Anchor Rods and Threaded Rods Guide

Diunggah oleh

lavenworkDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Anchor Rods and Threaded Rods Guide

Diunggah oleh

lavenworkHak Cipta:

Format Tersedia

ANCHOR RODS OR THREADED RODS

Cast-in-place anchor rods, illustrated in Figure 8-14, are generally made from unheaded

rod material or headed bolt material. Drilled-in anchor rods, illustrated in Figure 8-15,

are not normally used; their design is governed by manufacturers specifications. Refer

also to Cannon, Godfrey, and Moreadith (1981).

LRFD Specification Section A3.4 permits the use of unheaded rod material from the

following ASTM specifications as anchor rods or threaded rods: A36, A193, A354, A449,

A572, A588, and A687. Additionally, LRFD Specification Section A3.4 permits the use

of headed bolts conforming to the provisions of LRFD Specification Section A3.3 for use

as anchor rods. Headed bolts, however, are generally available only in lengths up to about

eight inches. Furthermore, designations such as ASTM A325, A490, and A307 apply only

to bolts manufactured with a head and it is, therefore, improper to specify unheaded

anchor rods or other similar threaded devices as ASTM A325, A490, or A307.

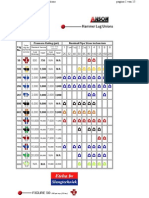

The availability and strength of the aforementioned ASTM specifications for unheaded

rod material and headed bolt material are summarized in Table 8-26. Suitable nuts may

be selected from ASTM A563 or ASTM A194 grade 7. Because base plates typically have

holes larger than oversized holes to allow for tolerances on the location of the anchor rod,

washers are usually furnished from ASTM A36 steel plate; they may be round, square,

or rectangular, are generally about

1

2

-in. thick, and generally have holes which are

1

16

-in.

larger than the anchor rod diameter.

Minimum Edge Distance and Embedment Length

The recommendations of Shipp and Haninger (1983) for minimum anchor-rod (concrete)

edge distance and embedment length for tensile forces, adopted from ACI 349, are

summarized in Table 8-26. The edge distance requirement is intended to prevent blow-out

of the side of the concrete foundation and is based on concrete with f

c

=3,000 psi. For

edge distance requirements for shear, refer to Shipp and Haninger (1983).

In addition to providing the recommended minimum embedment length, anchor rods

must extend a distance above the foundation that is sufficient to permit full thread

engagement of the nut; from RCSC Specification Section 2(b), the end of the [anchor

rod] will be flush with or outside the face of the nut when properly installed.

(a) Hooked (b) Headed (c) Threaded with Nut

L

h

Fig. 8-14. Typical cast-in-place anchor rods.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

8 - 88 BOLTS, WELDS, AND CONNECTED ELEMENTS

Note that it is seldom possible to fully tension anchor rods since the concrete usually

cannot provide the necessary anchorage.

Welding to Anchor Rods

Though not typical, welds must sometimes be used in lieu of nuts to attach anchor rods

to base plates. The use of weldable steels such as ASTM A36 or A572 is recommended

for this purpose; anchor-rod material which is quenched and tempered should not be

welded.

Hooked Anchor Rods

Hooked anchor rods should be used only for axially loaded columns to locate and prevent

the displacement or overturning of columns due to erection loads or accidental collisions

during erection. Additionally, high-strength steels are not recommended for use in hooked

rods since bending with heat may materially affect their strength.

For the hooked rod of Figure 8-14a, the tensile force is resisted through bond

development along the length and the mechanical anchorage of the hook. However,

because smooth rods do not always form a reliable bond (due to oil used in threading

among other things), the design of such anchor rods should be based upon the anchorage

provided by the hook only. To prevent the anchor rod from pulling out and straightening,

the hook should be designed to resist one-half the design tensile strength of the anchor

rod R

n

,

where

=0.75

R

n

=

t

F

u

A

g

In the above equation,

t

=0.75. From Fisher (1981), the bearing strength of the

concrete is:

0.7f

c

dL

h

Grout

Fig. 8-15. Drilled-in anchor rods.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

ANCHOR RODS OR THREADED RODS 8 - 89

Thus, the minimum hook length L

h min

is:

L

h min

=

R

n

2

0.7f

c

d

wheref

c

is the specified strength of the concrete, ksi. The total embedded anchor rod

length is then the hook length L

h

plus the minimum embedment length from Table 8-26.

