Cement Chapter 4

Diunggah oleh

shani5573100%(2)100% menganggap dokumen ini bermanfaat (2 suara)

249 tayangan11 halamanCement Chapter 4

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniCement Chapter 4

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

100%(2)100% menganggap dokumen ini bermanfaat (2 suara)

249 tayangan11 halamanCement Chapter 4

Diunggah oleh

shani5573Cement Chapter 4

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 11

4.

The Ball Mill

C E M E N T T E C H N O L O G Y N O T E S 2 0 0 4 43

4 . 1 I NT R ODUC T I ON

4 . 2 T E R MI NOL OGY

4 . 3 P R I NC I P A L P A R A ME T E R S

4 . 3 . 1 I NT R ODU C T I ON

4 . 3 . 2 DI A ME T E R

4 . 3 . 3 L E NGT H

4 . 3 . 4 V OL U ME

4 . 3 . 5 V OL U ME L OA DI NG

4 . 3 . 6 ME DI A C HA R GE

4 . 3 . 7 MI L L S P E E D

4 . 3 . 8 MI L L P OWE R

4 . 3 . 9 L I NI NG

4 . 3 . 1 0 DI A P HR A GM

4 . 3 . 1 1 ME DI A S I Z E S

4 . 3 . 1 2 ME DI A WE A R

4 . 3 . 1 3 P OWDE R L OA DI NG A ND R E S I DE NC E T I ME

4 . 3 . 1 4 MI L L A I R F L OW

4 . 3 . 1 5 MI L L T E MP E R AT U R E , C OOL I NG A ND WAT E R I NJ E C T I ON

contents chapter 5

C E M E N T T E C H N O L O G Y N O T E S 2 0 0 5 44

4.1 INTRODUCTION

The ball mill, or tube mill, is essentially a lined steel tube, which

is partially filled with grinding media (usually balls). The tube

rotates, thereby causing a cascading action of the media, which

the feed material passes through. Comminution takes place within

the cascading, cataracting and attrition actions of the media.

The ball mill is used in conjunction with other equipment to

form a range of different mill circuits. These are discussed in

Section 5.

Figure 45. Ball Mill.

4. THE BALL MILL

Inlet Trunnion

Step Lining Plates

First Chamber

Intermediate Diaphragm

Second Chamber

Classifying Lining Plates

Outlet Trunnion

Mill End Wall

Coarse Grinding Media

Fine Grinding Media

Outlet Diaphragm

contents chapter 4 chapter 5

C E M E N T T E C H N O L O G Y N O T E S 2 0 0 5 45

4.2 TERMINOLOGY

For simplicity, the ball mill can best be described by reference to

the main parts involved. (See Figure 45).

Mill Shell: The cylindrical tube

(usually rolled from steel plate)

Mill Ends: The circular castings bolted to the mill shell

Trunnions: The smaller cylinders at each end of the mill

which provide the inlet, outlet and main

bearing support

Liners: The metal plates, usually bolted, to the mill

shell and ends for wear protection

Mill Hood: The chamber between the mill exhaust

ducting and the mill end which is around the

outlet trunnion

Chamber: Compartment in the mill created from the

division of the mill by diaphragms

Diaphragm: The slotted plate which divides the mill tube

into chambers. Between chambers is the

intermediate whilst at the mill end is the

outlet diaphragm

Grinding Media: The steel balls (or cylpebs) which partially

fill the chamber and tumble with mill

rotation to achieve crushing and grinding

Mill Speed: Rotational speed (rpm) of the mill

(rpm)

Critical Speed: Mill speed at which particles just remain at

(rpm) mill liners as a result of centrifugal force

Volume Loading: The percentage of the mill volume (inside

(Vol%) liners) occupied by media

Powder Loading: A measure of the volume or weight of

material (not media) in the mill (See later)

Mill diameter: The diameter of the mill tube, either inside

(D) (m) the shell, or more usefully, inside the liner

Mill length: The length of the mill tube, either in total

(L) (m) (between mill ends) or a summation of the

effective chamber length

Chamber diameter: The diameter inside the lining in each

(D) (m) chamber

Chamber length: The effective length of each chamber (i.e.

(L) (m) between diaphragms, or mill end and

diaphragm, in chamber 1)

Mill Power: The installed power relates to the motor size

(kW) The gross drawn power relates to the actual

consumed power

The net power refers to either the gross

power less gearbox and motor losses, or an

estimate of power from the mill parameters

Specific Power The mill gross power divided by the product

Consumption: tonnes/hour

(kWh/t)

Slot Size: The average opening of the slots in the

(mm) diaphragms

Ball Size (mm): Ball diameter

Media density: The bulk density of the media in the mill

(t/m

3

)

Media charge (t): Usually the weight of media in the mill

Mill airflow: The volume of air passing through the mill

(m

3

/hr) (mill NOT filter)

Height above The distance from the liner to the media

charge: level

(HAC) (m)

Height above The distance from the liner to the material

powder: level

(HAP) (m)

Liner Step: Usually the depth of the protruding part of

(mm) the liner plate (in chamber 1)

Diaphragm The % diaphragm area that is open (i.e. slot

active area (%): area)

Diaphragm The % of the slot area blocked (usually by

blockages: nibs)

Media Grading: The size distribution of the balls

Mean Media The average ball size (usually on a weight

(mm): Size basis)

Clinker nibs: Usually the oversize clinker particles that

escape chamber 1 and build-up in chamber 2

(or the last chamber) or the diaphragm slots

Axial Samples: Material samples taken from inside the mill

(when stopped!)

Drum feeder: The large diameter drum, fitted externally to

the mill feed trunnion, with scoops and

lifters to pass material into the mill

Feed chute: A simple lined chute fitted into the trunnion

scrolls on the trunnion that assists material

into the mill

Coating: The adhesion of fine particles to the mill

internals, particularly to the balls and liners

4. THE BALL MILL

contents chapter 4 chapter 5

C E M E N T T E C H N O L O G Y N O T E S 2 0 0 5 46

4.3 PRINCIPAL PARAMETERS

4.3.1 INTRODUCTION

The preceding section attempted to list the most important

terminology involved in a ball mill. Below is additional

information concerning the principal parameters that are

involved in the evaluation of mill performance. Further details

are discussed in section 11 on mill testing.

4.3.2 DIAMETER

In most cases the most practical diameter will be the effective

diameter inside the lining. However in many manuals providing

basic mill data, the diameter will be inside the shell, thus there is

a single diameter for a given mill. For the diameter inside the

liner there will be a diameter for each chamber depending on

the thickness of the lining (often 50-80mm).

