11 Spe35396

Diunggah oleh

عبدالغفار بيزانJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

11 Spe35396

Diunggah oleh

عبدالغفار بيزانHak Cipta:

Format Tersedia

SPHDOE 35396

Analysis of Hydrofracture Geometry and Matrix/Fracture Interactions During

Steam Injection

A. R. Kovscek, Lawrence Berkeley National Laboratory, R. M. Johnston, CalResources LLC, and T. W. Patzek,

University of California and Lawrence Berkeley National Laboratory, SPE Members

Cqynght 19%5, S,wzcty O( Pelmkum Engmecrs, Inc

?hts paper wm prepared I,Ir prescnlamm m the lY(M SPWOOE Temh Symfnwium m! lmfmvetf

011 Recovery held In Tulsa, OK, 1 I -24 AfwIl 1996

This pqxr WM sclccmd for presentation hy (he SPE Program Commmce following rcwcw of

mformalmn cumainecf In an iihslracl suhmmed by [hc author(s) Contcnls of the pafur as

fmscnmd have mn been mvicwcd by the Sociely of Peuoleum Engineers and arc suhlcc! m

cmrcctum(s) hy [he author(s). The malcrt id, M presented. dot! no{ ncccsswtly rcflccl any

posmon of [he SOch?cy of Pemoleum Engmows or iu mcmfmrs Papers prescnud at SPE meelmgs

are sub)ecl m puhlicalmn rewew hy Wtmrlal Cmmniuecs of fhe SIxIeIy of Petroleum

Engntms. Pcnms.mon u> COPY IS resuuxd m an ahs!racl of nol more than 3(X) wmif.i Illwwrwons

may nm he copf The ahsmacl should comam c<msp:cu(ms acknowkdgmem 01 where and hy

whom [he ~apa was prcscntml WrHc Lthrartan, SPE P O Box 8333836, Richardson, TX 7S083-

M13fI USA, ft. 0-214-952-9435

Abstract

This is the second part of our analysis of a steam drive pilot in

the South Belridge Diatomite, Kern County, California. In

this pilot, steam is injected through two noncommunicating,

vertical hydrofractures (IN2U and IN2L) that nearly span the

entire 1000 ft tall diatomite column. In the first part, we

summarized pilot results for the initial 1200 days of steam

injection and examined steam convection and heating resulting

from injection into the lower hydrofracture.

Here we update the pilot response from 10/90 to 11/95.

We conclude that the cumulative oiI production in the far

(543N) and close (543P) producer was 106,000 and 55,000

BO, respectively, and the incremental oil production above

primary was 60,000 and 37,000 BO, respectively. This

translates to the total oil recovery of 9% OOIP and the

incremental oil recovery over primary of 6% OOIP after 5

years of steam injection. From our simulations of steam

injection in IN2U and IN2L, we estimate that 246,000 BS

CWE was injected to the west towards 543N and 102,000 BS

was injected to the east toward 543P. The cumulative oil

steam ratio (COSR) for the pilot was, therefore, 0.45, and the

incremental COSR was 0.28.

We also apply a high resolution numerical model

developed in the first paper to interpret the results of steam

injection through the upper hydrofmcture of the pilot. Results

of this analysis indicate that the upper injection hydrofiacture

was highly dynamic and asymmetrical while undergoing steam

injection. Steam flowed preferentially into the northern wing

of the hydrofracture which reached a final winglength of 250 ft.

To the south, hydrofracture winglength reached roughly 75 ft

and diatomite heating was weak. A dramatic temperature

response above the perforated interval of the upper injection

well suggests that a horizontal fracture, or network of natural

fractures, opened within the formation and linked to the

injection hydrofracture. Our analysis indicates that roughly 43

percent of the total injected steam migrated above the

perforations of the injection well, but remained within the

Diatomite, and flowed rapidly away from the fracture face b

to a large increase of hydraulic diffusivity of the formation.

Introduction

Thermal oil recovery in shallow, low permeability, and

hydraulically fractured reservoirs appears to be substantially

more efficient than conventional waterflooding. Thus, steam

drive for such reservoirs is under investigation as an alternative

secondary oil recovery process. To help assess the feasibility

of steam drive for oil recovery in diatomaceous oil-hearing

rocks, Shell Western E&P conducted the Phase I and II pilots

[1] in Section 29 of the South Belridge Diatomite, Kern

County, California.

This is the second paper of a two part series presenting

an interpretation of the Phase H pilot. In the pilot, two

separate hydrofractured injectors that are denoted IN2U and

IN2L, where the U and L refer to a single perforation across

the upper and lower portion of the Diatomite, are used to

deliver steam to the formation. In our first paper [2] (referred to

as Part 1), the pilot design, data collection program, and

geology were described along with a computationally simple

model for interpreting the pilot results. Part I also validated the

model by interpreting the results of steam injection through

IN2L.

519

2 ANALYSISOF HYDROFRACTUREGEOMETRY

SPE 35396

AND MATRIWFRACTURF INFRACTIONS DURING STFAM INJFCTION

Here, we concentrate on the results of steam injection

through IN2U which has the dckd complication of a

horizontal fracture extension in addition to an asymmetric

shape of the hydrofkacture. Finally, we compare the inferred

hydrofracture shapes deduced from the earlier microseismic

imaging study with the hydrofracture shapes from history

matching steam injection in IN2U and IN2L. The latter

comparison allows us to judge whether microseismic events

are indicative of heat delivery to diatomite.

First, we review the Phase II pilot design and update

pilot results through the end of 1995. Next, we present a

history match of the Phase 11 response to steam injection

through IN2U. Thirdly, the sequence of hydrofracture shapes

obtained for IN2U and IN2L are compared to the hydrofracture

shapes indicated by passive microseismic imaging of the

hydrofractunng process. Finally, the implications of relative

changes in hydraulic diffusivity, on the productivity of wells

are discussed.

Phase II Steam Drive Pilot

Figure 1 presents a plan view of the Phase II pilot area

including injection, production, and monitoring wells. The

two injectors, IN2U and IN2L, located in the center of the

figure are perforated from 1110 to 1460 ft and 1560 to 1910 ft,

respectively. The dual injectors allow separate control of steam

injection rates and pressures in the upper and lower portion of

the Diatomite. An earlier passive microseismic imaging study

[3] of the hydrofractures in these two wells indicated that while

the hydrofracture in IN2L appeared to be symmetric, that in

IN2U was highly asymmetric. The azimuth of both fractures

was found to be N21 E ~ 4. The dark diagonal line passing

through IN2U and IN2L gives this azimuth direction

graphically.

The close producer, 543P, is 40 ft to the east of the

injection wells and the far producer, 543N, is roughly 130 ft to

the west. Microseismic monitoring in 543P [4] indicated that

the hydrofracture in the well was nearly vertical and divided

into two separate zones corresponding to the most permeable

diatomite layers. Also, the upper most fractured zone extended

60 ft above the pforated zone. The azimuth of the

hydrofracture in 543P is reported as N25E * 5. Well 543N is

an old, full interval prcducer drilled and completed in October

1979. Again, the dark diagonal lines passing through the

production wells give the general direction of the

hydrofractures. The remaining wells, LO 11 to L015, MO] and

M02, are observation wells that measure the formation

temperature response and oil displacement.

