Velan Valve Customer Story en

Diunggah oleh

Rossmary PintoDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Velan Valve Customer Story en

Diunggah oleh

Rossmary PintoHak Cipta:

Format Tersedia

Velan Valve Corp.

, based in Montreal, Quebec,

designs and manufactures cast and forged

steel valves and steam traps for a wide range

of industries that rely on industrial-grade

equipmentfrom oil and gas to chemicals to

mining. When one of its top customers, Imperial

Oil, needed a forged globe valve with a high ow

coefcientand fastVelans engineering team

decided there was no time like the present to see

what their newly purchased Autodesk

Simulation

CFD solution could do.

Stan Isbitsky, senior engineering manager at

Velan, installed the CFD software and immediately

went to work within PTC

Creo

(formerly

Pro/ENGINEER

). To increase the valves ow

coefcient, we experimented with a wishbone-

shaped outlet, as opposed to having a single bore

on the center plane of the valve, says Isbitsky.

Once we conrmed a promising valve design in

Autodesk Simulation CFD, we machined and ow-

tested a physical prototype. We were within a few

percentage points of the calculated pressure drop

predicted by the software.

The parametric relationship Autodesk Simulation

CFD has with native PTC Creo assemblies and

automatic meshing features saved the engineers

at Velan valuable design time as well. I didnt

have to do anything special in terms of meshing,

says Ibitsky. I just specied a single mesh

parameter for the volume, and let the automatic

meshingwork.

With Autodesk Simulation CFD, Velans engineers

also were able to try out several different

scenarios, identify what was working, and use

physical prototyping as a nal verication tool.

This process allowed the team to shorten the

product development cycle by six weeks. We

could test out valve designs early in the process

with Autodesk Simulation CFD, which helped us

to improve our design substantially, says Isbitsky.

The traditional design process would have been

based more on intuition than science.

He adds, Autodesk Simulation CFD easily paid for

itself on that rst project.

To learn more about Autodesk Simulation CFD,

visit www.autodesk.com/simulationcfd.

Under pressure

Velan reduces its product development

cycle by six weeks the rst time it uses

AutodeskSimulation CFD

COMPANY

Velan Valve Corp.

LOCATION

Montreal, Quebec, Canada

SOFTWARE

Autodesk

Simulation CFD

Autodesk customer success story Velan Valve Corp.

Image courtesy of Velan Valve Corp.

We could test out valve designs

early in the process with

Autodesk Simulation CFD, which

helped us to improve our design

substantially. The traditional

design process would have

been based more on intuition

thanscience.

Stan Isbitsky

Senior Engineering Manager

Velan Valve Corp.

Autodesk and the Autodesk logo are registered trademarks or trademarks of Autodesk, Inc., and/or its subsidiaries and/or afliates in the USA

and/or other countries. Allother brand names, product names, or trademarks belong to their respective holders. Autodesk reserves the right

to alter product and services offerings, and specications and pricing at any time without notice, and is not responsible for typographical or

graphical errors that may appear in thisdocument. 2013 Autodesk, Inc. All rights reserved.

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Estimation Software For Presure VesselDokumen36 halamanEstimation Software For Presure VesselKarthikeyan Shanmugavel0% (1)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Project AgreementDokumen6 halamanProject AgreementRowin DizonBelum ada peringkat

- Network Analysis Chap. 4 First Order Differential EquationDokumen5 halamanNetwork Analysis Chap. 4 First Order Differential EquationSreeram Vijapurapu0% (1)

- Idlers - Medium To Heavy Duty PDFDokumen28 halamanIdlers - Medium To Heavy Duty PDFEd Ace100% (1)

- Riscv SpecDokumen32 halamanRiscv SpeckartimidBelum ada peringkat

- KST GlueTech 44 enDokumen80 halamanKST GlueTech 44 enLeandro RadamesBelum ada peringkat

- How To Measure MTFDokumen64 halamanHow To Measure MTFamtcorporationBelum ada peringkat

- Fiber Optic Trainer/ Fiber & OSP TechnicianDokumen7 halamanFiber Optic Trainer/ Fiber & OSP Technicianapi-78570706Belum ada peringkat

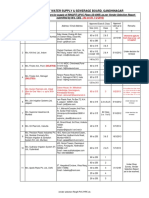

- GWSSB Vendor List 19.11.2013Dokumen18 halamanGWSSB Vendor List 19.11.2013sivesh_rathiBelum ada peringkat

- Compact 40/25Dokumen58 halamanCompact 40/25znim04Belum ada peringkat

- State ManagementDokumen16 halamanState Managementnegikamal703Belum ada peringkat

- Parallel Port Programming (PART 1) With CDokumen13 halamanParallel Port Programming (PART 1) With ChertzoliBelum ada peringkat

- SemDokumen31 halamanSemkaushik4208Belum ada peringkat

- EN 1991-1-4 NA enDokumen4 halamanEN 1991-1-4 NA enanuj3936100% (1)

- Panel 01-Eldora-Grand-1500V-2021-R01 - G1Dokumen2 halamanPanel 01-Eldora-Grand-1500V-2021-R01 - G1DHAVAL SHAHBelum ada peringkat

- Air-Bag: (1) Connector InformationDokumen34 halamanAir-Bag: (1) Connector InformationbakriramziBelum ada peringkat

- Electronic Dice Using LEDs Electrical Engineering ProjectDokumen16 halamanElectronic Dice Using LEDs Electrical Engineering Projectprakhar agarwal33% (3)

- Wireless Intelligent Network (WIN)Dokumen24 halamanWireless Intelligent Network (WIN)Nakul Gawande100% (1)

- Selling Your Contents To The WorldDokumen25 halamanSelling Your Contents To The WorldCreative Malaysia100% (1)

- Using Dapper Asynchronously inDokumen1 halamanUsing Dapper Asynchronously inGiovani BrondaniBelum ada peringkat

- Chapter 2 - 2 Plane Curvilinear MotionDokumen37 halamanChapter 2 - 2 Plane Curvilinear MotionAlfredo Ruiz ValenciaBelum ada peringkat

- Solar Module CellDokumen4 halamanSolar Module CellVinod BabhaleBelum ada peringkat

- Q3 NSP - SLP - RLPDokumen41 halamanQ3 NSP - SLP - RLPRushi RavalBelum ada peringkat

- Ain Tsila Development Main EPC Contract A-CNT-CON-000-00282 Subcontract N°: JI-2045/07-002BDokumen15 halamanAin Tsila Development Main EPC Contract A-CNT-CON-000-00282 Subcontract N°: JI-2045/07-002BAslaouiBelum ada peringkat

- Cisco Network DiagramDokumen1 halamanCisco Network DiagramĐỗ DuyBelum ada peringkat

- Ball Mill SizingDokumen10 halamanBall Mill Sizingvvananth100% (1)

- Dogging Guide 2003 - WorkCover NSWDokumen76 halamanDogging Guide 2003 - WorkCover NSWtadeumatas100% (1)

- Schneider EngineeringDokumen1 halamanSchneider EngineeringT.J. MayesBelum ada peringkat