SKF TMJL 100: Hydraulic Pump

Diunggah oleh

reinaldosidejuniorJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

SKF TMJL 100: Hydraulic Pump

Diunggah oleh

reinaldosidejuniorHak Cipta:

Format Tersedia

SKF TMJL 100

Hydraulic Pump

Instructions for use

EU-DECLARATION OF

CONFORMITY FOR MACHINERY

We, SKF Maintenance Products, Constructieweg 7,

3641 SB MIJDRECHT, The Netherlands, declare that this

HYDRAULIC PUMP

TMJL 100

is designed and manufactured in accordance with the Directive by the

Council of the European Communities of 14 June 1989, amended 20

June 1991, 14 June 1993 and 22 July 1993, on the approximation of

the laws of the Member States relating to machinery.

The Netherlands, 1 January 1995

Magnus Rydin

Table of contents Page

Safety recommendations . . . . . . . . . . . . . . . . . . . . 4

1. Description . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2. Technical data . . . . . . . . . . . . . . . . . . . . . . . . . 5

3. Operating instructions . . . . . . . . . . . . . . . . . . . . . 6

4. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.1 Replacing the oil . . . . . . . . . . . . . . . . . . . . . . . 7

4.2 Cleanliness . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.3 Spare part list . . . . . . . . . . . . . . . . . . . . . . . . 7

4.4 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . 7

SKF TMJL 100 3

Safety recommendations

As high pressures constitute a potential safety risk, the following

instructions must be considered:

The equipment should only be operated by trained personnel.

Always follow the operating instructions.

Check the pump and all accessories carefully before use. Never

use even slightly damaged components.

Make sure all air has been removed from the hydraulic system,

before pressurizing the pump.

Always use a pressure gauge.

Always prevent the workpiece/tool from being projected upon

sudden release of pressure (e.g. by use of retaining nut).

Never use the equipment above the stated maximum pressure.

Never adjust safety valves to work at pressures above the

maximum working pressure.

Do not extend the handle in order to reduce the required force to

reach maximum pressure. Use hand pressure only.

Never use the pump together with accessories which are rated

below the maximum pressure of the pump.

Use protective goggles.

Never modify the unit.

Use original parts only.

Only use clean, recommended hydraulic oils (e.g. SKF LHMF 300,

LHDF 900 or similar).

In case of any uncertainties as regards the use of the pump,

contact SKF.

4 SKF TMJL 100

1. Description

The TMJL 100 has a maximum pressure of 100 MPa (14.500 psi) and

delivers a volume per stroke of 1 cm

3

(0,06 in

3

).

It is mainly intended for use on HMV nuts, bolt tensioners, hydraulic

pullers etc, but is also suitable for other oil injection applications where a

maximum pressure of 100 MPa (14.500 psi) is required.

The pump is supplied with a 3 metre long, high pressure hose with quick

connection coupling. Mating quick connection nipple for attachment to

the workpiece is included.

The pump is filled with SKF mounting fluid LHMF 300 and comes with

an additional 1 litre can with the same fluid. Everything is packed in a

sturdy case.

The pump has an over-pressure valve and a pressure gauge.

The release valve is an integrated part of the pump head.

2. Technical data

Maximum pressure : 100 MPa (14.500 psi)

Volume per stroke : 1 cm (0,06 in)

Oil container capacity : 800 cm (49 in)

Handle force at 100 MPa : 320 N (70 lbf)

Pressure hose : 3 m (10 ft) long with quick connection

coupling

Connection nipple : G 1/4, external or internal thread

Oil viscosity of mounting fluid: 300 mm/s (1.400 SUS) at 20

o

C

Weight (filled with oil) : 13 kg (29 lb)

Designation : TMJL 100

SKF TMJL 100 5

3. Operating instructions

a) Check oil level by unthreading the container plug on the rear end of

the container. Make sure there is enough of oil for your complete

operation. For mounting bearings with the SKF Oil Injection Method,

or by means of an hydraulic nut, it is recommended to use an oil with

a viscosity of approximately 300 mm/s (1.400 SUS) at the operating

temperature.