Headed Anchor Rods

When anchor rods are required for a calculated tensile force T

u

, a more positive anchorage

is formed when headed anchor rods, illustrated in Figure 8-14b, are used. With adequate

embedment and edge distance, the limit state is either a tensile failure of the anchor rod

or the pull-out of a cone of concrete radiating outward from the head (Marsh and Burdette,

1985a) as illustrated in Figure 8-16.

The design tensile strength of the anchor rod is R

n

,

U

n

h

e

a

d

e

d

R

o

d

M

a

t

e

r

i

a

l

(

O

n

l

y

)

H

e

a

d

e

d

B

o

l

t

o

r

U

n

h

e

a

d

e

d

R

o

d

M

a

t

e

r

i

a

l

H

e

a

d

e

d

B

o

l

t

M

a

t

.

(

O

n

l

y

)

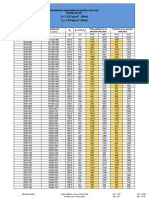

Table 8-26.

Anchor Rod Material Availability and Strength

Type

ASTM

Design.

Availability Strength

Minimum

Embdmt.

Length,

in.

Minimum

Edge

Dist., in.

e

Material

Type

b

Grade

Diameter,

d, in.

Proof

Load

Min.

Yield,

ksi

Min.

Tensile,

ksi

A36 C to 8 36 58 12d 5d

A572 HSLA 42 to 2 42 60 12d 5d

50 to 6 50 65 17d 7d

A588 HSLA, ACR to 4 50 70 17d 7d

over 4 to 5 46 67 17d 7d

over 5 to 8 42 63 17d 7d

A687 A, QT, NT

5

8 to 3 105 150

c

19d 7d

A354 A, QT BD

1

4 to 2

1

2 120 130 150 19d 7d

over 2

1

2 to 4 105 115 140 19d 7d

BC

1

4 to 2

1

2 105 109 125 17d 7d

over 2

1

2 to 4 95 99 115 17d 7d

A449

d

C, QT

1

4 to 1 85 92 120 17d 7d

1

1

8 to 1

1

2 74 81 105 17d 7d

1

3

4 to 3 55 58 90 17d 7d

A307 C to 4 60 12d 5d

A325

a,d

C, QT

1

2 to 1 85 92 120 17d 7d

1

1

8 to 1

1

2 74 81 105 17d 7d

A490

a,d

A, QT

1

2 to 1

1

2 120 150 19d 7d

a

Available with weathering (atmospheric corrosion resistance) characteristics comparable to ASTM A242 and

A588 steels.

b

A =Alloy Steel

b

ACR =Atmospheric-Corrosion-Resistant Steel

b

C =Carbon Steel

b

HSLA =High-Strength Low-Alloy Steel

b

NT =Notch-Tough Steel (CVN 15 @ 20 F)

b

QT =Quenched and Tempered Steel

c

Maximum (ultimate tensile strength)

d

Threaded rod material with properties meeting ASTM A325, A490, and A449 specifications may be obtained

with the use of an appropriate steel (such as ASTM A193, grade B7), quenched and tempered after fabrication.

e

Not less than 4 in.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

8 - 90 BOLTS, WELDS, AND CONNECTED ELEMENTS

Anda mungkin juga menyukai

- Welding and bolting requirements for structural steelDokumen10 halamanWelding and bolting requirements for structural steelIndra SidikBelum ada peringkat

- Article - Structural BoltsDokumen6 halamanArticle - Structural Boltsing_weroBelum ada peringkat

- Bolts, threaded parts and rivets allowable loadsDokumen2 halamanBolts, threaded parts and rivets allowable loadsMary MarasiganBelum ada peringkat

- Connection Design - Its Role in Steel DetailingDokumen9 halamanConnection Design - Its Role in Steel DetailingEduardo De Castro Cruz Jr.Belum ada peringkat

- Design of Welded Structures by BlodgettDokumen834 halamanDesign of Welded Structures by BlodgettLandon Mitchell92% (12)

- Connections and Tension Member DesignDokumen9 halamanConnections and Tension Member DesignVigneshwari MahamuniBelum ada peringkat

- Casing DesignDokumen49 halamanCasing DesignAmar BenAmar100% (1)