Injection in IN2U began on October 10, 1990 and IN2L

followed on October 24, 1990 and steam injection continues as

of the writing of this paper. Daily averages of the minute by

minute measurements of steam injection rate and pressure am

saved for each injection well. Also, the production response is

measured daily and temperature surveys in the observation

wells are run, on average, every 30 days between 800 and 2tXKl

ft at IO ft intervals.

Phase II Response. Significant heating of the formation

and oil production response occurred as a result of steam

injection. Increase in the size of the hydrofracture in IN2U

during steam injection resulted in a roughly 6-fold increase of

injectivity between 100 and 900 days of steam injection, as

shown in Fig. 2. Tip extensions in IN2L also manifested

themselves as substantial increases in steam injectivity [2]. III

Fig. 2, the second derivative of cumulative steam injection in

IN2U with respect to the square root of time increased

constantly at about 600 bbllday between 225 and 900 days. At

slightly more than 900 days, there is a sharp drop in

injectivity due to a near step-change decrmse in injection

pressure; however, the slope of the cumulative injection

quickly returns to roughly 600 bbl/day even though injectivity

decreased as a result of the decrease in injection pressure. The

reduction of injection pressure is also quite evident in the

cumulative injected steam history as a discontinuity at about

900 days. We attribute this last sharp decrease of injectivity to

the shutdown of the horizontal part of the injection fracture.

Both producers, 543P and 543N, show a substantial oil

response to steam injection. The near producer, 543P (Fig, 3),

responded to steam injection within the first 100 days, Its

cumulative oil production roughly tripled compared with that

calculated for a limited-interval primary producer in the M-

cycle that was pressure-depleted by 543N (Table 1). A strong

linkage with the IN2L hydrofracture resulted in steam

breakthrough at the producer and wellhead temperatures

approaching 320 F. To mitigate the steam breakthrough, a

packer was set in 543P that isolated the lower diatomite layers

where steam breakthrough had occurred from the remaining

productive interval of the well. As Fig. 3 shows, wellhead

temperature then decreased to 120 F and well productivity

improved. Even though the perforated interval in 543P spans

only 350 ft, its productivity has been as high 1300 BO/daysn,

In Section 29, average productivity of a full-interval,

undepleted prcducer on primary is 2300 BO/daysn. We

estimate that as of 11/95, 543P produced 37,000 BO above

primary.

The far producer, 543N, whose fractures span 850 ft of

the diatomite column, saw oil production increase from 40

BOPD at the beginning of the pilot to 150 BOPD. llre

extended production history of 543N (Fig. 4), shows some

interesting effects of steam injection on diatomite. Time mm

corresponds to November 1979 when this well was brought on

production. Steam injection begins some ten years later (60

dayslfl) and 543N begins to show oil production response to

steam at 680 days of steam injection (66 days] n). During the

initial period of oil production response, between 66 and 70

days~~, 543N appears to be plugging because the second

520

SPE 35396 A. R. KOVSCEK, R. M. JOHNSTON, AND T. W. PATZEK 3

derivative of production with respect to the square root of time

is -2500 bbl/day. That is, the oil production rate appears to k

beaded toward zero. After 70 days2, the curvature of the

cumulative oil production response changes, and the second

derivative of production with respect to time becomes +1300

bbl/day. This change in sign of the slope indicates that well

productivity has stopped decreasing and has actually begun to

improve Note also, that the improvement in productivity is

accompanied by a slow increase in wellhead temperature from

120 F to approximately 135 F.

Finally, a simple analytical match of oil production in

543N shows (diamonds in Fig. 4) that pressure interference

does become visible after 60 days *D, as the cumulative oil

versus square root of time curve begins to bend down. Thus,

the incremental oil response in 543N is estimated to be 60,000

BO as of 11/95.

Bottom Line. Between 10/1/90 and 11/15/95, 175,000 and

214,000 BS CWE were injected in IN2U and IN2L,

respectively. In the same time period, the cumulative oil

production in 543N and 543P was 106,000 and 55,000 BO,

respectively, and the incremental oil production above primary

was estimated to be 60,000 and 37,000 BO, respectively.

From our simulations of steam injection in IN2U and IN2L,

we estimate that 246,000 BS CWE were injected to the west

towards 543N and 102,000 BS were injected to the east toward

543P (Remember that there is no producer to the east of IN2U

and the pilot geometry causes asymmetrical steam flow.).

Therefore, the cumulative oil steam ratio (COSR) for the pilot

was 0.45, and the incremental COSR was 0,28. The bulk rock

volume of the pilot is calculated as 9,300,000 bbl accounting

for the asymmetrical pilot geometry. We estimate the pore atKI

oil volumes 10 be 4,400,000 and 1,410,000 bbl, respectively,

to the west and 504,000 and 162,000 bbl, respectively, to the

east of the injectors. Hence, the total oil recovery oil rvcovety

in the pilot was 9?Z0of OOIP and the incremental oil recovery

was 690 of OOIP after 5 years of steam injection.

Model Description

Our computational approach is to lump the parameters which

describe the first-order physics of steam movement in

diatomite into a single parameter, termed the hydraulic

diffusivity, thereby simplifying history matching. This

formulation leads to a second order, partial differential

equation, similar in form to a transient diffusion equation, that

describes the pressure profile in the steam-wcupied zone of

each layer of the Diatomite. The method of Marx ml

Langenheim [5] is then used to locate the steam front in mh

layer. Finally, the transient heat conduction equation is solved

for the temperature profile in the oil zone downstream of the

steam front. The hydraulic and thermal diffusivities as well as

hydrofiacture shape are then iterated to match the areal

temperature response in each layer of the Diatomite in the

Phase H pilot and the overall, cumulative steam injection.

Our approach is computationally efficient and leads to

multiple realizations of steamdrive dynamics in the Diatomite.

More importantly, this modeling effort provides the precursory

knowledge of fracture size and shape, as well as the relative

changes in formation permeability needed to simulate

steamdrive in the Diatomite with fully compositional,

multidimensional reservoir simulators.

The pressure diffusion equation is derived by writing

the usual continuum mass and energy balance equations for a

black-oil model reservoir simulation model and expanding

spatial derivatives. Neglecting high order derivative terms,

gravity, capillarity, and assuming saturated steam conditions

[2] yields

32p 1 +

&2 =--~ . . . . . . . . . . . . . . .. . . . . . . ...(l)

where the ratio of the total mobility of all phases, kT, upon

the total system compressibility, v, is the hydraulic diffusivity

Cl=lz

.. ....... . . ... . .

v

(2)

Here p is pressure, x is distance from the injection plane, and t

is time. Because the South Belridge Diatomite is so finely

layered [6] and hydrofracture length is generally greater than the

height of a layer, a one-dimensional equation suffices [2].

The position of the steam front, Xf, within each layer of

the Diatomite is obtained by performing a bulk heat balance in

the horizontal direction and assuming that layer properties am

uniform and constant, After neglecting interlayer heat transfer

we obtain

Xf =

\

Qi ~t

. . .. . . . .. . . . . .. .

(3)

,, MT&AT1

where Qi is the rate of heat injection, MT is the total

volumetric specific heat, Ac is the layer vertical cross sectional

area, and ATI (=T1 - To) is the saturated steam temperature at

the fracture face minus the initial layer temperature.