4.3.3 LENGTH

Like the diameter, the length is most useful when it is the

effective length of each chamber.

4.3.4 VOLUME

The effective volume of each chamber can be calculated using

the effective chamber diameter and length.

4.3.5 VOLUME LOADING

The chamber volume loading can be determined from knowledge

of the chamber volume, tonnes of media and media density.

e.g. assuming a chamber volume of 77.14m

3

, a media weight of

101 tonnes and a media density of 4.3 tonnes/m

3

, the volume

loading would be :-

Bulk media volume = 101 = 23.49m

3

4.3

Volume Loading = 23.49 = 30.4%

77.14

However, more typically, the volume loading is measured directly

from an internal examination of the mill. (See Section 11).

The volume loading is calculated from the measured diameter

and the height above the charge. There are a number of

empirical formulae, which can be used very easily, although the

volume loading can be best determined from first principles.

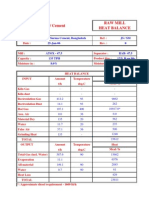

Figure 46. Example of Mill Data.

4. THE BALL MILL

Chamber: 1 Mill rpm: 14.6

Diameter: 4.45 HAC: 2.92

Length: 4.96 HAP: 3.17

Volume: 77.14 Media t/m

3

: 4.30

%Nc: 72.8

Vol Loading,% 30.4

Tonnes: 101.0

Powder, U 0.78

Net kW: 1435

Chamber %L: 38.4

Ball Piece No. Wt Tonnes

Size Wt. (%)

90 3015 5 25.4 25.6

80 2118 10 35.7 36.0

70 1419 10 23.9 24.1

60 893 10 15.0 15.2

0 0 0 0.0 0.0

0 0 0 0.0 0.0

0 0 0 0.0 0.0

Mean Size 77.1 mm 100 101.0

Chamber: 2 Mill rpm: 14.6

Diameter: 4.50 HAC: 3.05

Length: 7.95 HAP: 2.98

Volume: 126.44 Media t/m

3

: 4.50

%Nc: 73.2

Vol Loading,% 27.9

Tonnes: 158.5

Powder, U 1.16

Net kW: 2354

Ball Piece Average Pos 1 Pos 2 Pos 3

Size Wt. Wt Tonnes No. Wt No. Wt No. Wt

(%) (%) (%) (%)

60 893 2.2 3.5 1 6.7 0 0.0 0 0.0

50 517 4.2 6.6 2 7.8 1 4.7 0 0.0

40 265 9.3 14.7 8 15.9 5 12.0 0 0.0

30 112 6.4 10.1 12 10.1 8 8.1 1 1.0

25 65 17.9 28.4 50 24.3 40 23.5 10 6.0

20 33 30.8 48.8 90 22.4 80 24.0 150 46.0

17 20 29.2 46.3 85 13.0 150 27.7 250 47.0

100 158.5 100 100 100

Mean 24.7 30.0 25.0 19.0

Size

Summary Feed T/hr 110.0

Total T/hr 330.0 T/hr/m

2

21.0

Chamber Volume Media Media Mill Mill kWh/t Powder Powder Residence

Loading Tonnes Mean Power Power U Tonnes Time

Size Net Gross Mins

1 30.4 101.0 77.1 1435 1538 14.0 0.78 11.7 2.1

2 27.9 158.5 24.7 2354 2522 22.9 1.16 24.5 4.5

Total 259.4 3789 4060 36.9 36.2 6.6

Average 28.8 45.1 1.01

Gross/Net Factor: 1.07

contents chapter 4 chapter 5

C E M E N T T E C H N O L O G Y N O T E S 2 0 0 5 47

According to FLS, the volume loading is determined from:-

Vol % = 50 - 125 x (h - D/

2

)

D

Where h is the height above the charge and D is the diameter.

For the data given in Figure 46, the volume loadings are

calculated to be 30.5% and 27.8%.

From trigonometry it is possible to use the height above the

charge to calculate the area of the segment less the area of the

triangle to determine the area of the media. (See TIS MS007).

From this calculation the volume loadings are correctly

determined to be 30.4% and 27.9%. (See Figure 46).

Volume loadings are typically in the range 25-35%, but can be

20-45%.

TIS MS007. Volume Loading.

Area of Segment = r

2

Area of Triangle =

1

/

2

* r cos * 2 r sin

= r

2

cos sin

Area below level = a r

2

- r

2

cos sin

= r

2

( - cos sin)

Area of circle = ! r

2

Volume occupied = r

2

( - cos sin) / ! r

2

= ( - cos sin) / !

4.3.6 MEDIA CHARGE

Based on the measured volume loading the media tonnage is

determined using the media density. This is usually assumed to

be in the range 4.3 - 4.7 tonnes/m

3

.

4.3.7 MILL SPEED

The critical speed is where particles just centrifuge

(See TIS MS008).

The equations can be shortened to:-

Nc = 42.3

"D

Where D is the effective diameter.

TIS MS008. Mill Speed.

Critical Speed when mv

2

/r = mg

v

2

/r = g or v

2

= rg

v

2

= D/2g or v = (D/2 * g)

0.5

Also = (2 ! N)/60

N = (60 ) / (2 !)

Also v = r

= v/r

N

c

= (60 v)/(2 ! r)

N

c

= (60 v) / ( ! D)

N

c

= {60 (D/2 * g)

0.5

} / ( ! D)

N

c

= 42.3 / D

0.5

Where

m = mass

g = gravity

D = mill diameter

v = tangential velocity

= angular velocity

N = mill speed (rpm)

N

c

= mill critical speed (rpm)

Thus for the data shown in Figure 46 the critical speed is 20.00

rpm (using average of chamber 1 and 2 diameters) and thus the

actual speed of 14.60 rpm represents 73.0% of critical speed.

Typical mill speeds are in the range 65-80% although 75%

represents a typical average. Most mills have a fixed speed

although mills with variable speed drive do exist. This, in

theory, at least provides the option of obtaining the optimum

profile of cascading media as the liner wears or as the media

volume loading changes.

Since it is very easy to determine the mill speed (visually time 10

revolutions), it is recommended that this is done when

appropriate (relying on recorded data can sometimes lead to

errors).

4.3.8 MILL POWER

The gross drawn power of a mill can normally be measured

from the kWh meter. Often, average values are based on the

kWh totaliser readings together with run hours. However in

most cases it is better to take a spot reading or readings directly

from the kWh meter. This involves timing the dial on the kWh

meter to determine the number of revolutions in 1 hour, and

then using the kWh/rev factor on the meter to calculate the kW.

