Dynamic Model For LNG

Diunggah oleh

Vinh Do ThanhJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Dynamic Model For LNG

Diunggah oleh

Vinh Do ThanhHak Cipta:

Format Tersedia

Int. J. of Thermodynamics, Vol. 11 (No.

3) 123

Int. J. of Thermodynamics ISSN 1301-9724

Vol. 11 (No. 3), pp. 123-131, September 2008

A Dynamic Model for Liquefied Natural Gas Evaporation

During Marine Transportation

George G. Dimopoulos

*

, Christos A. Frangopoulos

School of Naval Architecture and Marine Engineering,

National Technical University of Athens Heroon Polytechniou 9,

157 73 Zografou Greece

Abstract

Marine transport of natural gas, predominately in the form of Liquefied Natural Gas

(LNG), is of growing importance in the global energy markets. LNG is transported with

vessels having cryogenic tanks without any means of external refrigeration. Hence, a

significant fraction of the cargo LNG volume evaporates during voyage, which is usually

called Boil-Off Gas (BOG). According to the type of the energy system, BOG can be

utilized as fuel, reliquefied or burned in an oxidizer. The handling of the boil-off gas during

the LNG vessel operation and the assessment of its thermodynamic properties are key

issues in the technical and economic assessment of the complete marine energy systems of

LNG vessels. A detailed dynamic boil-off model has been developed, which accounts for

the variation of BOG mass flow, composition and thermodynamic properties during

voyage. The model employs coupled non-linear vapor liquid phase equilibrium

thermodynamic equations and differential conservation equations describing the evolution

of LNG quantity and composition with time. Various solution and time discretization

schemes have been tested to assess the solution accuracy and stability. The model has been

used to investigate the variation of the LNG and BOG quantity, composition and

thermodynamic properties during typical voyage profiles of a case study LNG vessel.

Variations of the thermodynamic properties and of the quantity of BOG in the range of 6 to

10% during voyage have been found, having a significant impact in operation modes and

fuel consumption of the energy system. Results have been also compared with the

traditional approaches used in the marine technical practice.

Keywords: Liquefied natural gas, boil-off gas, vapor-liquid equilibrium, dynamic

simulation.

1. Introduction

Marine transport of natural gas is in the

form of Liquefied Natural Gas (LNG). LNG is

transported with vessels having cryogenic tanks

without any means of external refrigeration.

Therefore, a significant fraction of the cargo

LNG volume evaporates during voyage, which is

usually called Boil-Off Gas (BOG). According to

the type of the propulsion system of the vessel,

BOG can be utilized as fuel, reliquefied or

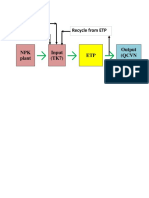

burned in a gasification unit as depicted in

Figure 1.

The assessment of the BOG quantity,

composition and thermodynamic properties

during voyage is of key importance for the

technical and economic assessment of the

complete marine energy systems of LNG vessels.

In this study a detailed dynamic boil-off

model has been developed, which accounts for

the variation of BOG mass flow, composition

and thermodynamic properties during voyage.

The model employs vapor-liquid equilibrium

calculations of the LNG mixture coupled with

dynamic species conservation over time.

LNG

BOG

Propulsion

(commonly used as primary fuel)

Reliquefication

(novel concept)

Thermal Oxidation / Gasification

(safety requirement)

Figure 1. Utilization of Boil Off Gas onboard

LNG vessels.

*

Author to whom correspondence should be

addressed. gdimop@lme.ntua.gr

Int. J. of Thermodynamics, Vol. 11 (No. 3) 124

This model is intended to be used in an

overall thermoeconomic optimization algorithm

for the complete energy system of LNG vessels.

Therefore, several simplifying assumptions have

been made in order to reduce the computing

time, while at the same time, preserving the

accuracy of the estimates of BOG mass flow,

composition and thermodynamic properties

during voyage.

2. Vapor-liquid Equilibrium

Liquefied natural gas is a multi-component

mixture, consisting of highly volatile organic and

inorganic species. Therefore, the coexistence of

both vapor and liquid phases of the LNG mixture

has to be considered. The equilibrium conditions

between vapor and liquid phase of a mixture of

n

S

species, are determined via a set of equality

conditions of the Gibbs free energy of each

species in each phase (Gyftopoulos and Beretta,

1991; Smith, et al., 1996):

i i

g S

G G , i 1, , n = =

l

K (1)

A more convenient, yet equivalent, set of

Vapor-Liquid Equilibrium (VLE) conditions is

derived by the use of fugacity of the species,

which is directly related to Gibbs free energy

(Gyftopoulos and Beretta, 1991). The use of

fugacity results in a significant simplification of

the VLE calculations and equilibrium conditions

are now described by equality of fugacity

between phases (Gyftopoulos and Beretta, 1991;

Smith, et al., 1996):

i i

g S

f f , i 1, , n = =

l

K (2)

In the general case, when considering real

gas or liquid behavior, fugacity of each species is

a function of both pressure and temperature. In

addition, fugacity of pure species is usually

expressed with the aid of fugacity coefficient,

according to the definition:

( ) ( ) f P, T P, T P = (3)

Fugacity coefficients are calculated from

the Equation Of State (EOS):

( ) ( )

0

P

P

dP

ln Z P, T 1

P

=

(4)

The explicit expression of the compressibility

factor Z depends on the selected EOS used to

describe the pure species and mixture behavior

(Gyftopoulos and Beretta, 1991).