Over the portions of the formation not swept by steam

heat transport occurs by thermal conduction. Consistent with

Eq. (l), one-dimensional heat conduction is described by

d2T 1 c?T

.

p= K& if-----------

(4)

where K (z~T) is the thermal diffusivity of the formation

521

4 ANALYSIS OF HYDROFRACTURE GEOMETRY SPE 35396

AND MATRI)VFRACTURF INFRACTIONS DURING STEAM INJFCTION

while K is the thermal conductivity.

History Match

To match cumulative steam injection into IN2U and the

temperature response at all monitoring wells in the Phase II

pilot, we follow the history matching procedure as outlined in

Part I and ref. [7]. The diatomite interval between 800 ad

1500 ft in depth is divided into 8 isolated layers of varying

thickness along geologic boundaries. The nodal spacing in the

horizontal or x-direction is 0.66 ft to the west of IN2U while

to the east it is 0.50 ft. Figure 5 displays the porosity log

from Well LO 15, and for comparison, the porosities for each

layer used in the simulations to follow as a solid dark line.

The simulation volume spans the diatomite cycles C through I

as denoted by Schwartz [6]. The light horizontal dashcxi lines

on Fig. 5 indicate the tops of these cycles.

Initial and boundary conditions for IN2U are identical to

the interpretation of the IN2L response. For instance, the

initial temperature is given by Eq. (29) of Part I and a 3.3

psi/ft pressure gradient in the horizontal direction is assigned

across the pilot area. A pressure gradient across the pilot area

exists due to 10 years of pressure depletion caused by

production from 543N. The injection pressure for simulation

is fixed by the injection pressure history for the pilot between

October 1989 and January 1994, as shown in Fig. 6.

Consistent with the analysis of IN2L, we make a capillary-

pressure correction to the downhole injection pressure.

Likewise, because production hydrofractures are under

compression, we again assign a 100 psia pressure at

production well 543N, even though the producers are pumped

off.

For history matching, the pressure and temperature

profiles are found sequentially for each layer. First, the short-

time temperature response, which is caused mainly by heat

conduction, is used to assign a thermal diffusivity to each

layer. Next, the hydraulic diffusivity and the area and shape of

the hydrofracture across each layer are allowed to vary in time

and are iterated until an acceptable match of temperature at all

of the observation wells and the cumulative steam injection is

found, The evolution of formation properties on each side of

IN2U is medeled separately. However, during the first 225

days of injection, the hydraulic diffusivities in corresponding

reservoir layers are constrained to be equal on both sides of the

hydrofracture. For the best match of the temperature response

to steam injection in IN2U, the volumetric heat capacity of

each layer in the steam zone varies between 66.0 and 72.5

BTU/ft3-OF, the thermal diffusivity of the oil zone ranges from

1.32 E-6 to 4.84 E-6 ft2/s, while permeability and hydraulic

diffusivity vary from a low of 0.010 mD and 1,26 E-6 ft2/s to

a high of 0.698 mD and 9.36 E-5 ft2/s.

In what follows, we describe the evolution of the heat

522

injecting part of the hydrofracture in IN2U, the match of the

cumulative injected steam, and the temperature responses in

seven observation wells. Figure 7 illustrates the evolution of

the shape of the hydrofracture in IN2U inferred from the

temperature responses in all of the observation wells and the

cumulative steam injection. Depths on the plot vary from the

top of the diatomite at 800 ft down to 1500 ft, while the

perforated interval of well IN2U is from 1110 to 1460 ft. Zero

on the x-axis indicates the location of IN2U. Positive distances

lie to the north of IN2U and negative distances to the south.

Hydrofracture shapes in the east and west directions reported in

Fig. 7 are, of course, mirror images of one another. The

hydraulic diffusivity of the diatomite rock varies across the

hydrofracture area. This variation is coded in grayscale at the

beginning of each time step shown in Fig. 7. A shading of

black indicates a hydraulic diffusivity of zero, and light gray

shading, a maximum hydraulic diffusivity of 1.0 E-4 ft2/s.

Note that Fig. 7 shows different histories of hydraulic

diffusivities for the eastern and western parts of the pilot.

Figure 8 presents the actual cold water equivalent (CWE)

of steam injected through IN2U, the results of the best history

match, and the volume of steam injected to the east of west of

the IN2U fracture plane from the history match as a function

of the square root of time, Measured pilot injection is given as

a thick dashed line while the predicted injection is a solid line

and agreement is excellent. At least two distinct regions of

injectivity are apparent in Fig. 8. At times less than roughly

17 daysl/2 (289 days) injectivity is quite low, but it increases

dramatically at later times. fIre increase of hydrofracture area at

308 days, shown in Figs. 7e and 7f, is largely responsible for

the increased injectivity. Additionally, Fig. 8 teaches that

significantly more of the injected steam flowed to the west of

IN2U as compared to the east.

The pilot temperature response and history match results

as a function of depth for the eastern portion of the pilot are

given in Figs. 9 to 12. The measured temperature response is

given as a dashed line and simulation results are given as

darkened circles connected by straight lines. Figure 9 displays

formation heating atLO15 and Fig. 10atLO12 between O md

1230 days. Notably, both plots show that substantial heating

of the diatomite occurred between the top of the diatomite at

roughly 800 ft and the top of the perforations at 1100 ft. Thus,

the hydrofracture shapes displayed in Fig. 7 extend some 300 ft

above the perforated interval to 800 ft. Interestingly, the

temperature responses displayed in Figs. 10 to 12 for wells

LO12, MO1, and M02, respectively, show that steam flow

and heating of the southern wing of the IN2U hydrofracture

was delayed for about 500 days of steam injection.

Temperature response was weaker and slower in the southern

wing of IN2U as compared with the northern wing. The

northern wing showed strong heating at times less than 500

days of steam injection with the strongest temperature

responses across the perforated interval.

SPE 35396 A. R. KOVSCE~ R. M. JOHNSTON, AND T. W. PATZEK 5

Figures 13 to 15 give the temperature history match for

the west side of IN2U. Figure 13 which displays the

temperature response for Well LO 14 shows undeniable

evidence of steam flow into diatomite layers above the

perforated interval, consistent with the results in Figs. 9 ad

10. A dramatic temperature response in the D and G cycles

between depths of880and 1120ftgreatly exceeds the response

measured at depths corresponding to the perforated interval.

Take, forexample, the Gcycleresponse between 308 and 560

days. In this time interval, theheating increases roughly by a

factor of 10. At 308 days, the temperature difference is

approximately 25 F while at 560 days it is 330 F. The

temperature data for Well LO13 which is farther from IN2U

and to the west of L014 also shows an exceptionally strong

temperature response above the perforated interval in the D and

G cycles. The maximum temperature increase at LO 13 in the

G cycle between 843 and 1230 days is nearly equal to that in

LO 14. These results indicate very rapid movement of steam

through the G cycle and are evidence for development of a

horizontal feature such as a horizontal fracture or network of

tilted fractures connected to the hydrofracture in IN2U.