(i.e. time 10 revolutions of the dial).

For example:

Meter factor = 3.210 kWh/rev

Time for 10 revs = 28.46 seconds

Therefore revs/hour = 1264.9

Therefore mill power = 4060 kW (revs x kWh)

hr revs

The net power of the mill can be estimated from the charge

weight, arm of torque and the angular velocity. Most plant

suppliers have their own formulae.

4. THE BALL MILL

r cos = h - r

= cos

-1

{(h - r)/r}

Height

Above

Charge

r

h

a

mv

2

/r

o

contents chapter 4 chapter 5

C E M E N T T E C H N O L O G Y N O T E S 2 0 0 5 48

One empirical formula which has been used is:-(See also TIS

MS009)

kW = 0.2846 x D x (1.073 - VOL%) x W x N

100

where D = effective chamber diameter (m)

Vol% = chamber volume loading (%)

W = chamber media weight (tonnes)

N = mill speed (rpm)

The formula is used to calculate the net power of each chamber.

For the data in Figure 46, these are 1435 kW and 2354 kW.

The gross power is seen to be some 7% higher than this, i.e. the

gross kW/net kW ratio is 1.07, (4060/3789). This factor is

usually in the range 1.05 - 1.10. Values outside this range can

be indicative of measurement errors or operating and design

problems.

4.3.9 LINING

The liner plates are either bolted or sometimes boltless, relying

on fixing by key from one plate to another. Bolted plates can

lead to individual fixing problems and leakage at bolt holes.

Boltless fixing avoids this problem, although replacement due to

damage or wear can become a major job.

The liner plate profiles vary according to the chamber in which

they are used since the aim is to promote a different movement

of media in each chamber (given that mill speed is fixed for each

chamber).

In chamber 1 the aim is to expand the charge to promote a

"cataracting" action for crushing of larger clinker pieces. Thus

the liner plates are stepped (See Figure 47), the step design

typically being 75-90mm. For efficient action, a minimum step

of 40mm is normally recommended. On average, the lining

thickness is typically around 75mm. Hence the difference

between inside shell diameter and effective diameter is usually

0.15m. (See Figure 46).

In subsequent chambers a "cascading" type of action is required

and smoother profile linings are used to promote a more

compact grinding. (See Figure 47).

In the second chamber of a 3 chamber mill a ripple lining is

often used with an effect someway between chamber 1 and 3.

Figure 47. Lining Plate Profiles.

In chamber 2 of 2 chamber mills it is often practised to have a

classifying lining to promote the classification of ball sizes, so

that the larger sizes remain near to the intermediate diaphragm

(See Figure 48) and the small sizes are displaced to the outlet

end.

Smoother profiles tend to have a thickness of around 50mm

thus reducing the inside shell diameter by around 0.1m.

Figure 48. Classifying Liner Plate Profiles.

4.3.10 DIAPHRAGM

The diaphragm plates divide the mill into chambers. They can

be of single plate type but more often are of double plate design

(See Figure 49). The plates are slotted with radial or more

usually circumferential slots, which retain the media within the

chambers and allow passage of material and air (See Figure 50).

Figure 49. Diaphragm Double Plate Designs.

4. THE BALL MILL

Carmen

F L Smidth

Pfeiffer

Slegten, Adjustable

Slegten-Magotteaux

contents chapter 4 chapter 5

C E M E N T T E C H N O L O G Y N O T E S 2 0 0 5 49

Figure 50. Diaphragm Slot Arrangements.

The active or open area of the diaphragm as a result of the slots

is typically around 5-10% of the total diaphragm area. Slot sizes

(widths) are ideally around 6mm for intermediate and 8mm for

the outlet. The outlet slots should always be marginally larger

than those of the intermediate diaphragm to avoid the build-up

of nibs (e.g. large clinker pieces) in the last chamber and the

outlet diaphragm.

Double plate diaphragms have lifter plates between the plates

(See Figure 49) to promote material transport through the

diaphragm. Naturally the flow rate of material through the

diaphragm is only a function of the total feed rate (assuming a

steady-state) and so the lifter action effectively controls the

filling level in the preceding chamber.

In some cases the lifting action can be too powerful and thus 1st

chambers are often operating with a low level of material. As a

result of this the so-called variable (or adjustable) diaphragm

was developed (See Figure 49), to provide a degree of

adjustment of the material filling level.

4.3.11 MEDIA SIZES

Media is used in a range of sizes in each chamber to provide:-

- a range of desired impact energies

- an element of charge densification

- a degree of stability of media grading when allowing

for wear (i.e. equilibrium charge)

- the ability to deal with a range of feed material

properties

Chamber 1

Here media is nearly always in the range 90 to 60mm. Sizes

above 90mm are rarely required and in any case risk breakage

of liners. Sizes below 60mm are often too small, and therefore

impact energy is too small, for sufficient preparation of clinker

in chamber 1. Mean size is typically in the range 75-78mm.

Chamber 2

Here media is often in the range 60-16mm depending on many

factors including overall mill design and manufacturers

philosophy.

When a wide range of sizes are deemed to be necessary then a

classifying liner is required to classify the media so that the

coarser sizes remain at the inlet end of the mill. It is often noted

that, particularly where there is no classifying liner, media

becomes naturally reverse classified, i.e. coarse sizes concentrate

at the mill outlet.

If nibs are a problem, these can often be classified to the mill

outlet with the small media thereby not being subjected to the

larger balls necessary for their breakage.

Mean media sizes are typically in the range 20-40mm

The influence of media sizes on mill performance is discussed

further in section 6.

4.3.12 MEDIA WEAR

The wear of media has significantly reduced in the last 10-20

years as a result of the developments in metallurgy. Typically,

wear rates are around 10-100g/tonne of cement ground.

Although wear is often quoted as g/t of cement it is more likely

that the majority of wear is a result of run hours or kWh.

Hence wear in terms of g/kWh is also used. An example of the

effect of media wear on annual media consumption is shown in

Figure 51.

Figure 51. Media Wear.

