada peringkat

- Oz - Hy - Etm - A320 - 214 - 19Dokumen126 halamanOz - Hy - Etm - A320 - 214 - 19Катя ВащенкоBelum ada peringkat

- AB6 Instructor Guide C1Dokumen2 halamanAB6 Instructor Guide C1Punthep PunnotokBelum ada peringkat

- Cal Cfom PDFDokumen447 halamanCal Cfom PDFStiliyana BakalovaBelum ada peringkat

- Dokumen - Tips - A380 Level I Ata 25 Equipmentfurnishings PDFDokumen54 halamanDokumen - Tips - A380 Level I Ata 25 Equipmentfurnishings PDFGuyBelum ada peringkat

- Day3 7 Go-Around PerformanceDokumen33 halamanDay3 7 Go-Around PerformanceGermanTobonBelum ada peringkat

- A320 MMEL Cross References REV02Dokumen12 halamanA320 MMEL Cross References REV02Carlos Augusto100% (1)

- Weight and Balance Manual MD Yv647tDokumen73 halamanWeight and Balance Manual MD Yv647tJesus GutierrezBelum ada peringkat

- Extended-Range Twin Engine Operations (ETOPS) Online Course: Table of ContentDokumen14 halamanExtended-Range Twin Engine Operations (ETOPS) Online Course: Table of ContentAirbus 320Belum ada peringkat

- Opp 1Dokumen181 halamanOpp 1Joel Agbetonyo0% (1)

- Ruge CF6Dokumen168 halamanRuge CF6Daniel LopezBelum ada peringkat

- QRH PAL Supplementary Rev. 4Dokumen32 halamanQRH PAL Supplementary Rev. 4Joanes SyBelum ada peringkat

- @ A318/A319/A320/A321: Printed in FRANCE © AIRBUS, 2004 All Rights ReservedDokumen28 halaman@ A318/A319/A320/A321: Printed in FRANCE © AIRBUS, 2004 All Rights ReservedVero GAtelesisBelum ada peringkat

- Readme (WWW - Ir DL - Com)Dokumen1 halamanReadme (WWW - Ir DL - Com)Youjinn MadBelum ada peringkat

- Objective: The Student Will Be Able ToDokumen18 halamanObjective: The Student Will Be Able ToJojit LEDESMABelum ada peringkat

- Brochure Intel NUCDokumen2 halamanBrochure Intel NUCDavid ZamoraBelum ada peringkat

- Report ProjectDokumen8 halamanReport ProjectNadeemBelum ada peringkat

- Dave Beson LetterWriter Now Available For RealtyJuggler Real Estate SoftwareDokumen3 halamanDave Beson LetterWriter Now Available For RealtyJuggler Real Estate SoftwarePR.com 2Belum ada peringkat

- Type L6B Load Cell: Short DescriptionDokumen3 halamanType L6B Load Cell: Short DescriptionNarciso LopesBelum ada peringkat

- Statement NOV2021 660307552-1Dokumen8 halamanStatement NOV2021 660307552-1Kumari AnshuBelum ada peringkat

- 50 Tools For Online Content CreationDokumen54 halaman50 Tools For Online Content CreationAshish UpadhyayBelum ada peringkat

- Operation Guide: Prismasync Remote ManagerDokumen70 halamanOperation Guide: Prismasync Remote ManagerJPauloBelum ada peringkat

- Design of Helical Antenna With Balun at 2.2 GHZ IJERTV7IS010118Dokumen3 halamanDesign of Helical Antenna With Balun at 2.2 GHZ IJERTV7IS010118Euvannisa JasminBelum ada peringkat

- All Fleet Extra 15W 40 - 101 14a PDFDokumen2 halamanAll Fleet Extra 15W 40 - 101 14a PDFpdealersBelum ada peringkat

- Utex Plunger PackingDokumen7 halamanUtex Plunger Packinganandkumar.mauryaBelum ada peringkat

- Grundfosliterature 5235944 PDFDokumen324 halamanGrundfosliterature 5235944 PDFĐạt TrầnBelum ada peringkat

- (Healthcare Technologies Series, 50) Agbotiname Lucky Imoize, Jude Hemanth, Dinh-Thuan Do, Samarendra Nath Sur - Explainable Artificial Intelligence in Medical Decision Support Systems-The InstitutionDokumen545 halaman(Healthcare Technologies Series, 50) Agbotiname Lucky Imoize, Jude Hemanth, Dinh-Thuan Do, Samarendra Nath Sur - Explainable Artificial Intelligence in Medical Decision Support Systems-The InstitutionCarlos QueirozBelum ada peringkat

- TXV Training DeckDokumen32 halamanTXV Training DeckJak JoniBelum ada peringkat

- Vmix 24 UserGuideDokumen236 halamanVmix 24 UserGuideAstraVistaBelum ada peringkat

- HL Paper1Dokumen15 halamanHL Paper1Soham MishraBelum ada peringkat

- Mahamad Yusri NO 29 JLN 3/61 TMN Damai Kencana, Sek 3 43650 Bandar Baru Bangi, SelDokumen3 halamanMahamad Yusri NO 29 JLN 3/61 TMN Damai Kencana, Sek 3 43650 Bandar Baru Bangi, SelSANJIBelum ada peringkat

- BestGrid EA 2.1 - (Cost $560) - For FREE - ForexCrackedDokumen9 halamanBestGrid EA 2.1 - (Cost $560) - For FREE - ForexCrackedVilayBelum ada peringkat

- Cloud Computing Prelim Exam 2Dokumen20 halamanCloud Computing Prelim Exam 2Gab TanhuecoBelum ada peringkat

- Sistem Bilga (Bilge System)Dokumen13 halamanSistem Bilga (Bilge System)Pingkan Amanda PusungBelum ada peringkat

- GP Air Dryer BrochureDokumen4 halamanGP Air Dryer BrochureAlejandra Rueda MendozaBelum ada peringkat

- Docbank: A Benchmark Dataset For Document Layout AnalysisDokumen12 halamanDocbank: A Benchmark Dataset For Document Layout Analysisroshan9786Belum ada peringkat

- Pharmacy - Computer Input & Output Devices - 1Dokumen27 halamanPharmacy - Computer Input & Output Devices - 1medgeek nmeBelum ada peringkat

- Statcom ThesisDokumen64 halamanStatcom ThesisAnonymous yD6Qpiq3100% (1)

- GK420 GT800 Datasheet ENG APAC EnglishDokumen2 halamanGK420 GT800 Datasheet ENG APAC EnglishMarino FroesBelum ada peringkat

- Project: List Title: Output Input DO AO AIDokumen21 halamanProject: List Title: Output Input DO AO AIobaiBelum ada peringkat

- DevlistDokumen8 halamanDevlistcolossusanirudhBelum ada peringkat

- Unit 1 Assignment in ResearchDokumen3 halamanUnit 1 Assignment in ResearchJovzBelum ada peringkat

- User Manual ETE/ETX Module MSC ETE-A945GSE-1: Intel Atom N270Dokumen55 halamanUser Manual ETE/ETX Module MSC ETE-A945GSE-1: Intel Atom N270AlejandroBelum ada peringkat