Possibly, the hydrofracture which is vertical between 1110 ad

1460 ft turned in the horizontal direction toward 543N in the

process of growing upward. However, this tkacture or network

of fractures does not extend from IN2U to 543N as steam

breakthrough did not occur in 543N until after roughly 3 1/2

years steam injection, Fig. 4. Across the H and the I cycles,

corresponding to the perforated interval, the temperature

response for LO 13 lags behind LO 14; the increase of

temperature between the constant square root of time intervals

is roughly constant indicating relatively little or no evolution

of the formation permeabilityy across those cycles.

Figures 13 and 14 do show some discrepancies between

the actual and model-predicted temperature response between

depths of 900 and 1100 ft. For LO 14 in Fig. 13, the values for

the predicted temperature increase at 843 and 1230 days in the

D and G cycles exceed the actual values by about 40 F. These

differences are caused by either an incorrect estimate of the

pressure profile in these two cycles or by measurement errors

in the temperature surveys. If the pressures across the D and G

cycles are lower than estimated, the corresponding saturatd

steam temperature will be less. On the other hand, the

temperature profiles across the D and G cycles at 843 and 1230

days am nearly vertical suggesting that the particulm

temperature logging tool may be measuring its maximum

temperature. Agreement between the actual and the model-

predicted temperature differences at 1230 days across the D ad

G cycles is much better in LO13.

The temperature history for well LO 11 is displayed in

Fig. 15. In addition to a temperature response above the

perforated interval, we can see strong, relatively early heating

of the formation to the northwest of IN2U, corroborating our

picture of strong, early-time steam flow in the northern wing

of the injection hydrofracture.

Putting aside the massive temperature response to the

west of IN2U above the perforated interval, the IN2U response

was more uniform across the perforated interval than in IN2L.

The temperature response at well LO11 is greater than the

LO 12 response by a factor of 2 to 3, but LO 11 is closer to the

hydrofracture plane and should show more rapid heating. As

shown in Figs. 11 and 15 of Part I, LO11 and L012 display

strong temperature responses in different cycles and much

vertical asymmetry of heating by steam injected in IN2L.

However, here both LO 11 and L012 display vertically

symmetric temperature responses. Across the G, H, and the

top of the I cycles in Figs. 10 and 15, the temperature profiles

have similar shapes. Also, comparing LO15 and LO 14 across

the depths corresponding to the perforated zone, we find

roughly the same degree of heating in both the eastern and

western portions of the pilot area.

Comparison to Microseismic Results

Passive imaging of the seismic energy released during the

hydrofracturing process in IN2U and IN2L [3] indicated that

each hydrofracture &tTered greatly in its initial shape and its

position with respect to the injection well. To compare the

microseismic results with the results presented here, Fig. 16

details the final shape of the IN2U aod IN2L hydrofractures

given in Figs. 7i and 7j with a dark line, while the darkerml

squares give the location of microseismic events obtained by

analyzing the arrival times of shear waves at the observation

wells.

Figure 16a demonstrates that the effective hydrotiactum

area resulting from steam injection in IN2U is greater than the

hydrofracture area indicated by microseismic imaging.

However, the microseismic events are consistent with the

shape of the fN2U hydrofracture found here, especially with the

large extent of the wing to the north of IN2U. Further, there is

little reason to expect that a hydrofracture undergoing

continuous steam injection at pressure gradients approaching

the fracturing gradient would not grow as IN2U apparently has.

Although the results presented here are non-unique, they ate

highly constrained. That is, we have matched both the

cumulative steam injection and the time varying areal

distribution of heat, Both of these quantities depend on

hydrofracture shape and the formation permeability. The

asymmetric wing of IN2U to the north across the G, H, and I

cycles is necessary to simulate a temperature response at MO 1,

but a matching, symmetric wing of equal length to the south

would lead us to over predict injection substantially.

Figures 16a and 7 indicate that the fracture in IN2U grew

upward substantially beyond the region of microseismic

activity. However, temperature surveys in the observation

wells and the cumulative steam injection indicate that the

fracture was contained within the diatomite and did not extend

to the overlying Tuhire formation. A full interval temperature

response plot given in Fig. 4 of ref. [7] does not show any

523

6 ANALYSIS OF HYDROFRACTURE GEOMETRY

SPE 35396

transfer of heat from the Diatomite to the Tulare by either

conduction or convection of steam. The steam mass balance

shown in Fig. 8 further supports this contention, in that our

simulations place all injected steam into the Diatomite while

correctly distributing heat across the pilot area at all time

levels.

Figure 16b teaches that the microseismic analysis of the

high-pressure hydrofracturing of IN2L yielded an initial

symmetric ,penny shape for the lower hydrofracture; however,

the shape after approximately 1000 days of steam injection

was roughly rectangular but still symmetric. In the upper

portions of the hydrofracture between 1500 and 1680 ft, wing

length found from history matching the Phase II steam

injection response and that indicated by the microseismic

events are roughly equal. As compared with the upper portion

of IN2L, the lower wings increased their length many fold.

Between 1850 and 1950 ft, the effective wing length has

increased from 10 to 15 ft up to roughly 100 ft. As in the case

of IN2U, there is little reason to expect that the hydrofracture

would not grow while undergoing continuous steam injection

near the fracturing gradient.

The comparison of microseismic imaging and the

effective heated areas of hydrofractures confirms that

microseismic events are diagnostic of the most active portions

of the hydrofracture and it shows that independent analyses

have yielded similar hydrofracture shapes and orientations for

the Phase H pilot. The hydrofracture in IN2U appeared to be

highly asymmetrical with a wing length around 250 ft,

whereas both analyses indicate that the hydrofracture in IN2L

is symmetrical with wing lengths of roughly 160 ft. Further,

regions of the Diatomite in which multiple microseismic

events were recorded, generally accepted steam more readily

than regions which showed little microseismic activity.

Discussion

Evolution of matrix hydraulic diffusivity also played a

profound role in the temperature response history of the pilot

area adjacent to IN2U. Consistent with the IN2L interpretation

in Part I, hydraulic diffusivities of individual layers on each

side of the hydrofracture were constrained to be equal for the

first 225 days of steam injection. Afhvard, the hydraulic

diffusivity in each simulation layer on either side of the

hydrofracture was allowed to evolve independently.

To the west, as shown by the grayscale shading in Fig.

7, hydraulic diffusivities were relatively low and uniform.

Between O and 308 days, hydraulic diffusivities across the

simulation grid remained constant or changed only slightly, At

308 days, the hydrofiacture extended significantly to the north

as indicated in Fig. 7e. Simultaneously, the shading of the

layers immediately above the perforated interval of IN2U

evolves from a dark to a lighter gray indicating a sharp increase

in the hydraulic diffusivity of these layers. Likewise, the

contrast of layer shading shows that the hydraulic diffusivity of

the region immediately above the perforated interval greatly

exceeds that across the remainder of the hydrofracture. At later

times shown in Figs. 7g and 7i, the shading lightens even

further. We conclude that a horizontal feature such as a fracture

or network of fractures is responsible for the dramatic

temperature increase above the perforated interval and to the

west of IN2U. Note that the extent of the horizontal fracturing,

as indicated by the shading in Figs. 7e, 7g, and 7i, appears to

be confined to the region around the wellbore,

Interestingly, except for the region above the perforated

interval with the dramatic temperature response, the hydraulic

diffusivities for the western portion of the pilot area appear to

be decreasing gradually over time. The shading in Figs. 7e, 7g,

and 7i across the depths 1200 to about 1450 ft darkens because

hydraulic diffusivity decreases slightly.