It is noted that the coefficients of all non-

ideal EOS for pure species are, in general,

different from those describing the behavior of a

mixture (Nasrifar and Bolland, 2006). In that

respect, based on Eq. (4), the fugacity coefficient

of a species i in its pure form has a different form

and value than the one when considering the

same species as a constituent of a mixture:

i i

(5)

The fugacity of a species i in a vapor

mixture is given (Smith, et al., 1996):

( ) ( )

i i i

g g g

f P, T P, T x P = (6)

The fugacity of a species i in a liquid

solution is given by (Smith, et al., 1996):

( ) ( )

i i i i i

i sat sat i

f P, T P , T x P C =

l l l

(7)

where C

i

is the Poynting correction factor, which

is defined by:

( )

i i

sat

i

v P P

C exp

RT

(

(

=

(

l

(8)

By inserting Eqs. (6), (7) and (8) in Eq. (2),

the general expression of the VLE conditions is

transformed to:

i i i i i

g g i sat i

S

x P x P C

i 1, , n

=

=

l l

K

(9)

Molar compositions of both the vapor phase

mixture and the liquid phase solution can be

determined by solving the system of VLE

conditions of Eq. (9) coupled with the necessary

molar conservation equations for a given

pressure and temperature of the thermodynamic

system.

For moderate pressures the Poynting

correction factor is close to unity (Gyftopoulos

and Beretta, 1991). In addition, under the

assumption of ideal gas behavior of the vapor

phase mixture, Eq. (6) is simplified to:

i i

g g

f x P = (10)

Furthermore, if ideal behavior of the liquid phase

solution is assumed, Eq. (7) is simplified to:

( )

i i i

sat

f x P T =

l l

(11)

Therefore, under these ideal behavior

assumptions of both the vapor and liquid phase

mixtures, the VLE conditions are simplified to

the ideal Raoults law (Gyftopoulos and Beretta,

1991):

( )

i i i

g sat

S

x P x P T

i 1, , n

=

=

l

K

(12)

The VLE conditions of Eq. (9), combined

with appropriate equations of state suitable for

natural gas mixtures, have been extensively used

Int. J. of Thermodynamics, Vol. 11 (No. 3) 125

for the accurate determination of natural gas

thermodynamic properties (Morch, et al., 2006;

Nasrifar and Bolland, 2006; Nasrifar, et al.,

2005; Ratanapisit and Ely, 1999). These studies

are more focused on providing methodology and

thermodynamic data for natural gas production,

processing, storage and pipeline transportation.

The marine transportation of LNG is

characterized by low (near atmospheric) storage

pressures and cryogenic temperatures (about

o

160 C ). In addition, the LNG mixture is also

characterized by the significantly higher

concentration of methane (above 80%) than the

concentration of all other constituents. In these

conditions, the assumptions of ideal gas for the

vapor phase mixture and of ideal solution for the

liquid phase are good approximations of the

behavior of the mixture (Gyftopoulos and

Beretta, 1991) and a good starting point for

modeling the multi-component mixture VLE.

In this study assumptions of ideal behavior

have been used, in order to assess the VLE

behavior of the complete LNG mixture.

However, the methodology and modeling

approach presented in Section 3 can be readily

extended to be used for real gas and liquid

behavior, with the aid of a suitable equation of

state for LNG constituent species and mixture

(Nasrifar and Bolland, 2006).

In addition, the developed model, presented

in Section 3, is a bulk evaporation model that

neglects surface evaporation effects. Complex

and detailed surface evaporation models of LNG

mixtures inside cryogenic tanks are widely

applied for the prediction of LNG roll-over,

sloshing motion and spill phenomena both in

land storage and marine transportation

(Heestand, et al., 1983; Munakata, et al., 1995;

Oestvold, 2006). However, these models require

a finite element analysis of the LNG storage tank

and therefore, are time consuming requiring a

large number of inputs. The purpose of this study

was to produce a simple model, with short

execution time capable of giving an accurate

estimate of the quantity and thermodynamic

properties of boil-off gas over time. Such a

model, of course, cannot be used in order to

simulate complex evaporation phenomena such

as rollover and sloshing inside LNG tanks.

3. Lng Evaporation Model

3.1. Traditional Approach

In the majority of LNG propulsion studies

appearing in the literature (Andrianos, 2006;

Levander and Hannula, 2004; MAN-B&W,

2004), certain drastic simplifying assumptions

are made regarding the available BOG quantity

and composition. Namely, the daily boil-off rate

is considered constant and the thermodynamic

properties of BOG are equal to those of pure

methane, which is the main constituent of natural

gas.

These assumptions may be acceptable for

preliminary evaluation of systems, but for

detailed thermoeconomic simulation and

optimization studies they have to be

reconsidered. This issue is empirically

acknowledged by the LNG propulsion system

designers (Kuver, et al., 2002; Laurilehto, 2000).

3.2. Boil-off gas Production

A detailed boil-off model is proposed in

this study. The developed model is based on the

solution of the VLE system of equations for the

LNG mixture within the cargo tanks of the

vessel.

The VLE is considered under the

assumptions of ideal behavior of both the

gaseous phase mixture and the liquid phase

solution. The model also takes into account that

the mass of BOG depends on the heat transfer

between the external environment and the LNG

through the cargo tank insulation (Chen, et al.,

2004).

