Design Memorandum For LP Chemcial Dosing System (Rev-1)

Diunggah oleh

suparnabhoseJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Design Memorandum For LP Chemcial Dosing System (Rev-1)

Diunggah oleh

suparnabhoseHak Cipta:

Format Tersedia

Page 1 of 12

FALGUNI SAHA

2009.08.25

13:55:45

+05'30'

BHEL DOCUMENTS NO.: PE-DC-320-154-A001

DEPTT: MECHANICAL AUXILIARY

REV. NO. 1 DATE:

2X500 MW TPS CHANDRAPUR EXPANSION PROJECT. SHEET

BHEL - PS-PEM: PPEI, PLOT NO-25, BHEL, NOIDA, SECTOR-16A, UP-201301.

DOCUMENT TITLE:

DESIGN PHILOSOPHY FOR

LP CHEMICAL DOSING SYSTEM.

1. 0 BRIEF DESCRIPTION OF THE SYSTEMS:

The Chemical Dosing System shall consist of Low Pressure (LP) Chemical dosing system and

NaOH dosing system at ECW Tank. LP dosing system shall be Hydrazine, Ammonia and NaOH

dosing system.

2.0 DESIGN BASIS

Chemical dosing system will be designed to dose required quantity of chemicals to maintain the

quality of boiler feed water and ECW system

3.0 LOW PRESSURE CHEMICAL DOSING:

3.1 HYDRAZINE DOSING SYSTEM:(TOTAL NO OF SKID= 2 NOS)

(Refer drg no. PE-DG-320-154-A001)

Residual oxygen present in feed water can be detrimental to feed cycle equipments. In order to

control the same continuous dosing of dilute solution of hydrazine is done at Boiler Feed

suction line immediately below the Deaerator storage tank only. Though provision has been

kept to dose hydrazine at Condensate discharge header at CPU outlet, Condensate Transfer

pump discharge header and Boiler filling line also, but dosing shall be done at one place at a

time. For this purpose one (1) no. skid mounted Hydrazine dosing system shall be provided.

Dosing system shall mainly comprise the following:

3.1.1 HYDRAZINE PREPRATION CUM METERING TANK (1 No)

A Hydrazine preparation cum metering tank for preparation and measuring the dilute Hydrazine

solution shall be provided. The tank shall be provided with accessories like motorized stirrer,

breather with vent, level gauge, level switch and overflow drain. A filling connection is provided

to fill the concentrated solution by hand pump in the tank.

The solution is then dosed to the required point with the help of dosing pumps.

3.1.2 HYDRAZINE DOSING PUMPS (TOTAL 2 Nos.)

Two nos.(2X100%) Positive displacement plunger type Dosing pumps with relief valves has

been provided.

A Y type strainer (2 x100%) shall be common for both pumps.

3.1.3 HAND PUMP (1 NO.)

A hand pump complete with flexible hose and couplings for transferring hydrazine from drum at

ground level to measuring tank is provided.

3.1.4 ASSOCIATED PIPING, VALVES ETC:

As indicated in the drawing and Data sheet-A.

3.1.5 CONTROL & INSTRUMENTATION

The normal mode of operation of hydrazine dosing system shall be from DDC MIS including ON

/ OFF command to individual pumps. However a local control panel consisting of Start Stop

push buttons, Indicating Lamp, Local / Remote selection, stroke position indicator, Rise / lower

push button to stroke position, local annunciation to be mounted & stroke position indicator on

the lamp shall be provided.

The normal mode of operation of dosing system shall be through DDC MIS, Local remote

selection is to be done with from remote (CR) and indication for the same should be provided

on local panel.

Local annunciation system shall be microprocessor based. All the local annunciations shall be

Page 2 of 12

BHEL DOCUMENTS NO.: PE-DC-320-154-A001

DEPTT: MECHANICAL AUXILIARY

REV. NO. 1 DATE:

2X500 MW TPS CHANDRAPUR EXPANSION PROJECT. SHEET

BHEL - PS-PEM: PPEI, PLOT NO-25, BHEL, NOIDA, SECTOR-16A, UP-201301.

DOCUMENT TITLE:

DESIGN PHILOSOPHY FOR

LP CHEMICAL DOSING SYSTEM.

suitably duplicated for which bidder shall provide free changeover contacts (1 NO + 1NC) rating

0.25 amp. / 220 V DC, 5.0 Amp, 240 V AC at the local panel.

The ON / OFF commands for individual pumps from local push buttons shall act on the

respective drives through DDC MIC.

The stroke position & adjustment will be done from DDC MIS and the stroke actuator shall be

suitable for accepting 4-20 mA DC signal. The pumps shall be provided with 24 V DC, 2-wire

LVDT Type position feed back transmitter to generate 4-20 mA DC signal to indicate stroke

position.

Following interlocks shall be provided.

At Low level in the tank.

x Running Dosing Pump shall be tripped.

x Stirrer motor of the tank shall be tripped.

Following annunciation shall be provided in DDCMIS and LCP.

x Running Dosing Pump trip.

x Stirrer motor trip

x Tank level low.