To the east, matrix hydraulic diffusivity for all

simulation layers remains constant or decrwses gradually as

indicated by the shading of Figs. 7f, 7h, and 7j. There are no

dramatic, or even slight, increases in hydraulic diffusivity. For

example, the shading for layers between 1200 and 1400 ft in

these figures darkens gradually. This indicates that the

formation may be gradually plugging toward the east.

Since increases in hydraulic diffusivity and temperature

response to the west far outweigh those to the east of IN2U,

greater steam injection to the west is expected. Figure 8

indicates that the calculated cumulative volume of steam that

flowed to the west is greater than that which flowed to the east

by a factor of about 3.5. Further, the east and west curves

begin to diverge at roughly 308 days when the west hydraulic

diffusivity first begins to increase.

To contrast steam flow in the formation adjacent IN2U

with that adjacent IN2L, Fig. 17 replots the cumulative steam

injection through IN2L [7], history match cumulative

injection, and the volumes of steam that flowed to the east and

west of IN2L from the history match. Here, steam flow to the

east and west is much more balanced. Initially, there is a

greater volume of steam injected to the west because the in

situ pressure gradient is directed toward producer 543N and aids

westward injection, At roughly 30 daysn, eastward cumulative

injection overtakes westward because there was rapid

propagation of steam along the boundary between the L and

the M cycles toward 543P leading to injector/producer linkage.

The hydraulic diffusivity histories for IN2L in Fig. 9 of

ref. [7], and for IN2U in Fig. 7 allow us to generalize about

the evolution of the diatomite formation during steam

injection in the Phase II pilot. In the absence of horizontal

fracturing which occurred above the perforated interval to the

west of IN2U, or the rapid propagation of steam along the

boundary between the L and the M cycles to the east of IN2L,

hydraulic diffusivity tends to decrease gradually over time.

Since hydraulic diffusivity is proportional to formation

permeabilityy, our model indicates that the Diatomite formation

524

SPE 35396 A. R. KOVSCEK, R. M. JOHNSTON, AND T. W. PATZEK 7

may plug gradually upon years of steam injection unless (i)

dramatic extensions of hydrofracture planes occur, (ii)

fracturing of the rock matrix perpendicular to the hydrofractures

occurs, and/or (iii) the formation is heated substantially

preventing silica precipitation.

The gradual decrease in hydraulic diffusivity over most of

the formation to the west of the injection hydrofracture planes

may be the cause of the decrease of productivity of 543N prior

to steam breakthrough. Recall, Fig. 4 shows that the second

derivative of production with respect to the square root of time

is negative. On the other hand, the productivity of the close

producer, 543P, in Fig. 3 increases even though some

plugging of the formation occurs to the east of IN2U amf

IN2L. Apparently, the large hydraulic diffusivities of the

diatomite matrix opposite IN2L, and the concomitant steam

influx to the east of the central portion of the hydrofracture as

indicated by the lightest shading in Figs. 9f, 9h, and 9j of ref.

[7] are sufficient to give 543P an overall increasing

productivity.

Further examination of Fig. 7 suggests that a sizable

fraction of the steam injected in IN2U flowed above the

perforated interval. To quantify this fraction, Fig. 18 plots the

ratio of the cumulative steam injected above the perforations to

the total cumulative injected steam in IN2U as a function of

the square root of time for our simulations. Between O and 8

days l/2 (64 days), the ratio gradually ramps up to 0.21 ad

then remains level until about 17.5 days 12 (308 days). Over

this time period, the hydraulic diffusivity of all simulation

layers remains approximately constant as indicated by the

grayscale shading in Fig. 4, At 308 days, the hydraulic

diffusivity of the layers immediately around the well and above

the top of the perforations increases sharply; hence, more

steam is injected into these layers relative to layers opposite

the well perforations. As Fig. 17 illustrates, the ratio of steam

injected above the perforated interval to the total injection

climbs to slightly less than 0.50 between 17.5 and 35.1

days 1/2 due to the contrast in hydraulic diffusivity for zones

above and below the top of the perforations. We calculate that

roughly 43% of the total injected steam contributed to heating

of diatomite cycles lying above the well perforations.

Conclusions

The Phase II steamdrive pilot in the South Belridge Diatomite

demonstrated that significant heating of the formation could be

achieved by injecting steam through two separate

hydrofiactures that span the entire 1000 ft reservoir column.

Heating in the pilot area was caused by both convection of

steam and hot condensate and heat conduction through zones of

the reservoir which steam did not sweep. Heating due to

convection was substantial and could not be neglected.

Steam injection totaled 390,000 BS CWE resulting in a

cumulative oil production of 160,000 BO and an estimated

incremental response of 100,000 BO. Further, the total oil

recovery in the pilot was gauged at 9~o of OOIP and the

incremental oil recovery at 6% of OOIP after 5 years of steam

injection.

Increases of steam injectivity for both injectors IN2U ml

IN2L was linked to the growth of the injection hydrofractures

and to increased formation hydraulic diffusivity. Solutions for

the shapes of the injection hydrofractures are highly

constrained by the areal distribution of heat available from

temperature surveys at the 7 observation wells employed in the

pilot and by the cumulative injected steam.

Comparison between hydrofracture shapes obtained in

this analysis and those obtained from locating the

microseismic events that cccurred during hydrofractunng was

favorable. Steam flow occurred in regions with large densities

of microseismic events. However, this comparison

demonstrated that hydrofracture shape during steam injection

evolved dynamically. Hydrofracture wings can, in some cases,

increase their length many fold during steam injection.

Specifically, analysis of diatomite heating caused by

steam injection through the upper hydrofracture which is

perforated over the interval 1100 to 1460 ft revealed:

1.

2.

3.

4.

Heating of the upper half of the Diatomite was highiy

asymmetrical in the horizontal direction. Substantially

more steam flowed into the northern wing of the

hydrofracture, as judged by temperature response, than

into the southern wing.

Horizontally, asymmetric heating was linked to the shape

of the injection hydrofracture for steam injection in both

IN2U and IN2L,

Above the perforated interval and to the west of IN2U,

formation temperature response was extreme and rapid.

This behavior was most likely caused by a horizontal

fracture or network of fractures originating near the

hydrotlacture in IN2U and pointed toward 543N. Since

this horizontal feature has large hydraulic diffusivityy,

much of the injected steam flowed above the perforated

interval of IN2U.

Except for regions of the Phase H pilot that exhibited

rapid heating reminiscent of a horizontal fracture and

prior to steam breakthrough at a production well,

hydraulic diffusivity either slowly decreased or remained

constant in time indicating a slow plugging of the

formation.

Acknowledgments

We thank Shell Western E&P for releasing the injection,

pressure, and temperature log data from the Phase H pilot, ml

also Drs. P. D. Patel and H. J. Vinegar of CalResources,

LLC. and Shell Development Co., respectively, for helpful

advice, We thank PV Technologies for donating computer time

525

8 ANALYSIS OF HYDROFRACTURE GEOMHRY SPE 35396

AND MATRIWFRACTURE INFRACTIONS DURING STFAM INJFCTION

andsoftware for reading and interpreting the raw temperature

data. Additionally, T. W. Patzek acknowledges unrestricted

research grants ffom Unocal.