For dismounting bearings, we recommend to use an oil with a

viscosity of approx 900 mm/s (4.100 SUS) at operating temperature.

b) Hold the pump horizontally or slightly tilted forwards in order to

secure oil supply.

c) Close the release valve on the right hand side of the pump without

using force.

d) Screw the quick connection nipple (G 1/4) into the application.

e) Connect the hose to the nipple by gently withdrawing the snap-ring

on the quick connector. The hose is disconnected in the same

manner.

f) Continue pumping until necessary pressure is reached for your

application. Maximum pressure is 100 MPa (14.500 psi) at which

pressure the safety valve will open.

g) Open the release valve, allowing superfluous oil to return to the oil

container.

Oil release valve

Handle block pin

Pressure gauge

6 SKF TMJL 100

4. Maintenance

4.1 Replacing the oil

When replacing the oil or after maintenance, make sure no air is trapped

in the system. This should be checked before attaching the hose to the

application by making sure only air-free oil comes out of the hose when

pumping.

Only use clean, recommended hydraulic oils.

4.2 Cleanliness

Keep the pump clean from dirt and metal particles in order to avoid

excessive wear.

4.3 Replacement parts

Designation Description

TMJL 100-1 Hand-pump (sub-assembly)

TMJL 100-2 Repair kit

TMJL 100-3 Gauge connection nipple

728245/3A Carrying case

729831 A Quick connection coupling, G 1/4

729832 A Quick connection nipple, G 1/4

729834 High pressure hose

1077587 Pressure gauge (100 MPa, 100 mm)

4.4 Accessories

Designation Description

LHMF 300/5 Mounting fluid (5 litre, 300 mm/s at

20 C)

LHDF 900/5 Dismounting fluid (5 litre, 900 mm/s at

20 C)

SKF TMJL 100 7

In line with our policy of continuous development of

our products we reserve the right to alter any part of the

above specification without prior notice.

Although care has been taken to ensure the accuracy of

this publication, SKF does not assume any liability for errors

or omissions.

SKF Maintenance Products

Copyright SKF 2001/07 www.mapro.skf.com

M

P

5

1

1

E

Anda mungkin juga menyukai

- Indium Tin Oxide PDFDokumen25 halamanIndium Tin Oxide PDFadhityaBelum ada peringkat

- Link-Belt 50ton PDFDokumen20 halamanLink-Belt 50ton PDFLucita VallejoBelum ada peringkat

- Aerial Lifts: & Other Elevating PlatformsDokumen42 halamanAerial Lifts: & Other Elevating PlatformsAlejandro8827Belum ada peringkat

- Rally 200Dokumen132 halamanRally 200Simard, Jean-MarieBelum ada peringkat

- Saes H 101VDokumen83 halamanSaes H 101Vacolombel100% (2)

- Maintenance InstructionsDokumen30 halamanMaintenance InstructionsAmir HodzicBelum ada peringkat

- MSDS PeakDokumen2 halamanMSDS PeakPaulus SBelum ada peringkat

- Testing A Double Acting Hydraulic Cylinder: Retract TestDokumen1 halamanTesting A Double Acting Hydraulic Cylinder: Retract TestAhmetBelum ada peringkat

- ANSI Inspection Form Boom Truck Cranes Fillable Template Loadking UPDATEDDokumen4 halamanANSI Inspection Form Boom Truck Cranes Fillable Template Loadking UPDATEDDaiver Lopez PadillaBelum ada peringkat

- Manual Stinger Mts FTDokumen16 halamanManual Stinger Mts FTFabian Andres CelyBelum ada peringkat

- Lube Box Application 2-21-2010Dokumen6 halamanLube Box Application 2-21-2010Fahad KhanBelum ada peringkat

- HYTORC Stealth Technical Manual enDokumen47 halamanHYTORC Stealth Technical Manual enGabriel Torres BenturaBelum ada peringkat

- Thumb Rules For Steel&Concrete DesignDokumen11 halamanThumb Rules For Steel&Concrete DesigngvgbabuBelum ada peringkat

- Bomba Centrifuga Frame A LD17Dokumen56 halamanBomba Centrifuga Frame A LD17richard_580Belum ada peringkat