4. THE BALL MILL

Circumferential Radial

Mill Power

Mill Production

Annual production

Run Hours

Media Wear

Chamber 1

Chamber 2

4060 kW

110 tonnes/hour

800,000 tonnes

7,273

50 g/tonne

101.0 tonnes

77.1 mm Mean size

158.5 tonnes

24.7 mm Mean Size

Calculations:

Annual Media Consumption = 40 tonnes

Media Wear = 1.35 g/kWh

Reduction in Mean Media Size

(assuming no top-up):

Chamber 1 Media Wear =

77.1 mm =

New weight =

New mean size =

Chamber 2 Media Wear =

24.7 mm =

New weight =

New mean size =

Reduction in Volume Loading:

Chamber 1 From

To

Chamber 2 From

To

(50 * 800000)

15.6 tonnes 15.4%

1899 g

1606 g

73.0 mm

24.4 tonnes 15.4%

62 g

52 g

23.3 mm

30.4 %

25.7 %

27.9 %

23.6 %

contents chapter 4 chapter 5

C E M E N T T E C H N O L O G Y N O T E S 2 0 0 5 50

For an annual production of 800,000 tonnes the media

consumption for 50g/t is 40 tonnes. In the example this equates

to 1.35g/kWh.

Mean media sizes (assuming no top-up) are seen to reduce to

73.0mm (from 77.1) and to 23.3mm (from 24.7) respectively.

4.3.13 POWDER LOADING AND RESIDENCE TIME

Cement grinding in a ball mill essentially involves the transport

of material through a rotating cylinder. In the simplest case

where there is no mixing as particles pass through the mill the

type of flow is referred to as "plug flow" and all the particles

have the same residence time in the mill.

Conversely, in the case where the contents of the mill are well

mixed and uniform in composition, such that the exit from the

mill has the same composition as the contents of the mill, the

flow is referred to as "back-mix" of "fully-mixed" flow.

In both cases, for steady-state conditions, the residence time is

simply defined as the ratio of the mass of material in the mill to

the feed rate, i.e.

Residence Time = W/F

Where W = hold-up of material in the mill (tonnes)

F = feed rate to the mill (tonnes/hour)

In practice however, the flow of cement through mills is non-

ideal (plug flow and fully-mixed flow being "ideal") because of

partial back mixing as a result of the mill internals (e.g. media,

diaphragms). Hence in reality there is a distribution of residence

times for particles in the mill with an overall mean residence

time, i.e. some particles remain in the mill for only a short time,

whilst others remain for a very long period.

The residence time distribution (RTD) and mean residence time

(MRT) can be determined in practice using tracer techniques,

such as that proposed by Frank Mardulier and details of the test

method can be found in his published articles.

The Grace method of Frank Mardulier involved the use of

sodium fluorescein as a pulse tracer added to the feed of the

mill. The concentration of tracer in the mill product is then

monitored starting at the time of addition and at regular

intervals for up to 60 minutes (longer for open-circuit mills,

shorter for closed-circuit mills).

A typical tracer curve is shown in Figure 52 for an open and

closed circuit mill.

The trace from a closed-circuit mill is complicated by the

presence of tracer in the rejects (hence the cyclic nature of the

curve). It is possible to mathematically correct this curve to

produce the equivalent of the open-circuit (Austin has a

publication on this) but it is quite complex. The mean residence

time can then be determined. It should be noted that this rarely

coincides with the peak, as the distribution of residence times is

usually skewed (See Figure 52). In most practical tests the peak

of the curve was used to estimate the mean residence time,

although in general this will be marginally shorter than the

actual one.

Figure 52. Residence Time Distribution.

4. THE BALL MILL

contents chapter 4 chapter 5

C E M E N T T E C H N O L O G Y N O T E S 2 0 0 5 51

From knowledge of the feed rate and the MRT, the hold-up can

be determined.

For example, from the data in Figures 46 and 51, we had a feed

rate of 110 tonnes/hour and say a circulating load (total feed

divided by fresh feed) of 300%. For a MRT of 6.8 minutes

determined by fluorescein tracer, we would calculate a hold-up

of 37.4 tonnes (See Figure 53).

Figure 53. Residence Time/Hold-Up/Void Filling Fluorescein

Tracing.

As a result of this, the steel/clinker ratio is 6.9. Typical ratios are

between 6 and 10, with the optimum around 8 (See section 6).

The determination of hold-up in this way, whilst accurate, is

somewhat involved and can be time consuming. Furthermore

the value of tonnes hold-up is not a very practical value unless

qualified by knowledge of other data such as feed rate,

circulating load and media charge.

A more useful value is the volume of material in the mill

compared to the volume of media. The steel/clinker ratio goes

someway to provide this, although can only be used to relate to

volume if densities are known and remain constant. This is

more or less true for the media but not so for the material (the

bulk density of clinker/cement can be anywhere between 1000

and 1700 kg/m

3

).

One means of relating volumes is to refer the volume of

material to the volume of voidage in the media charge, i.e. void

filling. This is a key parameter in the "Grace Factor" approach.

The media voidage will depend on the packing of the balls. For

dense packing the voidage can be as low as 40%, however when

allowing for end effects (i.e. the constraints of a chamber - sides

and ends) and a degree of charge expansion due to the material,

the value is typically in the range of 42-45%.

In our example (See Figure 53) the volume of voids for the

media in the mill is 25.86m

3

. For a bulk density of say 1400

kg/m

3

for the material in the mill we have a material volume of

26.7m

3

. Hence the percentage void filling is 103%. We shall see

later that this is on the high side for optimum grinding.

Another approach for assessing the powder loading is to directly

estimate during a mill internal inspection following a crash stop

(i.e. a mill stop with feed on). This involves an estimation of the

mean level of material relative to the media level and then the

combination of this with the height above charge measurement

to produce the effective height above powder (HAP) value.

Where the powder level is below the media level, the void filling

is simply the volume to the powder level divided by the volume

to the media level. In the example (Figures 46, 51, 53), in

chamber 1 we have HAC = 2.92, HAP = 3.17 (Powder was

250mm below media) and equivalent volume loadings of 30.4%

and 23.8%. Hence the percentage void filling is 78%.

Where the powder level is above the media level the void filling is:-

the volume to the powder level less the volume of

media steel (e.g. 0.57 * volume loading) divided by the

volume of voidage (i.e. 0.43 * volume loading). In the

example, in chamber 2 we have HAC = 3.05, HAP =

2.98 (powder was 70mm above media) and equivalent

volume loadings of 27.9% and 29.7%. Hence the

percentage void filling is 116% (not simply 106%).

See also TIS MS010.

From the void fillings it is of course then possible to estimate

the hold-up in tonnes using an assumed material density of say

1400 kg/m

3

. This is seen to be 36.2 tonnes from Figure 53.

Figure 53 (cont). Residence Time/Hold-Up/Void Filling Mill

Inspection Data.