3.1.6 FLUSHING

Condensate tapped from Condensate water line shall be used for flushing the various pipes

lines and pumps of the system as shown in P &I drawing.

3.2 AMMONIA DOSING SYSTEM :(TOTAL NO OF SKID= 2 NOS)

(Refer drg no. PE-DG-320-154-A002)

Boiler feed water/Condensate water should have proper pH in order to protect the system from

corrosion. In order to control the same dosing of dilute solution of Ammonia is done at

Condensate discharge header at CPU outlet only. Though provision has been kept to dose

ammonia at Boiler Feed suction line immediately below the Deaerator storage tank,

Condensate Transfer pump discharge header and Boiler filling line also, but dosing shall be

done at one place at a time. For this purpose one (1) no. skid mounted ammonia-dosing system

shall be provided. Dosing system shall mainly comprise the following:

3.2.1 SOLUTION PREPRATION CUM METERING TANK (1 No.)

A solution-preparation cum metering tank for preparation and measuring the dilute Ammonia

solution shall be provided. The tank shall be provided with accessories like motorized stirrer,

breather with vent, level gauge, and level switch, overflow drain. A filling connection is provided

to fill the concentrated solution by hand pump in the tank.

The solution is then dosed to the required point with the help of dosing pumps.

3.2.2 AMMONIA DOSING PUMPS (TOTAL 2 NOS)

Two nos. (2X100%) Positive displacement plunger type Dosing pumps with motor, relief valves

has been provided.

A Y type strainer (2 x100%) shall be common for both pumps.

3.2.3 HAND PUMP (1 NO.)

A hand pump complete with flexible hose and couplings for transferring Ammonia from drum at

ground level to measuring tank is provided.

3.2.4 ASSOCIATED PIPING, VALVES ETC:

As indicated in the drawing and Data sheet-A.

R1

Page 3 of 12

BHEL DOCUMENTS NO.: PE-DC-320-154-A001

DEPTT: MECHANICAL AUXILIARY

REV. NO. 1 DATE:

2X500 MW TPS CHANDRAPUR EXPANSION PROJECT. SHEET

BHEL - PS-PEM: PPEI, PLOT NO-25, BHEL, NOIDA, SECTOR-16A, UP-201301.

DOCUMENT TITLE:

DESIGN PHILOSOPHY FOR

LP CHEMICAL DOSING SYSTEM.

3.2.5 CONTROL & INSTRUMENTATION

The normal mode of operation of Ammonia dosing system shall be from DDC MIS including ON

/ OFF command to individual pumps. However, a local control panel consisting of Start Stop

push buttons, Indicating Lamp, Local / Remote selection, stroke position indicator, Rise / lower

push button to stroke position, local annunciation to be mounted & stroke position indicator on

the lamp shall be provided.

The normal mode of operation of dosing system shall be through DDC MIS, Local remote

selection is to be done with from remote (CR) and indication for the same should be provided

on local panel.

Local annunciation system shall be microprocessor based. All the local annunciations shall be

suitably duplicated for which bidder shall provide free changeover contacts (1 NO + 1NC) rating

0.25 amp. / 220 V DC, 5.0 Amp, 240 V AC at the local panel.

The ON / OFF commands for individual pumps from local push buttons shall act on the

respective drives through DDC MIC.

The stroke position & adjustment will be done from DDC MIS and the stroke actuator shall be

suitable for accepting 4-20 mA DC signal. The pumps shall be provided with 24 V DC, 2-wire

LVDT Type position feed back transmitter to generate 4-20 mA DC signal to indicate stroke

position.

Following interlocks shall be provided.

At Low level in the tank.

x Running Dosing Pump shall be tripped.

x Stirrer motor of the tank shall be tripped.

Following annunciation shall be provided in DDCMIS and LCP.

x Running Dosing Pump trip.

x Stirrer motor trip

x Tank level low.

3.3 NaOH DOSING SYSTEM: :(TOTAL NO OF SKID= 2 NOS)

(Refer drg no. PE-DG-320-154-A003)

Sodium Hydroxide (NaOH) dosing system is provided to dose NaOH solution in Equipment

cooling water lines to increase pH upto 9.5. The sodium hydroxide dosing is done in the ECW

cycle during the initial fill and for the compensation of cooling water for any leakage during

normal run. The 1% solution of NaOH is prepared manually by opening the inlet valve of DM

water and adding NaOH lye in basket. The NaOH is being dissolved by locally starting the

motorized stirrer. The dosing is done manually as per requirements of desired pH in ECW line

judged by trial basis. Normally the leakage is occasionally and of small quantity . At the low

level of solution in tank the solution is to be prepared again.

The dosing system consists of following.

3.3.1 ASSOCIATED PIPING, VALVES ETC:

As indicated in the drawing and Data sheet-A.

3.3.2 CONTROL & INSTRUMENTATION

The normal mode of operation of NaOH dosing system shall be from Local Control Panel.

Local annunciation system shall be microprocessor based. All the local annunciations shall be

suitably duplicated for which bidder shall provide free changeover contacts (1 NO + 1NC) rating

0.25 amp. / 220 V DC, 5.0 Amp, 240 V AC at the local panel.