- Din en 10328Dokumen7 halamanDin en 10328Tania DanielBelum ada peringkat

- Fa2.5i Fa5i Fa5ti MaintenanceDokumen16 halamanFa2.5i Fa5i Fa5ti Maintenancemohammad salleh50% (2)

- LSI gs550 PDFDokumen85 halamanLSI gs550 PDFIvan ivan budiBelum ada peringkat

- Cummins QSM11 engine spare parts listDokumen167 halamanCummins QSM11 engine spare parts listIvan Martínez LopezBelum ada peringkat

- DS50 Operators Manual Manitex Manitowoc 190014ADokumen21 halamanDS50 Operators Manual Manitex Manitowoc 190014AEdson EscobedoBelum ada peringkat

- W30 Wheel Loader with F.A.C.T. SystemDokumen6 halamanW30 Wheel Loader with F.A.C.T. Systemltovar01Belum ada peringkat

- HIAB14000XGDokumen267 halamanHIAB14000XGMigueBelum ada peringkat

- PMI Procedure PDFDokumen10 halamanPMI Procedure PDFMohammed Abdul Majid IrfanBelum ada peringkat

- DMM-3 Us004467 AndinaDokumen808 halamanDMM-3 Us004467 AndinaJUAN PABLOBelum ada peringkat

- XCMG Iflex5 Operators ManualDokumen69 halamanXCMG Iflex5 Operators ManualIslam AttiaBelum ada peringkat

- Ah 18851Dokumen89 halamanAh 18851Valeria MartinezBelum ada peringkat

- 1 Deck MachineryDokumen213 halaman1 Deck MachineryRAMESHBelum ada peringkat

- CA SS1 1.1-Clean and Maintain Kitchen PremisesDokumen17 halamanCA SS1 1.1-Clean and Maintain Kitchen PremisesAlexa Caorong100% (1)

- Vanair Compressor Maintenance ManualDokumen6 halamanVanair Compressor Maintenance ManualcarlosBelum ada peringkat

- Pts 1600 Cud S3at3 AppDokumen128 halamanPts 1600 Cud S3at3 ApptskumarBelum ada peringkat

- Instrucciones de Operacion BirielDokumen88 halamanInstrucciones de Operacion BirielCristhian RamirezBelum ada peringkat

- Iso 10100Dokumen16 halamanIso 10100jaime jeanpierre bernal olarte100% (1)

- Linkbelt HTC11100 SpecDokumen16 halamanLinkbelt HTC11100 SpecDaniel Cáceres TrujilloBelum ada peringkat

- Link Belt RTC8080tDokumen24 halamanLink Belt RTC8080tKreatif DesainBelum ada peringkat

- ELITE40 Operation Manual 1210Dokumen57 halamanELITE40 Operation Manual 1210Edgar Castañeda100% (1)

- ERKE Group, FUWA QUY 500 Crawler Crane CatalogDokumen94 halamanERKE Group, FUWA QUY 500 Crawler Crane CatalogerkegroupBelum ada peringkat

- Genie S60X Manual de OperaciónDokumen68 halamanGenie S60X Manual de OperaciónJorge Alberto Gomez100% (1)

- Wciagniki - Lancuchowe - Angielski STAHL CRANE SYSTEM GRUAS PUENTE PDFDokumen32 halamanWciagniki - Lancuchowe - Angielski STAHL CRANE SYSTEM GRUAS PUENTE PDFJose QuiroaBelum ada peringkat

- Service Manual XA060 - Version 05Dokumen68 halamanService Manual XA060 - Version 05Yacine GhanemiBelum ada peringkat

- DMF 5000 Series Users ManualDokumen62 halamanDMF 5000 Series Users ManualIlle Antoniu NicolaeBelum ada peringkat

- 3-5400 GB PDFDokumen16 halaman3-5400 GB PDFShijumon KpBelum ada peringkat

- VAG HYsec Hydraulic Brake and Lift UnitDokumen3 halamanVAG HYsec Hydraulic Brake and Lift UnitLuka Borna100% (1)

- Tower Crane ISO - 9927-3 - 2005Dokumen32 halamanTower Crane ISO - 9927-3 - 2005محمد ممدوحBelum ada peringkat