- Find specifications for ASTM A325 and A490 structural boltsDokumen6 halamanFind specifications for ASTM A325 and A490 structural boltsalexortiz83Belum ada peringkat

- Anchor Bolts Design of Headed Anchor BoltsDokumen12 halamanAnchor Bolts Design of Headed Anchor BoltsDoug LambBelum ada peringkat

- Casing DesignDokumen48 halamanCasing Designdrillinganaco60% (5)

- Tie Rod ManualDokumen20 halamanTie Rod Manualseminoles1Belum ada peringkat

- Specifying Bolt Length For High-Strength Bolts: Manual of Steel ConstructionDokumen12 halamanSpecifying Bolt Length For High-Strength Bolts: Manual of Steel Constructionpreds1717Belum ada peringkat

- Aa 036322 001Dokumen1 halamanAa 036322 001petronashscribdidBelum ada peringkat

- Predilla Assignment Module 3Dokumen15 halamanPredilla Assignment Module 3Justine PredillaBelum ada peringkat

- Helical PilesDokumen51 halamanHelical Pilesmateus45680% (5)

- Column Design With ExcelDokumen72 halamanColumn Design With ExcelAsifIqbalBelum ada peringkat

- Drilling Engineering: PETE 203Dokumen48 halamanDrilling Engineering: PETE 203sereptBelum ada peringkat

- Casing Design 2005Dokumen48 halamanCasing Design 2005serept0% (1)

- Probset PrelimDokumen45 halamanProbset PrelimAndrea MagtutoBelum ada peringkat

- 425 ch09 Lec.S12Dokumen46 halaman425 ch09 Lec.S12jemuelBelum ada peringkat

- A FEDS Structural BoltsDokumen6 halamanA FEDS Structural BoltsCrimsonPoshBelum ada peringkat

- App B Piping Specifications PDFDokumen4 halamanApp B Piping Specifications PDFirawan_epBelum ada peringkat

- Part 1045 Rail Track Support SystemsDokumen20 halamanPart 1045 Rail Track Support SystemsRio HandokoBelum ada peringkat

- 9282Dokumen13 halaman9282Frank StephensBelum ada peringkat

- Stress Relief Boreback BoxDokumen3 halamanStress Relief Boreback BoxDaisuke Numata100% (1)

- CAST STEEL GATE VALVES UNDER 40 CHARACTERSDokumen4 halamanCAST STEEL GATE VALVES UNDER 40 CHARACTERSsghinausBelum ada peringkat

- Pipeline Transportation Systems for LiquidsDokumen3 halamanPipeline Transportation Systems for LiquidsKrystle FlowersBelum ada peringkat

- Marine Anchor Design GuideDokumen28 halamanMarine Anchor Design GuideKevin SaaVedra CastañedaBelum ada peringkat

- Importance of Detailing Transverse Reinforcement for Beams, Columns and WallsDokumen3 halamanImportance of Detailing Transverse Reinforcement for Beams, Columns and WallssudarsancivilBelum ada peringkat

- A325 and A490 BoltsDokumen9 halamanA325 and A490 BoltsCHECcorp100% (1)

- AMT 100 Sample Finals QuestionsDokumen41 halamanAMT 100 Sample Finals Questionsanil thakurBelum ada peringkat

- Catalogo Tecnico Stud WeldingDokumen68 halamanCatalogo Tecnico Stud Weldingalexfc81Belum ada peringkat

- Minimum Threads Exposed at Each NutDokumen11 halamanMinimum Threads Exposed at Each NutSingaravel GanesanBelum ada peringkat

- Specifying Bolt Length For High-Strength Bolts: Manual of Steel ConstructionDokumen12 halamanSpecifying Bolt Length For High-Strength Bolts: Manual of Steel ConstructionalbertoxinaBelum ada peringkat

- 1 - Classification of CasingDokumen68 halaman1 - Classification of CasingnabiBelum ada peringkat

- Tema 9Dokumen300 halamanTema 9sudokuBelum ada peringkat

- AN BoltsDokumen8 halamanAN BoltsAnthony McfayBelum ada peringkat

- Opr0RAZ7 TMPDokumen4 halamanOpr0RAZ7 TMPSérgio BernardesBelum ada peringkat

- Bolt sizes and tightening torquesDokumen40 halamanBolt sizes and tightening torquesponcatoera83% (6)