Following inter-locks shall be provided at low Level in the mixing/storage tank.

Page 4 of 12

BHEL DOCUMENTS NO.: PE-DC-320-154-A001

DEPTT: MECHANICAL AUXILIARY

REV. NO. 1 DATE:

2X500 MW TPS CHANDRAPUR EXPANSION PROJECT. SHEET

BHEL - PS-PEM: PPEI, PLOT NO-25, BHEL, NOIDA, SECTOR-16A, UP-201301.

DOCUMENT TITLE:

DESIGN PHILOSOPHY FOR

LP CHEMICAL DOSING SYSTEM.

Running Stirrer motor of the tank shall be tripped.

Following fault indications shall be provided in DDCMIS and LCP:

x Stirrer motor trip

x Tank level low.

3.2.5 FLUSHING

Condensate tapped from condensate line shall be used for flushing the various pipelines and

pumps of the system as shown in P&I drawing.

4.0 DESIGN BASIS:

The following drawings/data sheets are enclosed for the reference:

PE-DG-320-154-A001 P&ID for Hydrazine dosing system.

PE-DG-320-154-A002 P&ID for Ammonia dosing system.

PE-DG-320-154-A003 P&ID for NaOH dosing system.

DATA SHEET A For above systems.

ANNEXURE-I Design Calculation for the above system.

Page 5 of 12

BHEL DOCUMENTS NO.: PE-DC-320-154-A001

DEPTT: MECHANICAL AUXILIARY

REV. NO. 1 DATE:

2X500 MW TPS CHANDRAPUR EXPANSION PROJECT. SHEET

BHEL - PS-PEM: PPEI, PLOT NO-25, BHEL, NOIDA, SECTOR-16A, UP-201301.

DOCUMENT TITLE:

DESIGN PHILOSOPHY FOR

LP CHEMICAL DOSING SYSTEM.

DATA SHEET A

Sl no. Description HYDRAZINE DOSING

SYSTEM

AMMONIA DOSING

SYSTEM

NaOH DOSING

SYSTEM

1.1.0 No. of skids per unit One (1) One (1) One (1)

1.1.1 No. of skids per station Two (2) Two (2) Two (2)

1.2.0 SOLUTION PREPARATION CUM METERING TANK

1.2.1 No. of tanks per Skid One (1) One (1) One (1)

1.2.2 Capacity 1200 Ltr. 1200 Ltr. 1000 Ltr.

1.2.3 Type Conical End. Conical End. Conical End.

1.2.4 Material of the tank SS-304 SS-304 SS-304

1.2.5 Thickness 3 mm. 3 mm. 3 mm.

1.2.6 Motorised Stirrer/agitator Provided Provided ( Provided

1.2.7 Breather with vent Provided Provided Provided

1.2.8 Level switch Provided Provided Provided

1.2.9 Level gauge Provided Provided Provided

1.2.10 Hand pump with flexible

hose.

One (1) One (1) Not applicable.

Dissolving basket Not applicable. Not applicable. Provided

1.3.0 METERING PUMP

1.3.1 Type of pump Positive displacement (Plunger type) Not applicable.

1.3.2 Mode of control Manual Manual Not applicable.

1.3.3 No. of pumps motor

assembly.

Two (2) nos. (2X100%) Two (2) nos. (2X100%) Not applicable.

1.3.4 Capacity (LPH) 0-50 LPH 0-50 LPH Not applicable.

1.3.5 Discharge pressure

(Kg/Cm

2

)

45 Kg/Cm

2

45 Kg/Cm

2

Not applicable.