4. THE BALL MILL

Data (Fluorescein Tracer):

Feed Rate =

Circulating Load =

Mean Residence Time (tracer) =

Media, Chamber 1 =

Media, Chamber 2 =

Volume, Chamber 1 =

Volume, Chamber 2 =

Volume Loading, Chamber 1 =

Volume Loading, Chamber 2 =

110 Tonnes/hour

300 %

6.8 Minutes

101.0 Tonnes

158.5 Tonnes

77.14 m

3

126.44 m

3

30.4 %

27.9 %

Calculations

MRT = Hold-Up/Feed rate

or Hold-Up = MRT * Feed Rate

Circulating Load = Total Feed rate/Fresh

Feed rate

Total Feed rate = (300/100 * 110) =

Hold-Up = (6.8/60 * 330) =

Steel/Clinker Ratio =

Media Volume, Chamber 1 =

Media Volume, Chamber 2 =

Void Volume, Chamber 1 =

Void Volume, Chamber 2 =

Void Volume, Total =

Cement Volume (assuming 1.4t/m

3

) =

Void Filling =

330 Tonnes/hour

37.4 Tonnes/hour

6.9

23.48 m

3

35.21 m

3

10.70 m

3

15.16 m

3

25.86 m

3

26.7 m

3

103 %

Data (Mill Internal Inspection):

Height above powder, Chamber 1 = 3.17 m

Height above powder, Chamber 2 = 2.98 m

Volume to powder level, Chamber 1 = 23.8 %

Volume to powder level, Chamber 2 = 29.7 %

Void Filling, Chamber 1 = 78 %

Void Filling, Chamber 2 = 116 %

Void Filling, Mill = 101 %

Hold-Up, Chamber 1 = 11.7 tonnes

Hold-Up, Chamber 2 = 24.5 tonnes

Hold-Up, Total = 36.2 tonnes

MRT = 6.6 Minutes

contents chapter 4 chapter 5

C E M E N T T E C H N O L O G Y N O T E S 2 0 0 5 52

Rarely will both methods (i.e. fluorescein tracing or mill

inspection) give the same results (or indeed be carried out at the

same time). The advantages and disadvantages are:-

Fluorescein Tracing:

Advantages: Theoretically more accurate for

tonnes hold-up

Provides additional RTD data

No need to stop the mill

Impressive technical service

Disadvantages: Involved procedure

Short-cuts will reduce accuracy (i.e.

no allowance for recycle and using

peak concentration only)

Mill operating tests only

Void filling relies on good estimate of

material bulk density

Mill Inspection:

Advantages: Direct measurement for void filling

Can be carried out in conjunction

with a wider mill inspection or audit

Provides individual chamber

information

Disadvantages: Hold-up requires good estimate of

material bulk density

Needs mill stop (can be advantageous if

in conjunction with a wider inspection)

Can be difficult to estimate (See

Section 11)

Often, in discussion with cement plants, it will be possible to

acquire an understanding of the typical or characteristic void

filling in a mill since they will undertake relatively frequent stops

on the mill (although the majority will be with the feed run out).

Knowledge like, "well below the media level" or "about the

same level" or "50mm" deep of material above the media" will

often be quoted. These could equate to "low void filling"(say

80%), "100% void filling" and "110% void filling" respectively.

Further information is provided in sections 6 and 11.

4.3.14 MILL AIRFLOW

The mill airflow refers to the volume of air passing the mill.

However much available data will refer to the air passing the

filter and exhaust. In-leaks, for example at the mill end, are

important and thus sometimes only 50% (or even less) of the

exhaust air will have passed through the mill.

In the past, where the average mill size was somewhat smaller

than today, mill airflows were often targeted at around 2-3

volume changes per minute (where the volume is the free

volume above the charge). More often the air requirement,

which is principally for heat and moisture removal, will be

designed in terms of kg/kg of air to cement. A typical design

value of 0.4 kg/kg will often be used, although the majority of

mills will operate below this at 0.1 to 0.3 kg/kg.

The airflow can be measured by:

- pitot (at the mill filter exhaust). Then make

allowances for the in-leaks

- anemometer (e.g. vane or hot wire)

- gas tracing

One practical method is to determine the volume of air at the

filter exhaust (usually by pitot) and then carry out a

temperature balance. Details are provided in TIS MS011. This

involves:-

- measure filter exhaust gas temperature and airflow

(correct to STP conditions)

- measure the temperature of the mill exit airflow

(mill exit cement temperature can be used)

- measure the ambient air temperature

- carry out a temperature balance to determine the

volume of air passing the mill

In the example in TIS MS011 for a filter airflow of 55,000

Nm3/hr at 74C, a mill exit temperature of 118C and an

ambient temperature of 15C, the mill airflow is estimated to be

only 31,500 Nm

3

/hr.

4.3.15 MILL TEMPERATURE, COOLING AND WATER

INJECTION

The majority of the kWh/tonne appear as heat, which results in

a rise in temperature of the material leaving the mill.

High milling temperatures result in a deterioration of the

grinding efficiency as a result of an increased tendency for

agglomeration and coating. Also a greater proportion of the

added gypsum will be dehydrated to hemihydrate and/or soluble

anhydrite (See Section 1).

For these reasons milling temperature is controlled by one or

more of the following:-

- airflow through the mill

- external water sprays

- internal water injection

- cooling air to the separator

- direct cooling of the separator rejects

In practice, all mills have some cooling from airflow whilst

some have additional water injection for cooling. External water

sprays are only usually found on smaller older mills. Modern

separators (See Section 5) often have a "straight through" air

circuit which provides significant cooling to the mill returns.

Separators have also been cooled by water jackets on occasion.

For correct mill cooling it is necessary to determine a mill heat

balance which assesses the sources of heat and the removal of

heat. A summary of these is shown in Figure 54.

Water injection either to the first chamber or both chambers

generally offers the most controllable form of mill cooling. As

an overall guide water injection should be limited to around 3%

by mass of fresh feed to the mill - 1% in chamber 1 and 2% in

chamber 2.

4. THE BALL MILL

contents chapter 4 chapter 5

C E M E N T T E C H N O L O G Y N O T E S 2 0 0 5 53

Figure 54. Mill Heat Balance.

Potential problems of internal water can occur, such as:-

- In chamber 1, localised cooling resulting in

hydration and blockages and coating of the

intermediate diaphragm

- In chamber 2, inadequate dispersion or targeting of

the water such that cement pre-hydration can occur

resulting in a reduction in strength levels.

The water should be dispersed into the media charge.