At any instant of time (t) of the voyage of

the vessel the VLE equations, which correspond

to a given LNG volume, composition and cargo

tank temperature, are:

( )

i i i

t

g g sat

S

x P x P

i 1, , n t [0, ]

=

=

l

K

(13)

By definition the molar composition of a mixture

or solution is:

i

i S

tot

N

x , i 1, , n

N

= = K (14)

Introducing Eq. (14) to Eq. (13) yields:

i i

i

tot tot

t

g

g sat

g

N N

P P

N N

| |

= |

|

\

l

l

(15)

The saturation pressure of each LNG

constituent is calculated by a generalization of

the Clausius Clapeyron relation called Antoine

equation (Smith, et al., 1996). Antoine equation

is a statistical three parameter fit of experimental

saturation pressure data:

( )

i

t i

10 sat i t

V i

b

log P a

T c

=

(16)

The values of the experimentally derived

equation parameters a, b and c are depicted in

TABLE I, for certain typical LNG constituents

used in this study (NIST, 2007).

Int. J. of Thermodynamics, Vol. 11 (No. 3) 126

The number of moles of each species is

conserved within the overall LNG mixture. The

total number of moles of each LNG species is

equal to the sum of the number of moles in the

vapor and liquid phase.

i i i

t t t

LNG g S

N N N , i 1, , n t = + =

l

K (17)

The energy required for the LNG

vaporization process is provided by the heat

transferred from the cargo tank to the liquid

(Chen, et al., 2004). At any instant of time, the

thermal energy entering the LNG volume is:

t

HT HT

dE Q dt =

&

(18)

The molar quantity of produced BOG is:

tot

LNG

t

t HT

g

t

vap

dE

N , t

h

=

%

(19)

The value of the heat transfer rate

HT

Q

&

can

be either analytically calculated by detailed heat

transfer analysis of the tank structure with its

insulation or, as used in this case, by empirical

estimation based on the average boil-off rate of

typical LNG vessels (Kuver, et al., 2002).

The enthalpy of vaporization of each

species (i) in the LNG mixture is calculated by

an experimentally derived equation (Somayajulu,

1988) of the form:

( ) ( )

( ) ( )

i

i

i i

m 1 m

t t t

vap i i i i

2 m 3 m

t t

i i i i

t

cr V t

i

cr tr

h A X B X

C X D X

T T

where: X

T T

+

+ +

= +

+ +

%

(20)

and A, B, C, D and m are substance dependent

parameters.

The total enthalpy of vaporization for the

LNG is:

S

LNG i i

n

t t t

vap LNG vap

i 1

h x h

=

=

% %

(21)

The values of the coefficients appearing in Eq.

(20) for various substances can be found in

(Somayajulu, 1988) and those used in this study

are given in TABLE I.

Equations (15), (17) and (19) constitute a

non linear system of

S

2 n 1 + equations. The

main parameters of this system are the cargo tank

temperature and the LNG mixture molar quantity

of each species (

i

LNG

N ). Equations (18), (21) and

(20) are auxiliary parameter equations for the

aforementioned system. The unknown quantities

of this system are the vapor phase (BOG) molar

quantities (

i

g

N ), the liquid phase molar

quantities (

i

N

l

) and the gas pressure (P

g

). The

number of unknowns is also

S

2 n 1 + , thus the

system can be solved with an appropriate non

linear method.

Once the system of equations is solved, the

molar compositions of liquid phase and BOG are

evaluated with Eq. (14). In addition, the lower

heating value and the molecular weight of BOG

are evaluated with the following equations:

S

i

n

t t

g g i

i 1

MW x MW

=

=

(22)

S

g i i

g

g

n

t t

u g u

i 1

t

u

t

u t

g

H x H

H

H

MW

=

=

=

% %

%

(23)

3.3. Dynamic Model

The variation of BOG quantity and

thermodynamic properties is assessed by a set of

differential equations modeling the dynamic

species conservation over time.

The rate of change of the molar quantity of

a given LNG species depends on BOG

evaporation rate, the need of additional boil-off

gas which is forcedly evaporated to cover the

propulsion needs of the vessel and the existence

of a reliquefication plant onboard the vessel.

Forced boil-off and reliquefication rates are

what are usually called in dynamic systems

terminology external disturbances of the

dynamic system, due to the fact that they are

time dependent functions the form of which is

determined by factors independent of the system

under study, i.e. the LNG evaporation process.

The set of differential equations describing

the dynamic species conservation is:

i

i i i

LNG

g frc rlq s

dN

N N N , i=1 n

dt

= +

& & &

K (24)

The BOG rate is calculated with the procedure

described in subsection 3.2 while the forced boil-

off and reliquefication rates are functions of the

LNG mixture composition, time, ship design and

voyage propulsion requirements:

( )

i i 1 n

s

frq frq LNG s

N f N , t, , i=1 n

=

=

1

u

K

&

K (25)

( )

i i 1 n

s

rlc rlc g s

N f N , t, , i=1 n

=

=

2

u

K

&

K (26)

where u

1

and u

2

are variables representing other

influences such as required BOG flow for

propulsion and auxiliary power, existence and

Int. J. of Thermodynamics, Vol. 11 (No. 3) 127

capacity of reliquefication plant, etc.

To account for temperature changes in the

LNG tanks during voyage due to heat transfer,

the dynamic model is supplemented with a

temperature rate of change equation:

( )

V

dT

c t

dt

= (27)

where c(t) is an empirical function or constant,

derived from experimental observations on LNG

vessels (Kuver, 2005; Kuver, et al., 2002).

TABLE I. VALUES OF PARAMETERS FOR EVALUATION OF THE SATURATION PRESSURE

AND ENTHALPY OF VAPORIZATION (NIST, 2007; Somayajulu, 1988).