1.3.6 All Wetted parts of pumps. SS-304 SS-304 Not applicable.

1.4.0 STRAINERS Not applicable.

1.4.1 No. of strainers Two (2X100%) Two (2X100%) Not applicable.

1.4.2 Type Y-Type Y-Type Not applicable.

1.4.3 Material of screen SS 304 SS 304 Not applicable.

1.4.4 Mesh Size 50(BS) 50(BS) Not applicable.

1.5.0 PIPING

1.5.1 Material SS-304 SS-304 SS-304

1.5.2 Material code ------------------ASTM A 312 TP 304 (Seamless)------

1.5.3 Diameter Main, Sampling & Drain Pipe-25 NB and Overflow pipe-25 NB

1.6.0 VALVES

1.6.1 Body, Cover, Yoke & Trim

Material

SS-304 SS-304 SS-304

1.6.2 Weld ends Socket weld ends Socket weld ends Socket weld ends

1.7.0 Fittings Forged steel to A182 F304, Dimension to ANSI B 16.11 socket weld ends.

1.8.0 Structural steel IS 2062 IS 2062

1.9.0 Flanges Pump suction /

discharge

-----------------ANSI B 16.5 CL 150 / ANSI B 16.5 CL 300----

1.9.1 RATING

1.9.1.1 Suction side ----------------------------Class ASA 150-----------------------------

1.9.1.2 Discharge side ----------------------------Class ASA 300-----------------------------

Page 6 of 12

DESIGN BASIS & CAPACITY SELECTION CRITERIA

HYDRAZINE DOSING

INPUT DATA

-MAX FLOW RATE AT DEARATOR OUTLET A T/HR 1720

-OPERATING PRESSURE AT DEARATOR OUTLET B KG/CM2(g) = 6.5

-DISSOLVED O2 AT DEARATOR OUTLET C ppm = 0.007

-NO. OF DEARATORS D No. = 1

-MAX FLOW RATE AT CEP DISCHARGE E M3/HR = 1386

-OPERATING PRESSURE AT CEP DISCHARGE F KG/CM2(g) = 26.5

-DISSOLVED O2 AT CEP DISCHARGE G ppm. = 0.021

-RESIDUAL HYDRAZINE AT HP/LP BFP DISCHARGE H ppm. = 0.02

-CONCENTRATION OF HYDRAZINE SOLUTION TO BE

DOSED

I % = 0.5

-PUMP INCREASED CAPACITY FACTOR K = 70

-CONCENTRATION OF HYDRAZINE IN MEASURING TANK CM % 35

-CAPACITY OF THE TANK REQUIRED FOR L Hrs. = 24

-MARGIN ASSUMED FOR TANKS FOR SIZING M % = 20

HYDRAZINE DOSING AT DEARATOR OUTLET

PUMP SIZING

QUANTITY OF HYDRAZINE REQUIRED (QH) Gm/Hr. = A(2*C+H)*50 / 32 = 91.38

VOLUMETRIC FLOW Ltrs. (VFH) LPH = QH / I*100 / 1000 = 18.28

DESIGN CALCULATION FOR 500 MW. (REV-1)