- EP 9 ES20 WA Operation Manual 20190912 20190924 173216Dokumen41 halamanEP 9 ES20 WA Operation Manual 20190912 20190924 173216delta stokBelum ada peringkat

- Hek GL Manual PDFDokumen62 halamanHek GL Manual PDFTaras KutsykBelum ada peringkat

- Manual For AGBS Rev02Dokumen20 halamanManual For AGBS Rev02Grandhi Venkata Satya KiranBelum ada peringkat

- PA25 v43 Maintenance ManualDokumen82 halamanPA25 v43 Maintenance ManualAnonymous ZLmk6mPPn50% (2)

- W-2119 & W-2120 Series: Parts Manual 823036ENDokumen12 halamanW-2119 & W-2120 Series: Parts Manual 823036ENsolrac4371Belum ada peringkat

- Ficha Tecnica - Tabla de Carga Sany 100Dokumen21 halamanFicha Tecnica - Tabla de Carga Sany 100Adm Rigger Crane SacBelum ada peringkat

- Carburetors & Mixers Model Ca100 CarburetorDokumen6 halamanCarburetors & Mixers Model Ca100 CarburetorCarlos Chumbiauca MorenoBelum ada peringkat

- Pioneer Avh p6600dvd p6650dvdDokumen218 halamanPioneer Avh p6600dvd p6650dvdxxxkillerBelum ada peringkat

- Fastner and Tooling Components. Fertrading Group Venezuela.Dokumen4 halamanFastner and Tooling Components. Fertrading Group Venezuela.Renso PiovesanBelum ada peringkat

- 2014 Dropsafe CatalogueDokumen15 halaman2014 Dropsafe CataloguehamzadarbarBelum ada peringkat

- AHQ 76 Nos - Hulift Semi Electric Manual Godrej NosDokumen22 halamanAHQ 76 Nos - Hulift Semi Electric Manual Godrej NosAnup Kumar singhBelum ada peringkat

- Iqan-Xa2 Instruction Book: Publ No HY33-8385-IB/UK Edition 2016-12-16Dokumen39 halamanIqan-Xa2 Instruction Book: Publ No HY33-8385-IB/UK Edition 2016-12-16feukamBelum ada peringkat

- Parts Manual for ZT20J (ZT68J) Telescopic Boom LiftDokumen183 halamanParts Manual for ZT20J (ZT68J) Telescopic Boom LiftLuis AlbertoAlmeidaSilvaBelum ada peringkat

- Patriot P-90-130 130ft Boom Crane Load Chart ManualDokumen98 halamanPatriot P-90-130 130ft Boom Crane Load Chart ManualDaniel ReyBelum ada peringkat

- SM Tm3989 Knott A4Dokumen1 halamanSM Tm3989 Knott A4Marc GlebBelum ada peringkat

- Gunnebo 2000Dokumen36 halamanGunnebo 2000Ed CalheBelum ada peringkat

- Grove GMK5165 SpecDokumen16 halamanGrove GMK5165 SpecHoward HoacBelum ada peringkat

- Blohm+Voss Pipe Handling Equipment ManualDokumen73 halamanBlohm+Voss Pipe Handling Equipment ManualIRWIN_DSOUZA100% (1)

- English - ComponentesDokumen2 halamanEnglish - ComponentesChristopher Jesus Reàtegui OlivaresBelum ada peringkat

- 80 US T (72.6 T) Lifting Capacity Rough Terrain Crane Sales Flyer Imperial/MetricDokumen2 halaman80 US T (72.6 T) Lifting Capacity Rough Terrain Crane Sales Flyer Imperial/MetricLuis Miguel Rivera SoplopucoBelum ada peringkat

- KPos Follow Target Mode Operator Manual (Release 8.2.0)Dokumen16 halamanKPos Follow Target Mode Operator Manual (Release 8.2.0)TonyBelum ada peringkat

- Potain HDT 80Dokumen4 halamanPotain HDT 80cerfabioBelum ada peringkat

- Maxiforce 2009 CatalogDokumen228 halamanMaxiforce 2009 CatalogMotokoy Sprekitik Takoykoy100% (1)