Antoine equation Eq. (16) Enthalpy of vaporization equation Eq. (20), m = 0.375

Species

a

i

b

i

c

i

A

i

B

i

C

i

D

i

T

tr, i

(K)

T

cr, i

(K)

CH

4

3.98950 443.028 -0.490 9.06452 1.52 -3.0519 1.18854 90.68 190.55

C

2

H

6

4.50706 791.300 -6.422 18.00355 4.43633 -10.2366 5.66822 90.348 305.33

C

3

H

8

4.01158 834.260 -22.763 23.97875 5.87352 -13.7851 8.79046 85.47 369.8

C

4

H

10

4.70812 1200.475 -13.013 27.75109 6.80611 -14.8685 9.12374 134.86 425.16

N

2

3.73620 264.651 -6.788 6.15835 0.77101 -1.59378 0.69579 63.15 126.2

4. Simulation Model

4.1. Model Description

The detailed dynamic BOG production

model, described in Subsections 3.2 and 3.3, has

been implemented in the MATLAB/Simulink

graphical simulation environment.

The model consists of three major groups of

sub-models (modules): The thermodynamic

calculations sub-models, the vapor-liquid

equilibrium non-linear algebraic solver module,

and the differential equations dynamic sub-

models. The main parts of the simulation model

structure in the MATLAB/Simulink environment

are depicted in Figure 2.

4.2. Numerical Solution

Various differential equation solvers and

time discretization schemes have been tested to

assess the solution accuracy and stability.

Three ordinary differential equation (ODE)

solvers have been tested: The Euler (ODE1), the

Runge-Kutta (ODE4) and the Dormand-Price

(ODE5) solver (Forsythe, et al., 1977). The

effect of the solver choice on solution accuracy

has been assessed. The calculated mass of BOG,

as a function of time, for solving the dynamic

model with each one of the three ODE solvers is

depicted in Figure 3.

The results indicate that ODE4 and ODE5

solvers yield exactly the same results, while

ODE1 solver yields only slightly different results

compared with the other two solvers. However,

the differences in results obtained with the ODE1

solver compared to the results from the other two

solvers are very small. Therefore, the Euler

scheme (ODE1 solver) has been used in this

study due to its simplicity and short execution

time.

A voyage of an LNG vessel and thus the

boil-off of gas last from 5 to 20 days at a

maximum. Therefore, the duration of the

dynamic boil-off phenomenon is of the same

order of magnitude.

Two time discretization schemes have been

considered: time intervals of one hour and time

intervals of one day. The effect of the

discretization schemes choice on the solution

accuracy has been assessed. The calculated mass

of BOG, as a function of time, obtained with

each one of the two discretization schemes is

depicted in Figure 4.

The results indicate that there is a small

difference in the results produced with the two

discretization schemes. By integration of the

instantaneous mass of BOG, the total mass of

BOG during a voyage has been calculated. The

total mass of BOG during voyage with one hour

time intervals is 2316.6 tons, while with one day

time intervals is 2315.9 tons. The difference

between the two values is 0.03%. Therefore, the

coarse one day time intervals have been used in

this study.

The aforementioned analysis indicated that

the proposed model can be implemented on a

computer code using a very simple ODE solver,

like the Euler scheme, and a coarse discretization

of time intervals up to 24 hours. These features

make the proposed model easy to implement

with a very short execution time.

Thus this model is particularly suitable to

be integrated in wider thermoeconomic

simulation and optimization studies of energy

systems of LNG vessels.

Int. J. of Thermodynamics, Vol. 11 (No. 3) 128

Initial

Calculations

LNG volume

density

composition

LNG

Molar

Composition

Set of

Differential Equations

Initial

Conditions

Natural

BOG

Forced

BOG

Liquid

Molar

Composition

Time variation

Initial Tank

Temperature

Tank Temperature

Variation

Thermodynamic Calculations

Liquid Molar

Composition

Species Saturation

Pressures

LNG Enthalpy of

Vaporization

VLE Calculations

Tank

Heat Transfer Rate

Initial Tank

Pressure

Natural

BOG

Forced BOG

Demand

Forced

BOG

Figure 2. BOG simulation model structure in the MATLAB/Simulink environment.

1.069

1.070

1.071

1.072

1.073

1.074

1.075

1.076

1.077

1.078

1.079

1.080

0 10 20 30

Sailing Days

B

O

G

m

a

s

s

f

l

o

w

(

k

g

/

s

)

ODE1

ODE4

ODE5

Figure 3. BOG mass flow derived with each one

of the ODE solvers.

1.069

1.070

1.071

1.072

1.073

1.074

1.075

1.076

1.077

1.078

1.079

1.080

0 10 20 30

Sailing Days

B

O

G

m

a

s

s

f

l

o

w

(

k

g

/

s

)

t = 24 h

t = 1 h

Figure 4. Variation of solution with respect to

the choice of the discretization interval.

5. Results

5.1. Case Study

The model has been used to investigate the

variation of the LNG and BOG quantity,

composition and thermodynamic properties

during typical voyage profiles of a case study

LNG vessel.

The initial composition of a typical Arab

gulf LNG, as well as typical values of the tank

heat transfer rate (see Eq. (18)) and temperature

rise rate (see Eq. (27)) are given in TABLE III.

The value of the heat transfer rate has been

calculated based on empirical estimation of the

average boil-off rate of typical LNG vessels

(Kuver, et al., 2002). The temperature rise rate

has been also derived from experimental data

from typical LNG vessels (Kuver, 2005; Kuver,

et al., 2002).

TABLE II. TYPICAL LNG COMPOSITION

AND CARGO PARAMETERS.