CaL Page 1

HENCE PUMP CAPACITY REQUIRED LPH = VFH * 100 / K = 26.11

PUMP SELECTED CAPACITY LPH = = 50

DISCHARGE PRESSURE OF PUMP SELECTED KG/CM2(g) = = 45.00

HYDRAZINE DOSING AT CEP DISCHARGE

PUMP SIZING

QUANTITY OF HYDRAZINE REQUIRED (QH) Gm/Hr. = E(2*G+H)*50 / 32 = 134.27

VOLUMETRIC FLOW Ltrs. (VFH) LPH = QH / I*100 / 1000 = 26.85

HENCE PUMP CAPACITY REQUIRED LPH = VFH * 100 / K = 38.36

PUMP SELECTED CAPACITY LPH = = 50

DISCHARGE PRESSURE OF PUMP SELECTED KG/CM2(g) = = 45.00

TANK SIZING

CAPACITY OF THE TANK REQUIRED MXS Ltrs. = MAX(VFH )*

L*D*(100+M)/100

= 773.39

CAPACITY OF THE TANK SELECTED (X) Ltrs. = = 1200.00

FINAL PARAMETERS SELECTED FOR HYDRAZINE DOSING

PUMP CAPACITY (LPH) 50

PUMP PRESSURE Kg/CM2(g) 45

PREPERATION CUM METERING TANK CAPACITY (Ltrs.) 1200

CaL Page 1

Page 7 of 12

AMMONIA DOSING

INPUT DATA

-MAX FLOW RATE AT DEARATOR OUTLET A M3/HR 1720

-OPERATING PRESSURE AT DEARATOR OUTLET B KG/CM2(g) = 6.5

-NO. OF DEARATORS D No. = 1

-MAX FLOW RATE AT CEP DISCHARGE E M3/HR = 1386

-OPERATING PRESSURE AT CEP DISCHARGE F KG/CM2(g) = 26.5

-AMMONIA DOSING RATE G PPM 0.25

-CONCENTRATION OF AMMONIA SOLUTION TO BE DOSED I % = 2

-CONCENTRATION OF AMMONIA SOLUTION IN

MEASURING TANK

O % = 30

-PUMP INCREASED CAPACITY FACTOR K = 70

-CAPACITY OF THE TANK REQUIRED FOR L Hrs. = 24

-MARGIN ASSUMED FOR TANKS FOR SIZING M % = 20

AMMONIA DOSING AT DEARATOR OUTLET

PUMP SIZING

QUANTITY OF AMMONIA REQUIRED (QH) Gm/Hr. = A * G = 430.00

VOLUMETRIC FLOW Ltrs. (VFH) LPH = QH *100 / I / 1000 = 21.50

HENCE PUMP CAPACITY REQUIRED LPH = VFH * 100 / K = 30.71

PUMP SELECTED CAPACITY LPH = = 50

AMMONIA DOSING AT CEP DISCHARGE

PUMP SIZING

CaL Page 2

QUANTITY OF AMMONIA REQUIRED (QH) Gm/Hr. = E * G = 346.50

VOLUMETRIC FLOW Ltrs. (VFH) Ltrs. = QH *100 / I / 1000 = 17.33

HENCE PUMP CAPACITY REQUIRED LPH = VFH * 100 / K = 24.75

PUMP SELECTED CAPACITY LPH = = 50

DISCHARGE PRESSURE OF PUMP SELECTED KG/CM2(g) = = 45.00

TANK SIZING

CAPACITY OF TANK REQUIRED (RX) Ltrs. = max(VFH) * L*D*M = 619.20

CAPACITY OF TANK SELECTED (X) Ltrs. = = 1200.00

FINAL PARAMETERS SELECTED FOR AMMONIA DOSING

PUMP CAPACITY (LPH) 50

PUMP PRESSURE Kg/CM2(g) 45

PREPERATION CUM METERING TANK CAPACITY (Ltrs.) 1200

CaL Page 2

Page 8 of 12

INPUT DATA

NORMAL FLOW RATE OF ECW LINES M3/HR = 3943

LEAKAGE FROM ECW LINE (SAY) % = 1

RATE OF SODIUM HYDROXIDE SOLUTION TO BE DOSED(

NTPC RECOMM.)

PPM = 2

STRENGTH OF NAOH SOLUTION TO BE PREPARED IN THE

TANK

% = 1

TANK SIZING

BASED ON LEAKAGE

TOTAL LEAKAGE OF WATER IN ONE HR M3 = 39.43

QUANTITIY OF 100% SODIUM HYDROXODE REQUIRED GR/HR = 78.86

VOLUME OF NAOH SOLUTION REQD GR = 7886

LTR 7.886

TANK SIZE REQUIRED FOR ONE DAY LTR = 189.26

TANK SIZE SELECTED LTR 500.00

BASED ON INITIAL FILLING IN ECW Cycles

VOLUME OF DM WATER IN ECW LINE FOR BOILER

AUXILIARY

M3 = 142

VOLUME OF DM WATER IN ECW TANK FOR BOILER

AUXILIARIES

M3 = 10

VOLUME OF DM WATER IN ECW LINE FOR TG AUXILIARY M3 = 101

VOLUME OF DM WATER IN ECW TANK FOR TG

AUXILIARIES

M3 = 10

MAX VOLUME OF DM WATER FOR PASSIVATION M3 = 263

QUANTITIY OF SODIUM HYDROXODE 100% REQUIRED GR = 526.00

VOLUME OF NAOH SOLUTION REQD GR = 52600

LTR = 52.6

DESIGN CALCULATION FOR SODIUM HYDROXIDE TANK

CaL Page 3

TANK SIZE SELECTED LTR = 1000.00

FINAL PARAMETERS SELECTED FOR SODIUM HYDROXIDE

DOSING SYSTEM

TANK CAPACITY (Ltr) = 1000

CaL Page 3

Page 9 of 12

P

a

g

e

1

0

o

f

1

2

FALGUNI SAHA

2009.08.25

13:56:06

+05'30'

P

a

g

e

1

1

o

f

1

2

FALGUNI SAHA

2009.08.25

13:56:16

+05'30'

P

a

g

e

1

2

o

f

1

2

1

FALGUNI

SAHA

2009.08.25

13:57:11

+05'30'

Anda mungkin juga menyukai

- V 21302 - Rev.2 CDokumen133 halamanV 21302 - Rev.2 Cpandiangv100% (1)

- TAYLOR FORGE - SIF CALCS - ES 3.9.2 r0, Design & Forming of Extruded OutletsDokumen6 halamanTAYLOR FORGE - SIF CALCS - ES 3.9.2 r0, Design & Forming of Extruded OutletsDDBelum ada peringkat

- Check Valve DatasheetDokumen4 halamanCheck Valve DatasheetSeptian FirdausBelum ada peringkat

- MR For Pig LauncherrDokumen34 halamanMR For Pig LauncherrSandeepNBabuBelum ada peringkat

- Kuwait Oil Company (K.S.C.) : Engineering GroupDokumen15 halamanKuwait Oil Company (K.S.C.) : Engineering GroupAravindan Ganesh KumarBelum ada peringkat

- Input From Simulation Result From Table or Chart AssumptionDokumen31 halamanInput From Simulation Result From Table or Chart AssumptionMohamed Mamdouh AbdelHameed100% (1)

- Operating Manual Sec 12 - Chemical Injection - Rev0Dokumen6 halamanOperating Manual Sec 12 - Chemical Injection - Rev0Anonymous aIuHKoKZjBelum ada peringkat

- Mucog 1910502 Mec DS 055Dokumen12 halamanMucog 1910502 Mec DS 055vinodBelum ada peringkat

- Specification For Firewater Pump Package S 721v2020 08Dokumen90 halamanSpecification For Firewater Pump Package S 721v2020 08Serge RINAUDOBelum ada peringkat

- GAP Complete PDFDokumen389 halamanGAP Complete PDFHassan GDOURABelum ada peringkat

- Calcs 4Dokumen19 halamanCalcs 4Syariful Maliki NejstaršíBelum ada peringkat

- Pressure Safety Valve Sizing Calculation Rev 01Dokumen4 halamanPressure Safety Valve Sizing Calculation Rev 01Fari NazariBelum ada peringkat

- Pig Receiver Data Sheet 91303 - 8 InchDokumen4 halamanPig Receiver Data Sheet 91303 - 8 InchSinaBelum ada peringkat