- Chapter 4 09Dokumen22 halamanChapter 4 09zhangjlBelum ada peringkat

- Combinationwireropesfoii Fishing Purposes-Specification: Indian StandardDokumen10 halamanCombinationwireropesfoii Fishing Purposes-Specification: Indian StandardGanga DaranBelum ada peringkat

- Design of Structural MembersDokumen153 halamanDesign of Structural Membersquiron20100% (1)

- Hamerlug Unions (Anson)Dokumen15 halamanHamerlug Unions (Anson)Leonardo ViannaBelum ada peringkat

- Beam Clamps: MaterialsDokumen20 halamanBeam Clamps: Materialsgreg_n5Belum ada peringkat

- Connections Manual ErrataDokumen31 halamanConnections Manual ErratalucianduBelum ada peringkat

- Anchor bolt design calculation for piperack foundationDokumen10 halamanAnchor bolt design calculation for piperack foundationArivoli JayaramanBelum ada peringkat

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDari EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsPenilaian: 4.5 dari 5 bintang4.5/5 (10)

- Pocket Guide to Flanges, Fittings, and Piping DataDari EverandPocket Guide to Flanges, Fittings, and Piping DataPenilaian: 3.5 dari 5 bintang3.5/5 (22)

- Solution Manual for 100 Genesys Design Examples: Second EditionDari EverandSolution Manual for 100 Genesys Design Examples: Second EditionBelum ada peringkat

- Structural Steel Design to Eurocode 3 and AISC SpecificationsDari EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsBelum ada peringkat

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyDari EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyBelum ada peringkat

- TENSION AISC Todos Los Perfiles 2005 PDFDokumen33 halamanTENSION AISC Todos Los Perfiles 2005 PDFEric CusiBelum ada peringkat

- lsp610 PDFDokumen1 halamanlsp610 PDFlavenworkBelum ada peringkat

- lsp611 PDFDokumen1 halamanlsp611 PDFlavenworkBelum ada peringkat

- Design of a 5-Ton Bridge CraneDokumen104 halamanDesign of a 5-Ton Bridge CraneAndres RestrepoBelum ada peringkat

- Solucionario AceroDokumen7 halamanSolucionario AceroMariano Zumaeta100% (1)

- Tipikal Dinding Penahan TanahDokumen8 halamanTipikal Dinding Penahan TanahOji FumetsunoBelum ada peringkat

- FlowchartDokumen2 halamanFlowchartmadafaca13Belum ada peringkat

- All Rights Reserved. No Part of This Chart May Be Reproduced or Distributed in Any Form, Without The Prior Written Permission of The Publisher. ADokumen1 halamanAll Rights Reserved. No Part of This Chart May Be Reproduced or Distributed in Any Form, Without The Prior Written Permission of The Publisher. AjggtzmBelum ada peringkat

- Types of Managers and Management Styles: Popmt@uoradea - Ro Dpop@uoradeaDokumen7 halamanTypes of Managers and Management Styles: Popmt@uoradea - Ro Dpop@uoradeaJimnadominicBelum ada peringkat

- Army Aviation Digest - Feb 1967Dokumen68 halamanArmy Aviation Digest - Feb 1967Aviation/Space History LibraryBelum ada peringkat

- SOLID-LIQUID EXTRACTIONDokumen4 halamanSOLID-LIQUID EXTRACTIONHarshal Agrawal100% (1)

- "Roughness": Filtering and Filtering and Filtering and Filtering and Surface Surface Texture TextureDokumen29 halaman"Roughness": Filtering and Filtering and Filtering and Filtering and Surface Surface Texture TextureZouhair BenmabroukBelum ada peringkat

- Mechanical Vapor RecompressionDokumen9 halamanMechanical Vapor Recompressionnarayana reddy0% (1)

- Risk in Clean RoomDokumen9 halamanRisk in Clean RoomABEERBelum ada peringkat

- McMurdo SART S4 v1 A4 06-13-2019Dokumen2 halamanMcMurdo SART S4 v1 A4 06-13-2019Felipe OliveiraBelum ada peringkat

- Simulation and Performance of Double Gate Finfet Devices: B.Sethupathy, P.Aruna PriyaDokumen3 halamanSimulation and Performance of Double Gate Finfet Devices: B.Sethupathy, P.Aruna PriyaKrisumraj PurkaitBelum ada peringkat