Substance Composition

(% molar)

Methane CH

4

89.90

Ethane C

2

H

6

6.00

Propane C

3

H

8

2.20

Butane C

4

H

10

1.50

Nitrogen N

2

0.40

HT

Q 600 kW =

&

@ter minal o

V

T 163 C = ,

V

dT 0.5 K / day =

3

V 150000 m =

Int. J. of Thermodynamics, Vol. 11 (No. 3) 129

5.2. Investigations

The first investigation has been the study of

the variation of BOG production rate and LHV

of a fully loaded LNG vessel of 150000 m

3

capacity for a 25 day voyage, without any forced

boil-off or reliquefication onboard. The results

are depicted in Figure 5.

From Figure 5 it can be readily deduced

that there is a significant variation of both BOG

mass and LHV, and consequently the assumption

of constant boil-off rate and pure methane LHV,

which is usually used in various studies, is not

correct.

The BOG mass flow rate decreases at the

begining of the voyage, reaches a minimum

value and then increases again. This behavior is

due to the fact that at the begining of the voyage,

when the tank temperature is the lowest, only the

more volatile components evaporate (methane

and nitrogen). These components have lower

molecular weights than the less volatile

components (ethane, propane and butane) and

cause a reduction of the MW of the BOG

mixture. The nitrogen content in BOG is higher

at the beginning of the voyage yielding low LHV

values. The nitrogen content decreases during

voyage and the LHV of BOG increases. As the

temperature increases during voyage, the heavier

components begin to evaporate and contribute to

the MW of the BOG mixture, thus increasing the

BOG mass flow rate. The LNG and BOG

compositions at the start and the end of the

voyage are presented in TABLE III.

The second investigation has been the

simulation of the BOG behavior with

simultaneous forced boil-off of LNG during

voyage. Forced boil-off is often necessary in

LNG vessel operation in order to cover the fuel

requirements of the propulsion plant.

1.066

1.068

1.071

1.073

1.075

1.077

0 5 10 15 20 25

Voyage Days

B

O

G

m

a

s

s

f

l

o

w

(

k

g

/

s

)

Traditional

approach

43000

44000

45000

46000

47000

48000

49000

50000

51000

0 5 10 15 20 25

Voyage Day

L

H

V

(

k

J

/

K

g

)

Methane Equivalent LHV

Figure 5. Variation of BOG mass flow and LHV

during voyage.

TABLE III. INITIAL AND FINAL MOLAR

COMPOSITIONS OF LNG AND BOG.

LNG (%) BOG (%)

Initial Final Initial Final

Methane

89.9 89.7 92.65 96.8

Ethane

6 6.24 0 0.01

Propane

2.2 2.29 0 0

Butane

1.5 1.56 0 0

Nitrogen

0.4 0.22 7.34 3.15

For the purpose of this study, a typical

propulsion unit of nominal power 25MW and a

thermal efficiency of 40% have been considered.

This assumption results in a required fuel heat

power input to the propulsion plant of 62.5MW.

In addition, the speed of the vessel, and

consequently the propulsion power, have been

considered constant throughout the voyage.

Therefore, at any instant of time the required fuel

heat power input has been the sum of the heat

input of the natural and the forced BOG.

Forced boil-off of LNG is performed by

extracting a small amount of the liquid from a

specially controlled cargo tank. Therefore, the

composition of the forced boil-off is that of the

LNG in the cargo tanks.

In the set of graphs of Figure 6, the

variation of the BOG (forced and natural) mass

flow, LHV and the volume of BOG that is

consumed from the propulsion power plant are

depicted. Forced boil-off is decreasing during

voyage due to the fact that the heating value of

the natural BOG increases and therefore, less

quantity of forced boil-off is needed to cover the

required heat input. The heating value of the

forced BOG is almost constant, since it is the

heating value of the LNG which has a small

variation with time due to the relatively small

quantity of LNG that is evaporated.

The natural BOG mass flow and LHV

variation through voyage, depicted in Figure. 6

have the same trends as those in the case with no

forced boil-off present Figure 5. This is due to

the fact that the same thermodynamic

mechanisms of VLE are also dominant in this

scenario. However, there are quantitative

differences in the amount of BOG mass flow and

the value of LHV. The variations of methane

and nitrogen compositions of BOG during

voyage are also depicted in Figure 7.

It must be noted that the forced boil-off has

a significant effect on both the quantity and the

heating value of the total BOG. If the BOG is

used as a fuel of the propulsion plant of the LNG

vessel, then the interrelation of the required fuel

input with the boil-off process becomes a key

issue in the thermoeconomic assessment of the

Int. J. of Thermodynamics, Vol. 11 (No. 3) 130

complete propulsion system.

6. Conclusion

A dynamic model for the evaporation of

LNG has been developed. The properties of the

boil-off gas during voyage have been assessed

and rough simplifying assumptions usually

employed in previous studies have been

removed. This model is a first step in the

simulation of the evaporation of LNG during

marine transportation and the thermodynamic

approach will be enhanced in subsequent studies.

The main benefit of this model is that it is

easy to implement, can be easily solved and has a

very short execution time. These features allow

for this model to be integrated in the

thermoeconomic simulation and optimization of

marine energy systems of LNG vessels.

The investigations performed in this study

indicated that the boil-off gas quantity and

quality significantly vary during a voyage and

therefore this variation must be taken into

account in the thermoeconomic assessment of

marine energy systems of LNG vessels.