- Pump Station Sample PagesDokumen5 halamanPump Station Sample PagesHedi Ben MohamedBelum ada peringkat

- Pig Launchers Recievers PDFDokumen9 halamanPig Launchers Recievers PDFgalih santosoBelum ada peringkat

- Pressure Vessel RulesDokumen15 halamanPressure Vessel RulesnirmalBelum ada peringkat

- vs1 DatasheetDokumen22 halamanvs1 DatasheetMojtabaBelum ada peringkat

- Mechanical Design Basics of Tall ColumnsDokumen45 halamanMechanical Design Basics of Tall Columnshardik5818Belum ada peringkat

- Limpet With Jacket Nozzle OrientationDokumen1 halamanLimpet With Jacket Nozzle OrientationArunkumar MyakalaBelum ada peringkat

- Pump SizeDokumen9 halamanPump SizedkumarBelum ada peringkat

- Diseño de ProcesoDokumen9 halamanDiseño de ProcesotinocamargoBelum ada peringkat

- Linan Dehydration UnitDokumen49 halamanLinan Dehydration UnitAndrew ArBelum ada peringkat

- Guide Document GE P312 4.1.2 I General ConsiderationsDokumen31 halamanGuide Document GE P312 4.1.2 I General ConsiderationsDiarista Thoma SaputraBelum ada peringkat

- Trip and Alarm Schedule-Rev-0Dokumen8 halamanTrip and Alarm Schedule-Rev-0anbesivam87_49857255Belum ada peringkat

- GF-WPK-J-CA-2001 - WP-K Calculation Note For Piping Stress Analysis - Rev 1 - RDokumen32 halamanGF-WPK-J-CA-2001 - WP-K Calculation Note For Piping Stress Analysis - Rev 1 - RRami KsidaBelum ada peringkat

- GBH Enterprises, LTD.: GBHE-EDG-0501Dokumen30 halamanGBH Enterprises, LTD.: GBHE-EDG-0501MosaddekBelum ada peringkat

- Coke Slurry PresentationDokumen27 halamanCoke Slurry PresentationAnupam VermaBelum ada peringkat

- MR and Technical Tender Pig Launcher 85c295Dokumen80 halamanMR and Technical Tender Pig Launcher 85c295Muthazhagan SaravananBelum ada peringkat

- v756373001xb - Mds Sludge Decant TankDokumen50 halamanv756373001xb - Mds Sludge Decant TankInamullah KhanBelum ada peringkat

- Overview of PV EliteDokumen35 halamanOverview of PV EliteVishaka ThekkedathBelum ada peringkat

- Ips e PR 850 PDFDokumen73 halamanIps e PR 850 PDFdeyanshu7Belum ada peringkat

- Korf Tutorial PDFDokumen17 halamanKorf Tutorial PDFAadi Khan100% (1)

- API 14C TablesDokumen10 halamanAPI 14C TablessegunoyesBelum ada peringkat

- Test Separator Trailer Prices 2013Dokumen3 halamanTest Separator Trailer Prices 2013hermit44535Belum ada peringkat

- CN Scrubber Dn3500 Rev04Dokumen58 halamanCN Scrubber Dn3500 Rev04becemBelum ada peringkat

- Process Engineer - Blowdown Valve (BDV) To Flare SystemDokumen4 halamanProcess Engineer - Blowdown Valve (BDV) To Flare SystemIOCPC100% (1)

- SEA WATER PresentationDokumen30 halamanSEA WATER Presentationmiths_0087100% (1)

- Norsok Standard Process SystemsDokumen131 halamanNorsok Standard Process SystemsJohnBelum ada peringkat

- 3-Phase Test Separators VVFDokumen2 halaman3-Phase Test Separators VVFPetroFisicBelum ada peringkat

- PE PipeDokumen54 halamanPE PipeMuhammad SalmanBelum ada peringkat

- MC-001-DS-M-002-120 DS For Condensate Separator Rev ADokumen4 halamanMC-001-DS-M-002-120 DS For Condensate Separator Rev AHeldiyan RamdhanBelum ada peringkat

- Bes 800 0103 PDFDokumen25 halamanBes 800 0103 PDFChuretaVieiraBelum ada peringkat

- bb1 DatasheetDokumen14 halamanbb1 DatasheetMojtabaBelum ada peringkat

- JET - DR1 - GI - 001 - Reva Issued 20130110 PDFDokumen1 halamanJET - DR1 - GI - 001 - Reva Issued 20130110 PDFFadria HandayaniBelum ada peringkat

- Equivalent PressureDokumen1 halamanEquivalent PressureSarfaraz KhanBelum ada peringkat

- Restriction Orifice Final CalculationDokumen1 halamanRestriction Orifice Final CalculationJasperTanBelum ada peringkat

- Design Guide Pumps and Pump Circuits: 650100-ME-DEG-0035 24-Oct-17Dokumen97 halamanDesign Guide Pumps and Pump Circuits: 650100-ME-DEG-0035 24-Oct-17Debraj PaulBelum ada peringkat