This work was supported by the Assistant Secretary for

Fossil Energy, Office of Gas and Petroleum Technology, under

contract No. DE-AC03-76FSOO098 to the Lawrence Berkeley

Laboratory of the University of California. This project was

initiated as part of the California Oil and Gas Alliance between

producers and national laboratories and is funded through the

Natural Gas and Oil Technology n Partnership.

Nomenclature

Ac=

K=

M=

P

=

Qi =

t

=

T=

x

=

Xf =

vertical fracture area, ft2

thermal conductivity, BTU/s-ft-F

volumetric specific heat, BTU/ft3-OF

pressure, psia

heat injection rate, BTU/ft3-s

time, s

temperature, F

horizontal distance, ft

steam front location, ft

Greek Letters

a = hydraulic diffusivity, ft2/s

K

=

thermal diffusivity, ft2/s

LT = total mobility, ft2/psi-s

v = total compressibility, psi-1

References

1.

2.

3.

4.

Johnston, R.M. and Shahin, G. T., Interpretation of

Steam Drive Pilots in the Belridge Diatomites, SPE

29621, presented at SPE 65th Western Regional Meeting,

Bakersfield, CA, March 1995.

Kovscek, A. R., Johnston, R. M., and Patzek, A. R.,

Evaluation of Rock/Fracture Interactions During Steam

Injection Vertical Hydrofractures, SPE 35396, presented

at SPE Western Regional Meeting, Bakersfield, CA,

March 1995.

Ilderton, D. C., Patzek, T. W., Rector, J. W., and Vinegar,

H.J., Passive Imaging of Hydrofractures in the South

Belndge Diatomites, SPE 28383, presented at SPE 69th

Annual Technical Conference, New Orleans, LA,

September 1994.

Vinegar, H. J., Wills, P. B., DeMartini, D, C.,

Shlyapobersky, J., Deeg, W. F. J., Adair, R. G., Wwpel,

J. C., Fix, J.E., and SorrelIs, G. G., Active and Passive

Seismic Imaging of a Hydraulic Fracture in Diatomite,

JPT (Jan. 1992), 44(1), 28-34, 88-90.

5.

6.

7.

Marx, J.W. and Langenheim, R, H., Reservoir Heating

by Hot Fluid Injection, Trans. AIME (1959), 216,312-

315.

Schwartz, D. E., Characterizing the Lithology,

Petrophysical Properties, and Depositional Setting of the

Behidge Diatomite, South Belridge Field, Kern County,

California, in Studies of the Geology of the San Joaquin

Basin, S.A. Graham and H.C. Olson, Editor, The Pacific

Section Society of Economic Paleontologists and

Mineralogists, Los Angeles, CA, (1988) 281-301.

Kovscek, A. R., Johnston, R. M., and Patzek, T. W.,

Interpretation of Hydrofracturv Geometry Using

Temperature Transients 1: Model Formulation ad

Verification, In Situ (1995), submitted, 1995.

Table 1. ID Simulation of Oil Production with

Pressure Interference

~[ 543P 543N Parameter

175 330 E-W producer spacing (ft)

300 290 Length of both wings of fracture (ft)

350 850 Pay thickness, w/o Brown Shale (ft)

1215 1450 Average Pay Depth (ft)

I

200(depl)

I

665 I P, (psia)

I

50 50 Producer BHP (psia)

0.19 0.19 Absolute permeability (mD)

0.5 0.5 Porosity (fraction)

30 30 Oil Gravity (API)

30 30 Rock Compressibility

200 4(H3 P-, for compressibility talc. (psia)

50 56 Oil saturation (%)

11 11 Gas saturaion (90)

I

0.33

I

0.37 I WOR for total mobility calculation

1 1.6 I GOR (mcf/stb) for total mobility

calculation

0.35 0.50 Fractional k,,, at which total

mobility is calculated

526

SPE 35396 A. R. KOVSCEK, R, M. JOHNSTON, AND T. W. PATZEK 9

543N

/

< G

100 ft

ig. 1 - Plan view of the Phase 11 steam drive pilot in

ection 29 of the South Belridge Diatomite.

0

0 10 20 30 40

Squara ROOSof Tima on Pmdwtkm Sims 10EKI(Oaya)

Fig. 3- Cumulative oil and water production in 543P.

Diamonds denote analytical solution.

0

0 10

------..1---- --,

20 30 40

Square Root of lime on Injection Since 10/90 (Days)

Fig. 2- Cumulative steam injection and slope in IN2U.

Note that slope of slope is +600 BCWE/day.

I

Inject Steam

Temperature

I

Oil

0 30 60 90

Sqrt(Days on Production)

Fig. 4- Cumulative oil and water production in 543N.

Diamonds denote analytical solution. Steam

injection started st 60 square root of dsys.

527

10 ANALYSIS OF HYDROFRACTURE GEOMETRY SPE 35396

AND MATRDUFRACTURF INFRACTIONS DURING S~

700

800

900

1000

-

...........-. ..-.. -.. .- . . ................... .... .... .. . .. ......

12

-

b

d

8 -

.=

~

v .

26 :

...)..,,.. . ............. ..............

m

2

k

$4

a

~

Q2

----- Actuat Pressure History

j

o

l . . ..l. .l. J . . ..l. J.. l.. . .

F

: ___

-

~

p -

.

,.--... -... -,---

-z Y+.

-.:

.%

..

..4%

-- ...

. ......

G

1

t

..........._.. -.. _~.-

b---! --

:

.........

~- F----33

1200

1300

1400

1500

!

9

. . . . . . . . . . . ..-... -... -. L. . r.+.. ._...-

.,,,,S,,

---

..........

--... *... ..

:.=+.

..

. . . . . ..Porosity L@

-_POrosity for Simulation .--:-.:

. ..-. ..-

-/

.. . .. ......

I

.. . .. .. .. ..

0.4 0.5 0.6 0.7

Porosity

Fig. 5 - Porosity log for Well L015 and porosities

by layer for history match.

o 5 10 15 20 2s 30 35

Square Root of Time (days 12,

Fig. 6. - Steam inJectlon pressure history for IN2U.

8CKt

~ ICOO

g Ilou

~ 1200

1300

1400

lSOQ

II,,,

8CX3

m

~ 1000

- 1100

i

I200

I300

1400

1500

/+,

803

~ Iftoo

- 1100

1

120U

1300

140Q

b

Ir@alllic

dlmsivily

(n% XId )

o 1.()

1S30

I

I I I

-1OOOKX3ZM:

i- w-m N2U ft)

1~

Distancefroy IN2U (ft)

.lCk a 100 200 3

Dis.lancef[gjnIN2U (ft]

-160 0 Iti 260 3

f3iSt,WEC froy IN2U(ft)

ml

m

~ lcoo

; 1100

~ 1200

1300

1400

1500

I!!l!lk

800

~ lm

; IIcm

g 12LIJ

131XI

1403

1500 1

Soo

~ 1000

- 1100

1

120Q

13CS3

1400

I&

1

15C0

I

I I I

.lm o 100 2m 3(

IXstsme fro)m1N2U(IV

r 1

.l&l 6 Kb Z& 3(

Distsnce f[m)m1N2U(ft)

-lb o 160 Z& 3(

DISISI)CC frorl IN2U (ft)

-160 0 160 2ti 31

Distancefm~ IN2U (fl)

800

900

~ lCOO

- llm

!