Natural BOG

1.069

1.070

1.071

1.072

1.073

1.074

1.075

1.076

1.077

1.078

1.079

1.080

0 10 20 30

Sailing Days

B

O

G

m

a

s

s

f

l

o

w

(

k

g

/

s

)

ForcedBOG

0.230

0.240

0.250

0.260

0.270

0.280

0.290

0.300

0.310

0.320

0 10 20 30

Sailing Days

B

O

G

m

a

s

s

f

l

o

w

(

k

g

/

s

)

Total BOG

1.310

1.320

1.330

1.340

1.350

1.360

1.370

1.380

1.390

0 10 20 30

Sailing Days

B

O

G

m

a

s

s

f

l

o

w

(

k

g

/

s

)

43000

44000

45000

46000

47000

48000

49000

50000

0 5 10 15 20 25 30

Sailing Days

L

H

V

(

k

J

/

k

g

)

Natural BOG

Forced BOG

Total BOG

0

1000

2000

3000

4000

5000

6000

7000

0 5 10 15 20 25

Sailing Days

B

O

G

V

o

l

u

m

e

(

m

3

)

Forced BOG

Natural BOG

Total Volume

of BOG

at the end

of the voyage:

7576m

3

Figure 6. Variation of natural, forced and total BOG quantity and LHV value during voyage.

0.90

0.92

0.94

0.96

0.98

1.00

0 5 10 15 20 25

Sailing Days

C

H

4

C

o

m

p

o

s

i

t

i

o

n

(

b

y

v

o

l

.

)

0.00

0.02

0.04

0.06

0.08

0.10

N

2

C

o

m

p

o

s

i

t

i

o

n

(

b

y

v

o

l

.

)

CH4

N2

Boil-off Gas

Figure 7. Variation of BOG methane and

nitrogen compositions during voyage.

Nomenclature

BOG Boil-off Gas

C Poynting correction factor

EOS Equation of state

f Fugacity

G Gibbs free energy

H

u

Lower heating value

LNG Liquefied Natural Gas

MW Molecular weight

n Number of intervals, species, etc.

N Number of moles of a substance

P Pressure

Q Heat

R Universal gas constant

T Temperature

x Molar composition

v Specific volume

Int. J. of Thermodynamics, Vol. 11 (No. 3) 131

V Volume

VLE Vapor-Liquid Equilibrium

u External variable

Z Compressibility factor

Greek letters

Activity coefficient

vap

h Enthalpy of vaporization

Time duration

Fugacity coefficient

Subscripts

cr Critical Point

frc Forced boil-off

g Gas, Vapor

HT Heat transfer

l Liquid

rlq Reliquefication

S Species

sat Saturation

tot Total

tr Triple point

V Cargo tank

Superscripts

Constituent of a mixture

~ Molar quantity

t Time

References

K. Andrianos, 2006, "Techno-economic

Evaluation of various Energy Systems for LNG

carriers", Diploma Thesis, National Technical

University of Athens, Athens, Greece.

Q. S. Chen, J. Wegrzyn and V. Prasad, 2004,

"Analysis of temperature and pressure changes in

liquefied natural gas (LNG) cryogenic tanks",

Cryogenics, Vol. 44, No. 10, pp. 701-709.

G. Forsythe, M. Malcolm and C. Moler, 1977,

Computer Methods for Mathematical

Computations, Prentice-Hall, New Jersey.

E. P. Gyftopoulos and G. P. Beretta, 1991,

Thermodynamics: Foundations and Applications,

Macmillan Publishing, New York (NY) USA.

J. Heestand, C. W. Shipman and J. W. Meader,

1983, "A predictive model for rollover in

stratified LNG tanks", AIChE journal, Vol. 29,

No. 2, pp. 199-207.

M. Kuver, 2005, "Small LNG carriers with

independent Type C tanks", Proccedings of 10th

TGE Symposium, Bonn, Germany.

M. Kuver, C. Clucas and N. Fuhrmann, 2002,

"Evaluation of propulsion options for LNG

carriers", Proccedings of GASTECH 2002, Doha,

Qatar.

M. Laurilehto, 2000, "Propulsion systems for

future LNG carriers" Wartsila Marine News, No.

3/2000, pp 20-23.

O. Levander and S. Hannula, 2004, "More gas

for LNG carriers" Wartsila Marine News, No.

3/2004, pp 6-11.

MAN-B&W, 2004, "LNG Carrier Propulsion by

ME-GI Engines and/or Reliquefaction", MAN

B&W Technical Papers (available at:

www.manbw.com).

O. Morch, K. Nasrifar, O. Bolland, E. Solbraa,

A. O. Fredheim and L. H. Gjertsen, 2006,

"Measurement and modeling of hydrocarbon

dew points for five synthetic natural gas

mixtures", Fluid Phase Equilibria, Vol. 239, No.

2, pp. 138-145.

T. Munakata, N. Lior and I. Tanasawa, 1995, "A

study of double-diffusive rollover in cylindrical

enclosures", Proceedings of the ASME Heat

Transfer Division, Vol. HTD 317, No. 1, pp.

279-291.

K. Nasrifar and O. Bolland, 2006, "Prediction of

thermodynamic properties of natural gas

mixtures using 10 equations of state including a

new cubic two-constant equation of state",

Journal of Petroleum Science and Engineering,

Vol. 51, No. 3-4, pp. 253-266.

K. Nasrifar, O. Bolland and M. Moshfeghian,

2005, "Predicting Natural Gas Dew Points from

15 Equations of State", Energy & fuels : an

American Chemical Society journal, Vol. 19, No.

2, pp. 12.

NIST, 2007, "U.S. U.S. National Institute of

Science and Technology (NIST) Standard

Reference Chemical Properties Database".

T. K. Oestvold, 2006, "Sloshing Analysis of

LNG Membrane Tanks", Proccedings of 50th

SIGTTO Panel Meeting, Vancouver, Canada.