- SKF 729124 Hydraulic PumpDokumen8 halamanSKF 729124 Hydraulic PumpAlvaro ZilianiBelum ada peringkat

- ConsoleApp CDokumen1 halamanConsoleApp CSalman AslamBelum ada peringkat

- Oim Full Update 20130125 212208Dokumen4 halamanOim Full Update 20130125 212208reinaldosidejuniorBelum ada peringkat

- Bloodshed Dev-C++ Is Distributed Under The GNU General Public License.Dokumen7 halamanBloodshed Dev-C++ Is Distributed Under The GNU General Public License.onaibaf13Belum ada peringkat

- SKF TIH 060-20: Swivel ArmDokumen4 halamanSKF TIH 060-20: Swivel ArmreinaldosidejuniorBelum ada peringkat

- SKF TIH 060-20: Swivel ArmDokumen4 halamanSKF TIH 060-20: Swivel ArmreinaldosidejuniorBelum ada peringkat

- Oim Full Update 20130125 212208Dokumen4 halamanOim Full Update 20130125 212208reinaldosidejuniorBelum ada peringkat

- Calculating Involute Gear Teeth ParametersDokumen3 halamanCalculating Involute Gear Teeth ParametersreinaldosidejuniorBelum ada peringkat

- ReadmeDokumen2 halamanReadmereinaldosidejuniorBelum ada peringkat

- 09 030402Dokumen2 halaman09 030402reinaldosidejuniorBelum ada peringkat

- Dev CPP NewsDokumen5 halamanDev CPP NewsAndrew HubbardBelum ada peringkat

- Oimlog 20130925 140950Dokumen1 halamanOimlog 20130925 140950reinaldosidejuniorBelum ada peringkat

- UPDATED CONTENTSDokumen13 halamanUPDATED CONTENTSreinaldosidejuniorBelum ada peringkat

- 05 040000Dokumen2 halaman05 040000reinaldosidejuniorBelum ada peringkat

- 01 030001Dokumen1 halaman01 030001reinaldosidejuniorBelum ada peringkat

- 01 050100Dokumen1 halaman01 050100reinaldosidejuniorBelum ada peringkat

- 00 020105Dokumen1 halaman00 020105reinaldosidejuniorBelum ada peringkat

- ReadmeDokumen2 halamanReadmereinaldosidejuniorBelum ada peringkat

- 02 000000Dokumen1 halaman02 000000reinaldosidejuniorBelum ada peringkat

- 00 020102Dokumen2 halaman00 020102reinaldosidejuniorBelum ada peringkat

- 00 020100Dokumen1 halaman00 020100reinaldosidejuniorBelum ada peringkat

- 00 020101Dokumen1 halaman00 020101reinaldosidejuniorBelum ada peringkat

- UPDATED CONTENTSDokumen13 halamanUPDATED CONTENTSreinaldosidejuniorBelum ada peringkat

- TK2Dokumen3 halamanTK2reinaldosidejuniorBelum ada peringkat

- 00 020103Dokumen1 halaman00 020103reinaldosidejuniorBelum ada peringkat

- 00 010000Dokumen3 halaman00 010000reinaldosidejuniorBelum ada peringkat

- Oim Full Update 20130125 212208Dokumen4 halamanOim Full Update 20130125 212208reinaldosidejuniorBelum ada peringkat

- 00 000000Dokumen1 halaman00 000000reinaldosidejuniorBelum ada peringkat

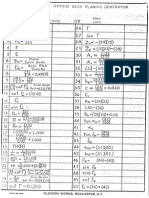

- 7, Special Calc SheetsDokumen4 halaman7, Special Calc SheetsreinaldosidejuniorBelum ada peringkat

- Flange de LigacaoDokumen2 halamanFlange de LigacaoreinaldosidejuniorBelum ada peringkat

- Marten Terpstra, Johan G. Van Veen (Auth.), Marten Terpstra, Johan G. Van Veen (Eds.) - Heat Pipes - Construction and Application - A Study of Patents and Patent Applications-Springer NetherlandsDokumen391 halamanMarten Terpstra, Johan G. Van Veen (Auth.), Marten Terpstra, Johan G. Van Veen (Eds.) - Heat Pipes - Construction and Application - A Study of Patents and Patent Applications-Springer NetherlandsJed MansouriBelum ada peringkat