- Engineered Engineered: Thermal Maintenance S Stems For Urea Systems For Urea Applications PPDokumen31 halamanEngineered Engineered: Thermal Maintenance S Stems For Urea Systems For Urea Applications PPdzungBelum ada peringkat

- OLGA 7-NotesDokumen10 halamanOLGA 7-NotesraminabkBelum ada peringkat

- Sample Treated Water Storage Tank Detailed DrawingDokumen8 halamanSample Treated Water Storage Tank Detailed DrawingnamasralBelum ada peringkat

- Technical Evaluation HAM BAKERDokumen1 halamanTechnical Evaluation HAM BAKEReko123Belum ada peringkat

- Bes 800-103Dokumen25 halamanBes 800-103Jose GuerreiroBelum ada peringkat

- FB-150 FQ-150 Basket Strainer PDFDokumen1 halamanFB-150 FQ-150 Basket Strainer PDFroyert80Belum ada peringkat

- Pressure Testing of Unfired Pressure Vessels: ScopeDokumen9 halamanPressure Testing of Unfired Pressure Vessels: Scopebenedicto soto mestanzaBelum ada peringkat

- Case Study - Crude Oil Desalter VesselDokumen2 halamanCase Study - Crude Oil Desalter VesselAshfaq AnwerBelum ada peringkat

- Trac Loc BrochureDokumen4 halamanTrac Loc Brochureulas100% (1)

- Bulletin 71.4MR108 PDFDokumen20 halamanBulletin 71.4MR108 PDFBledarBelum ada peringkat

- Basis of Design - Pig Reciever 16 Design 2014Dokumen27 halamanBasis of Design - Pig Reciever 16 Design 2014Andreas SchlagerBelum ada peringkat

- 96 CH Report DHI 96 2021-22 (LPG Bullet)Dokumen114 halaman96 CH Report DHI 96 2021-22 (LPG Bullet)Gilberto YoshidaBelum ada peringkat

- Chemical DosingDokumen24 halamanChemical DosingIskerBelum ada peringkat

- Recommended Noise CriterionDokumen4 halamanRecommended Noise CriterionsuparnabhoseBelum ada peringkat

- Cooling Water Treatment NoteDokumen13 halamanCooling Water Treatment Notesuparnabhose100% (1)

- REL-DBR Mech-R1.Dokumen17 halamanREL-DBR Mech-R1.suparnabhoseBelum ada peringkat

- k8v07 Raikheda CHH GlanceDokumen4 halamank8v07 Raikheda CHH GlancesuparnabhoseBelum ada peringkat

- Boiler Performance Test ProcedureDokumen16 halamanBoiler Performance Test ProceduresuparnabhoseBelum ada peringkat

- Section B1Dokumen7 halamanSection B1suparnabhoseBelum ada peringkat

- M574LEA7 - Mandatory Spares BTGDokumen23 halamanM574LEA7 - Mandatory Spares BTGsuparnabhoseBelum ada peringkat

- F146c-Ma-02 CHP List of Equipment & Material - Reviewed Track ChangeDokumen10 halamanF146c-Ma-02 CHP List of Equipment & Material - Reviewed Track ChangesuparnabhoseBelum ada peringkat

- Steam TurbinesDokumen24 halamanSteam Turbinesrt_sendhilBelum ada peringkat

- Volume - Ii Section - M0 Technical Specification: Specification For Compressed Air System GMR Energy LimitedDokumen50 halamanVolume - Ii Section - M0 Technical Specification: Specification For Compressed Air System GMR Energy LimitedsuparnabhoseBelum ada peringkat

- F146c-Ma-01 Specification For Coal Transportation SystemDokumen23 halamanF146c-Ma-01 Specification For Coal Transportation SystemsuparnabhoseBelum ada peringkat

- Rosa Flowelement DBR Rev1 10april'2007Dokumen7 halamanRosa Flowelement DBR Rev1 10april'2007suparnabhoseBelum ada peringkat

- Compressors Capacity ControlDokumen12 halamanCompressors Capacity Controlvalentinlupascu33100% (1)

- Final Approved DM Plant Riepl RTPP Cem 119 R 5004 r3Dokumen148 halamanFinal Approved DM Plant Riepl RTPP Cem 119 R 5004 r3suparnabhoseBelum ada peringkat

- 11V02 Acc SPC M 0001 V2 Part BDokumen100 halaman11V02 Acc SPC M 0001 V2 Part BsuparnabhoseBelum ada peringkat

- 11V02 Acc SPC M 0001 V2 Part ADokumen182 halaman11V02 Acc SPC M 0001 V2 Part Asuparnabhose100% (1)

- 11V02 Acc SPC M 0001 V2 Part CDokumen39 halaman11V02 Acc SPC M 0001 V2 Part CsuparnabhoseBelum ada peringkat

- 11V02 Acc SPC M 0001 V2 Part DDokumen58 halaman11V02 Acc SPC M 0001 V2 Part DsuparnabhoseBelum ada peringkat

- k8v12 m1 Section IDokumen32 halamank8v12 m1 Section IsuparnabhoseBelum ada peringkat