J. Ratanapisit and J. F. Ely, 1999, "Application

of New, Modified BWR Equations of State to the

Corresponding-States Prediction of Natural Gas

Properties", International Journal of

Thermophysics, Vol. 20, No. 6, pp. 1721-1735.

J. M. Smith, H. C. Van Ness and M. M. Abbott,

1996, Introduction to chemical engineering

thermodynamics McGraw-Hill, New York (NY)

USA.

G. R. Somayajulu, 1988, "New equations for

enthalpy of vaporization from the triple point to

the critical point", International Journal of

Thermophysics, Vol. V9, No. 4, pp. 567-575.

Anda mungkin juga menyukai

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Studies On Drying Kinetics of Solids in A Rotary DryerDokumen6 halamanStudies On Drying Kinetics of Solids in A Rotary DryerVinh Do ThanhBelum ada peringkat

- 4244 12672 1 PB PDFDokumen15 halaman4244 12672 1 PB PDFVinh Do ThanhBelum ada peringkat

- Proper Air-Fuel Ratios for Starting, Idling, Accelerating & MoreDokumen9 halamanProper Air-Fuel Ratios for Starting, Idling, Accelerating & MoreVinh Do ThanhBelum ada peringkat

- Air-Fuel Ratio, Lambda and Engine Performance: AFR M MDokumen12 halamanAir-Fuel Ratio, Lambda and Engine Performance: AFR M MVinh Do ThanhBelum ada peringkat

- 4244 12672 1 PB PDFDokumen15 halaman4244 12672 1 PB PDFVinh Do ThanhBelum ada peringkat

- NPK-15 8 15Dokumen5 halamanNPK-15 8 15Vinh Do ThanhBelum ada peringkat

- Effects of Drying Parameters On Heat Transfer During DryingDokumen13 halamanEffects of Drying Parameters On Heat Transfer During DryingVinh Do ThanhBelum ada peringkat

- Modeling and Simulation of A Co-Current Rotary Dryer Under Steady ConditionsDokumen8 halamanModeling and Simulation of A Co-Current Rotary Dryer Under Steady ConditionsVinh Do ThanhBelum ada peringkat

- Modelling and Simulation of A Direct Contact Rotary DryerDokumen16 halamanModelling and Simulation of A Direct Contact Rotary DryerVinh Do ThanhBelum ada peringkat

- Recycle From ETP Make Up H2O DAP, UreaDokumen1 halamanRecycle From ETP Make Up H2O DAP, UreaVinh Do ThanhBelum ada peringkat

- The Heart of Operations - World Cement - 02-2015Dokumen4 halamanThe Heart of Operations - World Cement - 02-2015fetniBelum ada peringkat

- Tinh Luong Nuoc Bay HoiDokumen22 halamanTinh Luong Nuoc Bay HoiVinh Do ThanhBelum ada peringkat

- Dryer CalculationsDokumen4 halamanDryer CalculationsVinh Do Thanh0% (1)

- Ansi B16-104Dokumen1 halamanAnsi B16-104Monica Suarez100% (1)

- Aoac - Methods.1.1990. MoistureDokumen2 halamanAoac - Methods.1.1990. MoistureVinh Do ThanhBelum ada peringkat

- Multi-Use Chair DesignDokumen7 halamanMulti-Use Chair DesignVinh Do ThanhBelum ada peringkat

- Review On Development of Polypropylene Manufacturing ProcessDokumen11 halamanReview On Development of Polypropylene Manufacturing ProcessShweta Yadav100% (1)

- PEP Report 267A: Ihs ChemicalDokumen8 halamanPEP Report 267A: Ihs ChemicalVinh Do ThanhBelum ada peringkat

- 1 0ProjectManagementProceduresDokumen8 halaman1 0ProjectManagementProceduresRamiesRahmanBelum ada peringkat

- CRACKER A PC Based Simulator For Industr PDFDokumen6 halamanCRACKER A PC Based Simulator For Industr PDFVinh Do ThanhBelum ada peringkat

- Equivalent Grades of Cast IronsDokumen2 halamanEquivalent Grades of Cast IronsVinh Do ThanhBelum ada peringkat

- Natural Evaporation RateDokumen16 halamanNatural Evaporation RateVinh Do ThanhBelum ada peringkat

- Metal Price IndexDokumen1 halamanMetal Price IndexVinh Do ThanhBelum ada peringkat

- Mau Giay Uy Quyen Bang Tieng AnhDokumen3 halamanMau Giay Uy Quyen Bang Tieng AnhVinh Do ThanhBelum ada peringkat

- DRS 279-2015 Organic Fertilizer - SpecificationDokumen17 halamanDRS 279-2015 Organic Fertilizer - SpecificationVinh Do ThanhBelum ada peringkat

- Estimating Evaporation From Water SurfacesDokumen27 halamanEstimating Evaporation From Water SurfacesVinh Do ThanhBelum ada peringkat

- How To Calculate Heat Load - 5 StepsDokumen1 halamanHow To Calculate Heat Load - 5 StepsVinh Do ThanhBelum ada peringkat

- Optimization of Wall Thickness For Minimum Heat LossesDokumen9 halamanOptimization of Wall Thickness For Minimum Heat LossesVinh Do ThanhBelum ada peringkat

- How To Calculate Heat Load - 5 StepsDokumen1 halamanHow To Calculate Heat Load - 5 StepsVinh Do ThanhBelum ada peringkat