Dispersion is usually achieved by atomisation with air. However

a very fine atomised water spray can be directly taken by the

mill venting airflow, and therefore be less effective.

Second chamber injection at the intermediate diaphragm is the

most beneficial point of injection, although requires well

maintained equipment.

When using internal water any other sources of water should

also be taken into account, e.g. raw materials, air.

One method of assessing the maximum water input is to assess

the dew-point temperature of the mill exhaust. Ellerbrock (ZKG

1/88 pp1-12) has suggested a maximum dew point temperature

of 70C to avoid any deterioration of cement characteristics.

Mills typically operate with dew-point temperatures of 40C.

Details are provided in TIS MS012.

4. THE BALL MILL

HEAT INPUT HEAT OUTPUT

Mill Power

1

Clinker1

Gypsum

Other Feed

Rejects

Water, injection

2

Water, air

Air

Chemical Reaction

Cement

Water (evaporation)

Convection

Airflow

Gypsum Dehydration

Dust

Comments:

(1) Principal heat input

(2) Typical Water Injection 0 - 3%

Chamber 1: 0 - 1%

Chamber 2: 0 - 2%

Dew Point Temperature 70C maximum

40C typical

contents chapter 4 chapter 5

Anda mungkin juga menyukai

- Preparation of Turkey Red OilDokumen16 halamanPreparation of Turkey Red OilHimanshu Jha73% (11)

- Design Calculations For Pressure VesselsDokumen73 halamanDesign Calculations For Pressure Vesselsshani5573Belum ada peringkat

- SDM Cyclone SizingDokumen7 halamanSDM Cyclone Sizingmohamed_sahnoun_enisBelum ada peringkat

- VRM-Fill Data Only in Yellow Cells: Total Feed (MT) Clinker (MT) Gypsum (MT) Slag (MT)Dokumen2 halamanVRM-Fill Data Only in Yellow Cells: Total Feed (MT) Clinker (MT) Gypsum (MT) Slag (MT)Sahadeb Manna100% (1)

- Raw Mill Nozzle Ring Area 8/6/2019 11:02: 4.47 m2 m2 m2 m2 m2 3.57 m2Dokumen6 halamanRaw Mill Nozzle Ring Area 8/6/2019 11:02: 4.47 m2 m2 m2 m2 m2 3.57 m2Bùi Hắc HảiBelum ada peringkat

- Jet Bit Nozzle Size SelectionDokumen46 halamanJet Bit Nozzle Size SelectionBharat BhattaraiBelum ada peringkat

- International Chemistry Olympiad Problems Volume 03 (2009-2013)Dokumen291 halamanInternational Chemistry Olympiad Problems Volume 03 (2009-2013)Science Olympiad Blog75% (4)

- Calculation Sheet: Padeye Calculations LoadsDokumen15 halamanCalculation Sheet: Padeye Calculations Loadsshani5573Belum ada peringkat

- 04 MillingDokumen21 halaman04 MillingMKPashaPasha100% (1)

- R A R F U: % Passing Size, M Feed Coarse FinesDokumen3 halamanR A R F U: % Passing Size, M Feed Coarse FinesAli HüthütBelum ada peringkat

- Productivity Long-HoleDokumen16 halamanProductivity Long-HoleSujib BarmanBelum ada peringkat

- Chuong 2-Roller MillDokumen24 halamanChuong 2-Roller MillAmit Sharma0% (1)

- MT French AdvancedDokumen64 halamanMT French AdvancedperacBelum ada peringkat

- ZeiselDokumen98 halamanZeiselGirne100% (1)

- Report On Cement MillDokumen9 halamanReport On Cement MillYounas Khan100% (1)

- False Air - Measuerment OverviewDokumen11 halamanFalse Air - Measuerment OverviewVijay BhanBelum ada peringkat

- Finish Grinding by Roller PressDokumen3 halamanFinish Grinding by Roller PressManish Verma100% (3)

- QUESTIONNAIRE FOR PYROPROCESSING MODIFICATION COMPANYDokumen8 halamanQUESTIONNAIRE FOR PYROPROCESSING MODIFICATION COMPANYVijay BhanBelum ada peringkat

- Optimizing Raw Mills PerformanceDokumen9 halamanOptimizing Raw Mills PerformanceIrshad HussainBelum ada peringkat

- Roller Press 1Dokumen4 halamanRoller Press 1bipinagarwalBelum ada peringkat

- Motion of Particles in FluidDokumen26 halamanMotion of Particles in FluidSubakti HungBelum ada peringkat

- Fourier Transform TablesDokumen9 halamanFourier Transform TablesOrder17Belum ada peringkat

- MT French Vocabulary Course PDFDokumen48 halamanMT French Vocabulary Course PDFsuigeneris11Belum ada peringkat

- Study of The Grinding Balls Distribution Inside The MillDokumen2 halamanStudy of The Grinding Balls Distribution Inside The Millsempatik721Belum ada peringkat

- 9 - RAWGRINDING CementDokumen28 halaman9 - RAWGRINDING CementAnoop Tiwari100% (2)

- Blue Book Cor Us 20041011Dokumen960 halamanBlue Book Cor Us 20041011ccbserialk100% (1)

- VDZ-Onlinecourse 4 5 enDokumen30 halamanVDZ-Onlinecourse 4 5 enAnonymous iI88LtBelum ada peringkat

- 4 - False Air Profile Dry Preheater KilnDokumen1 halaman4 - False Air Profile Dry Preheater KilnSundara SubramaniyanBelum ada peringkat

- CLNKRCLRTYPES-GRTROTPLANETRYDokumen32 halamanCLNKRCLRTYPES-GRTROTPLANETRYJoko Dewoto100% (4)

- Conveyor Belt Installtion SplicingDokumen71 halamanConveyor Belt Installtion SplicingMatthew Butler75% (4)

- Common Problems in Cement Plant: One Issue From Each SectionDokumen7 halamanCommon Problems in Cement Plant: One Issue From Each SectionYhaneBelum ada peringkat

- MILL OPTIMISE June 99-DBDokumen53 halamanMILL OPTIMISE June 99-DBmohamedredaBelum ada peringkat

- Review RollerPress OperationsDokumen331 halamanReview RollerPress OperationsAnonymous 3ESYcrKPBelum ada peringkat

- Vibration Analysis On BearingsDokumen67 halamanVibration Analysis On BearingsronfrendBelum ada peringkat

- How To Conduct A Ball Mill AuditDokumen7 halamanHow To Conduct A Ball Mill Auditsafwat hassan100% (1)