- Port Ps PDFDokumen2 halamanPort Ps PDFluisBelum ada peringkat

- Even Sem - Odd Sem - MD MS - MA, MSC, MCom - Previous - Final Main Exam Result 2021 - Mahatma Jyotiba Phule Rohilkhand UniversityDokumen2 halamanEven Sem - Odd Sem - MD MS - MA, MSC, MCom - Previous - Final Main Exam Result 2021 - Mahatma Jyotiba Phule Rohilkhand UniversityprashantBelum ada peringkat

- Register for a WordPress account in 5 easy stepsDokumen5 halamanRegister for a WordPress account in 5 easy stepsPutriBelum ada peringkat

- Myers Et Al - Clear and Present ThinkingDokumen214 halamanMyers Et Al - Clear and Present ThinkingAEBelum ada peringkat

- Object-Oriented Programming (OOP) Lecture No. 5Dokumen40 halamanObject-Oriented Programming (OOP) Lecture No. 5Muhammad ZeeshanBelum ada peringkat

- Miners RuleDokumen2 halamanMiners Ruleபிரபாகரன் ஆறுமுகம்Belum ada peringkat

- Independent University, Bangladesh: Term Paper (Group Assignment)Dokumen16 halamanIndependent University, Bangladesh: Term Paper (Group Assignment)Johan Tausifur RahmanBelum ada peringkat

- 104 Joycecaroloates Wrug ElectraDokumen1 halaman104 Joycecaroloates Wrug ElectraAnca LascuBelum ada peringkat

- Aadhaar is proof of identity, not citizenshipDokumen1 halamanAadhaar is proof of identity, not citizenshipPARTAPBelum ada peringkat

- Mahusay Module 4 Acc3110Dokumen2 halamanMahusay Module 4 Acc3110Jeth MahusayBelum ada peringkat

- Mastercam 8.1 Beta 4: New Verification Engine in Beta 4! Sub-Programs Post ChangesDokumen48 halamanMastercam 8.1 Beta 4: New Verification Engine in Beta 4! Sub-Programs Post ChangesSaul Saldana LoyaBelum ada peringkat

- VUCG Guia de Instalacion y Comisionamiento en Ingles 1ZSC000562-AAY en Rev 1 - LowDokumen56 halamanVUCG Guia de Instalacion y Comisionamiento en Ingles 1ZSC000562-AAY en Rev 1 - Lowarmandoa71565Belum ada peringkat

- PandoraFMS Alerts WhatsappDokumen6 halamanPandoraFMS Alerts Whatsapppacolo89Belum ada peringkat

- AdultChatDkz - ENGLISH - Freelance Worker-SignedDokumen5 halamanAdultChatDkz - ENGLISH - Freelance Worker-SignedDanielBelum ada peringkat

- Chapter 3Dokumen12 halamanChapter 3Raymond LeoBelum ada peringkat

- Container Stuffing Advice for Reducing Cargo DamageDokumen16 halamanContainer Stuffing Advice for Reducing Cargo DamageBerkay TürkBelum ada peringkat

- Nordson EFD Ultimus I II Operating ManualDokumen32 halamanNordson EFD Ultimus I II Operating ManualFernando KrauchukBelum ada peringkat

- Ese 570 Mos Inverters Static Characteristics: Kenneth R. Laker, University of Pennsylvania, Updated 13feb12 1Dokumen44 halamanEse 570 Mos Inverters Static Characteristics: Kenneth R. Laker, University of Pennsylvania, Updated 13feb12 1het shahBelum ada peringkat

- Product Code Threaded Rod Size (R) Lenght (L) MM Pitch (MM) Minimum Proof Load (N) Microns ( ) Bundle QuantityDokumen1 halamanProduct Code Threaded Rod Size (R) Lenght (L) MM Pitch (MM) Minimum Proof Load (N) Microns ( ) Bundle QuantityKABIR CHOPRABelum ada peringkat

- Public Dealing With UrduDokumen5 halamanPublic Dealing With UrduTariq Ghayyur86% (7)

- How To Set Up Simulator Ard MMDokumen12 halamanHow To Set Up Simulator Ard MMJayakrishnaBelum ada peringkat

- Concept MappingDokumen8 halamanConcept MappingRashid LatiefBelum ada peringkat