1200

1300

1400

k

1W3

[

[ 1 f I

-h ii Ilk 2&l 360

-Kk o 100 203 300

Distancefr~jnIN2U(ft)

Distancefy IN2U [ft)

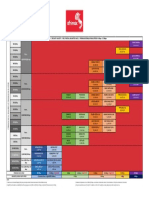

Fig. 7- Side vtew of IN2U fracture zone and hydrtmtic diffusivtdca for history matching (a) wcsti O-25days, (b) em O-25days,

(c) westi 25-308 days, (d) eesti 25-308 days, (e) west30S-547 days, (fl eest:308.547 days, (g) wrst: 547-850 days, (h) esstiS47-850 days,

(i) west: 850-1230 days, (j) eask850-1230 days.

528

SPE 35396 A. R. KOVSCEK, R. M. JOHNSTON, AND T. W. PATZEK

11

200 . . . .

Upptk Inj~ctor:IN2~ 1 1

100 .

5

0

0 5 10 15 20 25 30 35

Square Root of Time (days 2,

Fig. 8 - Steam injection history for IN2U including steam

injection to the eastern and western portions of the pilot.

700

800

900

1000

1300

1400

1500

Observation Well L015 ~

. . .. .. .. .. .. .. ..... ..... . ... .. .. .. .. .. .. .. .. .. .. .. .. .. .. ,-----

;... .. .. .. .. .. .. .. .. .. .. .. ... .. .. .. .. .. .

... .. .. .. .. .. .. .. .. .. .. .. j.. ..----- .. .

0 50 100 150 200 250

Temperature Increase (F)

Fig. 9 - Temperature survey (dashed lines) and history

match (symbols and solid lines) results In Well L015.

700

[ I I I

Observation Well LOl~ g

I

800 L.-*W

. .... .................... .... .... ..................... .... ...

J

... ............... .... .... .... .... .......p..._.. _..

d

-Ri~i

*-.s - i

>. c]

...-.

900

D

.

1000 :.+: i .................... .... .... ..................... .... ...

~ .:

>, -. ~*. G

~1 loo . + - :

I

--- y .

a

.:

\

:.

-. :-.;

.:- ;

1200

H

2s9 d 559 d S43 d i ~

1

is.--.=%.

....-... -...+...............i....-... -...4

::wd I 11

...................~ ...._. _..

. . . .. .... ............... ..... .... .... ................ .... .... ...

1500

0 50 100 150 200 250

Temperature Increase (F)

Fig. 10 - Temperature survey (dashed lines) and history

match (symbols and solid lines) results in Well L012.

700

1 I I I

Observation Well MO1 ~

~

J

800

.4-,. --.;+-... . . . . . . . ..y---- . O-. . . y. !-. . . - . . . . . p- . . -, . . .

c:

..............................-... -... +...-... ...............-... -

900

D

1000

.... .... .... .................... ..+...-. . .. ........... .... ....

~

G:

~....-. ..-. ... .. .. .... .. .. . +...-...-...-

%

n

H;

-+-...-... -.-. +-. -... - .....~....-. ..-... -

1

14004-

~

...... .... .... ..............:....-. -.-... +..._...-----j...._..._.-. #

1500

i 1 1 i

1

0 50 100 150 200 250

Temperature Increase (F)

Fig. 11 - Temperature survey (dashed lines) and history

match (symbols and solid lines) results in Well MO1.

529

12 ANALYSIS OF HYDROFRACTURE GEOMETRY

SPE 35396

AND MATRDUFRACTURF INFRACTIONS DURING STFM INJFCTION

700

1 1 I I

Observation well MOj 1 i

800

I

... .. ... .. .. . . .. .. .. .. ... . ... .. ... .. .. .. . .. .. .. .. .. .. .. .. .. .. .

c

1

900 L-""-"-""-"-'-:"-" -"-"-"-'"+-""-"-""-"-"-':"-"-"-"-"-' -:-"-"-"-"--3

-vii ~

D

*.

1000 . ......w._.._...- ....c.. ............-... -..<-...-..~_...-...--

-:

*:

\

.

.-+ . . .

G

---- .

...--...*,.4............-.. !-...-... -..i ---------- 1 I*.. ....

f;

. ... .... .................... .. . .... .... .... .... .... .

i

...........+ . .... ....... ........ .+.. .- ...+...- ,----

0 50 100 150 200 250

Temperature Increase (F)

Fig. 12 - Tern erature survey (dashed lines) and history

f match (symbo s and solid lines) results in Well M02.

7oo~. . . . . . . . . ..c . . . ...1 l!... . . l. . [ . . . . . . . . . J

~Observation Well LO14 ! ~

800 .Vq<:

.. .. .. .. .. .. .. .. . .. .. .. .. .. .. .+_.. m_.,_-

-~ $~ ]

.-

. - --

c:

900 a %:.-$ ------- 2:=-----

.

:-- --~-~ D

1000 ,.-

,..- +..- .... .... ..

4-

: .-=. - ...-. .--h .- ...-.

--+.-t

n

~

= 1100 --mw,:.;:-$:... -

,..-, -.+. .-.. .. .... ..

~ -. ##. -

! 308;d .- >-;;

{

n 1200 . 32 : 1 84~~~*:

H

: .

<.

*

..-..! -560 d.... -~.

-H- -----+-------

1300 - :

/

:----

,Olq, ,f

;230d :

1,:

I

!# --i

1400 1. f-* ; ::; ;

l;

:-+;

, .,._..L -.-+.. -... ~.. *.. -... ----- ...-*. -_...- .... ..

*: ---*..-

1500

0 100 200 300 400

Temperature Increase (F)

Fig. 13 - Temperature survey (dashed lines) and history

match (symbols and solid lines) results In Well L014.

700

, ,

Observation Well L013 ;

80 O& . .. .. .. .. .. .. . .. .. .. . .. . ..+ .. . .. . .. .. .. .. .. .. .. .. .. .. .. .

c

-. -.--. --.-*.--. --... ....................I . :-..

900 \

---%

----- :

--- +...

.

-. --:

---

~1

D

--:. .

1000 -...::.:+. -.-+-:-2 - -% --g.% .--...

~

..:

~---- :

.=--,---- - G

4-. G

s1100 560 d..843 ;~~;j--j :

~

/{

. . .... ...+.. -... -... -...

-.

1200 ! $-230 d j

,

,: ,1 :

1

..: .... . . -.+. ---------- ..+-...-. ... ...

1300

1

p---w - .

.-.-+ ----- ----+ ---- -_... +..+ .. .. .. .. .. .. .

1500

1. . . . . . . . . 1. ..

0 100 200 300 400

Temperature Increase (F)

Fig, 14 - Temperature survey (dashed lines) and history

match (symbols and solid lines) results in Well L013.

700

1 # 1

Observation Well LO1l ! i

800

900

1000

~

~ 1100

~

Q 1200

1300

1400

1500

0 100 200 300 400

Temperature Increase (F)

Fig. 15 - Temperature survey (dashed lines) and history

match (symbols and solid lines) results in Well LO1l.