- Ball Charge Design Methods GuideDokumen12 halamanBall Charge Design Methods GuidePaulo VidasBelum ada peringkat

- Modern Cement Grinding Systems ComparedDokumen14 halamanModern Cement Grinding Systems ComparedCao Ngoc AnhBelum ada peringkat

- Heat Balance Kiln & Cooler P 6: InstructionsDokumen32 halamanHeat Balance Kiln & Cooler P 6: Instructionstika100% (1)

- Loesche Seminar VCM Study Dec03Dokumen132 halamanLoesche Seminar VCM Study Dec03stelios nikoladosBelum ada peringkat

- 5) Flow Measurement - stagECC - Rev1 2009Dokumen49 halaman5) Flow Measurement - stagECC - Rev1 2009hmaza shakeelBelum ada peringkat

- Lucie MillDokumen50 halamanLucie MillJoko DewotoBelum ada peringkat

- Cement Mill Calculation DesaignDokumen1 halamanCement Mill Calculation DesaignHilmy MuhammadBelum ada peringkat

- 081 - TSP HUA400 20080305 Kiln Audit Dec07Dokumen30 halaman081 - TSP HUA400 20080305 Kiln Audit Dec07mkpq100% (2)

- Raw Mill Heat BalanceDokumen1 halamanRaw Mill Heat BalanceElwathig Bakhiet100% (1)

- 08 Rp-Trouble ShootingDokumen26 halaman08 Rp-Trouble Shootingaff bearBelum ada peringkat

- Measurements of The Quality of Cement Produced From Looped LimestoneDokumen30 halamanMeasurements of The Quality of Cement Produced From Looped LimestoneCharlie Dean100% (1)

- Vertical roller mill grinding efficiencyDokumen11 halamanVertical roller mill grinding efficiencybkchoudhury1993Belum ada peringkat

- User Guide PDFDokumen27 halamanUser Guide PDFbulentbulut100% (1)

- Tromp Curve Calculations and ResultsDokumen3 halamanTromp Curve Calculations and Resultsrecai100% (2)

- .Improvement in Performance of Ball Mill in Cement GrindingDokumen4 halaman.Improvement in Performance of Ball Mill in Cement Grindingdeni jakaBelum ada peringkat

- Impact of Process Parameters On QualityDokumen25 halamanImpact of Process Parameters On QualityDineshBelum ada peringkat

- VRM C SimulatorDokumen19 halamanVRM C SimulatorIrshad HussainBelum ada peringkat

- Grinding and Classifying Technology For Slag: Replacement Factors DryingDokumen6 halamanGrinding and Classifying Technology For Slag: Replacement Factors DryingGerman Gabriel Anaya Vega100% (1)

- Cement Grinding Vertical Roller Mills Versus Ball Mills 1654248086Dokumen17 halamanCement Grinding Vertical Roller Mills Versus Ball Mills 1654248086Salah Romdani100% (1)

- MC V0 B000 TOC v7 0 1 PDFDokumen171 halamanMC V0 B000 TOC v7 0 1 PDFcassindrome100% (2)

- Improvement of Productivity Using Tromp Curve MeasDokumen11 halamanImprovement of Productivity Using Tromp Curve MeasRachit Bansal BJ20099Belum ada peringkat

- CM2 Process Media Mix Up 2014 2015Dokumen31 halamanCM2 Process Media Mix Up 2014 2015Junaid MazharBelum ada peringkat

- Cairo Technical Center VRM Design and ComponentsDokumen54 halamanCairo Technical Center VRM Design and ComponentsMujahid BalochBelum ada peringkat

- Increasing cement grinding capacity with vertical roller mill technologyDokumen7 halamanIncreasing cement grinding capacity with vertical roller mill technologymahreza189100% (2)

- Cement Production Operator Training GuideDokumen7 halamanCement Production Operator Training GuidemkpqBelum ada peringkat

- Cement Kiln Dust CKD Methods For ReductioDokumen21 halamanCement Kiln Dust CKD Methods For ReductiofaheemqcBelum ada peringkat

- Cement Chapter 2Dokumen19 halamanCement Chapter 2shani5573Belum ada peringkat

- Cyclone Sizing Selection GuideDokumen18 halamanCyclone Sizing Selection GuideLuis VelasquezBelum ada peringkat

- Maximizing Alternative Fuel Use in Cement ProductionDokumen4 halamanMaximizing Alternative Fuel Use in Cement Productionmohamadi42100% (1)

- enDokumen22 halamanenAnonymous iI88LtBelum ada peringkat

- 031 Introduction Cement Grinding With Ball Mill SystemsDokumen4 halaman031 Introduction Cement Grinding With Ball Mill SystemsCesar Orlando Guarniz JustinianoBelum ada peringkat

- Pyro-processing system flow overviewDokumen1 halamanPyro-processing system flow overviewVijay BhanBelum ada peringkat

- Ball Mill OptimiztionDokumen8 halamanBall Mill OptimiztionShakil AhmadBelum ada peringkat

- Grate Cooler Thermal AnalysisDokumen14 halamanGrate Cooler Thermal Analysisaman131Belum ada peringkat

- Rotary Kilns: Transport Phenomena and Transport ProcessesDari EverandRotary Kilns: Transport Phenomena and Transport ProcessesPenilaian: 4.5 dari 5 bintang4.5/5 (4)

- Foundation For Roller PressDokumen3 halamanFoundation For Roller PressRollerJonny0% (1)

- Lab Chi ML EngDokumen7 halamanLab Chi ML EngHilmy MuhammadBelum ada peringkat

- Mustafa Kamal Pasha: Calender For 2011Dokumen4 halamanMustafa Kamal Pasha: Calender For 2011shani5573Belum ada peringkat

- Year-End Tax Planning Calculator1Dokumen18 halamanYear-End Tax Planning Calculator1shani5573Belum ada peringkat

- 1UIADokumen7 halaman1UIAshani5573Belum ada peringkat

- Currency Rate Calculator1Dokumen1 halamanCurrency Rate Calculator1shani5573Belum ada peringkat

- Pile Load Test: (Source: Pile Design and Construction by M.J. Tomlinson, 1994)Dokumen4 halamanPile Load Test: (Source: Pile Design and Construction by M.J. Tomlinson, 1994)Arvin BhurtunBelum ada peringkat

- A4-P 1.0 enDokumen4 halamanA4-P 1.0 enshani5573Belum ada peringkat

- Gear BoxDokumen4 halamanGear Boxshani5573Belum ada peringkat

- Pile LOad Test AADokumen1 halamanPile LOad Test AAshani5573Belum ada peringkat

- Process Systems Process System - Introduction: System Levels in Ore / Minerals ProcessingDokumen12 halamanProcess Systems Process System - Introduction: System Levels in Ore / Minerals ProcessingepaccoyBelum ada peringkat