- Investigation of Sensible Heat Storage and Heat Insulation in The Exploitation of Concentrated Solar EnergyDokumen5 halamanInvestigation of Sensible Heat Storage and Heat Insulation in The Exploitation of Concentrated Solar EnergyradanpetricaBelum ada peringkat

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Fontargen AJ PDFDokumen282 halamanFontargen AJ PDFantonyBelum ada peringkat

- Chm580 Experiment 3Dokumen9 halamanChm580 Experiment 3ohhiBelum ada peringkat

- Add Nordic Semiconductor DFU To SDK Example: Bluetooth Low EnergyDokumen32 halamanAdd Nordic Semiconductor DFU To SDK Example: Bluetooth Low EnergyDaniel Ernesto EspitiaBelum ada peringkat

- Smartdek Design ManualDokumen48 halamanSmartdek Design ManualranddyBelum ada peringkat

- LP Galvo Scanner LaserphotoDokumen16 halamanLP Galvo Scanner LaserphotoCostin DinamaxBelum ada peringkat

- Probset 8Dokumen7 halamanProbset 8Adrian PamintuanBelum ada peringkat

- Product Manual For Resilient Seated Cast Iron Air Relief Valves For Water Works Purposes ACCORDING TO IS 14845: 2000Dokumen5 halamanProduct Manual For Resilient Seated Cast Iron Air Relief Valves For Water Works Purposes ACCORDING TO IS 14845: 2000Tanmoy DuttaBelum ada peringkat

- Answer All The Questions. No Negative Marks For Wrong Answers. Please Do Not Mark Anything On The Question PaperDokumen13 halamanAnswer All The Questions. No Negative Marks For Wrong Answers. Please Do Not Mark Anything On The Question PaperMainak DeBelum ada peringkat

- Vector Integration - GATE Study Material in PDFDokumen10 halamanVector Integration - GATE Study Material in PDFTestbook BlogBelum ada peringkat

- Maths Class VIII: Chapter As Per NCERT LessonsDokumen1 halamanMaths Class VIII: Chapter As Per NCERT Lessonsabhijeet_sangwanBelum ada peringkat

- Ray OpticsDokumen41 halamanRay OpticsHannah VsBelum ada peringkat

- Syngas Synthesis & Its UseDokumen18 halamanSyngas Synthesis & Its UseAekkasit SenaartBelum ada peringkat

- Journal of King Saud University - Computer and Information SciencesDokumen10 halamanJournal of King Saud University - Computer and Information SciencesArunima MaitraBelum ada peringkat

- Eiffic/Efuf (T:, RFRDT (FrrtfuDokumen17 halamanEiffic/Efuf (T:, RFRDT (FrrtfuRamasubba RajuBelum ada peringkat

- Introduction To Probability: Business Statistics: Communicating With Numbers, 4eDokumen52 halamanIntroduction To Probability: Business Statistics: Communicating With Numbers, 4eRetno Ajeng Anissa WidiatriBelum ada peringkat

- Carbolite CWF1313 004 - 3216Dokumen44 halamanCarbolite CWF1313 004 - 3216dev-nullBelum ada peringkat

- Model For Calculating The Refractive Index of DiffDokumen5 halamanModel For Calculating The Refractive Index of DiffNANBelum ada peringkat

- Magnetic Field Analysis of SynRel and PMASynRel Machines With Hyperbolic Flux Barriers Using Conformal MappingDokumen10 halamanMagnetic Field Analysis of SynRel and PMASynRel Machines With Hyperbolic Flux Barriers Using Conformal MappingedumacerenBelum ada peringkat

- Blockchain Technology For Cloud Storage - A Systematic Literature ReviewDokumen33 halamanBlockchain Technology For Cloud Storage - A Systematic Literature ReviewNgocBelum ada peringkat

- Fire ZoneDokumen8 halamanFire ZoneKannan NBelum ada peringkat

- CHAPTER 6 Coordinate Geometry Module ExercisesDokumen15 halamanCHAPTER 6 Coordinate Geometry Module ExercisesBid Hassan75% (8)

- ACL Injuries in The Female Athlete: Causes, Impacts, and Conditioning Programs Frank R. Noyes Sue Barber-WestinDokumen658 halamanACL Injuries in The Female Athlete: Causes, Impacts, and Conditioning Programs Frank R. Noyes Sue Barber-WestinluizamgoBelum ada peringkat

- Student's Error Analysis in Finishing Mathematic Word Problem Based Newman AnalysisDokumen11 halamanStudent's Error Analysis in Finishing Mathematic Word Problem Based Newman AnalysisguanyitorBelum ada peringkat

- HistoryDokumen87 halamanHistoryMatthew MathewsBelum ada peringkat

- Dynamic Programming Algorithm Explained in ECE 551 LectureDokumen11 halamanDynamic Programming Algorithm Explained in ECE 551 Lectureadambose1990Belum ada peringkat

- I. 8-Bit Microprocessors Architecture, Instruction Set and Their ProgrammingDokumen4 halamanI. 8-Bit Microprocessors Architecture, Instruction Set and Their ProgrammingSaorabh KumarBelum ada peringkat

- Generator Protection Application GuideDokumen106 halamanGenerator Protection Application GuideJorge Alberto Chavarría Sacasa100% (1)

- Measuring AssignmentDokumen3 halamanMeasuring AssignmentArnab BhattacharyaBelum ada peringkat

- Lsi/Csi: 24-Bit Dual-Axis Quadrature CounterDokumen12 halamanLsi/Csi: 24-Bit Dual-Axis Quadrature CounterWilliam Méndez PérezBelum ada peringkat

- OOPS AbapDokumen188 halamanOOPS Abapraky036950% (2)