SPE 35396 A. R. KOVSCEK, R. M. JOHNSTON, AND T. W. PATZEK 13

1000 & . .. .. .. .... ....+ ..... ..... .. .. .. .. .. .. .. ... .. ....~

1300

1400

>-... -,..- .... ..................... .... .... ..............

-1oo 0 100 200 300

Distance From IN2U (ft)

Fig. 16a - Comparison of IN2U fracture shape from

history matching at 1230 days and microseismic events.

1400

..... .... .... ... .... .... ...--.:. -... - .... .... .... ...--------

..... .... ...- ,.+...-..-. ..--.; .-... - ...-... -.*.-. ... .... . ..

2000

-200 -100 0 100 200

Distance from IN2L (ft)

Fig. 16h - Comparison of IN2L fracture shape from

history matching and 1050 days and microseismlc events.

1

Lower Injector: IN2L ~

Y ~

E

150

[

.........

~

C%.-

u&

~-

~ :100

..........

:Z

4

Sb

*

s-

6

----= Actual Injection

50

z

O 5 10 15 20 25 30 35

Square Root of Time (daysi)

Fig. 17 - Steam injection history for IN2L including steam

injection to the eastern and western portions of the pilot.

0.6 , 1 r

- Upper Injector: IN2U ~ ~ ~

:; ::; :

,..,..... ...........;.,..,,.,,.,:.,..,..,,.,:,,..,..,,..:..................,,.,.,

0.4 -;:::

:........................y........-

0.3 -

;;; ;

::: :::

::: ::

0.1 -

;;; ;;;

;;; ;;;

;:: ::: :

0

0 5 10 15 20 25 30 35 40

Square Root of Time (days 2,

Fig. 18 . Fraction of cumulative steam injected above

the perforated interval of IN2U.

531

Anda mungkin juga menyukai

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Spe113975 PDFDokumen9 halamanSpe113975 PDFعبدالغفار بيزانBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5795)

- Spe113918 PDFDokumen16 halamanSpe113918 PDFعبدالغفار بيزانBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Spe109017 PDFDokumen9 halamanSpe109017 PDFعبدالغفار بيزانBelum ada peringkat

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Spe113510 PDFDokumen10 halamanSpe113510 PDFعبدالغفار بيزانBelum ada peringkat

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Spe113937 PDFDokumen15 halamanSpe113937 PDFعبدالغفار بيزانBelum ada peringkat

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- Spe114336 PDFDokumen8 halamanSpe114336 PDFعبدالغفار بيزانBelum ada peringkat

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Spe114346 PDFDokumen13 halamanSpe114346 PDFعبدالغفار بيزانBelum ada peringkat

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Spe113464 PDFDokumen10 halamanSpe113464 PDFعبدالغفار بيزانBelum ada peringkat

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- API 620 Vs API 650Dokumen5 halamanAPI 620 Vs API 650govimanoBelum ada peringkat

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- 연대경제대학원 석사학위논문 학술정보원등록 최종본Dokumen121 halaman연대경제대학원 석사학위논문 학술정보원등록 최종본0514bachBelum ada peringkat

- Mariveles ChlorinatorDokumen1 halamanMariveles ChlorinatorJhn Cbllr BqngBelum ada peringkat

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Diffusion of Helium Through QuartzDokumen5 halamanDiffusion of Helium Through QuartzElenaBelum ada peringkat

- LCD Interfacing With Microcontroller 8051Dokumen50 halamanLCD Interfacing With Microcontroller 8051Darshan Vala100% (2)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Cessna 525 LimitationsDokumen16 halamanCessna 525 LimitationsCesar BanchoffBelum ada peringkat

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Compresores TecumsehDokumen139 halamanCompresores TecumsehRicardo EstrellaBelum ada peringkat

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- 3g 4g Call FlowDokumen16 halaman3g 4g Call Flowpoiuytreza26Belum ada peringkat

- Reference Letter of DR Zaka EmadDokumen2 halamanReference Letter of DR Zaka EmadRMRE UETBelum ada peringkat

- Final Validation Report - 8MW Cirompang Mini Hydro Power PlantDokumen112 halamanFinal Validation Report - 8MW Cirompang Mini Hydro Power PlantAzraMuratovic0% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- DM No. 312, S. 2021Dokumen3 halamanDM No. 312, S. 2021sherileneBelum ada peringkat

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Dm02 FTTM AdvDokumen36 halamanDm02 FTTM AdvAnonymous 5cMeyYyxhBelum ada peringkat

- ABB - PCS 6000 STATCOM - Reference ListDokumen8 halamanABB - PCS 6000 STATCOM - Reference ListProyectos IPC S.A.S - Manuel CadenaBelum ada peringkat

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Basic Ship Design PhasesDokumen1 halamanBasic Ship Design PhasesJhon GreigBelum ada peringkat

- Mobile Master Card PayPass TSM Functional Requirements v1-0Dokumen40 halamanMobile Master Card PayPass TSM Functional Requirements v1-0Wiraj GunasingheBelum ada peringkat

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Technical Data: An Innovative & Cutting-Edge Digital Radiography SystemDokumen12 halamanTechnical Data: An Innovative & Cutting-Edge Digital Radiography SystemJacques GamelinBelum ada peringkat

- AASHTO - LRFD (Design Example For Steel Girder Superstructure Bridge - 2003)Dokumen698 halamanAASHTO - LRFD (Design Example For Steel Girder Superstructure Bridge - 2003)Ridwan Kris50% (2)

- York R410ADokumen2 halamanYork R410AArabiat76Belum ada peringkat

- 2520 995 RevBDokumen52 halaman2520 995 RevBgovindarulBelum ada peringkat

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Afrimax Pricing Table Feb23 Rel BDokumen1 halamanAfrimax Pricing Table Feb23 Rel BPhadia ShavaBelum ada peringkat

- Ethics Thesis PaperDokumen15 halamanEthics Thesis PaperEric LeggettBelum ada peringkat

- 58MM Printer Programmer Manual-20161207 PDFDokumen31 halaman58MM Printer Programmer Manual-20161207 PDFsatryaBelum ada peringkat

- DeltaBox Catalogue UK 2021Dokumen37 halamanDeltaBox Catalogue UK 2021Philip G. SantiagoBelum ada peringkat

- EPSON WF-6090, WF-6530, WF-6590 Series Service Manual Page 121-140Dokumen20 halamanEPSON WF-6090, WF-6530, WF-6590 Series Service Manual Page 121-140Ion IonutBelum ada peringkat

- CV Europass 20160805 Kolla EN PDFDokumen2 halamanCV Europass 20160805 Kolla EN PDFKeshav KollaBelum ada peringkat

- Sloba Dragovic - ResumeDokumen3 halamanSloba Dragovic - ResumeSloba DragovicBelum ada peringkat

- Specialty Lubricants Molykote®: 44MA GreaseDokumen2 halamanSpecialty Lubricants Molykote®: 44MA GreasefadhlidzilBelum ada peringkat

- 14 Design of Bolted JointsDokumen13 halaman14 Design of Bolted JointsPRASAD32675% (4)

- Cs - cp56 64 74 Specalog (Qehq1241)Dokumen20 halamanCs - cp56 64 74 Specalog (Qehq1241)firman manaluBelum ada peringkat

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Coloumns & StrutsDokumen14 halamanColoumns & StrutsWaseem AhmedBelum ada peringkat