- On 17Dokumen2 halamanOn 17shani5573Belum ada peringkat

- Marvelous FishesDokumen51 halamanMarvelous FishesMushtaq M.ChinoyBelum ada peringkat

- MD20.12 Gear Units Fast Track en Es ItDokumen22 halamanMD20.12 Gear Units Fast Track en Es ItJosueNorrisBelum ada peringkat

- Equipment - Elect Kiln 2Dokumen26 halamanEquipment - Elect Kiln 2shani5573Belum ada peringkat

- A4-P 1.0 enDokumen4 halamanA4-P 1.0 enshani5573Belum ada peringkat

- SHUTDODokumen13 halamanSHUTDOshani5573Belum ada peringkat

- Alternative Mixed: Cost /ton $ Cost /ton $ Cost /ton $ Cost /ton $Dokumen3 halamanAlternative Mixed: Cost /ton $ Cost /ton $ Cost /ton $ Cost /ton $shani5573Belum ada peringkat

- Square FootingDokumen9 halamanSquare Footingshani5573Belum ada peringkat

- Knowledge ManagementDokumen298 halamanKnowledge Managementshani5573Belum ada peringkat

- Virus Signature DatabaseDokumen1 halamanVirus Signature Databaseshani5573Belum ada peringkat

- Arrangement of EquipmentDokumen4 halamanArrangement of Equipmentshani5573Belum ada peringkat

- Army Welfare Trust Nizampur Cement Plant: Electrical DepartmentDokumen18 halamanArmy Welfare Trust Nizampur Cement Plant: Electrical Departmentshani5573Belum ada peringkat

- 2nd Line Presentation Dated 12-07-2003Dokumen5 halaman2nd Line Presentation Dated 12-07-2003shani5573Belum ada peringkat

- Lucky Cement Limited Karachi Project: SR No. Date LINE Equipments Defect/Deficiencies/ProblemsDokumen4 halamanLucky Cement Limited Karachi Project: SR No. Date LINE Equipments Defect/Deficiencies/Problemsshani5573Belum ada peringkat

- Three-Dimensional Effects For Supported Excavations in ClayDokumen7 halamanThree-Dimensional Effects For Supported Excavations in ClayrkBelum ada peringkat

- Review of Literature On Probability of Detection For Liquid Penetrant Nondestructive TestingDokumen51 halamanReview of Literature On Probability of Detection For Liquid Penetrant Nondestructive TestingVicky GautamBelum ada peringkat

- Worksheet: ProofsDokumen3 halamanWorksheet: ProofsPCHANFANBelum ada peringkat

- Inline Desilter ManualDokumen18 halamanInline Desilter ManualdesaviniciusBelum ada peringkat

- Job 1 SksoDokumen5 halamanJob 1 SksoFajAr OkTaBelum ada peringkat

- ANSYS Model of A Cylindrical Fused Silica Fibre-01Dokumen15 halamanANSYS Model of A Cylindrical Fused Silica Fibre-01lamia97Belum ada peringkat

- Dr. Mezmer's Psychopedia of Bad PsychologyDokumen378 halamanDr. Mezmer's Psychopedia of Bad PsychologyArt Marr100% (5)

- Ewald SphereDokumen57 halamanEwald SphereMohammad Rameez0% (1)

- Effect of Speration in Modified BitumenDokumen12 halamanEffect of Speration in Modified BitumenyadavameBelum ada peringkat

- Modeling of Synchronous Generators in Power System Studies: October 2016Dokumen12 halamanModeling of Synchronous Generators in Power System Studies: October 2016aswardiBelum ada peringkat

- The Weighted Histogram Analysis Method (WHAM) : Michael AndrecDokumen14 halamanThe Weighted Histogram Analysis Method (WHAM) : Michael AndrecWilliam AgudeloBelum ada peringkat

- Reciprocating compressor performance analysis using computer simulationDokumen9 halamanReciprocating compressor performance analysis using computer simulationLeandro Garcia VelaBelum ada peringkat

- Chapter 2 1 - Linear EquationsDokumen23 halamanChapter 2 1 - Linear Equationsapi-263209117Belum ada peringkat

- Offshore Pipeline Hydraulic and Mechanical AnalysesDokumen25 halamanOffshore Pipeline Hydraulic and Mechanical AnalysesEslam RedaBelum ada peringkat

- Aditya and VarahaDokumen7 halamanAditya and VarahaVibhats VibhorBelum ada peringkat

- The Synchronus Rotor Instability Phenomenon - Morton Effect PDFDokumen9 halamanThe Synchronus Rotor Instability Phenomenon - Morton Effect PDFabdullah buttBelum ada peringkat

- LTV 816 T LITE ONElectronicsDokumen10 halamanLTV 816 T LITE ONElectronicsEstebanLiBelum ada peringkat

- Design Project: SEV200 - Geotechnical Investigation and Design Last Update: 09/05/2020Dokumen12 halamanDesign Project: SEV200 - Geotechnical Investigation and Design Last Update: 09/05/2020abdulqadirghoriBelum ada peringkat

- Levee Drain Analysis in SlideDokumen12 halamanLevee Drain Analysis in SlideAdriRGBelum ada peringkat

- Samuel Glasstone - Thermodynamics For Chemists PDFDokumen532 halamanSamuel Glasstone - Thermodynamics For Chemists PDFRimmon Singh100% (2)

- 2018 MunsellelectronicDokumen9 halaman2018 MunsellelectronicCristian Camilo Quitian MoralesBelum ada peringkat

- Numericals - RajasthanUniversity - Papers End Sem ChemDokumen20 halamanNumericals - RajasthanUniversity - Papers End Sem ChemJanmendraBelum ada peringkat

- Static Mixers for Solid-Solid MixingDokumen8 halamanStatic Mixers for Solid-Solid MixingSalsa_Picante_BabyBelum ada peringkat

- Bhavans Public School, Doha - Qatar: Model Question Paper 2016-17 MathematicsDokumen4 halamanBhavans Public School, Doha - Qatar: Model Question Paper 2016-17 MathematicsSanthosh KrishnanBelum ada peringkat

- Name: Teacher: Date: Score:: Identify The Properties of MathematicsDokumen2 halamanName: Teacher: Date: Score:: Identify The Properties of MathematicsMacPapitaBelum ada peringkat