- Cooling Tower CalculationDokumen32 halamanCooling Tower CalculationMohammed Alnefayei100% (10)

- Coal Feeder Catalog (Color)Dokumen10 halamanCoal Feeder Catalog (Color)suparnabhoseBelum ada peringkat

- Project Thesis Refining of Used Motor Oil Using Solvent ExtractionDokumen77 halamanProject Thesis Refining of Used Motor Oil Using Solvent ExtractionSyed Waqas Haider50% (2)

- Phytochemical StudyDokumen4 halamanPhytochemical StudyBayanmunkh AltangerelBelum ada peringkat

- Antioxidant Capacity of Some Turkish Pomegranate Genotypes Grown in Siirt RegionDokumen6 halamanAntioxidant Capacity of Some Turkish Pomegranate Genotypes Grown in Siirt RegioniajerBelum ada peringkat

- CEeNews2 04Dokumen6 halamanCEeNews2 04Antonio MezzopreteBelum ada peringkat

- Activated Sludge Microbiology Problems and Their ControlDokumen21 halamanActivated Sludge Microbiology Problems and Their ControlDaniel Pérez100% (1)

- 8.2 (B) Identification of GasesDokumen20 halaman8.2 (B) Identification of GasesFidree AzizBelum ada peringkat

- Proctor Compaction TestDokumen5 halamanProctor Compaction Testsanduni89% (28)

- DesalinizaciónDokumen48 halamanDesalinizaciónLoren AlayoBelum ada peringkat

- Waterproofing and Weatherproofing MaterialsDokumen37 halamanWaterproofing and Weatherproofing MaterialsSanjay Areyoukiddingme Somnath50% (2)

- Biosurfactant 7Dokumen8 halamanBiosurfactant 7Aranrie MosesBelum ada peringkat

- MCQs All With KeysDokumen47 halamanMCQs All With KeysSana UllahBelum ada peringkat

- Biochem Lipids Module 5Dokumen16 halamanBiochem Lipids Module 5Jemina Rafanan RacadioBelum ada peringkat

- 04 Script Examples Solid Liquid ExtractionDokumen11 halaman04 Script Examples Solid Liquid ExtractionLei YinBelum ada peringkat

- A Review On Energy Harvesting Potential From Living Plants: Future Energy ResourceDokumen17 halamanA Review On Energy Harvesting Potential From Living Plants: Future Energy ResourceEzequiel CancliniBelum ada peringkat

- BOS-M.Sc. Syllabus - 23-09-VBSPU 2022Dokumen57 halamanBOS-M.Sc. Syllabus - 23-09-VBSPU 2022Susheel MishraBelum ada peringkat

- Grade 11 Physics Module6Dokumen83 halamanGrade 11 Physics Module6JohnRenzoMolinarBelum ada peringkat

- The Ideal Gas Law and Gas Stoichiometry Hon)Dokumen3 halamanThe Ideal Gas Law and Gas Stoichiometry Hon)Camilo RosasBelum ada peringkat

- T1 - Standard Thermodynamic QuantitiesDokumen17 halamanT1 - Standard Thermodynamic QuantitiesNorhaszanBelum ada peringkat

- Kesetimbangan LarutanDokumen123 halamanKesetimbangan LarutanFirda SafitriBelum ada peringkat

- 16ME104-SHREYAS Sem Rep VtuDokumen20 halaman16ME104-SHREYAS Sem Rep VtuPhone Pe0% (1)

- Studies On Chemical Resistance of Low Water/cement Ratio ConcretesDokumen10 halamanStudies On Chemical Resistance of Low Water/cement Ratio ConcretesMaziar MehravarBelum ada peringkat

- Experiment No. 4.1Dokumen4 halamanExperiment No. 4.1Rianne Danielle CarsulaBelum ada peringkat

- Spectrofluorimetry: Minia University Faculty of Pharmacy Department of Analytical ChemistryDokumen35 halamanSpectrofluorimetry: Minia University Faculty of Pharmacy Department of Analytical ChemistryAhmed Zaghloul100% (2)

- Bio Assignmnet 1Dokumen15 halamanBio Assignmnet 1api-535572482Belum ada peringkat

- Standard Thermo Data 298 KDokumen12 halamanStandard Thermo Data 298 KRebecca FrancisBelum ada peringkat

- tmp2D3D TMPDokumen7 halamantmp2D3D TMPFrontiersBelum ada peringkat

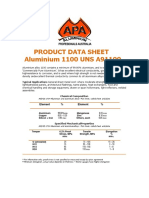

- 1100-Data Sheets PDFDokumen3 halaman1100-Data Sheets PDFPaturu VijayBelum ada peringkat

- QC of SuppositoriesDokumen36 halamanQC of Suppositoriesroma imtiazBelum ada peringkat

- Sanosil S010 - EngDokumen11 halamanSanosil S010 - EngSophie TranBelum ada peringkat

- Etatron Chemical Resistance Chart UploadedDokumen35 halamanEtatron Chemical Resistance Chart Uploadedatiq124Belum ada peringkat