- Creep and Creep FailuresDokumen2 halamanCreep and Creep FailurespresleBelum ada peringkat

- 18.5200 MUS KS01 Foam SeparatorDokumen32 halaman18.5200 MUS KS01 Foam SeparatorIndra KushwahaBelum ada peringkat

- Laboratory Experimental Testing and Development of An Efficient Low Pressure ES-SAGD ProcessDokumen8 halamanLaboratory Experimental Testing and Development of An Efficient Low Pressure ES-SAGD Processpedro aguilarBelum ada peringkat

- Manual-De-Usuario Deshumidificador PDFDokumen18 halamanManual-De-Usuario Deshumidificador PDFSoyManuBelum ada peringkat

- Project TopicsDokumen16 halamanProject TopicsVasu VermaBelum ada peringkat

- Keywords: Sanitary Napkins, Chlorine, Uv-Vis SpectrophotometryDokumen10 halamanKeywords: Sanitary Napkins, Chlorine, Uv-Vis SpectrophotometryFajar PriyonoBelum ada peringkat

- Housing & CouplingDokumen12 halamanHousing & Couplingmajid fardniaBelum ada peringkat

- Unit 3 Production and Cost AnalysisDokumen6 halamanUnit 3 Production and Cost Analysismanjunatha TK100% (1)

- 01 Heating PL 2017 Rs v03 Svu 5.4 FinalDokumen77 halaman01 Heating PL 2017 Rs v03 Svu 5.4 FinalKajak Klub DrinaBelum ada peringkat

- Almasol 1250-1251 Product Info PDFDokumen2 halamanAlmasol 1250-1251 Product Info PDFmehmetaliozgurBelum ada peringkat

- 2020 - 1 s2.0 S0020722520301853 MainDokumen20 halaman2020 - 1 s2.0 S0020722520301853 MainG DBelum ada peringkat

- Air Lift Design Pumps PDFDokumen5 halamanAir Lift Design Pumps PDFinggerman100% (1)

- Astm A513 PDFDokumen3 halamanAstm A513 PDFgaminBelum ada peringkat

- Sigma mixer description and specificationsDokumen1 halamanSigma mixer description and specificationsBalRam DhimanBelum ada peringkat

- SC2057 PDFDokumen3 halamanSC2057 PDFA MahmoodBelum ada peringkat

- TM620 LeafletDokumen4 halamanTM620 LeafletÖzgürMetinBelum ada peringkat

- Cooling: Operating Temperature Arrhenius Equation Radiation Transformer Oil Mineral Oil PaperDokumen2 halamanCooling: Operating Temperature Arrhenius Equation Radiation Transformer Oil Mineral Oil PaperVishnu PillaiBelum ada peringkat

- DSU Manual PDFDokumen204 halamanDSU Manual PDFCarlos Alberto RuedaBelum ada peringkat

- Assignment: Q.N.1. in A Turning Operation, It Was Observed That The Tool Life Was 150 Minutes When The CuttingDokumen7 halamanAssignment: Q.N.1. in A Turning Operation, It Was Observed That The Tool Life Was 150 Minutes When The CuttingAnkesh KapilBelum ada peringkat

- Renewal Parts - YK Mod F and Later HA-HB-HE-HG - G, H & J Series CompressorsDokumen112 halamanRenewal Parts - YK Mod F and Later HA-HB-HE-HG - G, H & J Series CompressorsKannan KrishnamoorthyBelum ada peringkat

- 4806 en MiraDRAIN 9800 TDSDokumen2 halaman4806 en MiraDRAIN 9800 TDSabdalla el-saadaneyBelum ada peringkat

- 3M Cold Shrink Silicone Rubber Termination QT-III: InstructionsDokumen16 halaman3M Cold Shrink Silicone Rubber Termination QT-III: InstructionsEliazer GonzalezBelum ada peringkat

- Part 1Dokumen82 halamanPart 1Jaydeep ZankatBelum ada peringkat